Control method for tobacco redrying automatic swinging and batching robot clusters

A technology for re-curing and controlling methods of tobacco leaves, which is applied in the direction of program control, comprehensive factory control, electrical program control, etc., can solve the problems of not being able to fully satisfy the automatic swing handle of red-cured tobacco leaves and not being intelligent enough, and improve the quality of red-cured tobacco leaves. , reduce labor requirements, improve the effect of formula precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

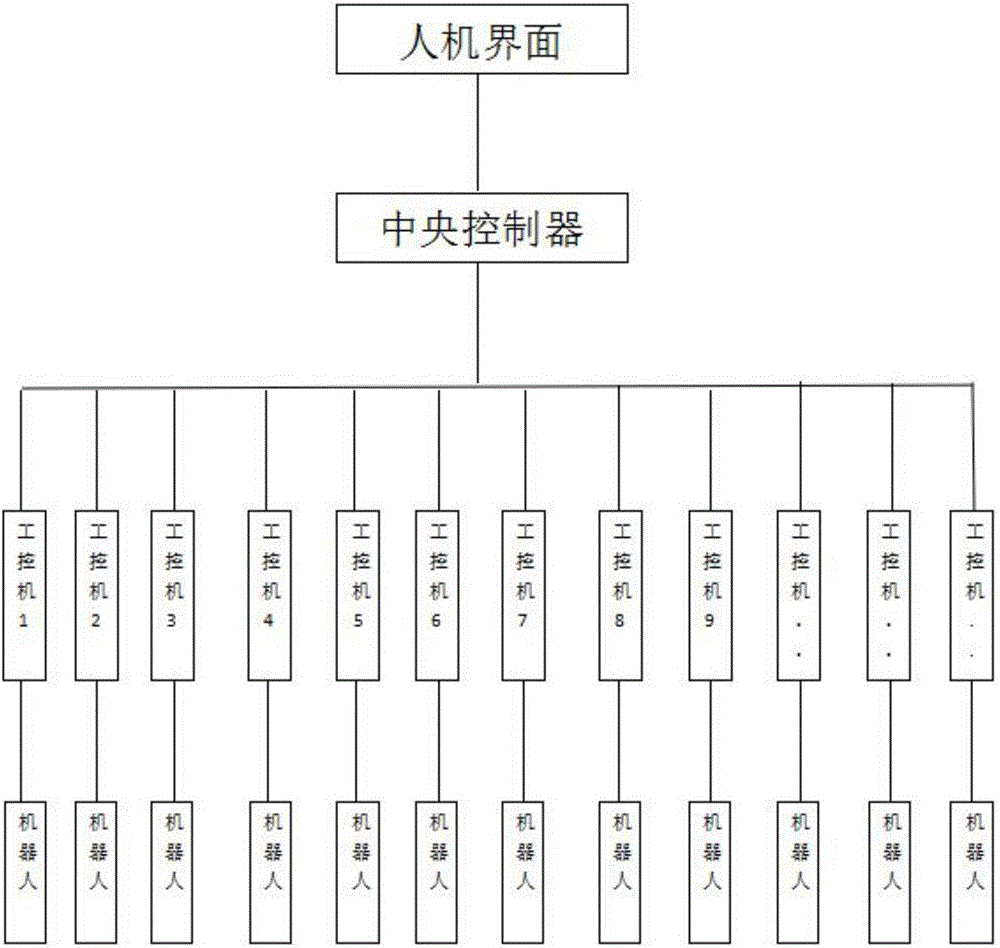

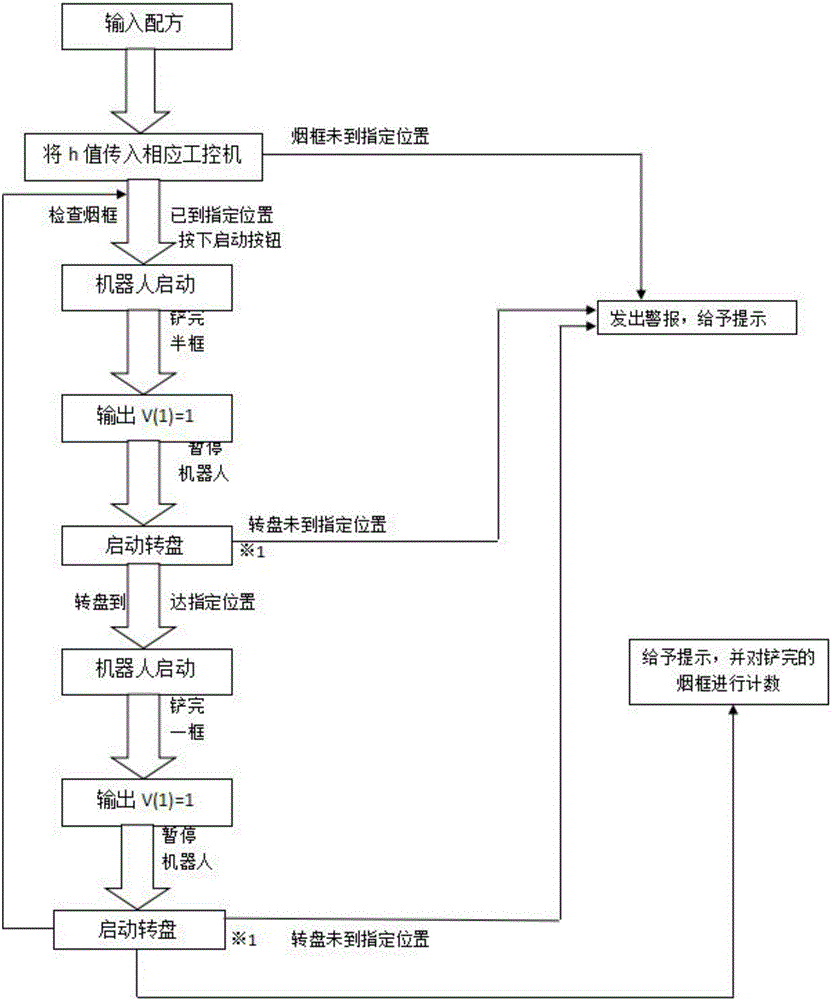

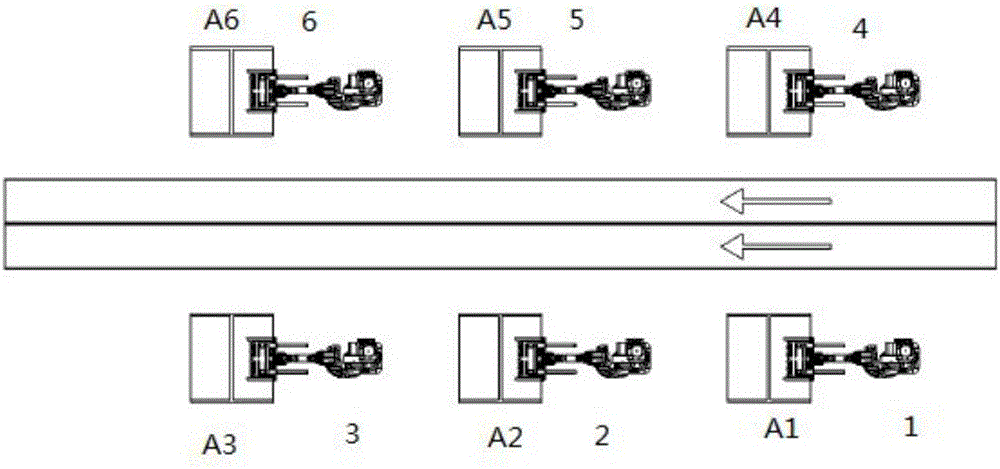

[0025] Such as Figure 1 ~ Figure 4 As shown, there are 4 conveying belts in the recured tobacco leaf pendulum production line. There is a partition in the tobacco leaf frame, which divides the tobacco leaf frame into two vertically from the middle, and each conveyor belt sends the tobacco leaves to a unified tobacco leaf receiving device. Each conveyor belt There are 3 swing-handle batching robots next to them, and the swing-handle batching robots are numbered from 1 to 12 respectively. Assume that a total of 12 grades of tobacco leaves are required to produce a cigarette, and the ratio relationship between each tobacco leaf is A1:A2...A12, In order to realize this proportional formula relationship, the thickness of each single pendulum batching robot that grabs the tobacco leaves meets A1:A2...A12=h1:h2...h12, and the values from h1 to h12 are transmitted through communication All relevant swing-handle batching robots coordinate their actions to complete actions accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com