Novel high efficiency reactor

A reactor, high-efficiency technology, applied in chemical/physical/physicochemical fixed reactors, chemical instruments and methods, dissolution, etc., can solve the problem of material blockage and crusting, continuous operation of equipment, difficult control of material reaction conditions, and operation High cost and other issues, to achieve the effect of continuous and efficient operation of equipment, precise and efficient automatic control, and outstanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

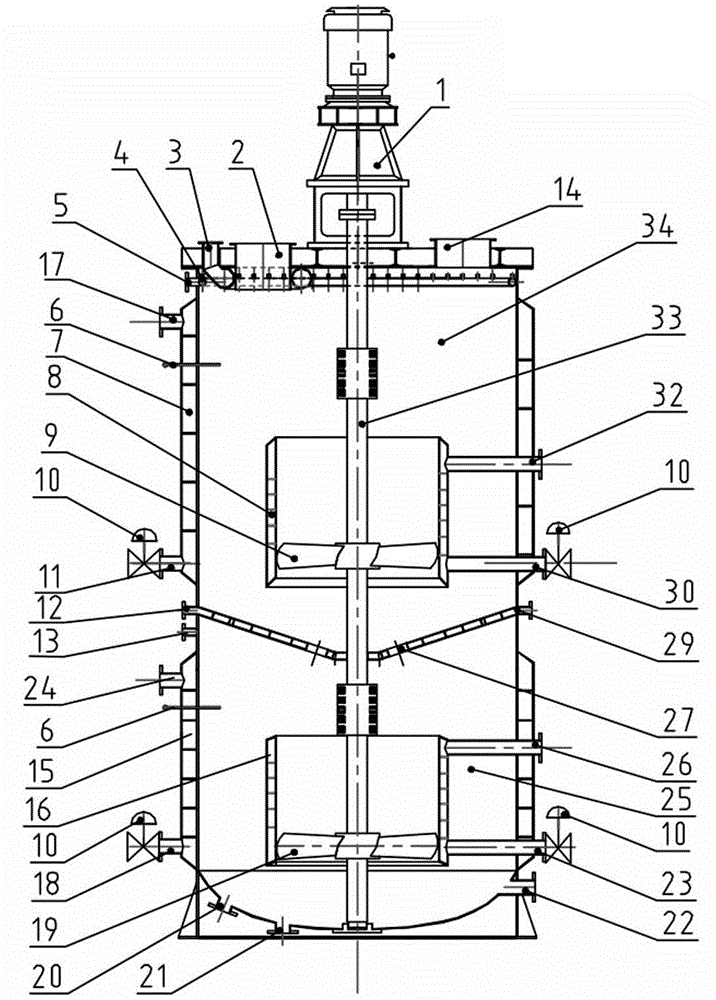

[0016] see figure 1 , a novel high-efficiency reactor, comprising a reactor body, said reactor body comprising an upper reaction zone 34 and a lower reaction zone 25, an intermediate heat exchange insulation is provided between said upper reaction zone 34 and said lower reaction zone 25 Plate 27, the inside of the reactor body is provided with a stirring shaft 33, and the stirring shaft 33 is connected to the reducer 1 provided on the upper part of the reactor body; the surface of the upper reaction zone 34 is respectively provided with a feed port 2 and inspection port 14, the side wall of the feed inlet 2 is provided with a feed anti-scarring device 3, and the side wall of the upper reaction zone 34 is respectively provided with a solution inlet 5, an upper heat exchange jacket 7 and a temperature sensor 6. The upper heat exchange jacket 7 is respectively provided with an upper heat exchange medium outlet 17 and an upper heat exchange medium inlet 11, and the solution inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com