Patents

Literature

111results about How to "Guaranteed reaction temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

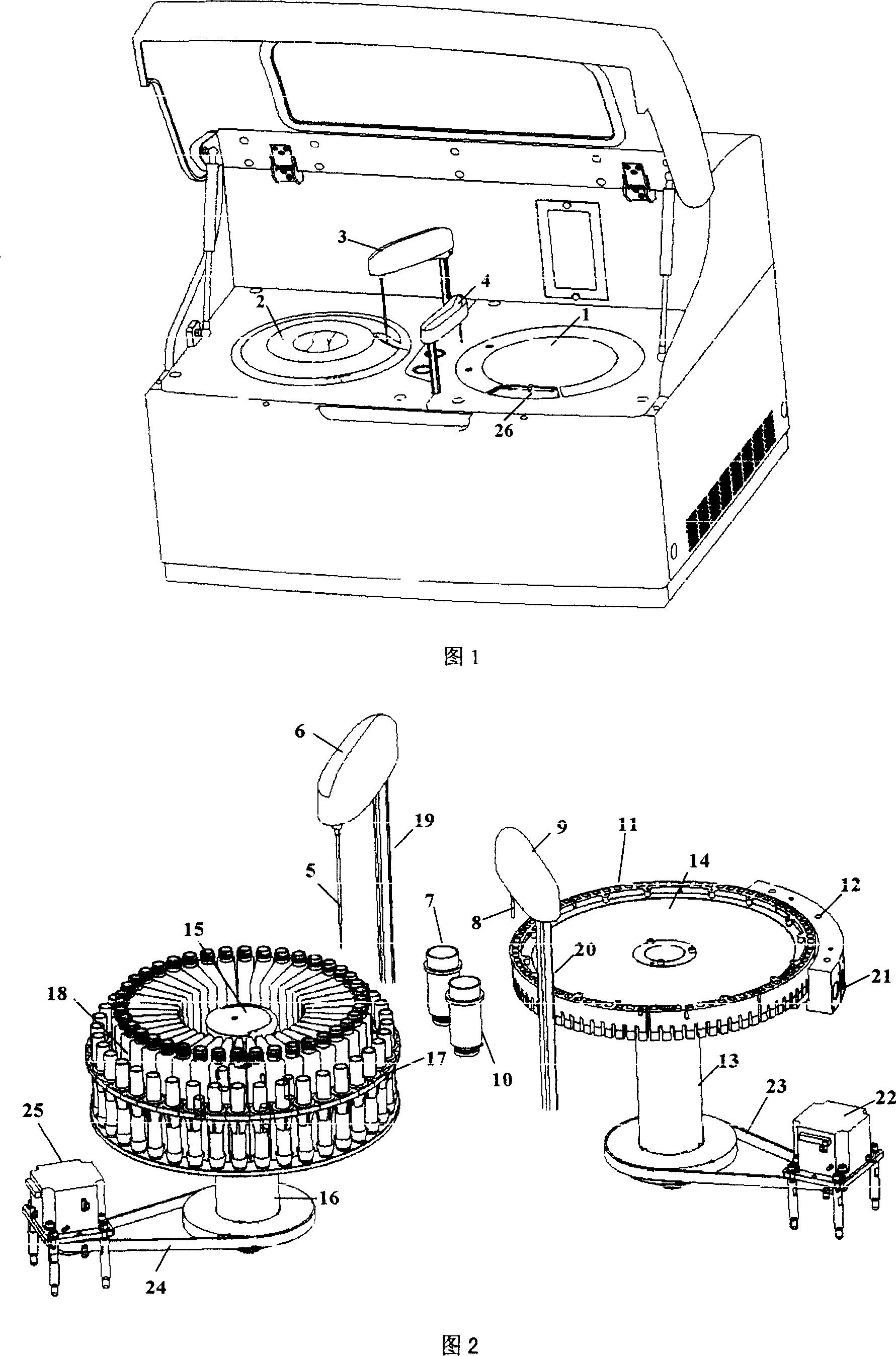

Full-automatic biochemical analyzer and analysis method thereof

ActiveCN1963527APreserve the variance of sample loading timeKeep the differenceSamplingColor/spectral properties measurementsPhysical chemistryReaction temperature

This invention relates to composite multiple channel total automatic biological analyzers, which comprises reaction disc element, sample and agent memory disc elements, sample in element and mixture bar element. The invention can use one piece of liquid drawing probe for adding agent and sample, wherein, the fix probe mechanic arm is set with heating block to draw probe agent for pre-heating to achieve best reaction temperature as human once reaction cup.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

