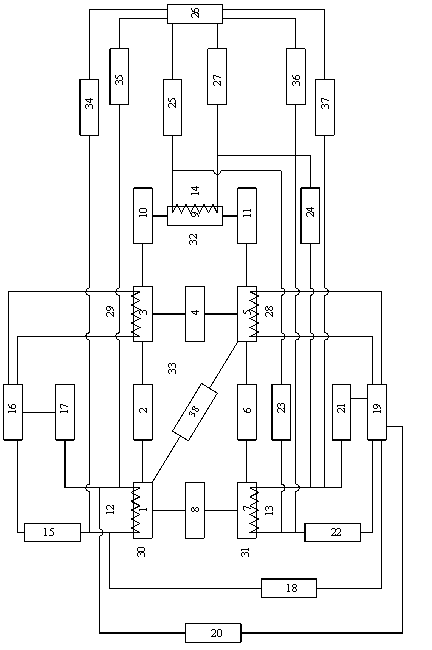

Variable temperature heat source driving efficient adsorption refrigeration system and refrigeration method

An adsorption refrigeration and heat source technology, applied in the field of thermodynamic systems, can solve the problems of not considering the operation process of the three-effect adsorption refrigeration system, system performance limitations, etc., and achieve the effect of high-efficiency and continuous output of cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

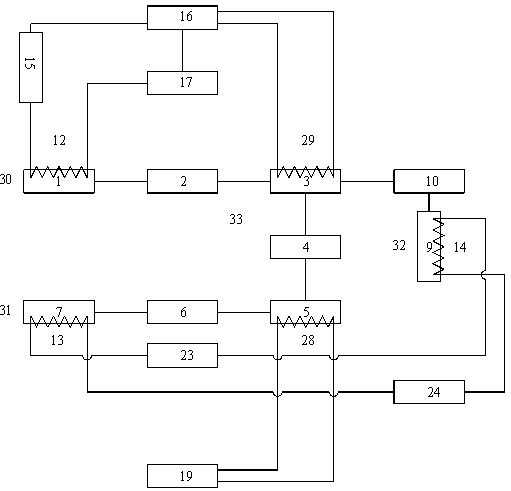

Embodiment 1

[0058] In this example, the gas adsorbate charged in the system is NH 3 , the first solid adsorbent filled in the first reactor is BaCl 2 , the second solid adsorbent filled in the second reactor is PbCl 2 , the third solid adsorbent filled in the third reactor is CuCl 2 ; The first heat source is CHS solution at a temperature of 10 degrees, the second heat source is air at a temperature of 30 degrees, and the third heat source is a solar collector at a temperature of 85 to 250 degrees.

[0059] In this embodiment, the cooling capacity is continuously output under the condition that the temperature of the heat source changes, and the operation process is as follows:

[0060] When the temperature of the third heat source is higher than 220°C, that is, 220°C

[0061] In the first stage, the first gas regulating valve, the second gas regulating valve, and the fourth gas regul...

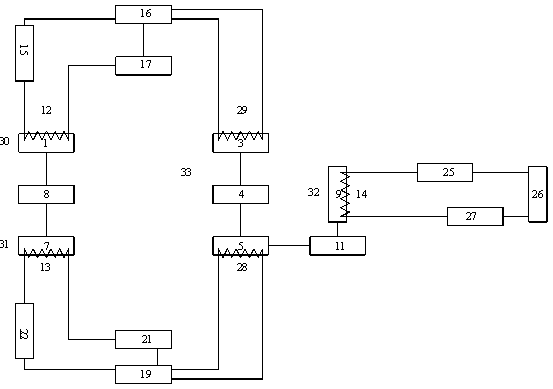

Embodiment 2

[0070] The system structure of this embodiment is the same as that of Embodiment 1, except that the first solid adsorbent filled in the first reactor is PbCl 2 , the second solid adsorbent filled in the second reactor is MnCl 2 , the third solid adsorbent filled in the third reactor is NiCl 2 ; The first heat source is low-temperature brine with a temperature of 0 degrees, the second heat source is air with a temperature of 30 degrees, and the third heat source is steam with a temperature of 105 to 350 degrees.

[0071] In this embodiment, the cooling capacity is continuously output under the condition that the temperature of the heat source changes, and the operation process is as follows:

[0072] When the temperature of the third heat source is 335°C

[0073] In the first stage, open the first gas regulating valve, the second gas regulating valve, and the fourth gas regu...

Embodiment 3

[0082] The system structure of this embodiment is the same as that of Embodiment 1, except that the first solid adsorbent filled in the first reactor is BaCl 2 , the second solid adsorbent filled in the second reactor is PbCl 2 , the third solid adsorbent filled in the third reactor is CoCl 2 ; The first heat source is low-temperature salt water with a temperature of 0 degrees, the second heat source is ambient water with a temperature of 20 degrees, and the third heat source is a boiler with a temperature of 80 to 250 degrees.

[0083] In this embodiment, the cooling capacity is continuously output under the condition that the temperature of the heat source changes, and the operation process is as follows:

[0084] When the temperature of the third heat source is 220°C

[0085] In the first stage, open the first gas regulating valve, the second gas regulating valve, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com