Efficient passive spent fuel pool cooling system adopting jet technology

A technology of spent fuel pool and cooling system, applied in cooling devices, nuclear power generation, reactors, etc., can solve the problems of small heat transfer coefficient, difficult to obtain condensation effect, small driving pressure head, etc. Personnel and environmental safety, the effect of increasing the driving pressure head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the specific embodiments described in the following examples.

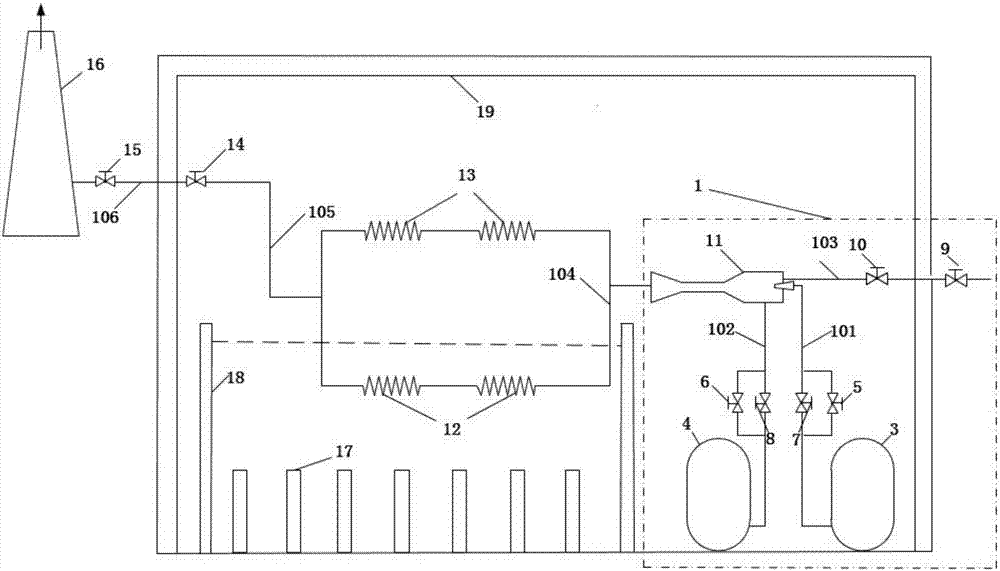

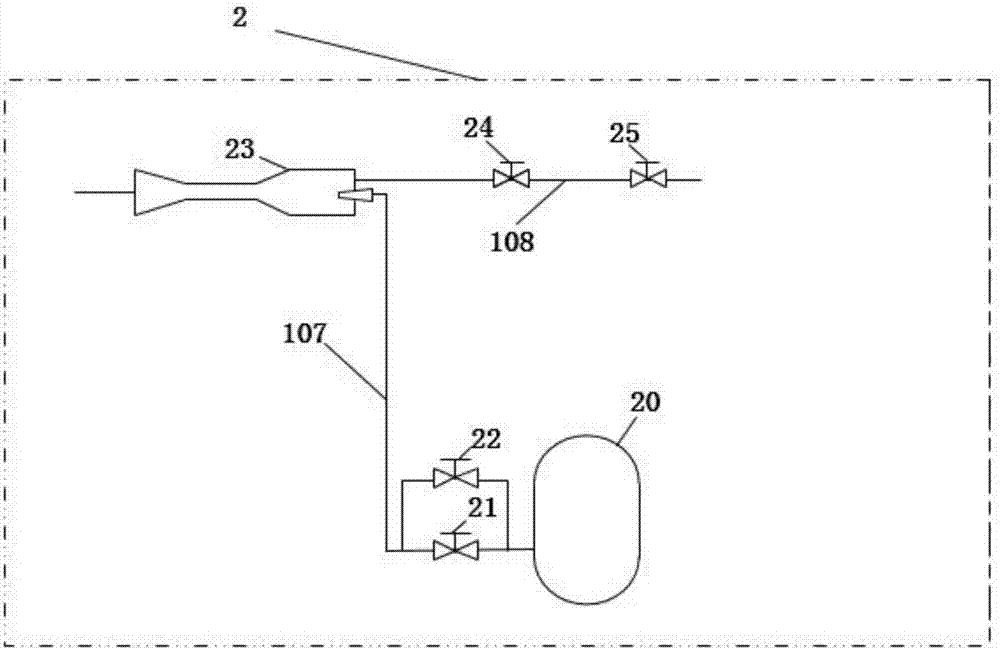

[0023] combine figure 1, a high-efficiency passive spent fuel pool cooling system using injection technology provided by the present invention includes: injection subsystem, heat exchanger inlet pipe section 104, water space heat exchanger 12, air space heat exchanger 13, heat exchanger outlet Pipe section 105, chimney 16 and associated piping and valves. Among them, the injection subsystem has two structures: the injection subsystem 1 includes a high-pressure gas storage tank 3, a water storage tank 4, an air-(gas, water) injector 11, a high-pressure gas storage tank outlet pipe section 101, and a water storage tank outlet pipe 102. Air inlet pipe section 103 and related pipes and valves; injection subsystem 2 includes high-pressure gas t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com