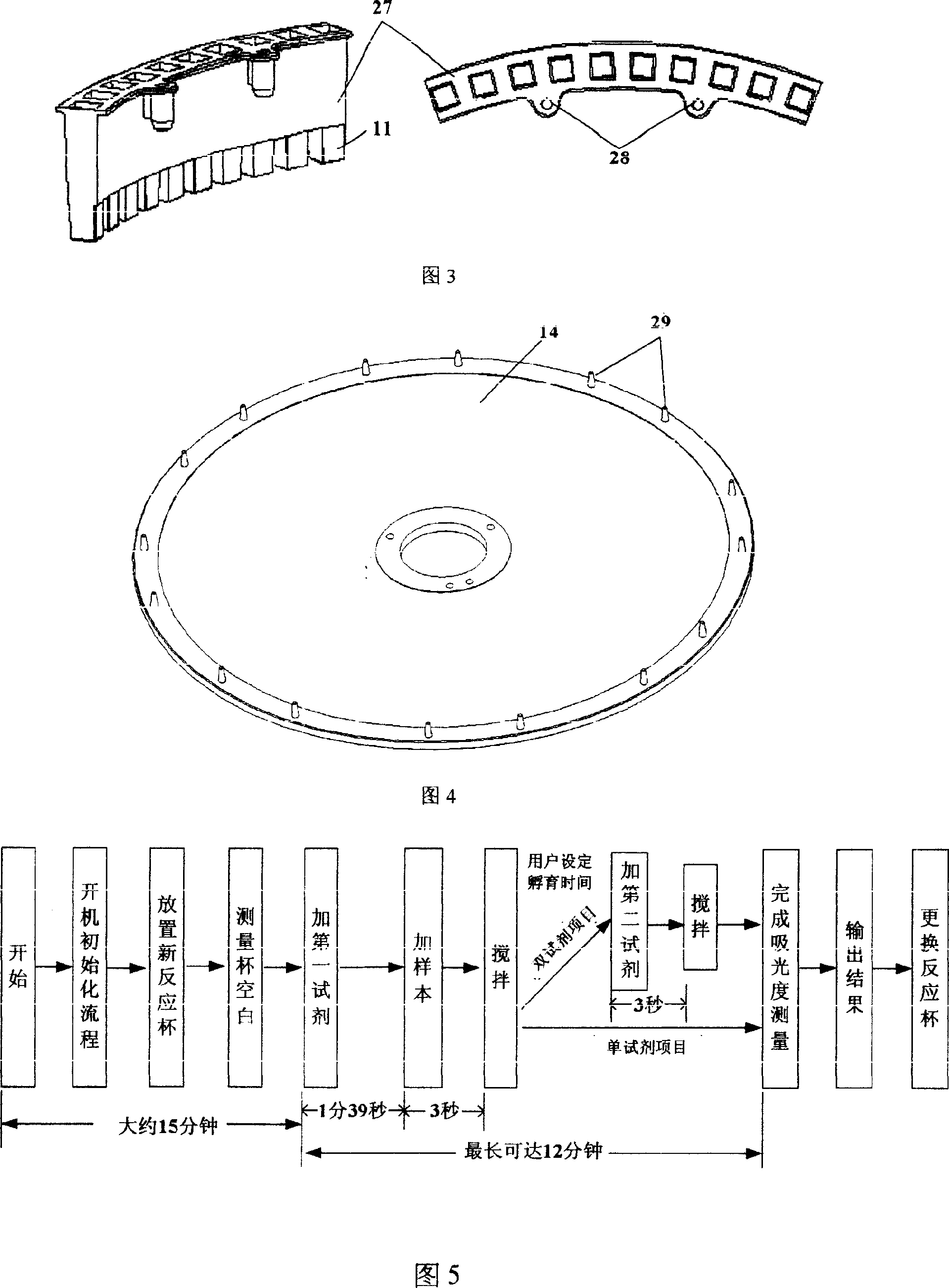

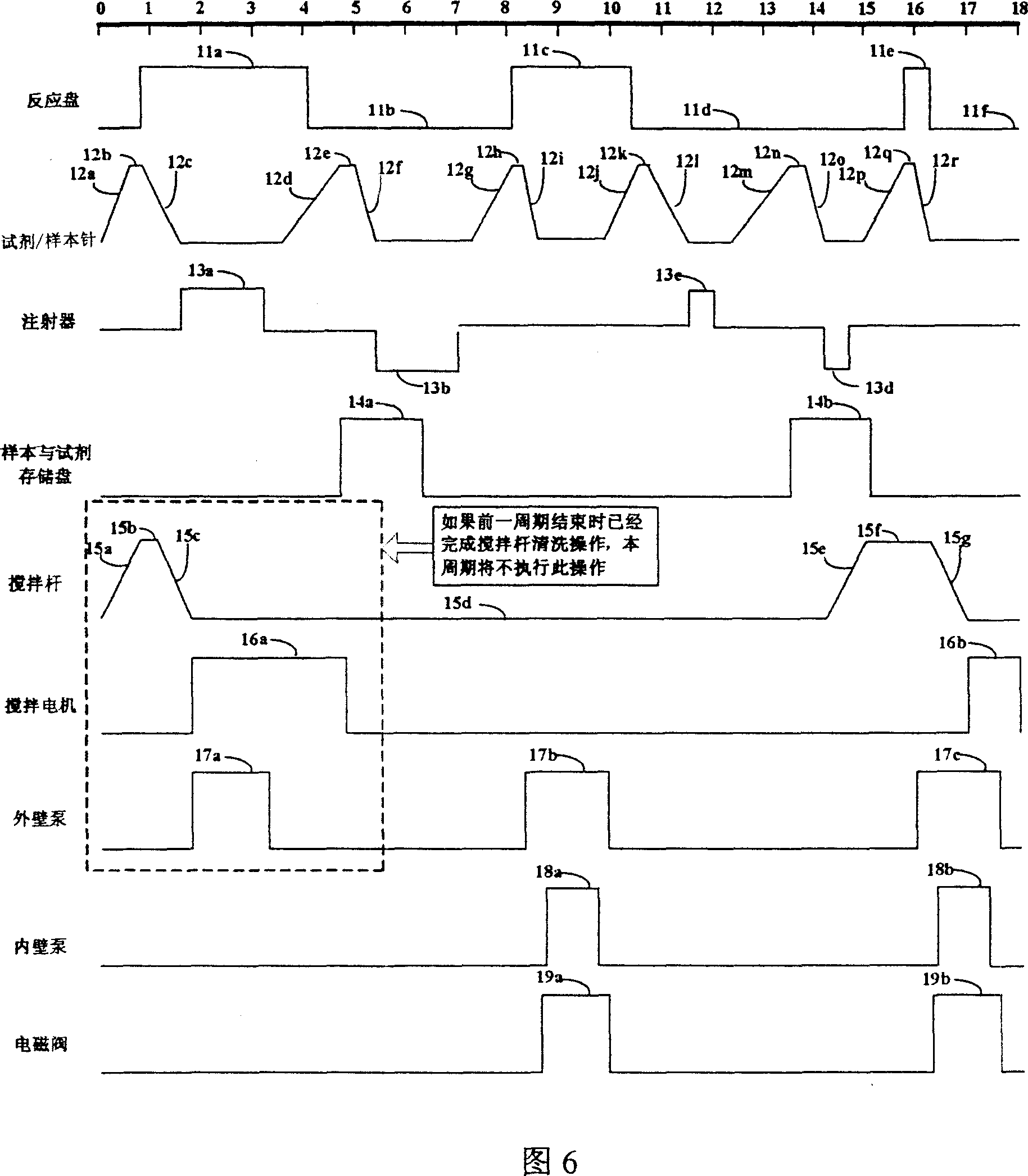

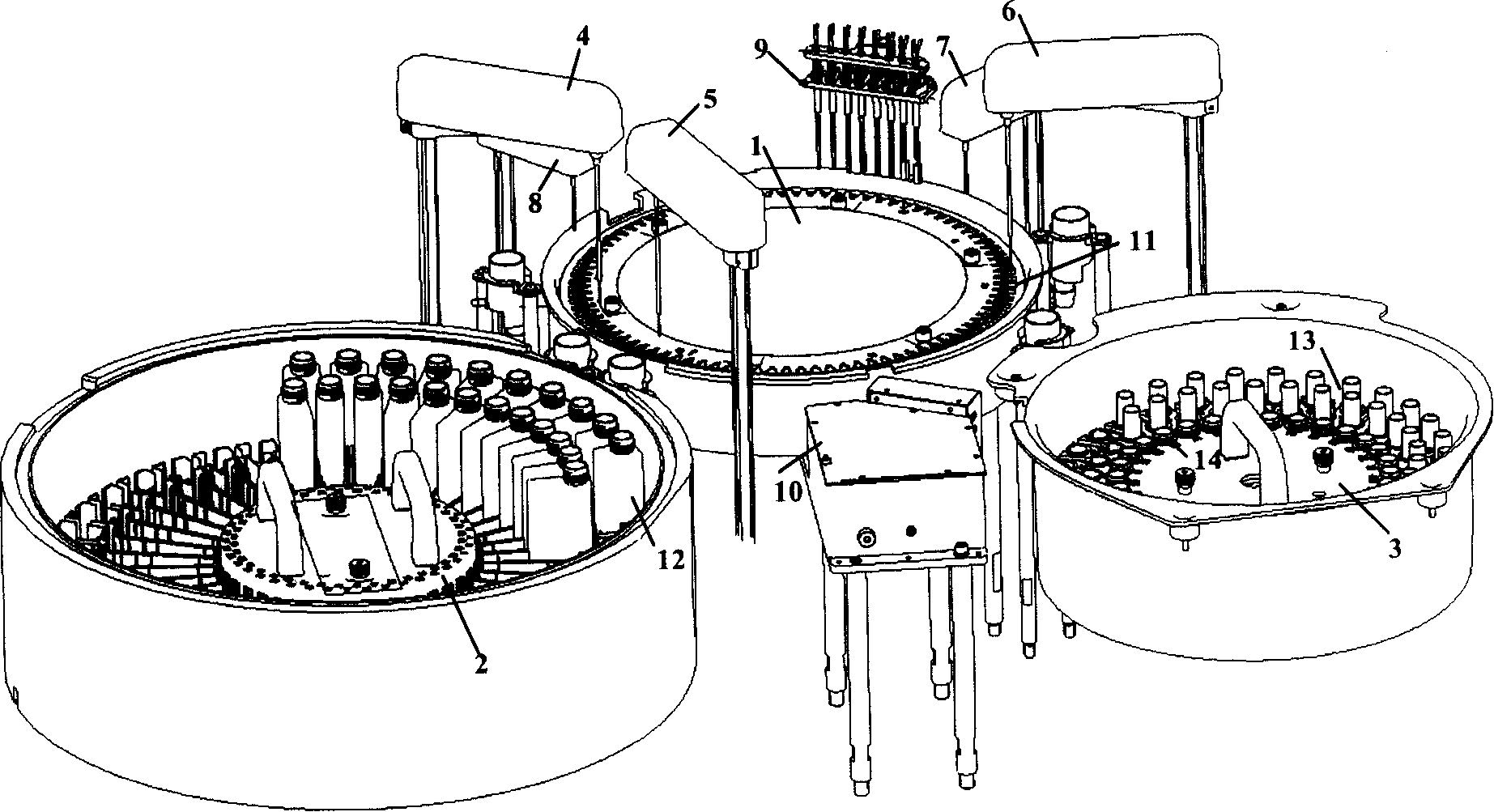

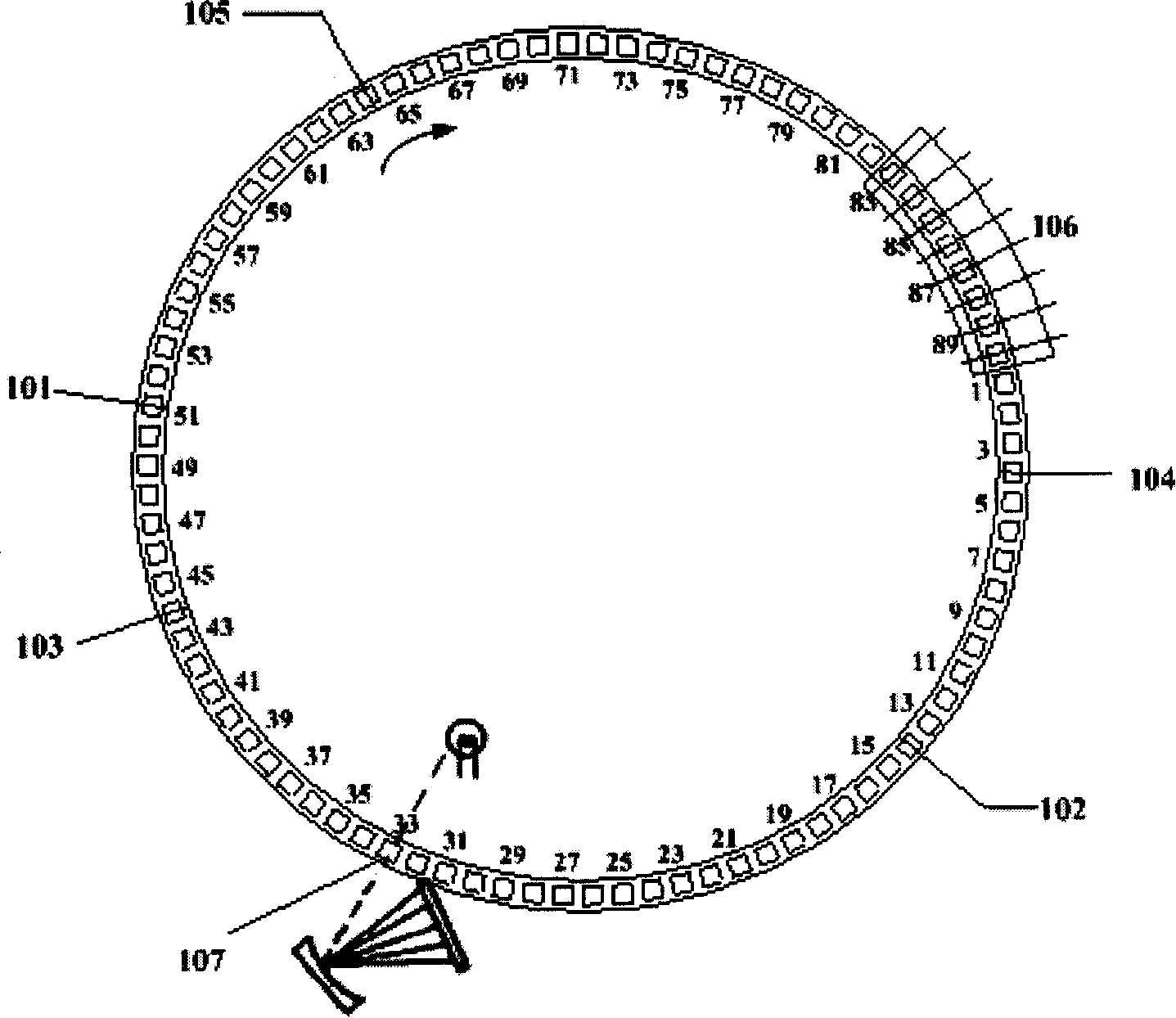

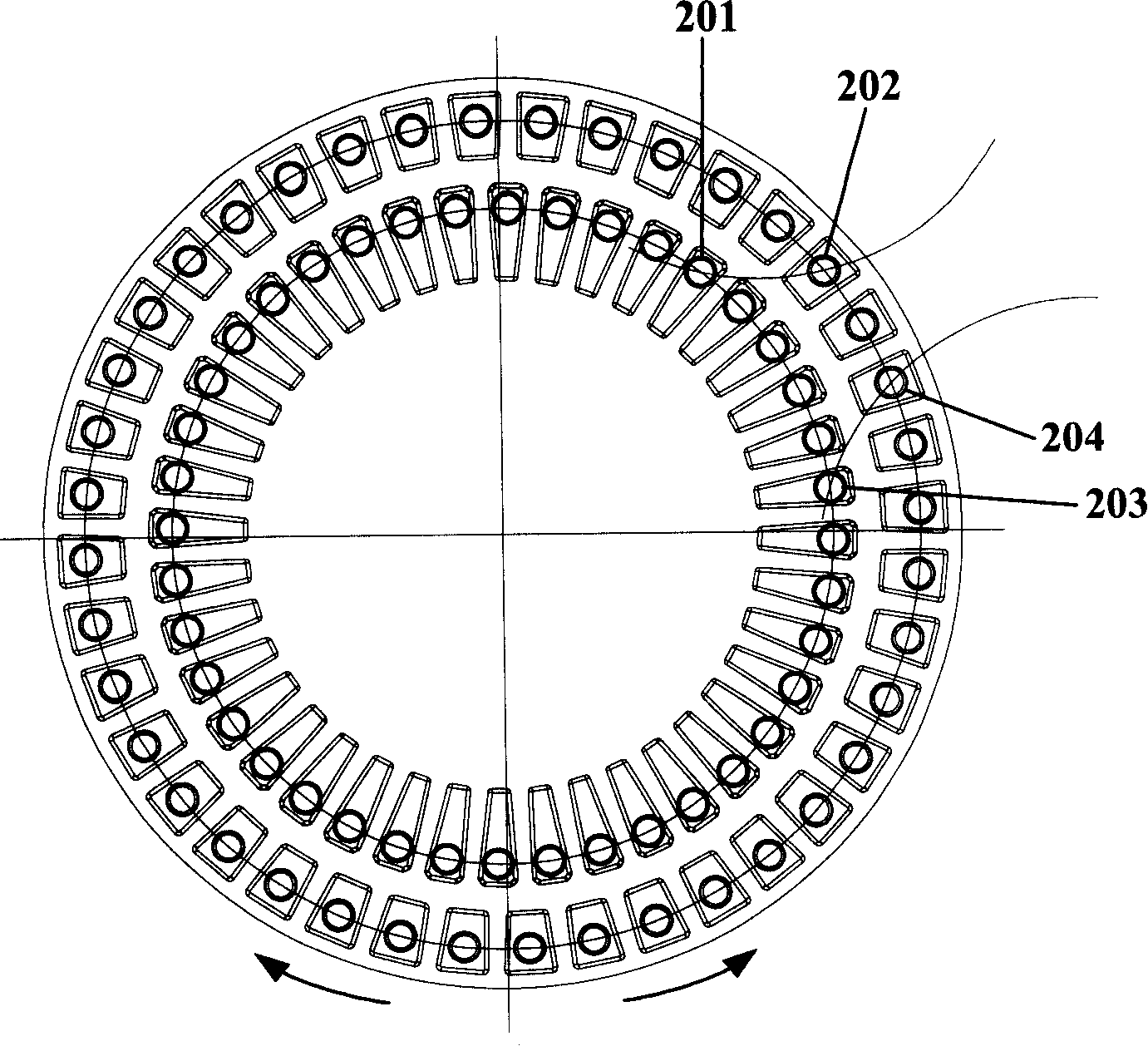

Full-automatic biochemical analysis method and device

ActiveCN101169450AReduce cross contaminationWork fasterMaterial analysis by optical meansBiological testingWork periodWork cycle

The invention discloses a full automatic biochemical analysis method. A serial of reaction vessels move to make at least one reaction vessel passing through an optical measuring channel in the work period of holding prior sample sampling operation on a serial of reaction vessels arranging in a ring shape to the next sample sampling operation, moreover, within the working period, making a serial of reaction vessels to stop adding sample in midway. A first reagent adding position and a sample adding position in spacing distribution orderly are arranged in the moving route journey of a serial of reaction vessels, when a serial of reaction vessels stop for adding the sample, adding the sample to the reaction vessels in the sample adding position; when stopping in the midway, adding the first reagent to the reaction vessel positioned in the first reagent adding position, moreover in relation to each reaction vessel, the working period of adding the sample lags the working period of adding the first reagent. The method can reduce the cross pollution of reagent and improve the working speed.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

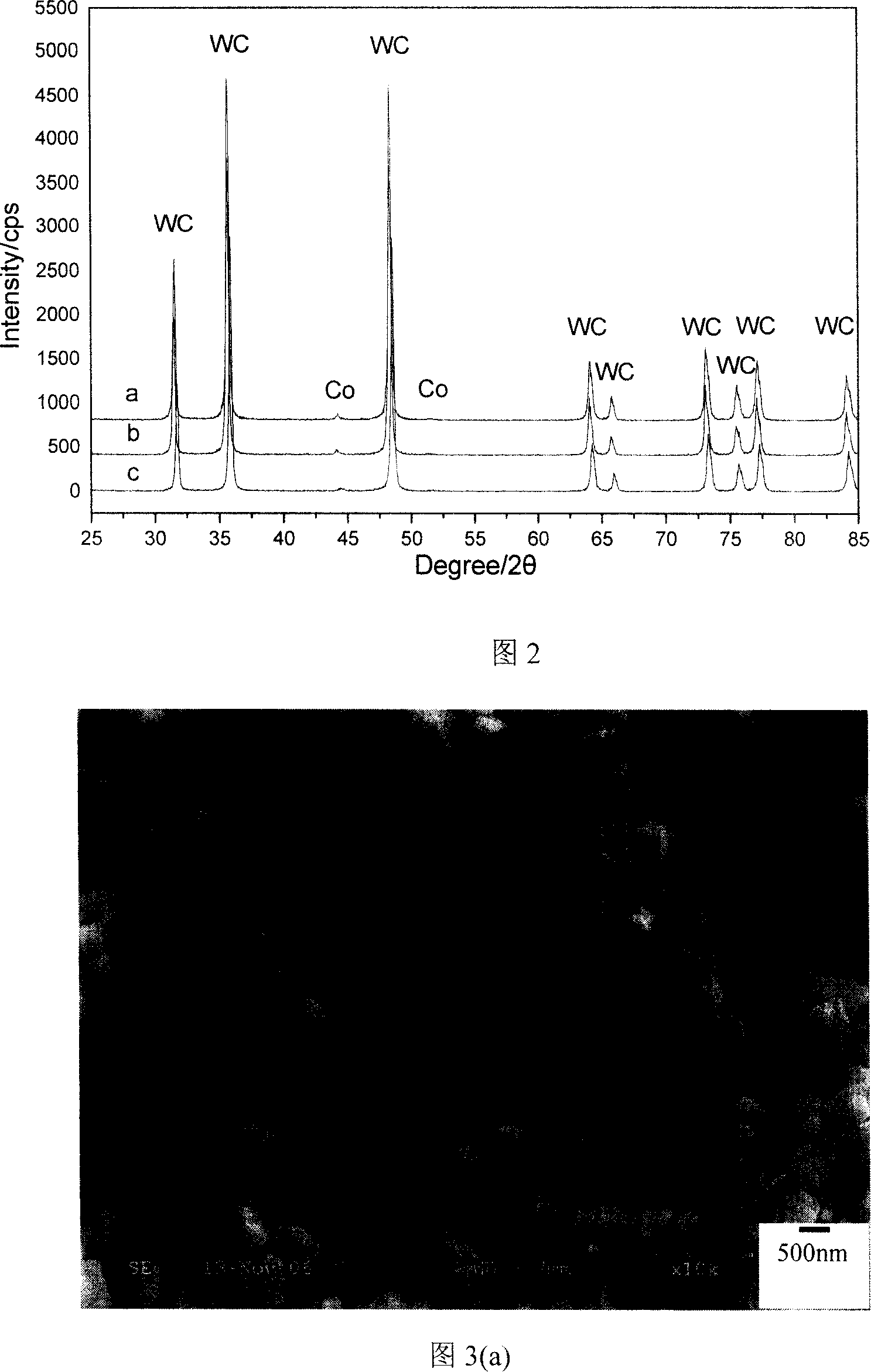

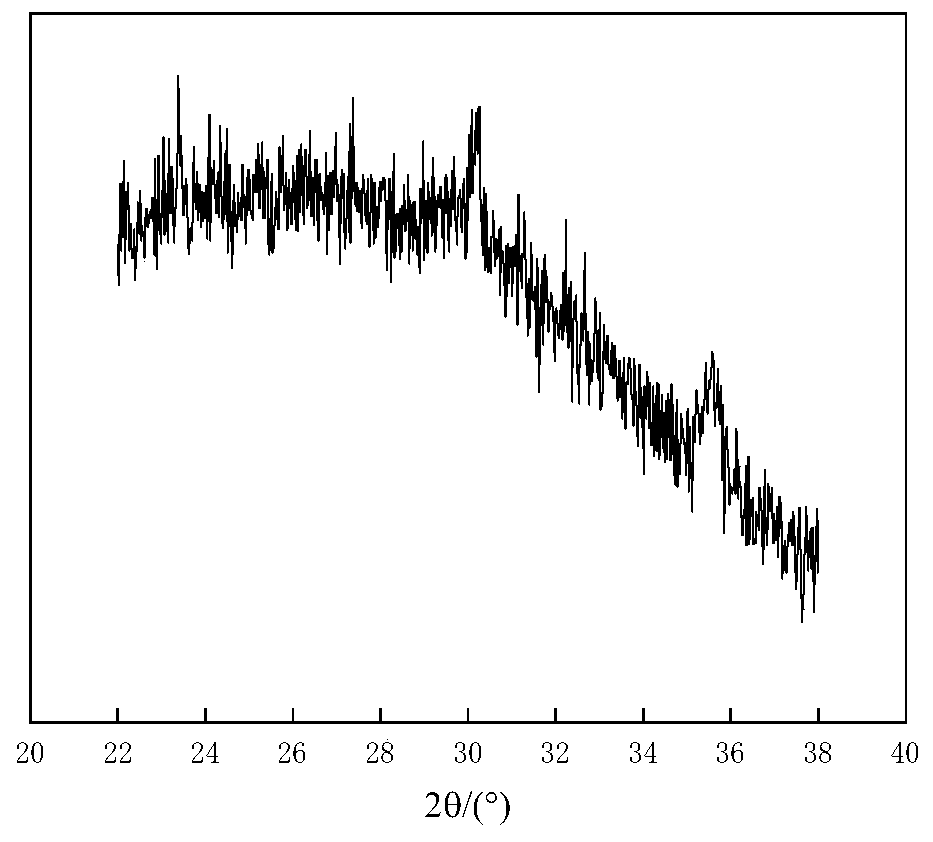

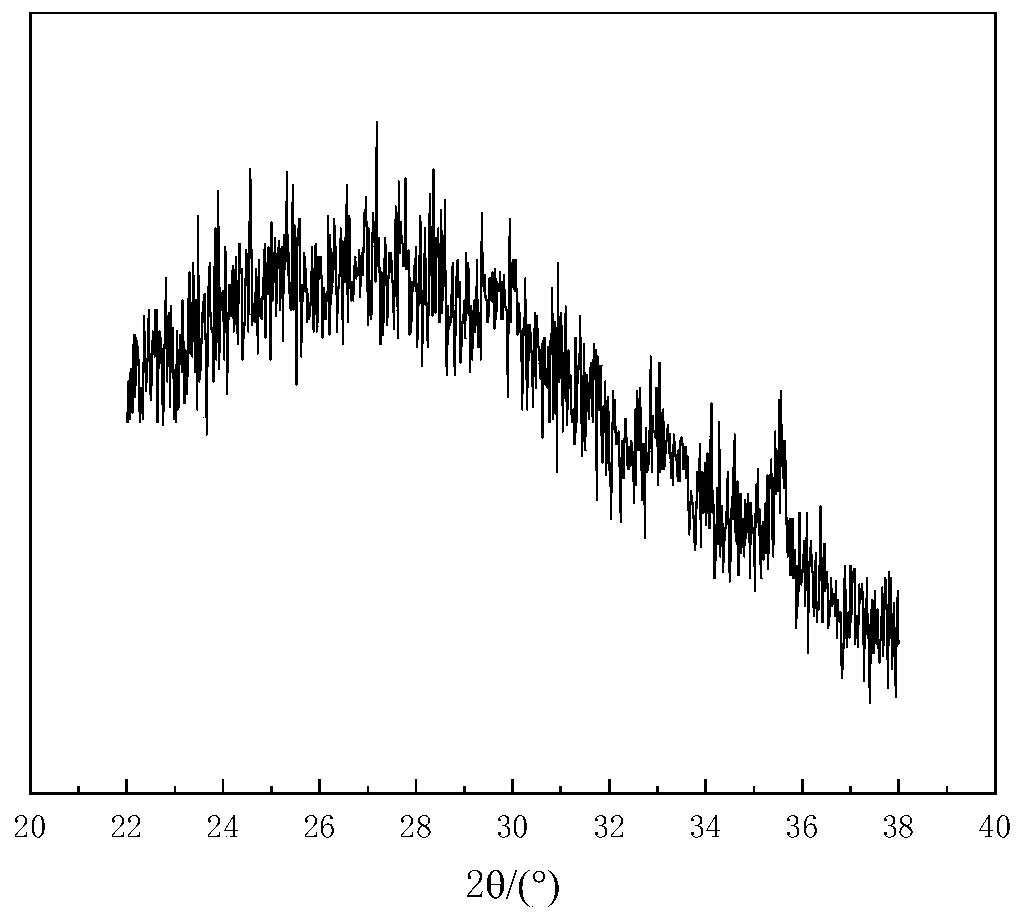

Simple fast preparing process of superfine WC-Co composite powder

The simple fast preparation process of superfine WC-Co composite powder belongs to the field of nanometer powder preparing technology. The preparation process includes the following steps: mixing WO2.9, Co3O4 and carbon black material in the required Co content; ball milling the mixture in a ball milling into superfine powder and cold pressing; heating in a vacuum furnace at vacuum condition to produce redox and carbonizing reaction at heating rate of 15-30 deg.c / min, reaction temperature 1050-1150 deg.c for 3-4 hr. The present invention has simple preparation path and short technological process, and obtains WC-Co composite powder of average particle size smaller than 400 nm.

Owner:BEIJING UNIV OF TECH

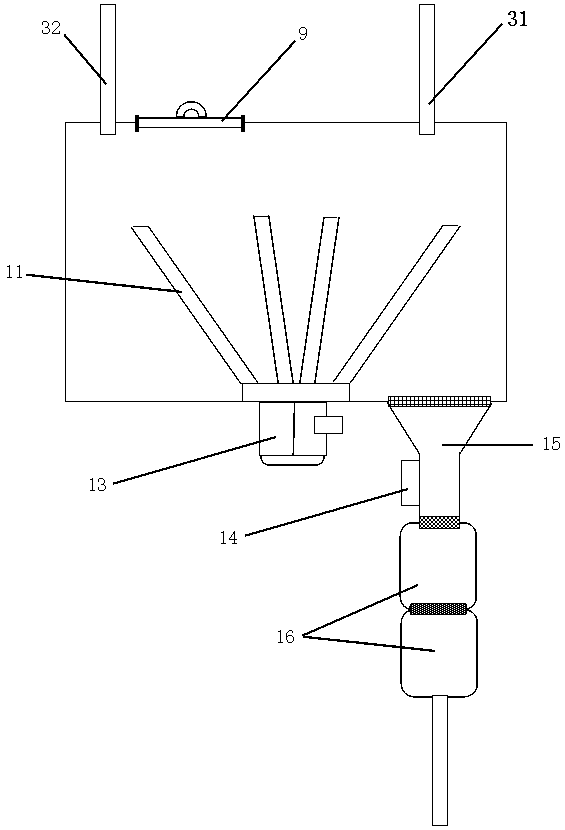

CTP synthesis technology of rubber scorch retarder and device thereof

ActiveCN101624364AReduce chance of decompositionAdequate responseOrganic chemistryChemical/physical/physico-chemical stationary reactorsImideSulfuryl

The invention relates to a CTP synthesis technology of rubber scorch retarder and a device thereof. The technology comprises the following steps of: continuously adding cyclohexyl sulfenyl chloride and phthalimide sodium salt into a tube type reactor, continually adding with nitrogen, momentary completely mixing the cyclohexyl sulfenyl chloride and the phthalimide sodium salt at the tube type reactor and reacting, adding materials into a condensation kettle, and continuously stirring to have a condensation reaction under consistent temperature. The invention also provides a special tube type reactor. By adding a pipeline condensation reaction, the invention can reduce the decomposition probability of the cyclohexyl sulfenyl chloride, thereby heightening yield efficiency to be more than 92% and purity to be more than 98%.

