Control method and control system of utilizing high-concentration organic raw material for biogas fermentation

A technology for organic raw materials and biogas fermentation, applied in specific-purpose bioreactors/fermenters, fermentation, biochemical equipment and methods, etc., can solve problems such as inapplicability to the application environment, increased construction costs, and complicated processes, and achieve Realize the effect of continuous and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

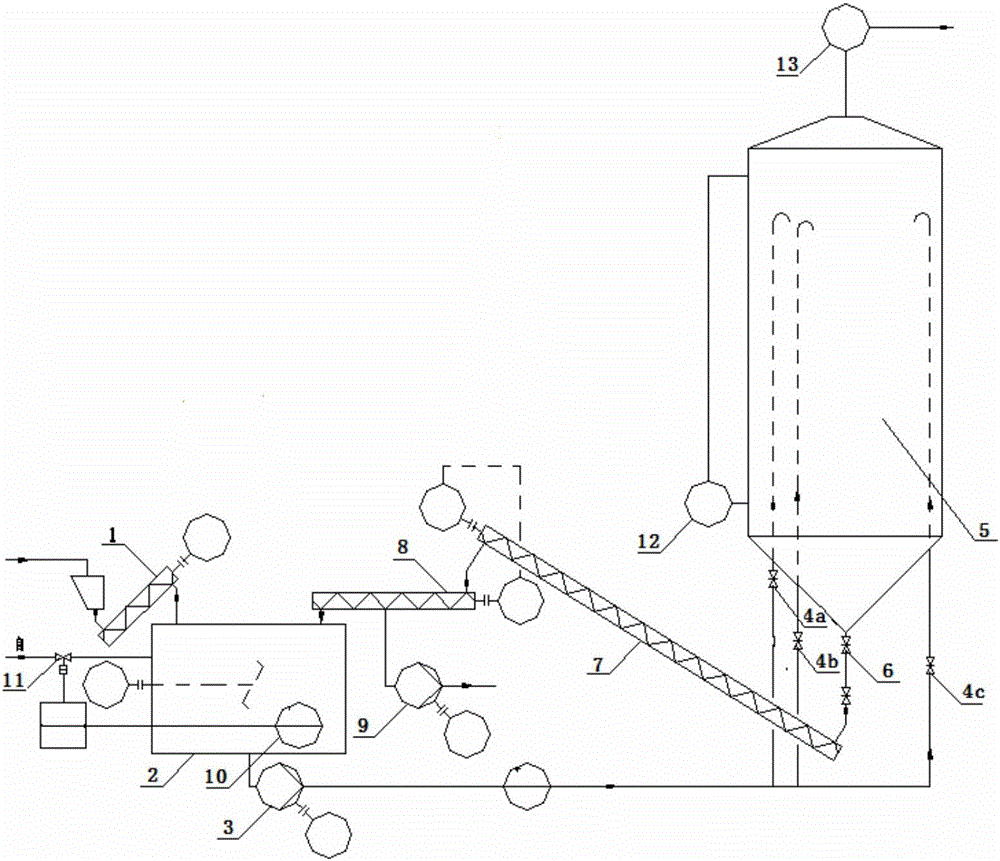

[0026] Embodiment 1: Dry fermentation system control of organic domestic waste materials

[0027] 1. Start the fermentation system. First, use the first feeding device to transport the organic domestic waste with a TS (solid content) of 20% to the stirring and temperature-raising regulating tank, and then open the second feeding device to transport 1 / 3 of the volume of the vertical anaerobic fermentation tank. , so that a large number of methanogens grow.

[0028] 2. Mix and heat up the fermentation raw materials. Turn on the discharge screw conveying device and the discharge distribution device, and return the fermented biogas slurry to the mixing and heating regulating tank according to the ratio of 7 times the quality of the new material, and mix it with the original organic domestic waste in the stirring and heating regulating tank Temperature adjustment, the temperature in the tank reaches 38°C, the steam valve continues to open, and the temperature of the stirring and ...

Embodiment 2

[0032] Example 2: Control of High Concentration Municipal Sludge Dry Fermentation System

[0033] 1. Start the fermentation system. First, use the first feeding device to transport high-concentration municipal sludge with a TS of 22% to the stirring and temperature-raising regulating tank, and then open the second feeding device to transport the sludge of 1 / 3 of the volume of the vertical anaerobic fermentation tank, so that Methanogens grow in abundance.

[0034] 2. Mix and heat up the fermentation raw materials. Turn on the discharge screw conveying device and the discharge distribution device, and return the fermented biogas slurry to the mixing and heating regulating tank according to the ratio of 6 times the quality of the new incoming material, and mix it with the original high-concentration municipal sludge in the stirring and heating regulating tank Carry out mixing and temperature rise adjustment, the temperature in the tank reaches 38°C, the steam valve continues t...

Embodiment 3

[0038] Example 3: Control of pig manure and corn stalk dry fermentation system

[0039] 1. Start the fermentation system. First, use the first feeding device to transport fresh pig manure and corn stalks with a TS of 18% to the stirring and temperature-raising regulating tank, and then open the second feeding device to transport 1 / 4 of the volume of the fermentation tank. grow.

[0040]2. Mix and heat up the fermentation raw materials. Turn on the discharge screw conveying device and the discharge distribution device, and return the fermented biogas slurry to the mixing and heating regulating tank according to the ratio of 5 times the quality of the new material, and mix it with the original fresh pig manure and corn in the stirring and heating regulating tank. The straw is mixed and adjusted to increase temperature, the temperature in the tank reaches 38°C, the steam valve continues to open, and the temperature of the mixing and heating adjustment tank is raised; during the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com