Printing paper stack dividing and conveying device

A technology for conveying devices and printing paper, which is applied in the fields of printing paper conveying devices and printing paper stacking conveying devices, and can solve problems such as injury to operators, paper damage, equipment damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

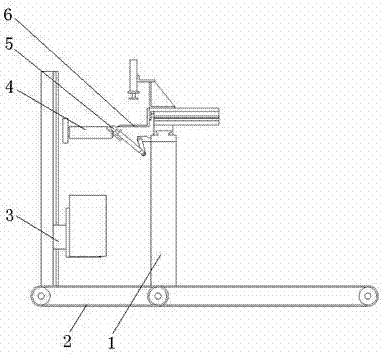

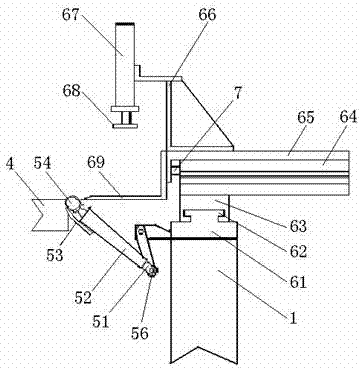

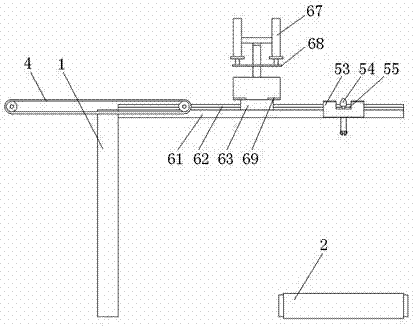

[0022] The printing paper stacking conveying device provided by the present invention comprises a frame 1, a low conveyor belt 2, a high conveyor belt 4 and a lifter 3 arranged on the frame 1, and the low end of the lifter 3 is matched with the output end of the low conveyor belt 2 The high-end end is matched with the input end of the high-position conveyor belt 4, and a fork stack clamping translation mechanism 6 and a stacking mechanism 5 are provided between the hoist 3 and the high-position conveyor belt 4, wherein:

[0023] The fork stack clamping translation mechanism 6 includes a horizontal beam 61 with a first slide rail 62 on the frame 1, a first slide block 63 on the first slide rail 62, and a first slide block 63 on the first slide rail 62. The second slide rail 64 on the block 63, the second slide block 65 that is located on the second slide rail 64, the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com