Owner:SHANDONG YANGGU HUATAI CHEM

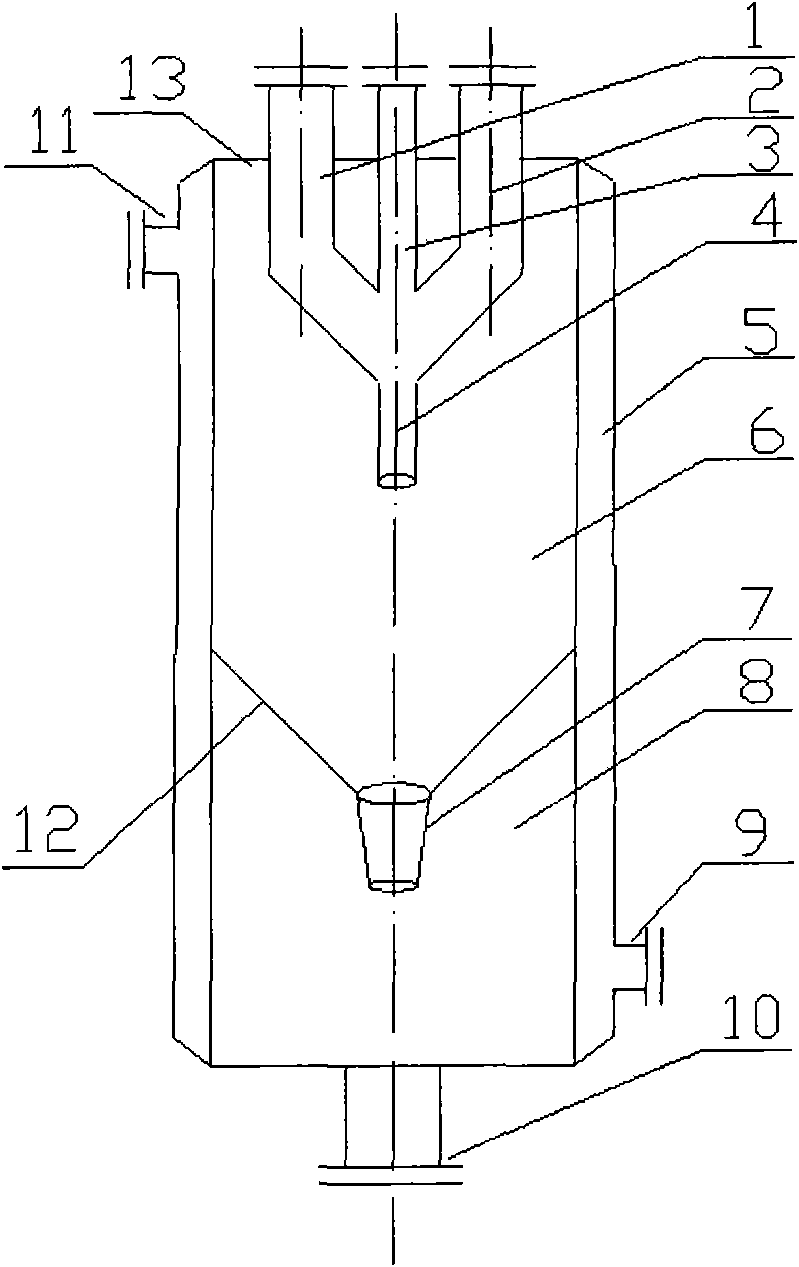

Supercritical water oxidation system and starting method thereof

ActiveCN107500462AAvoid problems such as fouling and cloggingRealize the heating effectMultistage water/sewage treatmentWater/sewage treatment by oxidationEnvironmental engineeringOxygen

The invention relates to the technical field of resource and environment, in particular to a supercritical water oxidation system and a starting method thereof. The system comprises a fuel branch, evaporable water branches, a waste liquid branch, an oxygen branch, a water membrane reactor and a mixer; the fuel branch and the waste liquid branch are respectively connected to the mixer, and the mixer is connected with a raw material inlet of the water membrane reactor; the evaporable water branches are respectively connected to a raw material inlet and a side wall surface of the water membrane reactor, and the oxygen branch is connected with an oxygen inlet of the water membrane reactor. The supercritical water oxidation system adopts the fuel as a starting simulation material to start the supercritical water oxidation reaction of the simulation material, thereby achieving an effect for warming a furnace; then the real waste liquid is gradually used to substitute the fuel, so that the waste liquid can be directly injected into the reactor without being preheated.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

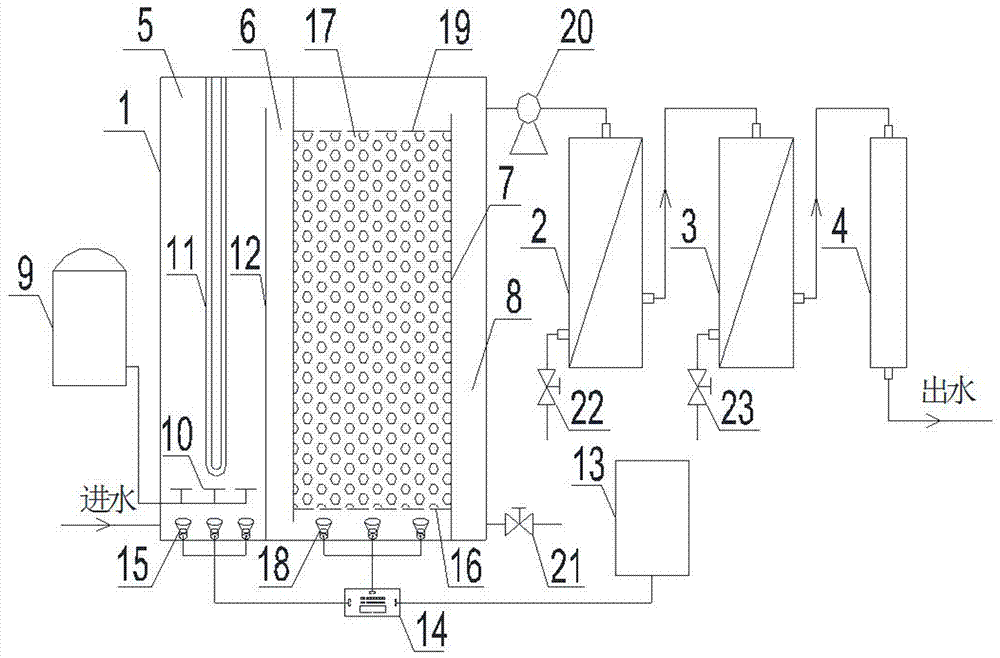

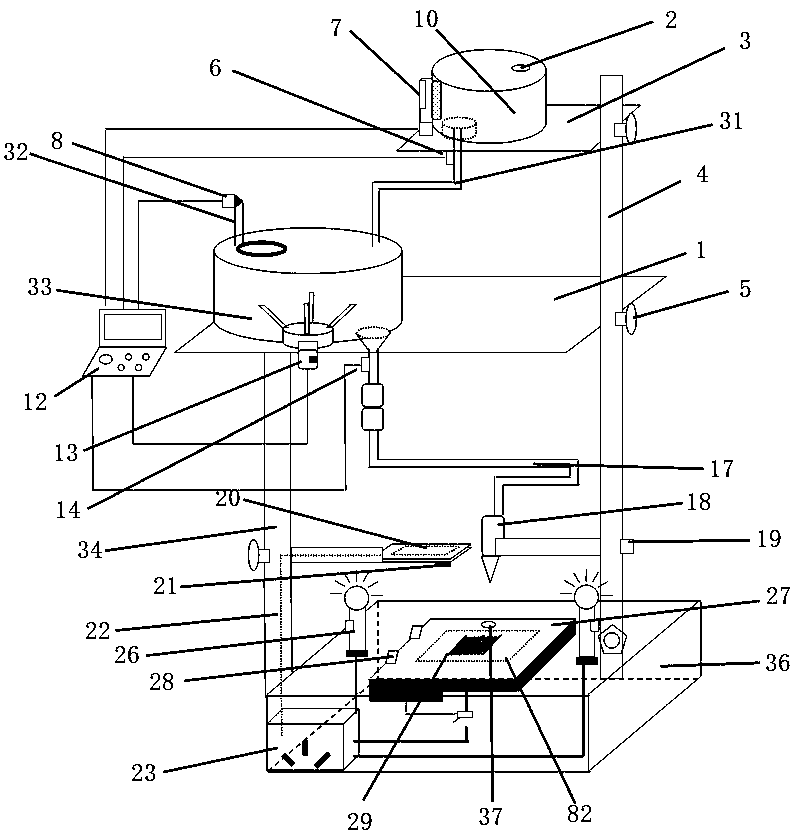

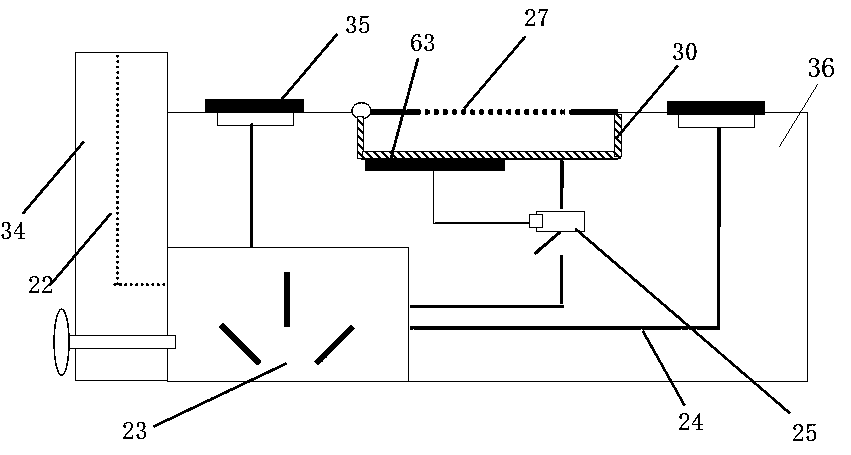

Multistage oxidation-membrane separation collaborative water treatment system and process for light-sound-electricity coupled energy field

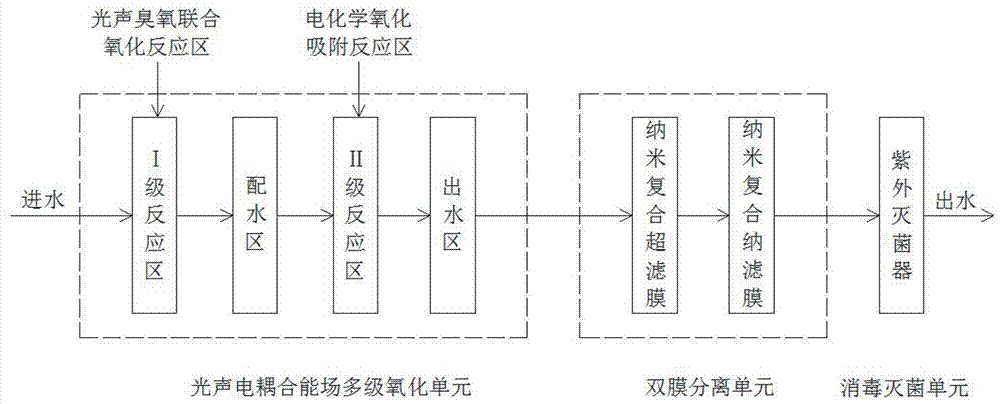

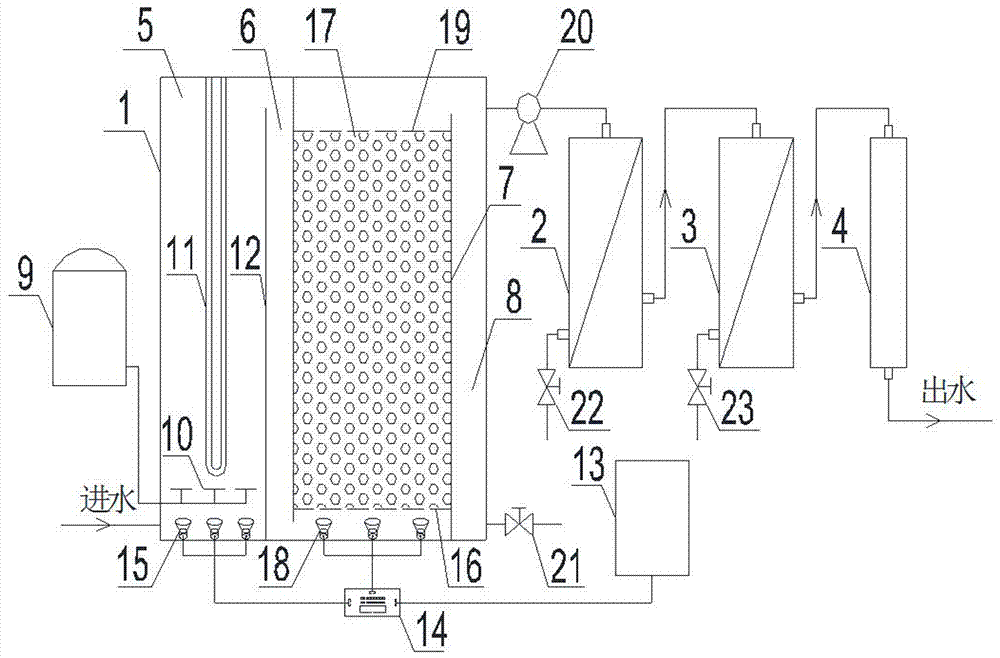

PendingCN107986538AReduce pollutionExtended cleaning cycleWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsUltrafiltrationSeparation technology

The invention relates to a multistage oxidation-membrane separation collaborative water treatment system and a process for a light-sound-electricity coupled energy field. The multistage oxidation-membrane separation collaborative water treatment system comprises three parts, namely a light-sound-electricity coupled energy field multistage oxidation unit, a dual-membrane separation unit and a disinfection and sterilization unit, wherein the light-sound-electricity coupled energy field multistage oxidation unit comprises a light-sound-electricity coupled energy field multistage oxidation reactorprovided with a light-sound ozone joint oxidation reaction zone and an electrochemical oxidation adsorption reaction zone; the dual-membrane separation unit consists of a first-stage nano-composite ultrafiltration membrane and a second-stage nano-composite ultrafiltration membrane; the disinfection and sterilization unit adopts an ultraviolet sterilizer. By using a coupling synergistic effect among an ozone oxidation technology, an ultraviolet photoxidation technology, an ultrasonic oxidation technology, an activated carbon adsorption technology, an electrochemical oxidation technology, a membrane separation technology and the like, the multistage oxidation-membrane separation collaborative water treatment system is efficiently integrated to form an integral inseparable reaction system ofwhich all parts are synergized; the multistage oxidation-membrane separation collaborative water treatment system can be used for carrying out multistage oxidation and degradation on organic pollutants in a water body and then separating and removing the organic pollutants, and effectively removing organic salts, in particular to high valence salt ions.

Owner:LANZHOU JIAOTONG UNIV

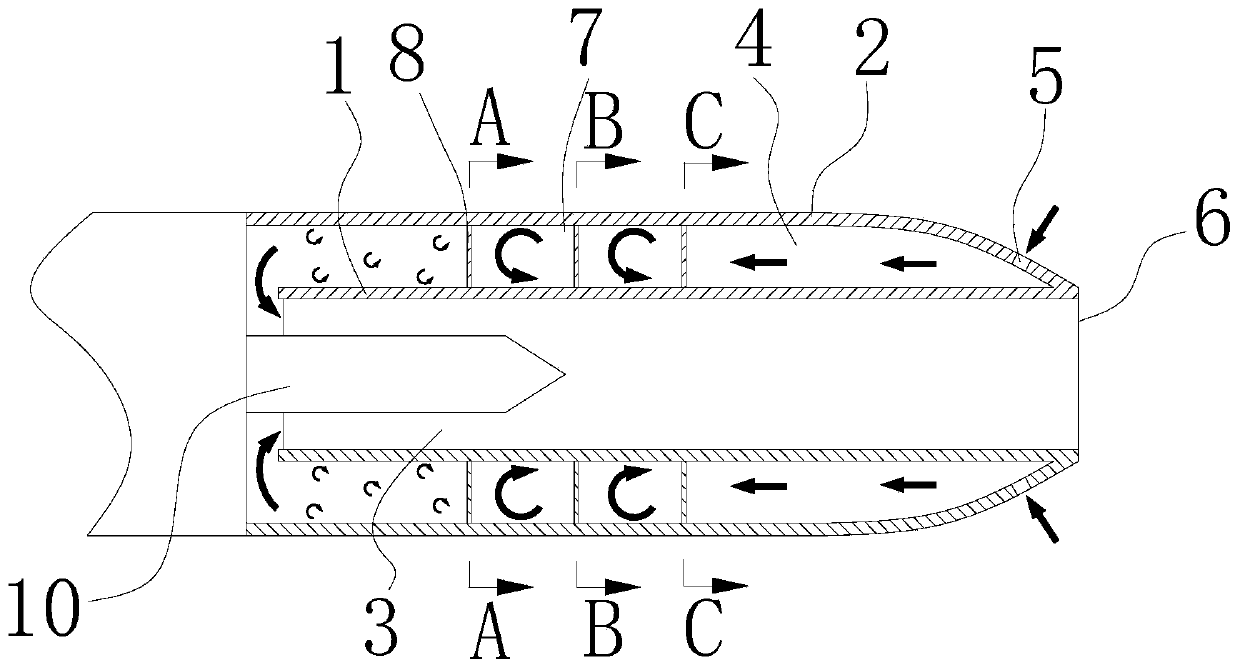

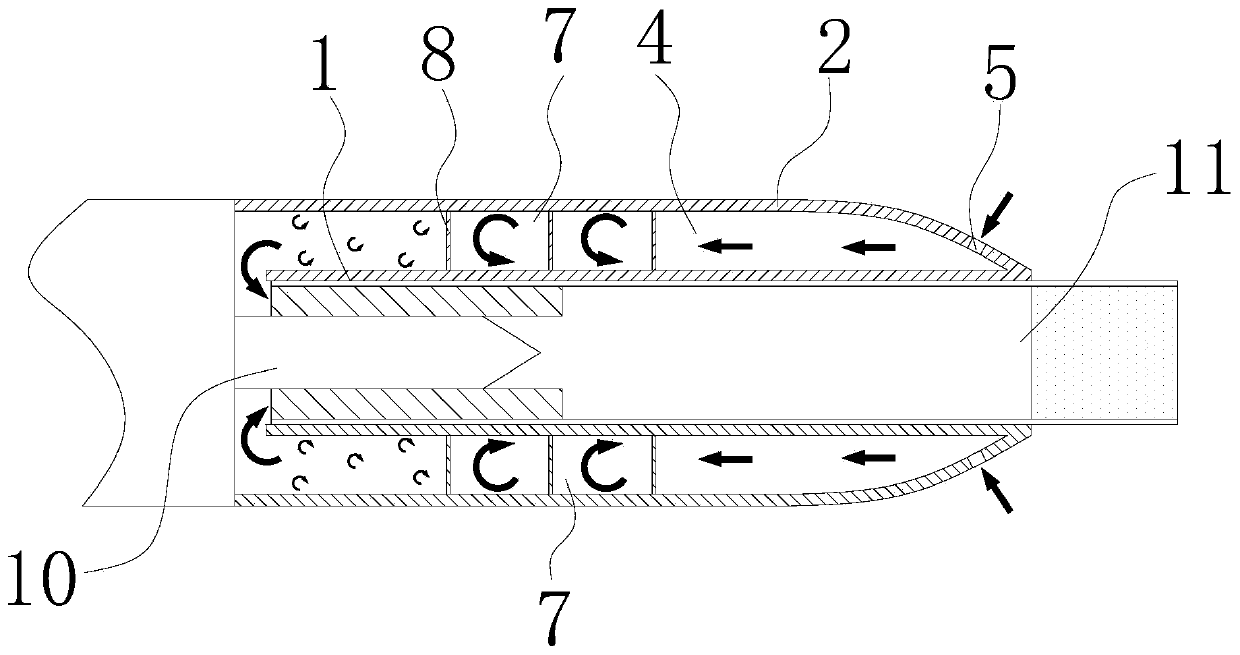

Heating cigarette smoking set gas path structure and heating cigarette smoking set

ActiveCN110623313AReduce the temperatureImprove user experienceTobacco devicesInlet channelCooling effect

The invention relates to the field of heating cigarettes, in particular to a heating cigarette smoking set gas path structure and a heating cigarette smoking set. The invention provides the heating cigarette smoking set gas path structure capable of uniformly preheating air and effectively reducing the temperature of an outer wall, wherein the heating cigarette smoking set gas path structure comprises an inner sleeve and an outer wall; a smoke gas generation cavity is formed in the inner sleeve; the inner sleeve is nested in the outer wall; an air inlet channel is arranged between the inner sleeve and the outer wall; an air inlet of the air inlet channel is located in one side close to a smoking end of the smoke gas generation cavity; an air outlet of the gas channel is communicated with the air inlet end of the smoke gas generation cavity; and a turbulence generator is arranged in the air inlet channel. According to the structure, a counter-rotating cooling structure is adopted, the cooling effect of the wall of the heater is enhanced by forming the swirling flow by forming the double-rotating gas flow, the preheating airflow with more uniform temperature field distribution is formed, the temperature of the smoke gas inlet during smoking is suitable, and the utilization rate of the heat source is improved to the maximum extent.

Owner:SICHUAN SANLIAN NEW MATERIAL CO LTD +1

Process for synthesizing 2-chloro-5-chloromethylpyridine

InactiveCN1631881AAvoid evaporation lossPrevent polymerization and cokingOrganic chemistryOrganic chloride compoundPyridine

A method for synthesizing 2-chlorine-5-chloromethyl pyridine, uses 2-chlorine-5- as the raw material, organic chloride as solvent, in the conditions of temperature:80-180deg.C and normal pressure, initiate by chloride or light, through choosing chlorination reaction to synthesize 2-chlorine -5-chloromethyl pyridine directly. The invention has high conversion rate and utilization ratio of raw material little coking in chlorination reaction, and high seletivity and productivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

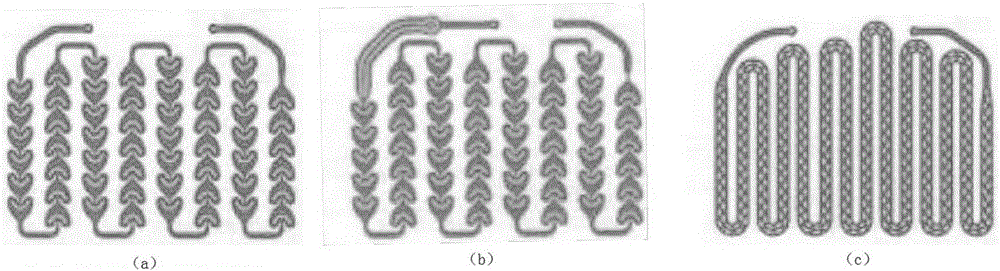

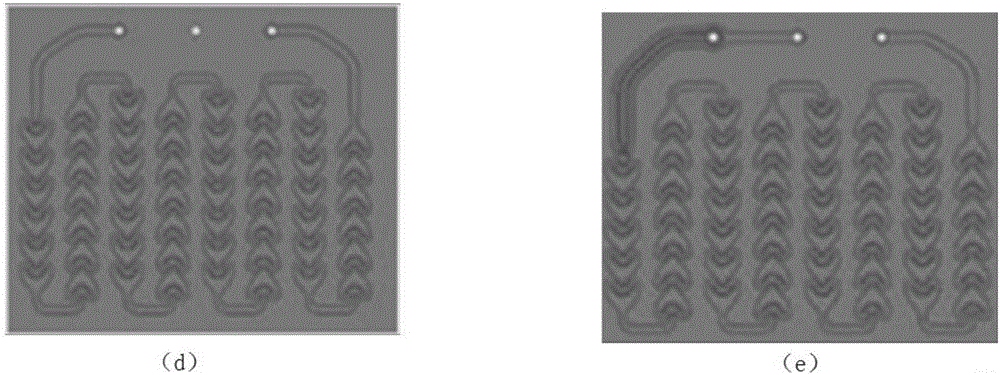

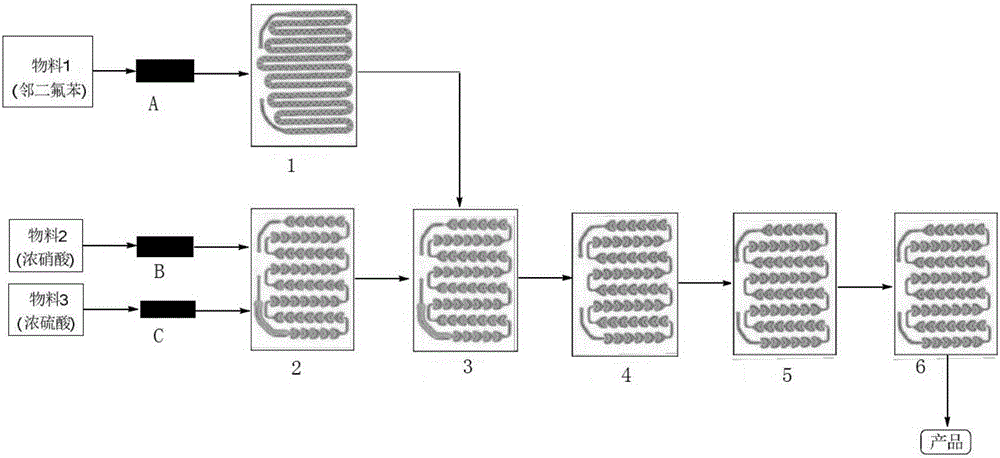

Method for synthesizing 3-fluoro-4-(4-morpholinyl)aniline by using micro-channel reactor

ActiveCN106397358AReduce energy consumptionEfficient mass and heat transferOrganic chemistryAcetic acidHydrogen

The invention provides a method for synthesizing 3-fluoro-4-(4-morpholinyl)aniline by using a micro-channel reactor. The micro-channel reactor comprises a preheating module group composed of one or more parallely-connected preheating modules and a reaction module group composed of one or more tandemly-connected reaction modules, wherein the preheating module group is series connection with the reaction module group. The method comprises the following steps: separately preheating difluorobenzene, concentrated nitric acid and concentrated sulfuric acid, then subjecting the preheated difluorobenzene, concentrated nitric acid and concentrated sulfuric acid to a reaction in the reaction module group and carrying out treatment so as to obtain 3,4-difluoronitrobenzene; dissolving 3,4-difluoronitrobenzene in an organic solvent, adding organic base, dissolving morpholine in the organic solvent, carrying out preheating, allowing the obtained solution to enter the reaction module group for a reaction and carrying out treatment so as to obtain 4-(2-fluoro-4-nitrophenyl)morpholine; and dissolving 4-(2-fluoro-4-nitrophenyl)morpholine in ethyl acetate, adding a catalyst, carrying out preheating, allowing the obtained solution and hydrogen to enter the reaction module group for a reaction and carrying out treatment so as to obtain 3-fluoro-4-(4-morpholinyl)aniline. The method has the advantages of low energy consumption, high yield, high product purity, safety, flexibility, etc.

Owner:HEILONGJIANG XINCHUANG BIOLOGICAL TECH DEV CO LTD

Preparation method of halohydrocarbon-free alpha-cyanoacrylate

ActiveCN102030681ANot easy to hydrolyzeEasy to controlCarboxylic acid nitrile preparationOrganic compound preparationHalohydrocarbonMethyl carbonate

The invention relates to a preparation method of halohydrocarbon-free alpha-cyanoacrylate, which comprises the following steps: mixing cyanoacetate and methyl carbonate in a reaction kettle, simultaneously mixing formaldehyde and a base catalyst in a charging hopper, then adding the mixture of the formaldehyde and the base catalyst to the reaction kettle at twice, performing a refluxing and condensation reaction at 78 DEG C under normal pressure, adding a dehydration solvent methyl carbonate to dehydrolyze after the condensation reaction is finished, adding an anionic polymerization inhibitor phosphorus pentoxide and a free radical polymerization inhibitor, and depolymerizing and distilling at 155-210 DEG C at a vacuum degree of 0.5-30 mmHg to obtain an alpha-cyanoacrylate coarse monomer; and rectifying the coarse monomer to obtain a high-purity alpha-cyanoacrylate refined monomer, wherein the yield of the alpha-cyanoacrylate refined monomer is more than 75%, and the purity of the alpha-cyanoacrylate refined monomer is 99%. The invention has the advantages of no pollution, energy conservation and high yield and high purity of the obtained product, and is stable in reaction, thereby being suitable for popularization and application.

Owner:山东禹王和天下新材料有限公司

Iron cobalt composite carbon copper catalyst for continuous production of 4,4-diaminodiphenyl ether as well as method

InactiveCN110639553ASimple compositionLow costOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsDiaminodiphenyl etherPtru catalyst

The invention discloses an iron cobalt composite carbon copper catalyst for continuous production of 4,4-diaminodiphenyl ether as well as a method. The catalyst takes carbon coated foam copper as a carrier and loads Fe, Co and noble metal; and the mass contents of the Fe, the Co and the noble metal in the catalyst are sequentially 0.1 to 1.0 percent, 0.1 to 0.8 percent and 0.1 to 0.9 percent. The4,4-diaminodiphenyl ether is continuously produced by adopting the iron cobalt composite carbon copper catalyst, by taking 4,4-dinitrodiphenyl ether as a raw material and by performing nitro hydrogenation reaction on a catalyst bed by a trickle bed, the catalytic reaction efficiency is high, the reaction heat is concentrated, the carbon coated foam copper carrier can disperse the active componentsof the catalyst well, also can rapidly remove reaction heat and guarantees that the reaction is conducted within the proper temperature range rapidly and stably, the raw material conversion rate is 100 percent, the selectivity of target products is more than 99.9 percent, the catalyst property is stable, the catalytic reaction is too simple the catalytic reaction heat is recoverable, the heat energy utilization efficiency is high, and environmental friendliness is realized.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

Method for purifying diamond or cubic boron nitride abrasive

ActiveCN103043658ANo incomplete responseSave electricityNitrogen compoundsOther chemical processesPyrophylliteHexagonal boron nitride

The invention relates to a method for purifying a diamond or cubic boron nitride abrasive. The method comprises the following steps: adding sodium hydroxide and potassium hydroxide to diamond or cubic boron nitride containing pyrophyllite silicate, hexagonal boron nitride and silicon oxide; stirring the sodium hydroxide and the potassium hydroxide as well as the diamond or cubic boron nitride for reaction; controlling an internal temperature at 130-150 DEG C and controlling an external temperature range at 240-250 DEG C; 2-4 hours later, closing a heating system; and discharging a product through a discharging product. Through the adoption of the method provided by the invention, product quality is absolutely guaranteed; in addition, uniformity is kept in stirring; a fact that purity reaches reaches requirements of purifying reaction consistency is guaranteed; impurities and incomplete reaction phenomenon are avoided; the sodium hydroxide and the potassium hydroxide are saved by 70 % according to process statistics; the comprehensive cost is reduced by 50 %; and very good promotion and application values are obtained.

Owner:FUNIK ULTRAHARD MATERIAL

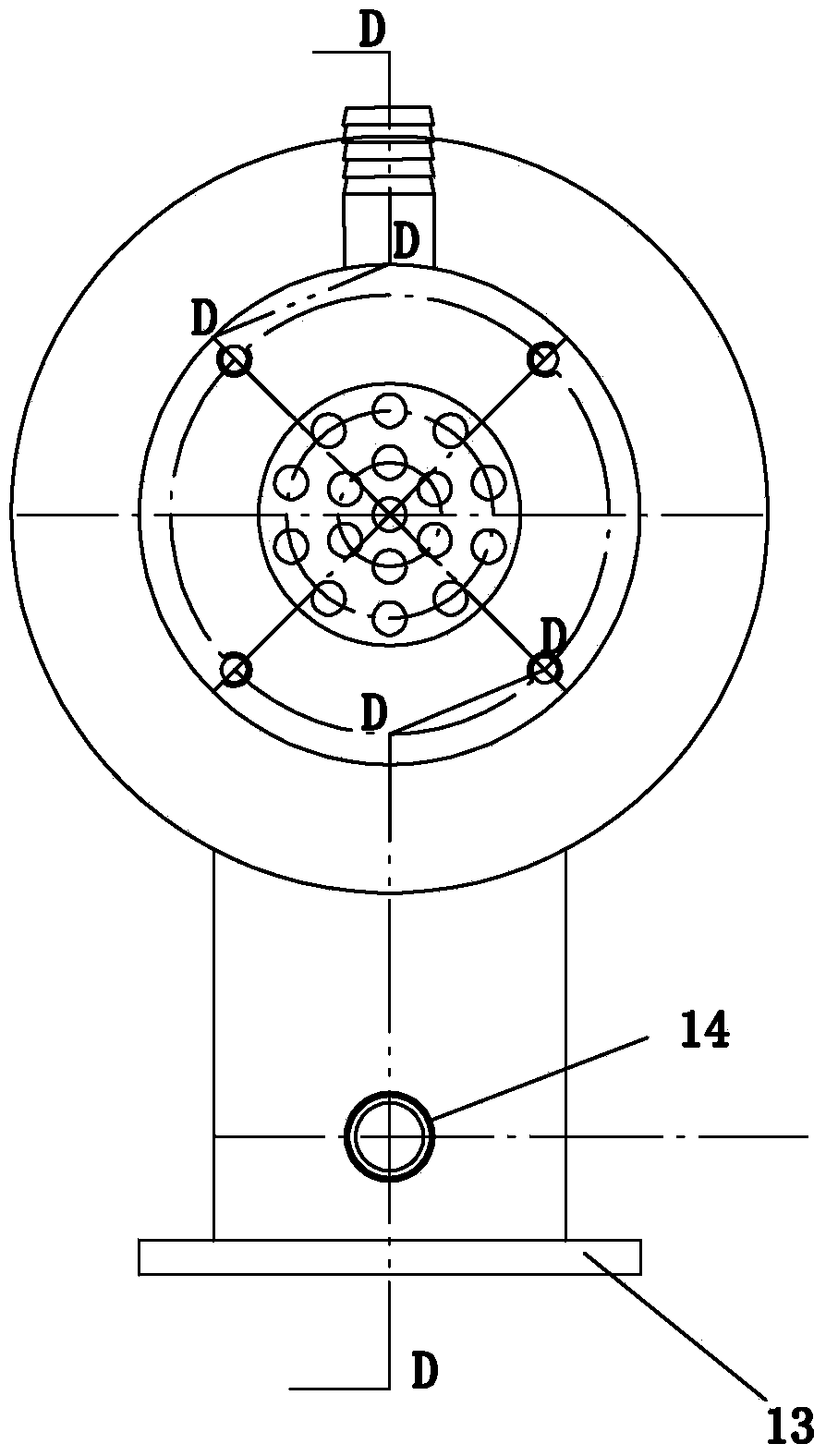

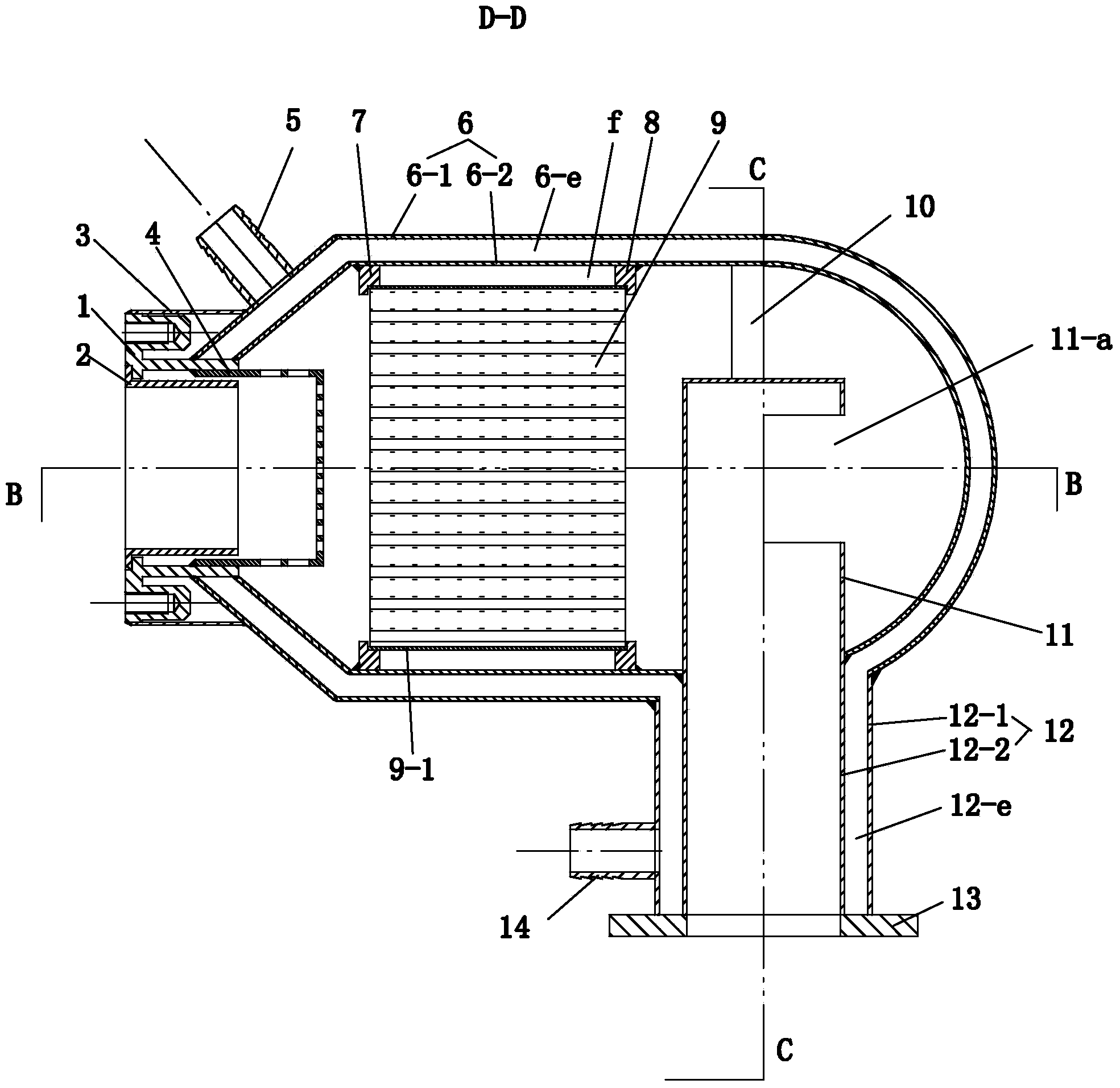

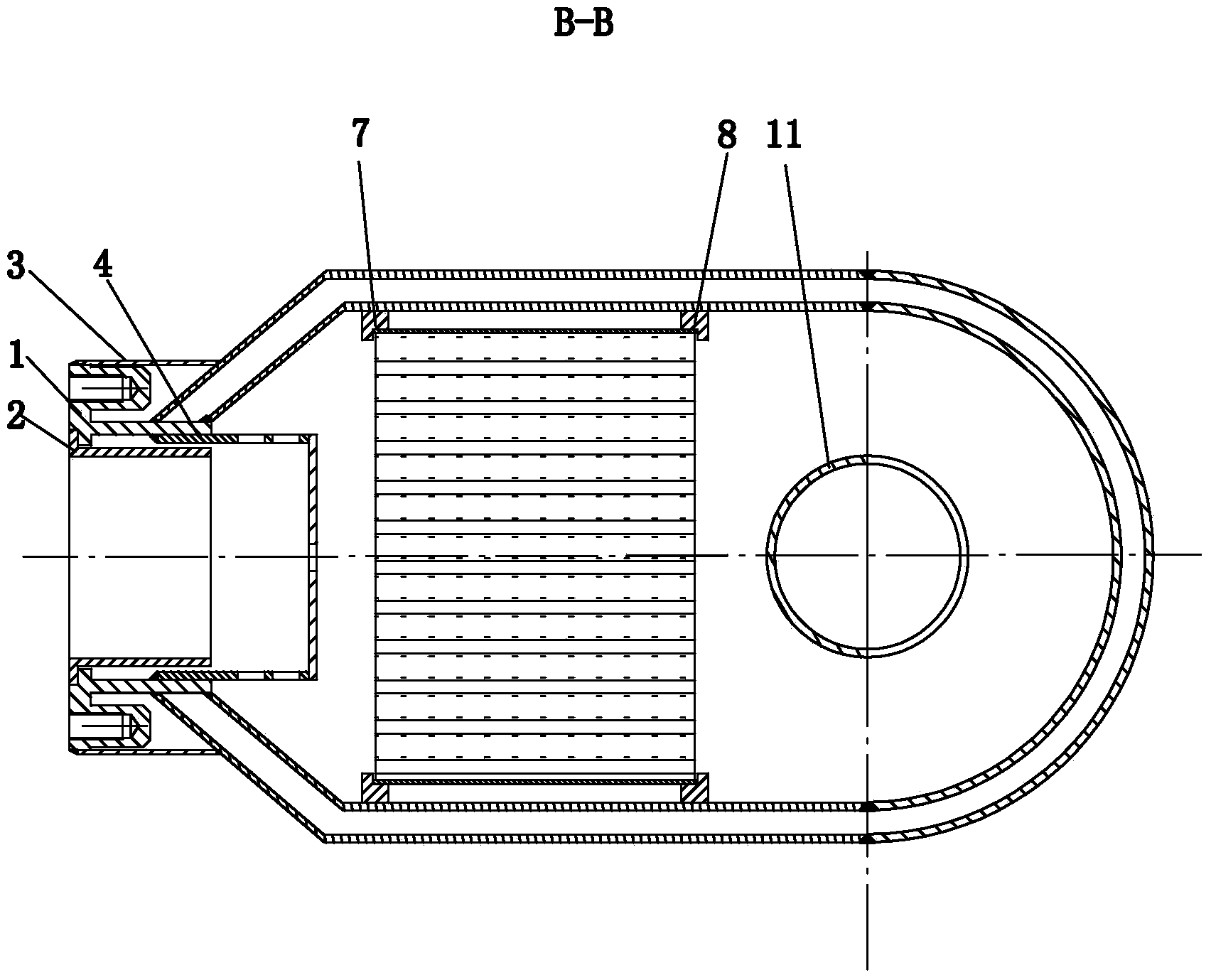

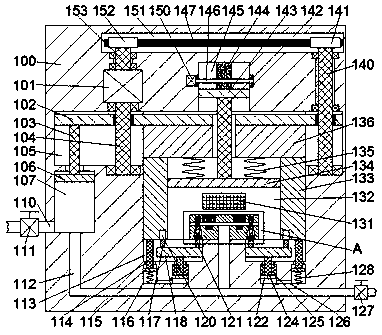

Water-cooling-type tail gas cleanup device of explosion-proof diesel engine

ActiveCN104005815AReduce surface temperatureGuaranteed reaction temperatureExhaust apparatusSilencing apparatusThermal insulationWater cooling

A water-cooling-type tail gas cleanup device of an explosion-proof diesel engine is provided with a front flange, a rear flange, a shell and a DOC core. The front flange is fixed to the front end of a main body shell, a thermal-insulation flange is arranged in the front flange, the rear half portion of the front flange is connected with a flow guide cover, the rear of the flow guide cover goes deep into the main body shell, a front space ring and a rear space ring are arranged on the inner wall of the middle of the main body shell, the DOC core is clamped between the front space ring and the rear space ring, an annular area outside the cylindrical surface of the DOC core between the front space ring and the rear space ring is an air isolation area, an inner shell of a lower shell extends upwards to form a flow guide pipe, an air outlet hole is formed in the cylindrical surface, facing the wall of a hemispheroid cavity, of the flow guide pipe, and the rear flange is installed at the lower end of the lower shell. Through the water-cooling-type tail gas cleanup device, not only is the surface temperature of the diesel engine made to reach the standards, but also high conversion efficiency of the DOC core can be guaranteed.

Owner:CHANGZHOU DEV & MFR CENT

Two-step isolation type full non-chlorine full cotton stalk bleaching pulp cleaning production process

ActiveCN101435165AControl concentrationAccurate measurementPulp bleachingCellulose material pulpingMaterials preparationPulp and paper industry

The invention discloses a clean production technology of two-step isolation type totally chlorine-free and whole cotton stalk bleaching pulp, which has the advantages of simplifying the process, saving cost, reducing pollution, saving energy and the like. The clean production technology comprises the following steps of: 1) material preparation: the whole cotton stalk plant material is treated with cotton-shell removal, leave removal and cutting-off; 2) steaming and water washing; 3) discongesting: the whole cotton stalk material is sent to a compressing and discongesting machine for compression and discongesting; 4) first-step dipping: a one-step bleaching solution is used for dipping the whole cotton stalk material released from the compressing and discongesting machine, and the dipping is maintained; 5) first-step bleaching: the dipped whole cotton stalk material is heated and bleached; 6) jordaning of a first stage: the bleached whole cotton stalk material is ground into unscreened stock by a pulping machine; 7) second-step dipping: the unscreened stock ground by the pulping machine is dipped by using a second-step bleaching solution; 8) second-step bleaching: the unscreened stock treated with second-step dipping is heated and bleached; 9) jordaning of a second stage: the unscreened stock treated with second-step bleaching is ground and dissolved into water pulp; 10) pulp washing and pulp shoving; and 11) stock screening and pulp forming.

Owner:山东凯隆材料科技有限公司

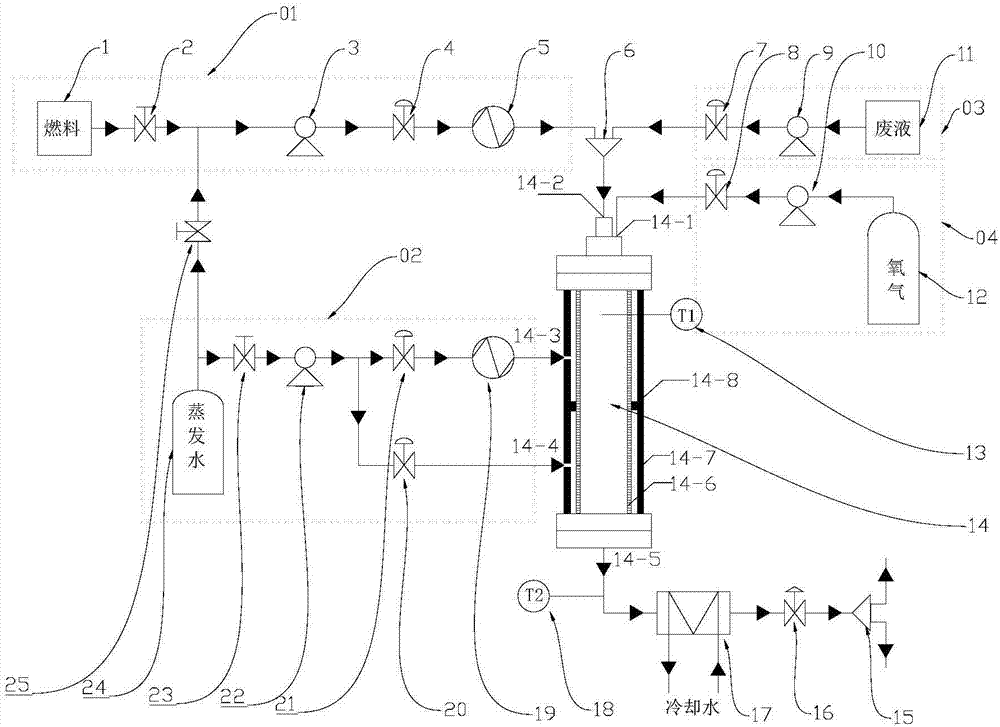

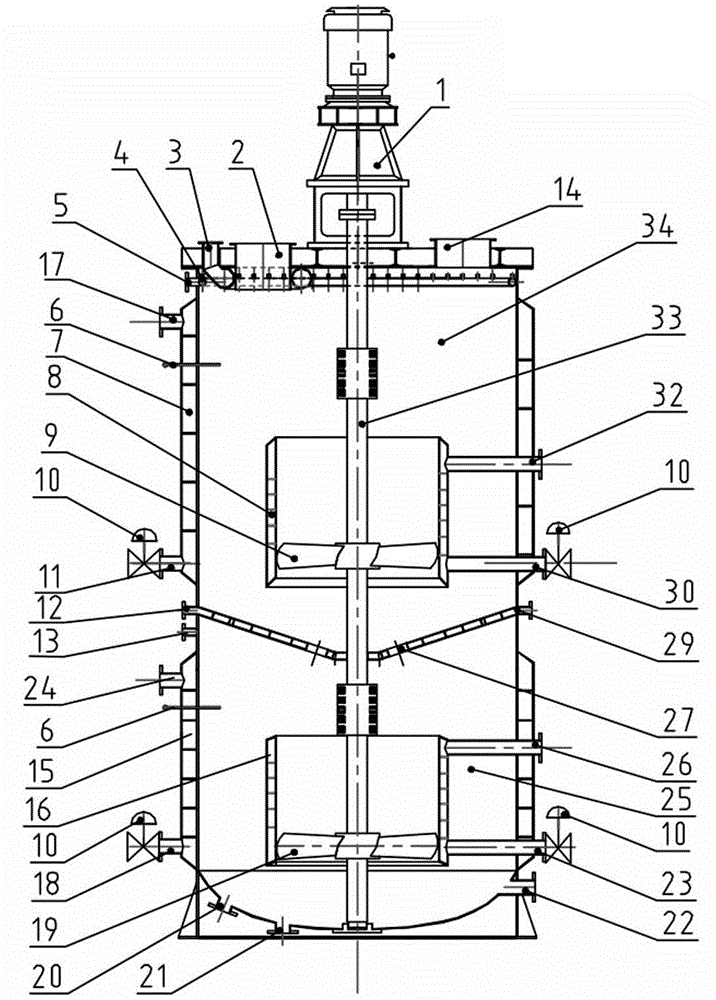

Novel high efficiency reactor

ActiveCN104941554AUniform temperatureQuality improvementMixer accessoriesChemical/physical/physico-chemical stationary reactorsAutomatic controlNuclear engineering

The invention discloses a novel high efficiency reactor, which comprises a reactor body, the reactor body comprises an upper reaction zone and a bottom reaction zone, an intermediate heat exchange separator plate is arranged between the upper reaction zone and the lower reaction zone, a mixer shaft passes through the reactor body, the mixer shaft is connected to a speed reducer arranged on the upper part of the reactor body, an upper heat exchange jacket and an upper inner heat exchange guide shell are respectively arranged on the upper reaction zone; a lower heat exchange jacket and an lower inner heat exchange guide shell are respectively arranged on the lower reaction zone; a temperature sensor arranged on the reactor body and an automatic regulating valve are respectively connected to an automatic control device, and automatic accurate control of the reaction of the materials in the reactor body can be realized. Compared with prior art, a structure of the high efficiency reactor is simple, accurate automatic control can be realized, continuous high efficiency operation of the high efficiency reactor can be carried out, material reaction effect is ensured, effect of the large-scale reactor is more protruding, and a novel development of the novel reactor can be provided.

Owner:吴巴特尔 +2

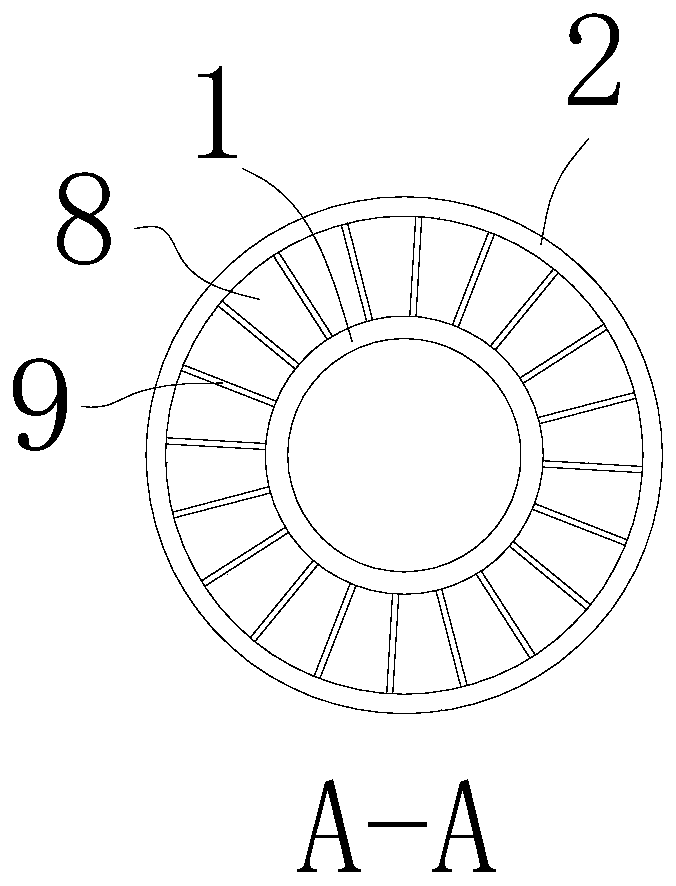

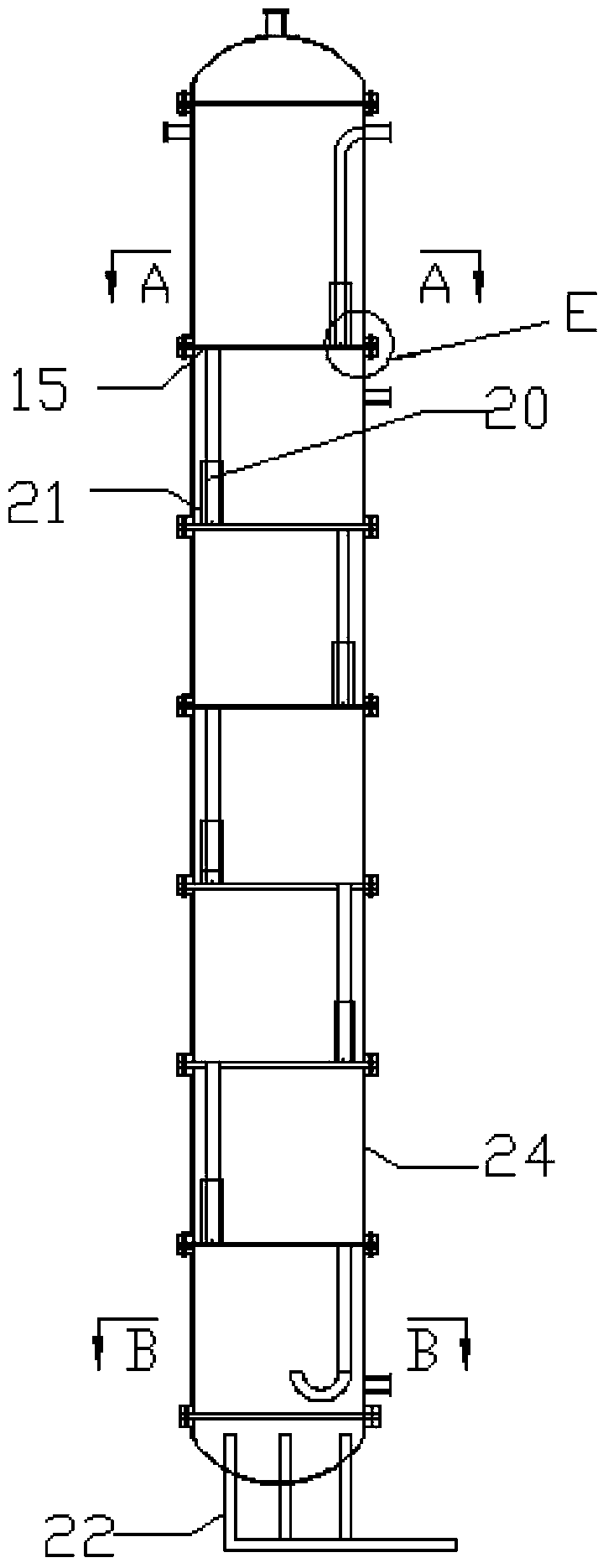

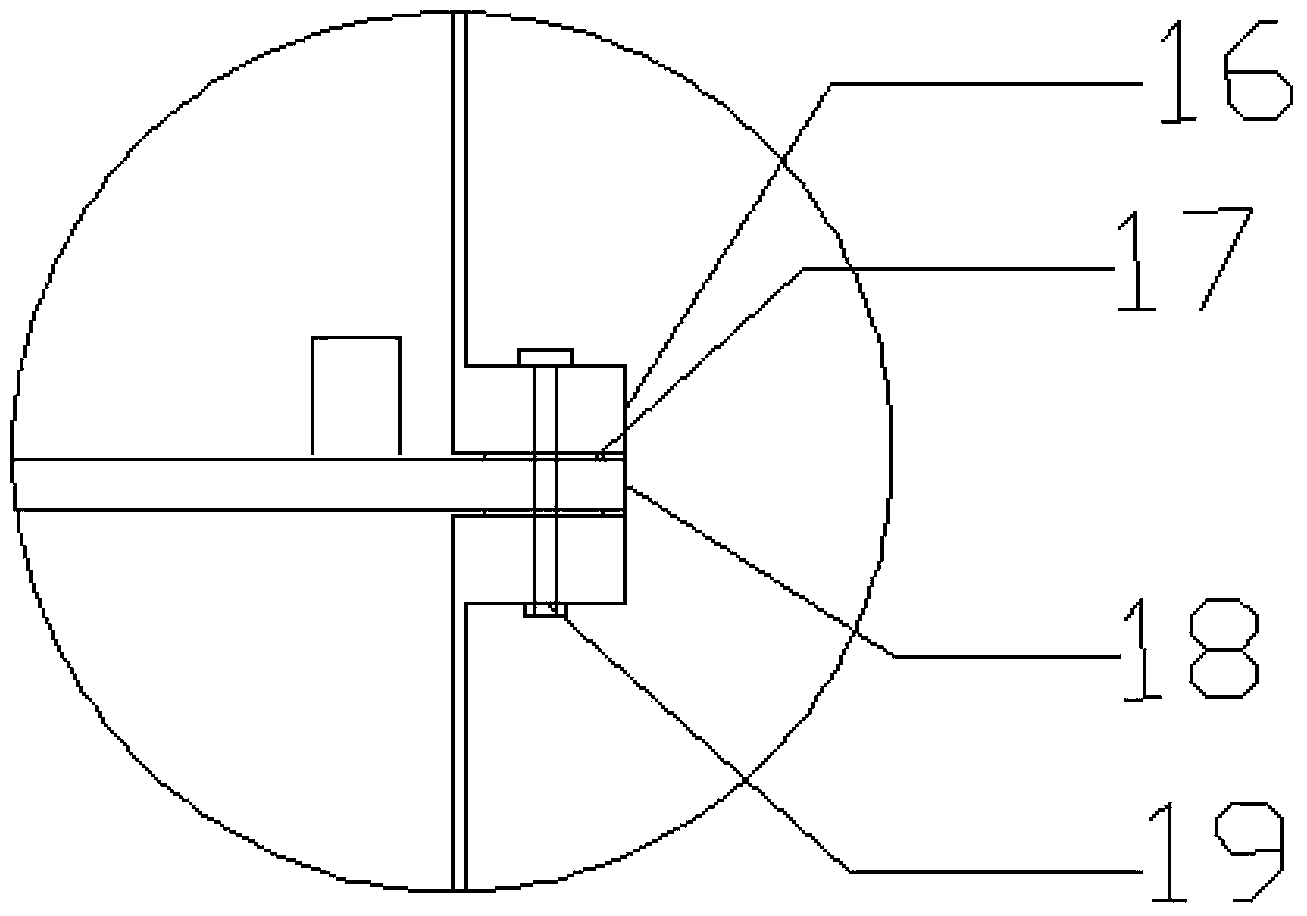

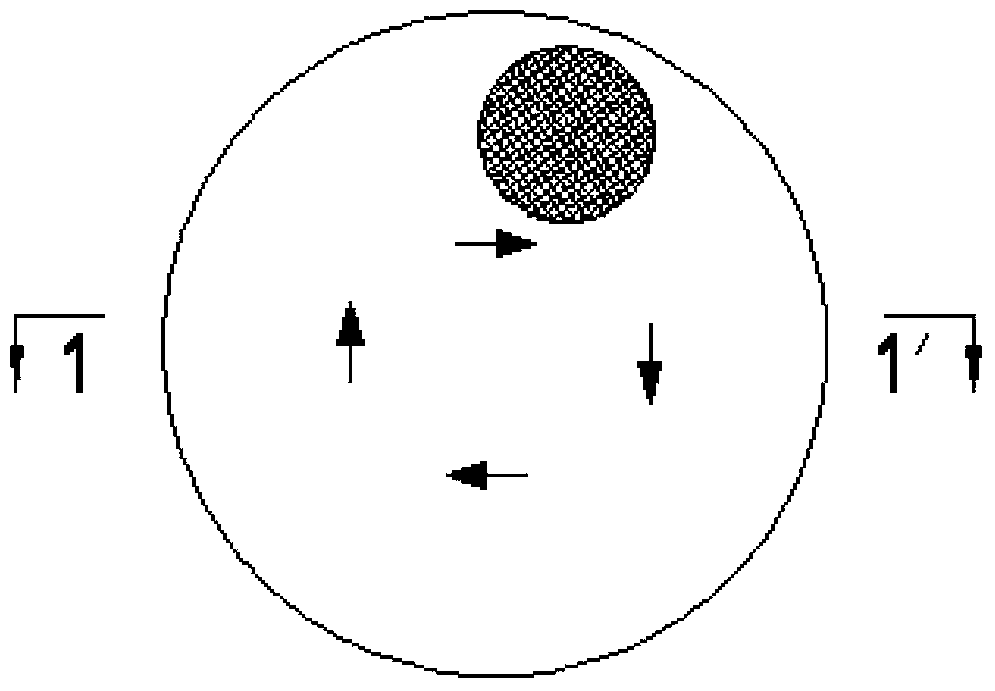

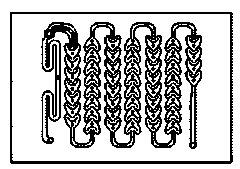

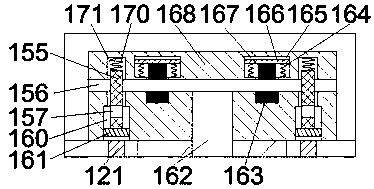

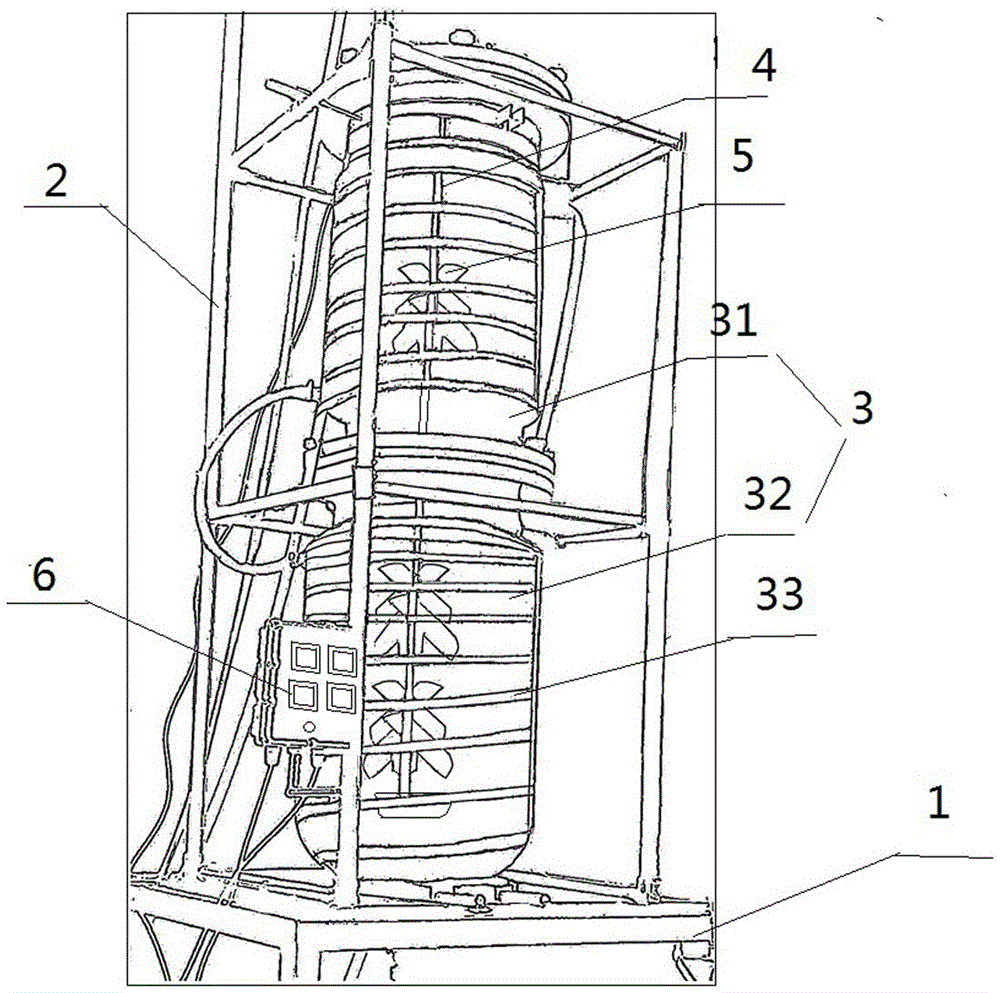

Rotational flow plate glycerinum chlorination bubbling reaction tower and device for producing epichlorohydrin

ActiveCN103406077AGuaranteed reaction temperatureImprove mass transfer efficiencyPreparation by halogen introductionLiquid-gas reaction processesThree levelEngineering

The invention provides a rotational flow plate glycerinum chlorination bubbling reaction tower which comprises a tower body, wherein the tower body comprises a plurality of rotational flow plates in a combined manner; the diameter of a sieve pore in each rotational flow plate is 3-20 mm; the trepanning directions of the upper parts of the sieve pores rotate clockwise or anticlockwise; the angle of a chamfer at the bottom of the sieve pore in the rotational flow plate is 5-85 degrees; a plurality of gas distribution pipes are arranged at the bottom of the tower body; open pores of gas distribution pipes are formed in the gas distribution pipes; each open pore and the horizontal line form an angle of 0-75 degrees; the diameter of the open pore is 0.5-20 mm. The invention further provides a device for producing epichlorohydrin and a use method of the device, wherein the device is composed of three levels of rotational flow plate glycerinum chlorination bubbling reaction towers which are connected in series, so that the floor area of the traditional reaction kettle is effectively saved, a liquid phase reactant is in better contact with a gaseous phase reactant, the reaction time is saved, the reaction efficiency is high and the productive rate is increased.

Owner:CHINA TIANCHEN ENG +1

PE (Poly Ethylene) heat shrink film and preparation method thereof

The invention relates to a PE (Poly Ethylene) heat shrink film, which relates to the technical field of high polymer materials. The PE heat shrink film is prepared from the following raw materials in parts by weight: 3-9 parts of low density polyethylene, 23-41 parts of high density polyethylene, 25-45 parts of metallocene polyethylene, 18-40 parts of ultra-high molecular weight polyethylene and 2-10 parts of polyethylene wax. The invention also discloses a preparation method of the PE heat shrink film. The PE heat shrink film prepared by the method has the advantages of good flexibility, impact resistance, high tearing resistance, small possibility of damaging, moisture prevention, big percentage of contraction, high intensity and high toughness.

Owner:桐城市华猫软膜有限公司

Preparation method of nano silicon dioxide/rosin modified urea-formaldehyde resin

ActiveCN104725775AShort curing timeImprove resin performanceNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesChemistryRosin

The invention belongs to the technical field of urea-formaldehyde resin preparation, and particularly relates to a preparation method of a nano silicon dioxide / rosin modified urea-formaldehyde resin. The method comprises the following steps: preparing a urea-formaldehyde resin from urea and formaldehyde by a weak alkali-weak acid-weak alkali technique, and modifying with nano silicon dioxide and rosin to obtain the nano silicon dioxide / rosin modified urea-formaldehyde resin. The method has the advantages of simple technique and accessible raw materials, and is suitable for industrialized mass production. The prepared urea-formaldehyde resin has the advantages of favorable viscosity, high softening point, low free formaldehyde content, environment friendliness, higher water resistance, favorable toughness and improved aging resistance, is suitable for artificial board production, and can be used as an adhesive in material binding, bamboo / wood processing, paper binding, steel paints, multicolor pattern paints and other industries.

Owner:桂林兴松林化有限责任公司

Method for preparing o-nitro anisole by using micro-channel reaction apparatus

InactiveCN105503610APrecise control of reaction conditionsEasy to operateOrganic chemistryOrganic compound preparationO-NitroanisoleReaction rate

The present invention provides a new method for preparing o-nitro anisole by using a micro-channel reactor, particularly application of a micro-channel reactor with an enhanced mass transfer unit structure to carry out a continuous flow o-nitro chloro benzene etherification reaction. According to the present invention, the mass transfer and the heat transfer can be completed dependent on the kinetic energy of the fluid without the mechanical stirring process under the reactor operation condition higher than the normal temperature, the space time reaction rate of the micro-channel reactor can be substantially improved, the temperature fluctuation and the concentration fluctuation during the reaction process can be avoided, the phenomena such as temperature runaway and overheating do not exist, and the reaction process is safe.

Owner:CHINA PETROLEUM & CHEM CORP +1

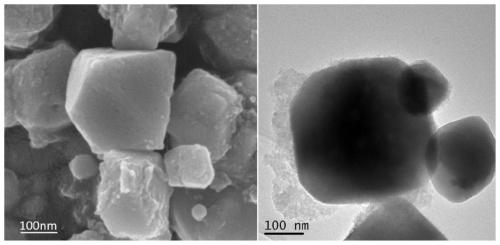

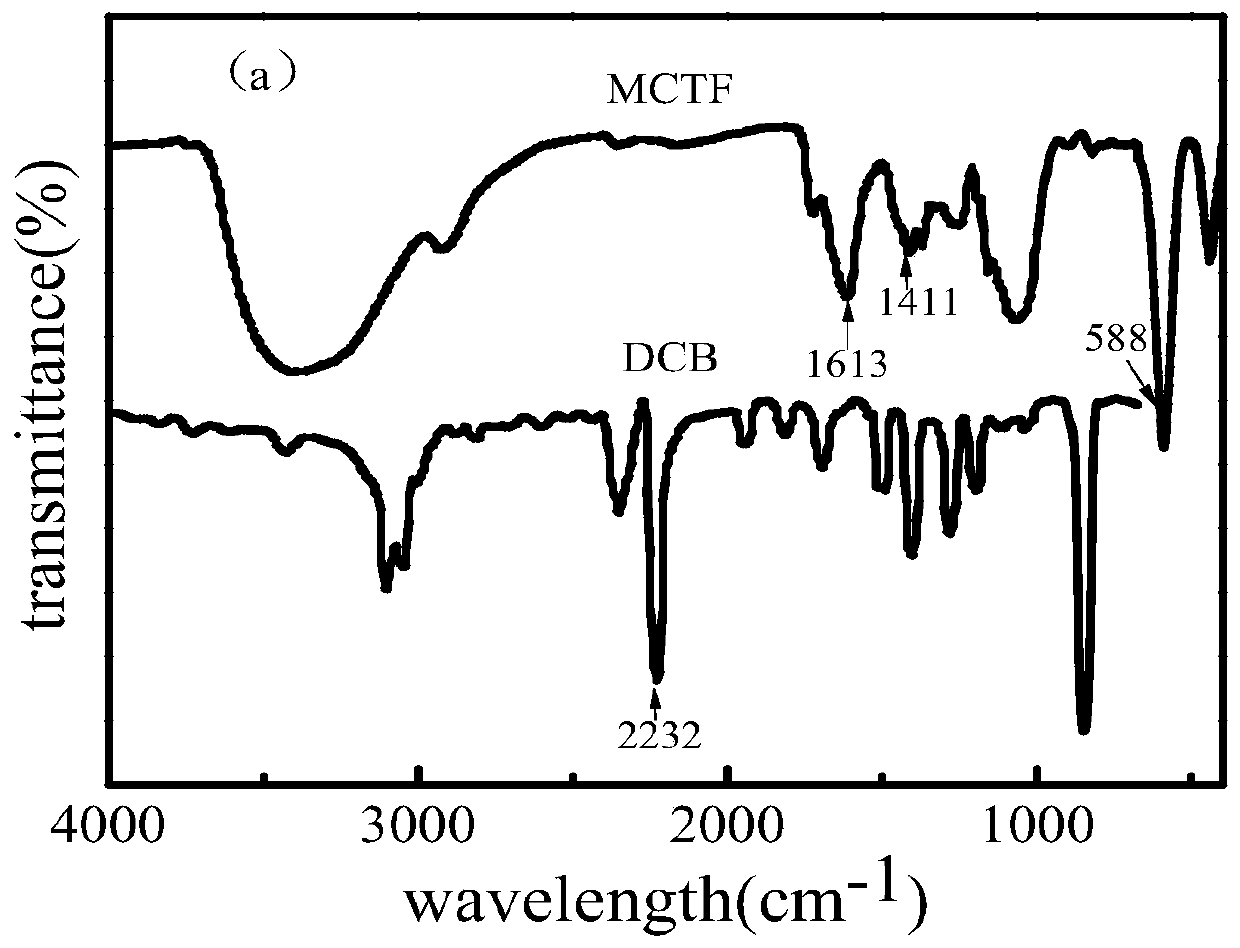

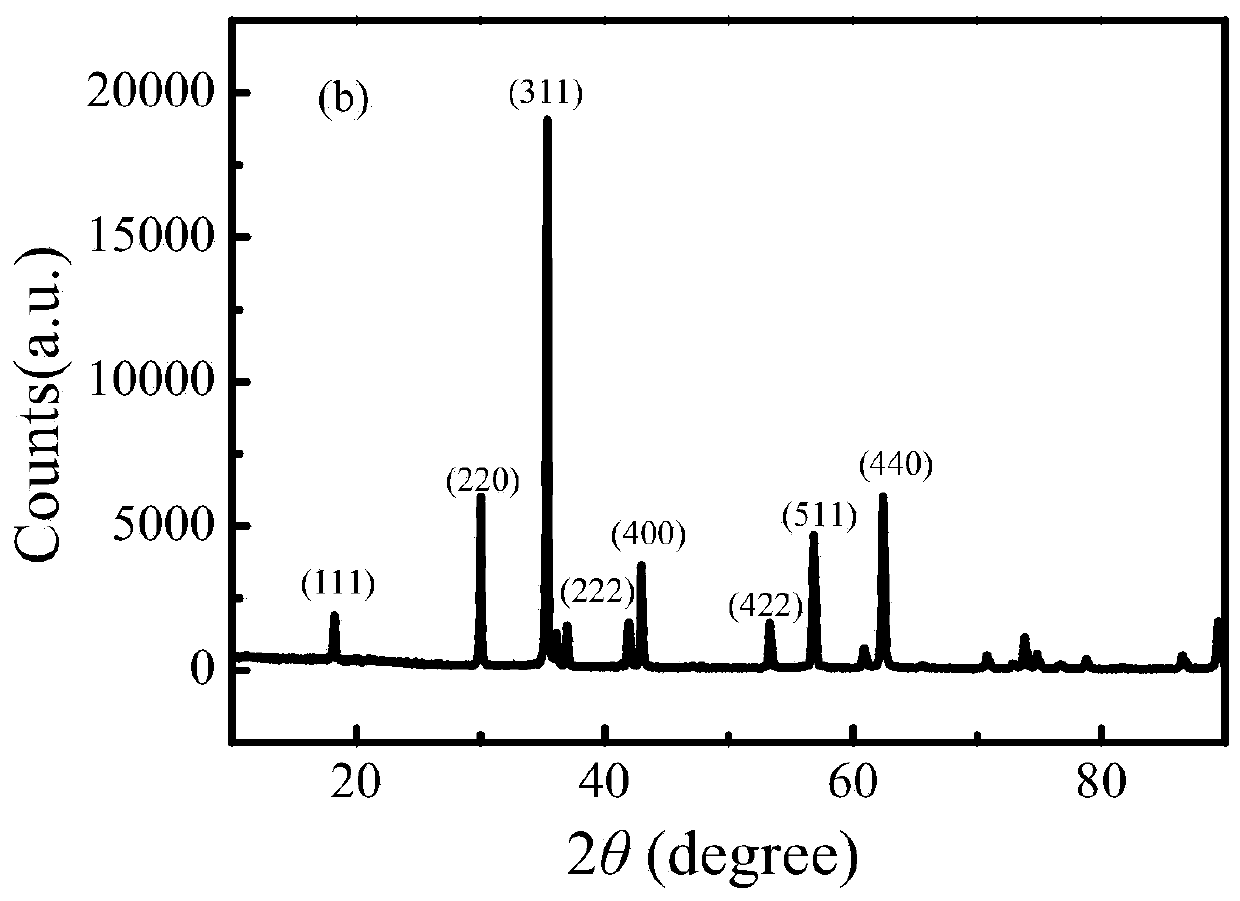

Magnetic covalent triazine framework material, and preparation method and application thereof

ActiveCN110204714AGuaranteed reaction temperatureEasy to recycleOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsMicrowaveWastewater

The invention relates to a magnetic covalent triazine framework material, and a preparation method and an application thereof. The magnetic covalent triazine framework material comprises a covalent triazine framework and Fe3O4. The magnetic covalent triazine framework material of the invention is magnetic, is convenient to recycle, can be used in wastewater treatment, and also can be used in the degradation of antibiotics as a catalyst. The preparation method of the invention is characterized in that terephthalonitrile is rapidly condensed with microwaves as a heat source and Fe3O4 as a microwave absorption and transmission medium. The presence of the Fe3O4 makes a powder aggregate in the reaction process in order to make the powder not prone to fly over, so the reaction is complete.

Owner:SUZHOU UNIV OF SCI & TECH

Device and method for detecting pesticide residue and nitrite based on scanning code type paper chip

ActiveCN109444120AReduce testing costsControl the detection timeMaterial analysis by observing effect on chemical indicatorImaging processingPesticide residue

The invention relates to a device and a method for detecting pesticide residue and nitrite based on a scanning code type paper chip by adopting a microfluidic technology and an image processing technology to identify, detect and record the pesticide residue and nitrite harmful substances. The method includes, arranging a plurality of layers of microfluidic paper chips inside a heating chip detection cavity, wherein a plurality of layers of the microfluidic paper chips consist of five layers which are glued together from top to bottom, each layer has a chip bar code detection areal adding, by adropper, mixed liquid into a chip sample inlet drop by drop; showing, by the chip bar code detection area of each layer, different colors according to a composition of the sample mixed liquid; imaging and scanning, by intelligent mobile equipment, a color development result of a plurality of layers of the microfluidic paper chips to obtain a detection result. The method applies an inhibition principle of organophosphorus pesticides on acetylcholine esterase and a diazonium coupling reaction of aminobenzenesulfonic acid and N-1-naphthylethylenediamine dihydrochloride under an acidic condition,and integrates automatic sample introduction, intelligent heating, reaction, color development and result analysis, recording and processing.

Owner:JIANGSU UNIV

Method for preparing food-grade xylose by utilizing waste liquid generated in production process of viscose staple fibers

The invention relates to a method for preparing food-grade xylose by utilizing waste liquid generated in a production process of viscose staple fibers. The method comprises the following steps: carrying out optimized combination on the waste liquid generated by a squeezing procedure in a viscose staple fiber production process through utilizing a series connection type nanofiltration membrane and electrodialysis; hydrolyzing, neutralizing and de-coloring, carrying out ion exchange, carrying out membrane concentration, evaporating, crystallizing and drying to obtain a xylose finished product. According to the method provided by the invention, the food-grade xylose is prepared by taking hemicellulose in the waste liquid generated in a viscose production process, and the problem that a lot of waste liquid containing the hemicellulose in the viscose production process cannot be treated effectively prior to discharge, so that social environmental pollution is caused is solved; the hemicellulose in the waste liquid is used as a raw material for producing the xylose, and a new way is provided for sources of the raw materials of the xylose.

Owner:唐山三友集团兴达化纤有限公司

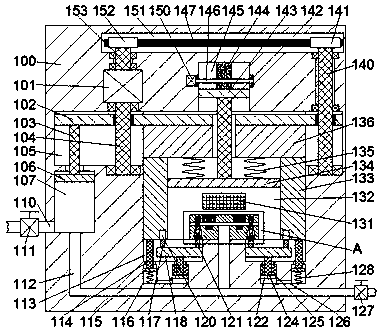

High-temperature and high-pressure reaction kettle with on-line sampling device

InactiveCN110038484AReduce the temperatureGuaranteed tightnessWithdrawing sample devicesPressure vessel componentsEngineeringHigh pressure

The invention discloses a high-temperature and high-pressure reaction kettle with an online sampling device. The high-temperature and high-pressure reaction kettle comprises a main shell and a reaction cavity formed in the main shell. An operation table is fixedly arranged on the end wall of the lower side of the reaction cavity. A movable door is arranged in the end wall of the front side of thereaction cavity. A driving mechanism with a power motor as a main body is arranged in the main shell. The pressurizing device in the reaction cavity is driven by the driving mechanism to move downwards, and a gate between the cooling device and the reaction cavity is opened when the pressurizing device presses downwards, so that the internal space of the reaction cavity is compressed and cooling is carried out; when the temperature in the reaction cavity reaches a preset value, the pressure in the reaction cavity is further finely adjusted through a cam device. The device is simple in structure; through a compact transmission relationship, the cooling and pressurizing processes of the reaction cavity are completed; in addition, the well-designed sealing structure ensures that the temperature and the pressure intensity of the reaction cavity are not changed within a long time.

Owner:杭州虹妍服饰有限公司

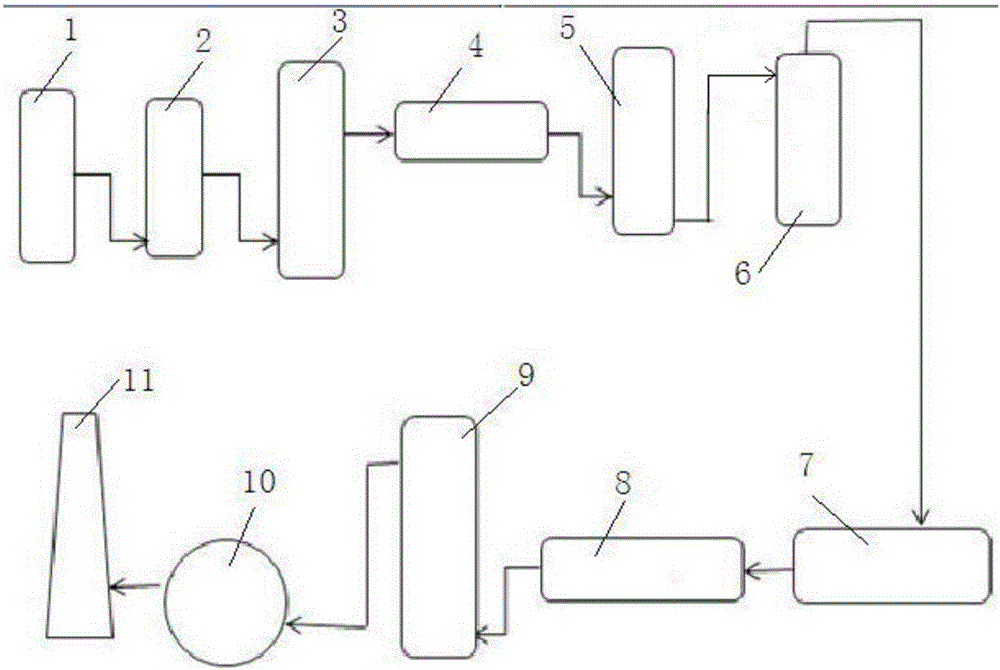

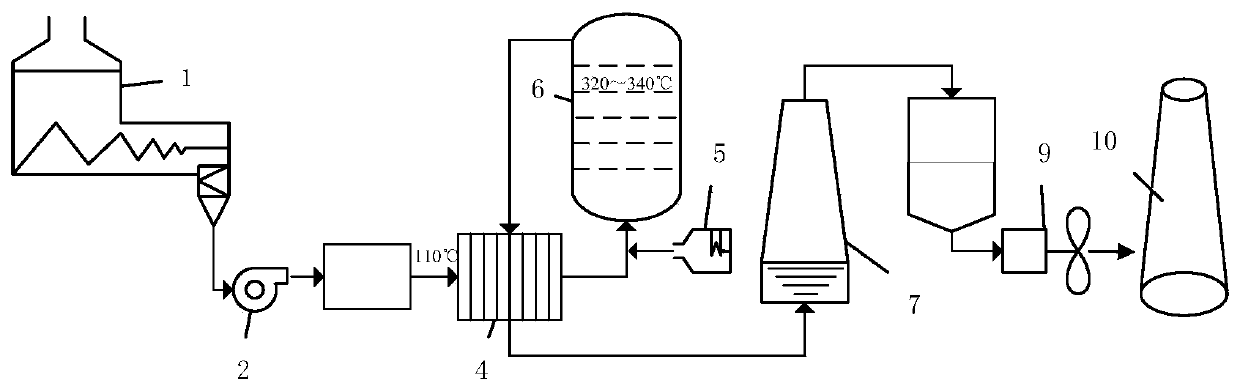

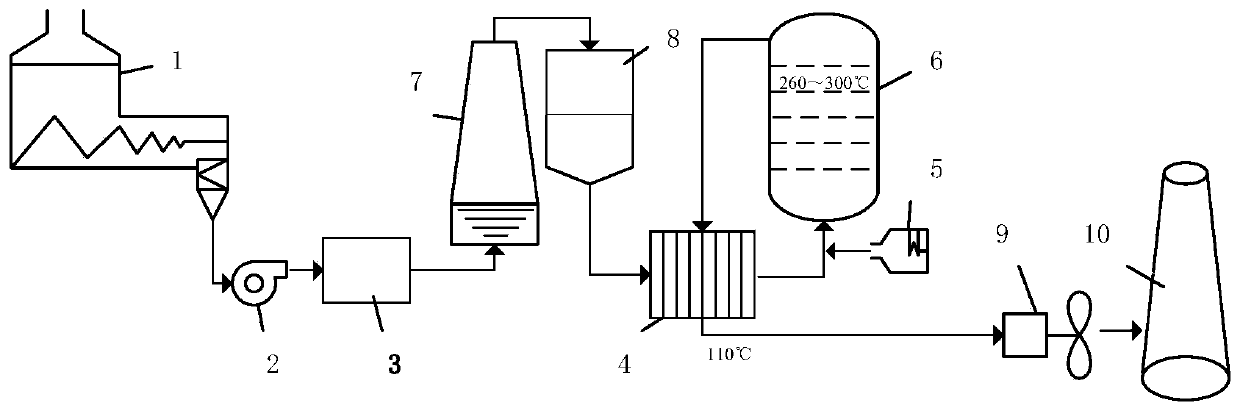

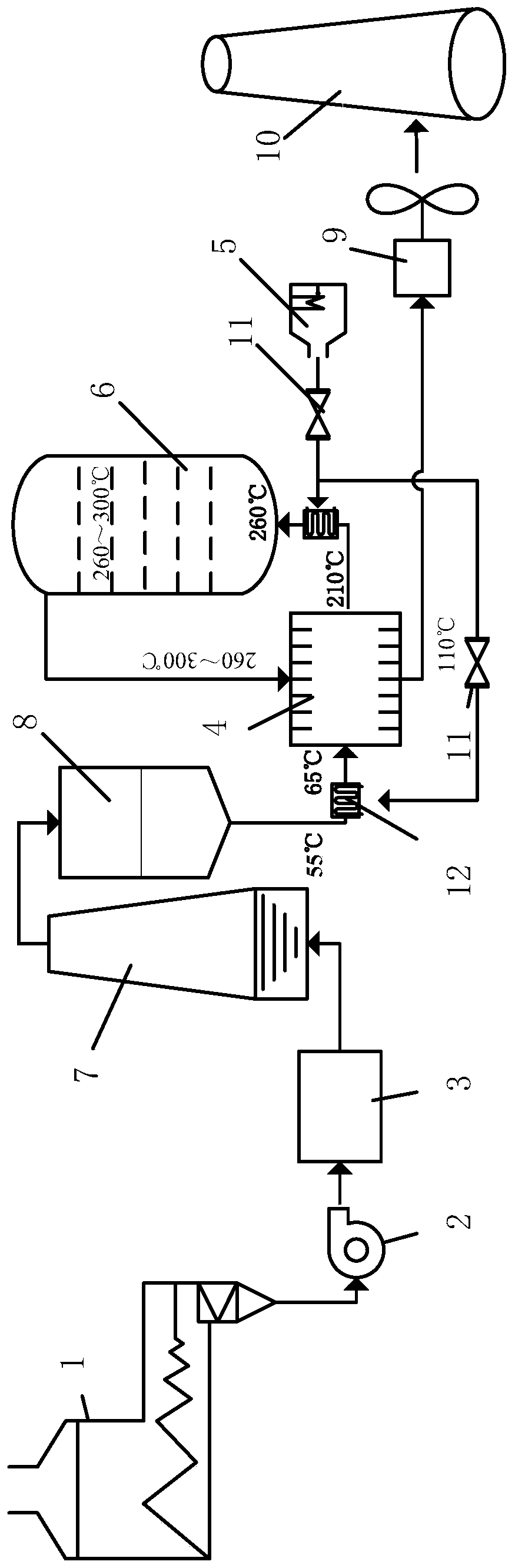

Boiler denitration process taking ammonia-containing waste gas as denitration agent

ActiveCN106582226ALow costLess investmentDispersed particle separationLiquid waterExhaust gas emissions

The invention relates to a boiler denitration process taking ammonia-containing waste gas as a denitration agent. The boiler denitration process includes the steps: generating raw process gas by a gasification furnace; enabling the raw process gas to enter a carbon washing tower and then enter a conversion furnace; enabling the raw process gas to enter an ammonia washing tower through a heat exchange system; forming ammonia-containing washing water in the ammonia washing tower; enabling the ammonia-containing washing water to enter a stripping tower; forming the ammonia-containing waste gas after stripping in the stripping tower; enabling the ammonia-containing waste gas to enter a waste gas mixer; mixing the ammonia-containing waste gas with secondary air of a boiler; enabling the mixed gas to enter the boiler through a boiler air supply system to perform denitration reaction; exhausting the denitrified boiler waste gas from a chimney through an induced draft fan. The ammonia-containing waste gas serves as the denitration agent, resources are utilized, waste gas emission pollution is decreased, and flue gas denitration cost is remarkably reduced. In the denitration process, compared with traditional SNCR (selective non-catalytic reduction) denitration, the denitration process has the advantages that liquid water vaporization latent heat consumption and heat waste are decreased, and nitric oxide emission concentration is lower than 100mg / m<3>.

Owner:JIUTAI ENERGY INNER MONGOLIA

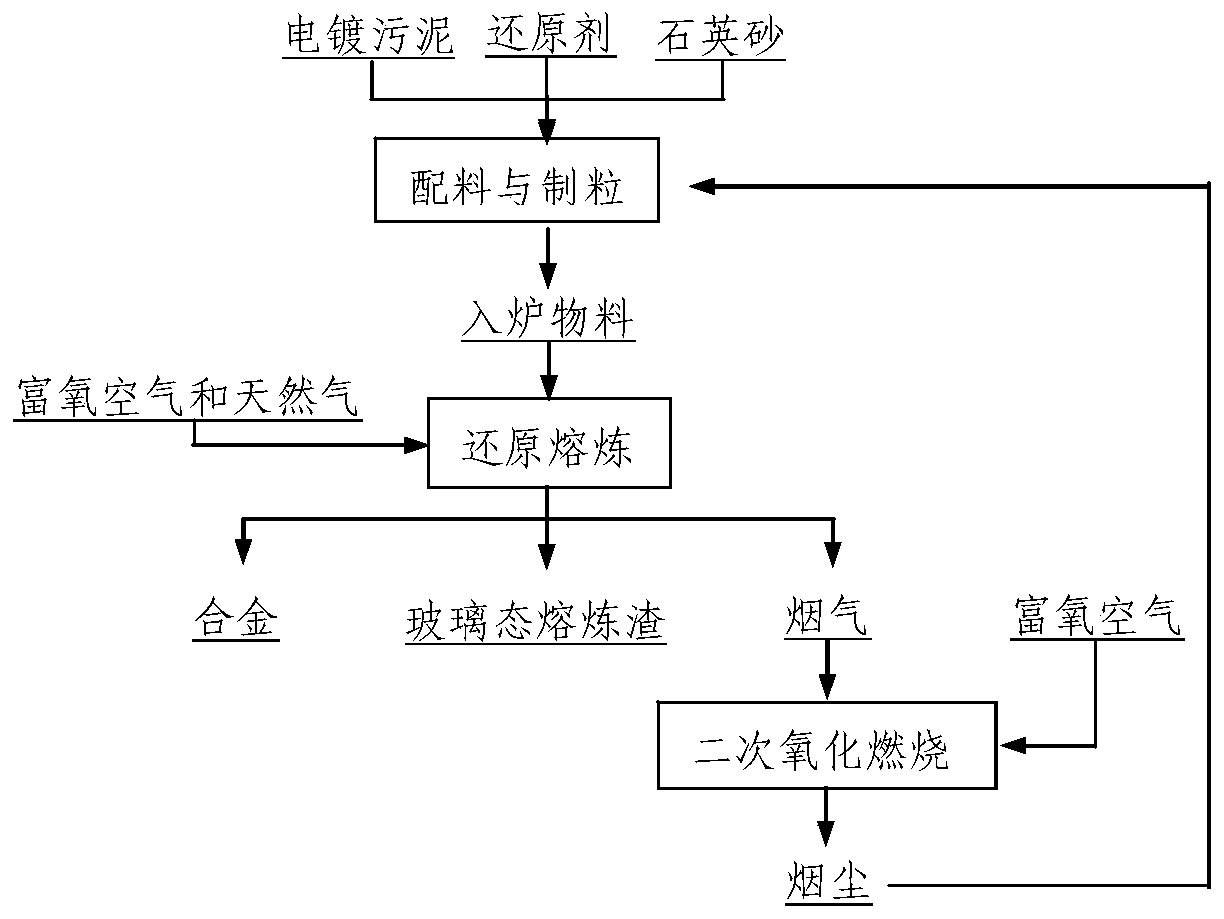

Method for harmlessly treating electroplating sludge

ActiveCN110951966AGood recycling benefitsReduce labor intensityCement productionProcess efficiency improvementSlagSludge

The invention relates to a method for harmlessly treating electroplating sludge. The method comprises the following steps that the electroplating sludge, a reducing agent and quartz sand are proportioned according to a certain ratio, and mixing and granulating are carried out in a granulator to obtain a furnace-in material; and the furnace-in material is added into a smelting furnace, natural gasand oxygen are introduced, reducing atmosphere is controlled to carry out reduction smelting, and glassy-state smelting slag and alloy are obtained. According to the method, the obtained smelting slagis no longer hazardous waste with leaching toxicity characteristics, and can be used as a building material and the like; and the alloy is further separated and purified, valuable metal in the electroplating sludge can be efficiently recovered through reduction smelting, the recovery rate of copper and nickel can reach 90% or above, the valuable metal is good in recovery benefit, low in labor intensity, short in treatment time, friendly in operation environment, and mature and reliable in process.

Owner:CENT SOUTH UNIV

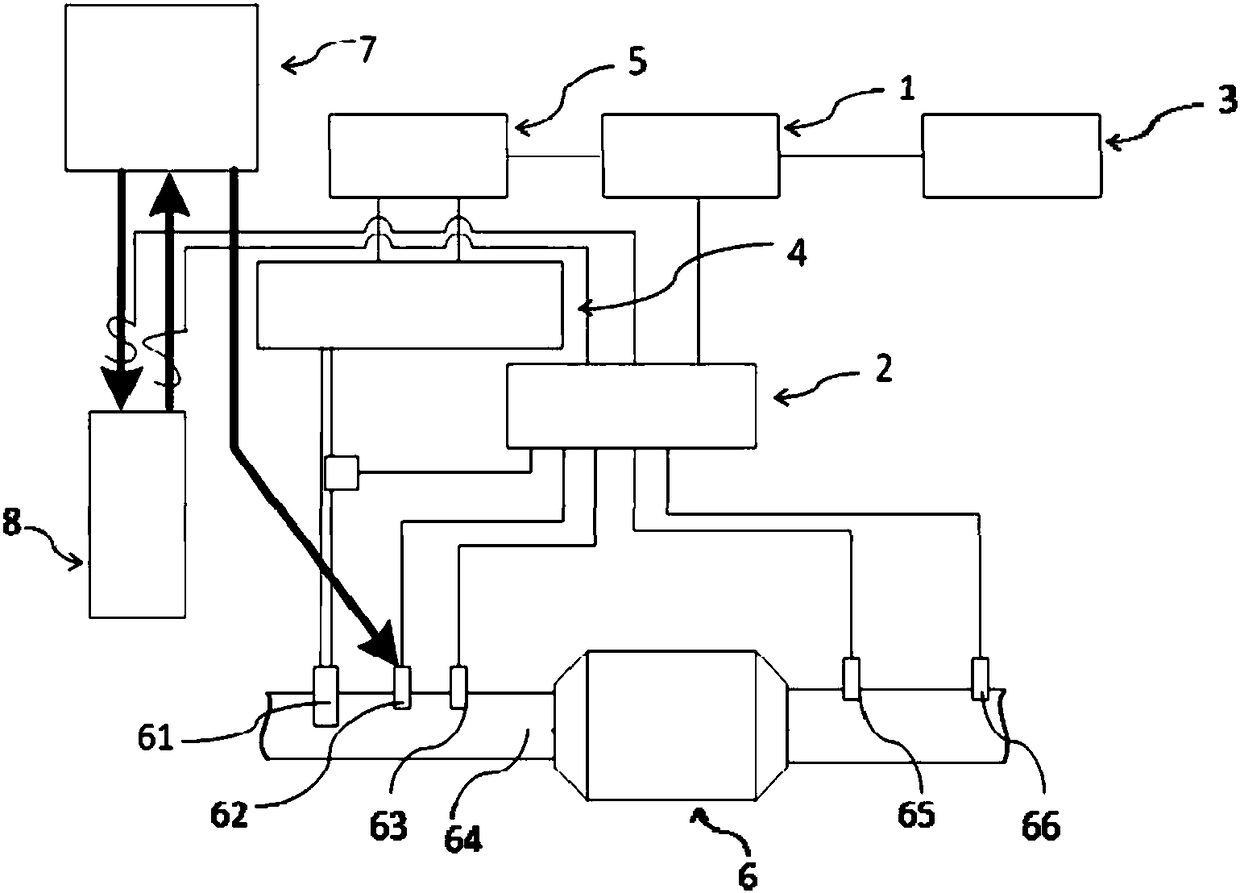

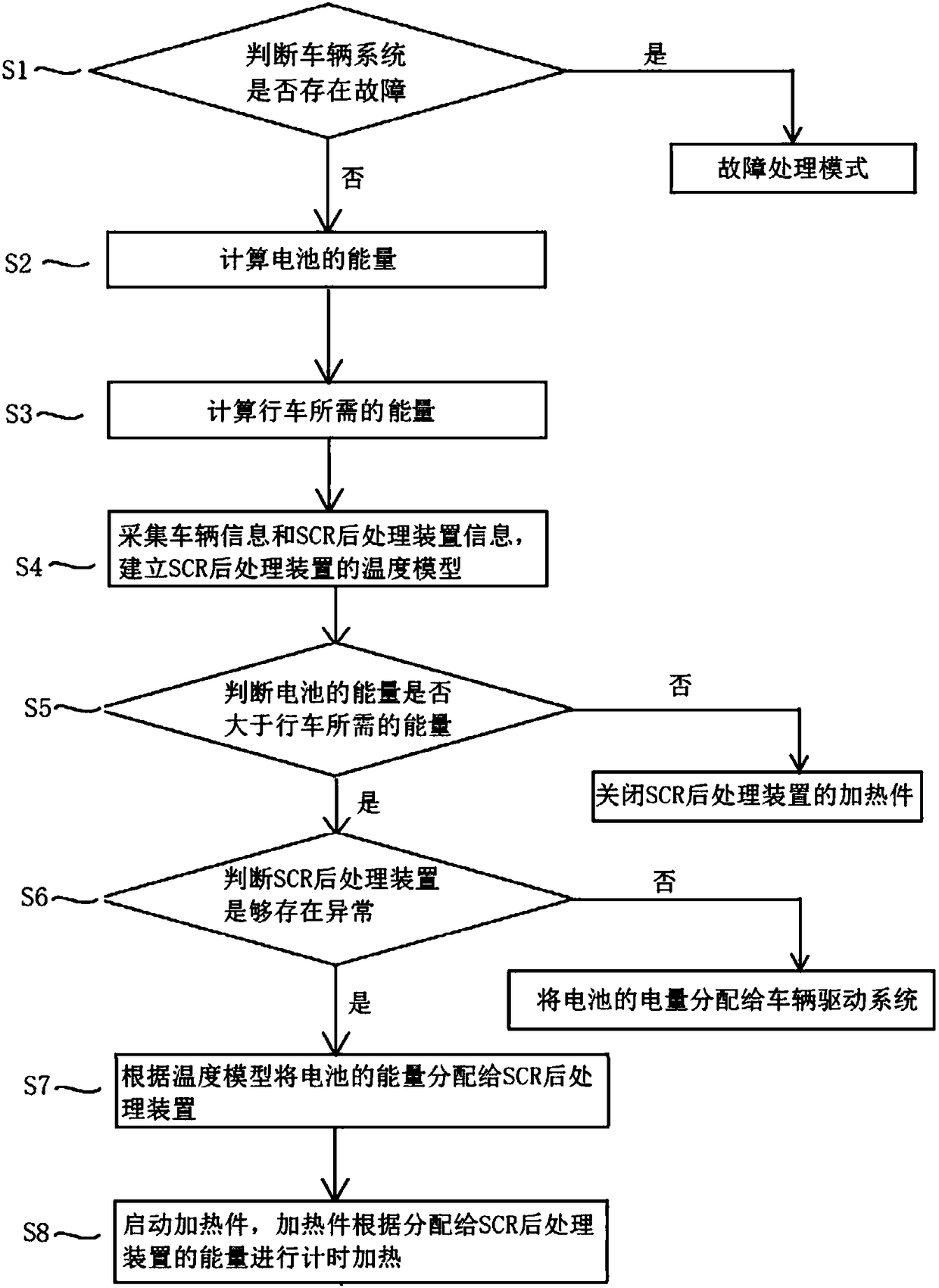

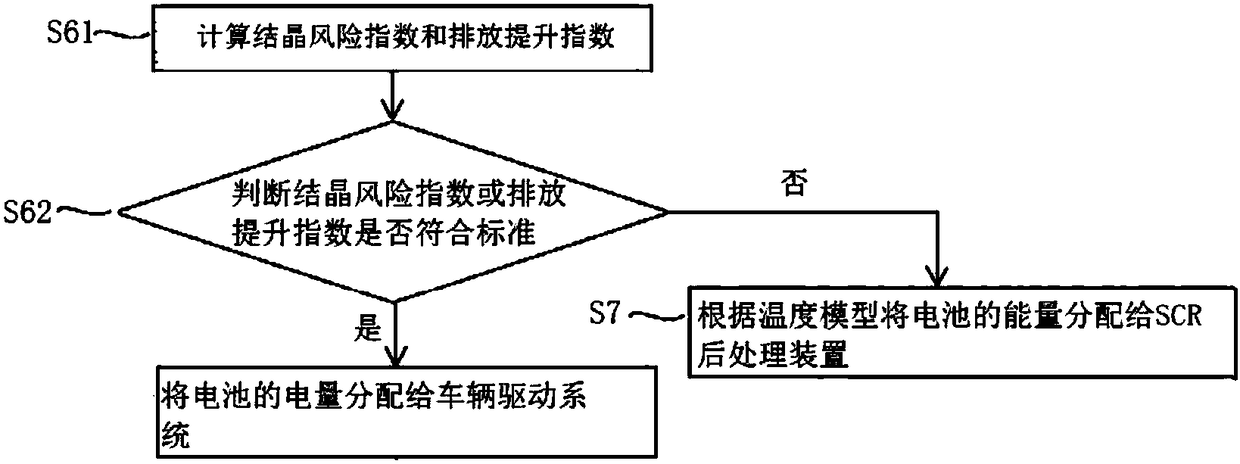

SCR thermal management system based on 48V micro hybrid power system and energy-saving priority control method

ActiveCN108583565AGuaranteed service lifeGuaranteed economyHybrid vehiclesControl devicesElectrical batteryReaction temperature

The invention discloses an SCR thermal management system based on a 48V micro hybrid power system and an energy-saving priority control method thereof. The SCR thermal management system comprises a vehicle control unit connected with a battery with 48V voltage, wherein the vehicle control unit is used for evaluating the condition of a vehicle, calculating the energy required for driving, distributing the energy of the battery and issuing a work instruction; the vehicle control unit is electrically connected with an SCR post-processing device control unit; and the SCR post-processing control unit controls the start or stop of heating elements in the SCR post-processing device according to the work instruction. Based on the SCR thermal management system, the energy of the battery is effectively distributed according to the energy required by the vehicle to ensure the service life of the battery, and a power system of the vehicle and SCR heating can both obtain the required energy and make full use of electric energy so that the economy of the whole vehicle can be guaranteed, the reaction temperature of the SCR post-processing device is guaranteed, and the treatment effect is improved. In addition, the crystallization risk of the SCR post-processing device is eliminated, and the use effect of the SCR post-processing device is guaranteed.

Owner:杭州休伦科技有限公司

Efficient glue reaction kettle and working method thereof

ActiveCN105921092ASimple structureEasy to operateChemical/physical/physico-chemical stationary reactorsEngineeringRaw material

Owner:江苏驰太新材料有限公司

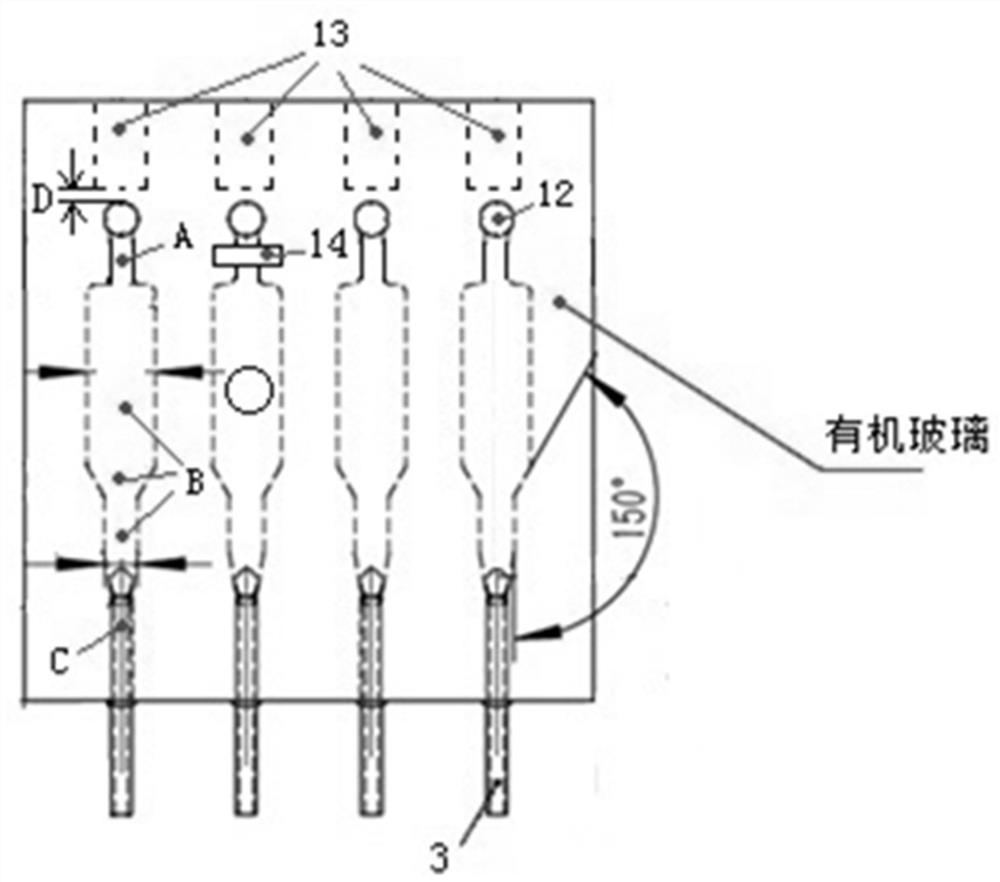

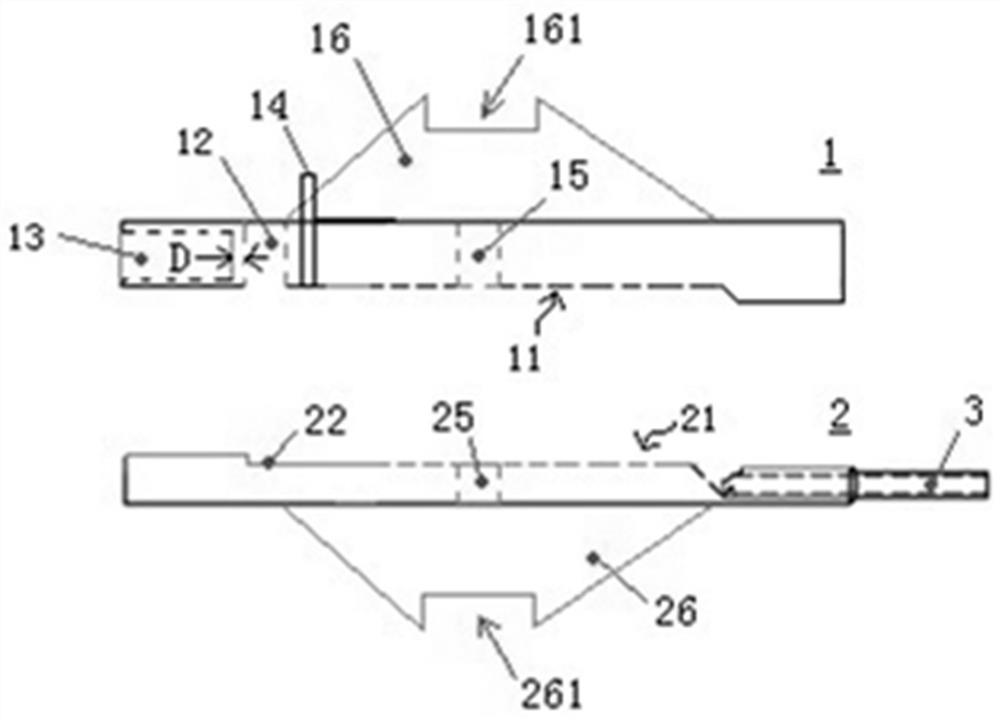

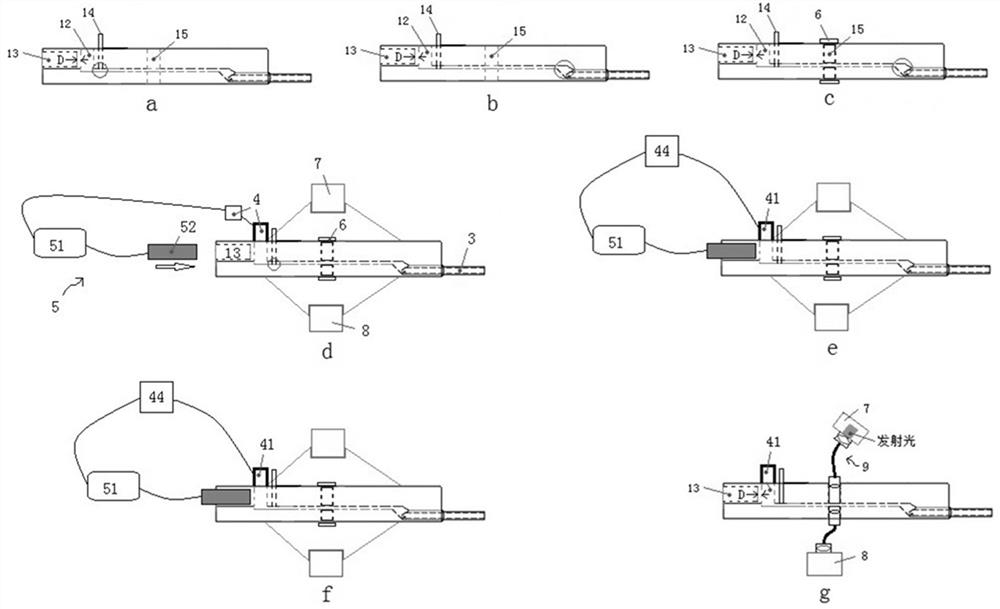

Sample-residue-free heat-insulating and reusable multifunctional cell counting and imaging device

ActiveCN114054113AGuaranteed reaction temperatureRealize the temperature control functionBiological particle analysisLaboratory glasswaresTemperature controlThermal insulation

The invention provides a sample-residue-free heat-insulating reusable multifunctional cell counting and imaging device which comprises a first substrate and a second substrate which can be matched with each other to form at least one micro-channel, wherein the first substrate and the second substrate are respectively provided with a first flow channel wall and a second flow channel wall which are matched with each other to form the at least one micro flow channel, the first flow channel wall and the second flow channel wall being respectively provided with a super-hydrophobic / hydrophobic thermal insulation material layer or formed by super-hydrophobic / hydrophobic thermal insulation materials, or the hydrophobic thermal insulation material is formed in the first substrate material and the second substrate material around the first flow channel wall and the second flow channel wall. Heat insulation detection and residue-free export of the sample are realized, so that the optical detection device is convenient to position under multiple visual angles; when an inlet heating device and an infrared temperature measurement interface are introduced into the device, the temperature control function of the reagent and the sample can be realized; and convenient material setting and specific reaction conditions are provided for various micro-channel biochemical experiment requirements.

Owner:高分(北京)生物科技有限公司

Method and system for double-heating SCR denitration of sintering flue gas

PendingCN110841481AMeet the real needs of mixingSolve the blockageDispersed particle separationPtru catalystFlue gas

The invention discloses a method and a system for double-heating SCR denitration of sintering flue gas. The method comprises the following steps: desulfurizing the sintering flue gas, and mixing the desulfurized sintering flue gas with high-temperature flue gas for the first time; then allowing mixed flue gas to exchange heat with denitrated flue gas; mixing heat-exchanged flue gas with the high-temperature flue gas for the second time, and carrying out denitration; and subjecting the denitrated flue gas to heat exchange, and carrying out discharging. The method provided by the invention mainly solves the problem of GGH blockage after heating in medium-and-low-temperature SCR denitration; after desulfurization is completed, the denitrated flue gas is mixed and heated with the high-temperature flue gas for the first time, so wet flue gas is guaranteed to be changed from an unsaturated state to an overheated state, and the blockage probability of a heat exchanger is reduced; and secondary mixing and heating are carried out before the denitrated flue gas enters an SCR denitration reactor, so the reaction temperature of a catalyst is guaranteed, and the denitration efficiency is improved.

Owner:BEIJING JINGCHENGKELIN ENVIRONMENTAL PROTECTION TECH +1

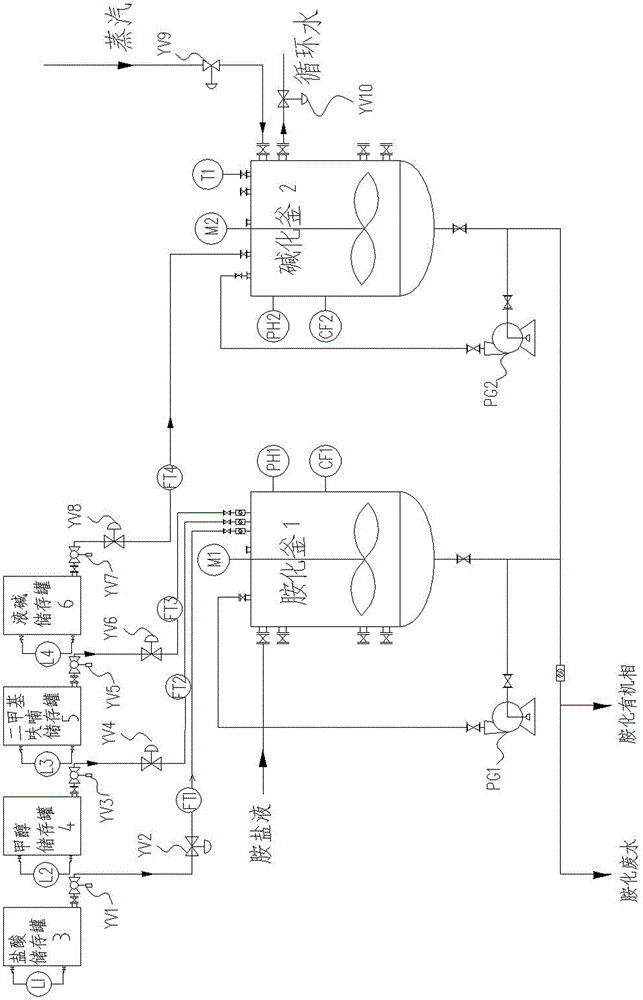

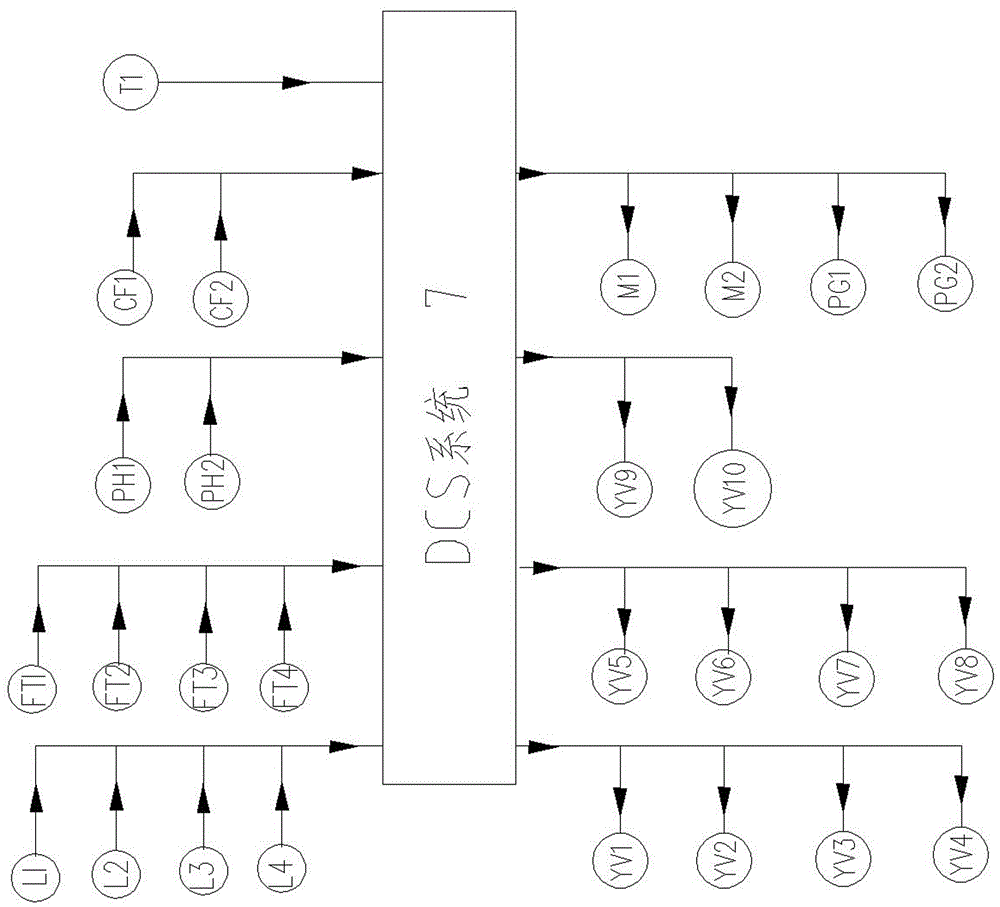

DCS control system used for amination workshop section in methyl cyclopentenolone production line

ActiveCN105541576AGuaranteed reaction temperatureSmooth responseOrganic compound preparationCarbonyl compound preparationProduction lineControl system

The invention discloses a DCS control system used for an amination workshop section in a methyl cyclopentenolone production line. According to the invention, connecting pipelines of a hydrochloric acid storage tank, a methanol storage tank, a dimethylfuran storage tank and a liquid alkali storage tank with an amination kettle and an alkalization kettle are respectively provided with a flow meter; a PH meter, a component analyzer and a temperature sensor are correspondingly arranged on the amination kettle and the alkalization kettle; and the DCS control system controls devices like all cut-off valves and regulating valves according to feedback datum of the sensor on the amination workshop section, strictly and accurately controls process steps and drop-by-drop addition amount of reaction raw materials in the amination workshop section, realizes real-time control of steam and recycled water, and guarantees reaction temperature, so stable reaction process and more complete reaction are realized; human factors are eliminated; and the rate of finished products is improved.

Owner:ANHUI JINGHE IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com