Method and system for double-heating SCR denitration of sintering flue gas

A technology of sintering flue gas and flue gas heater, which is applied in the direction of separation methods, chemical instruments and methods, and separation of dispersed particles, which can solve problems such as blockage and achieve the effect of flexible selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

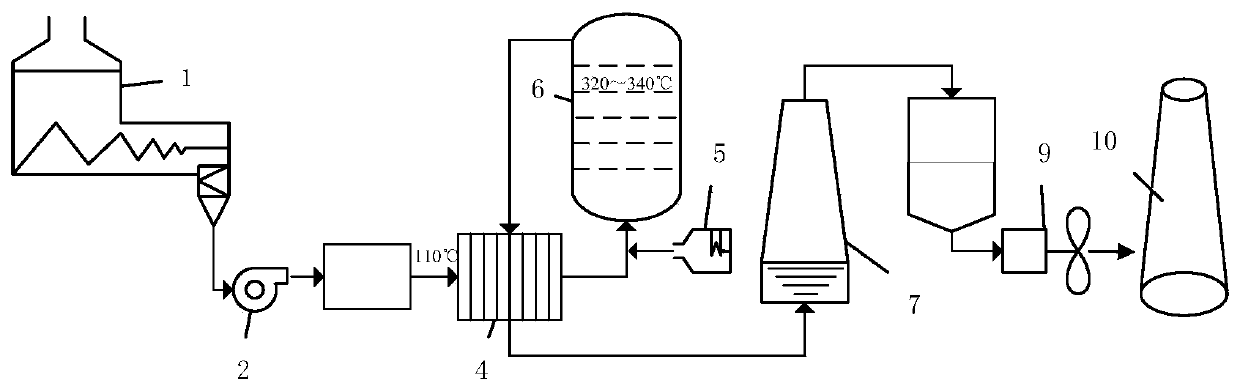

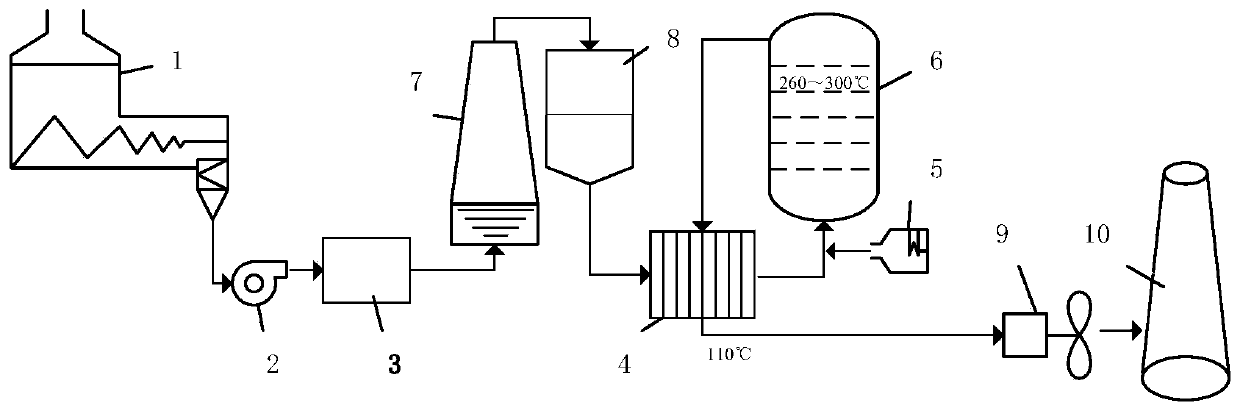

Method used

Image

Examples

Embodiment Construction

[0045] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

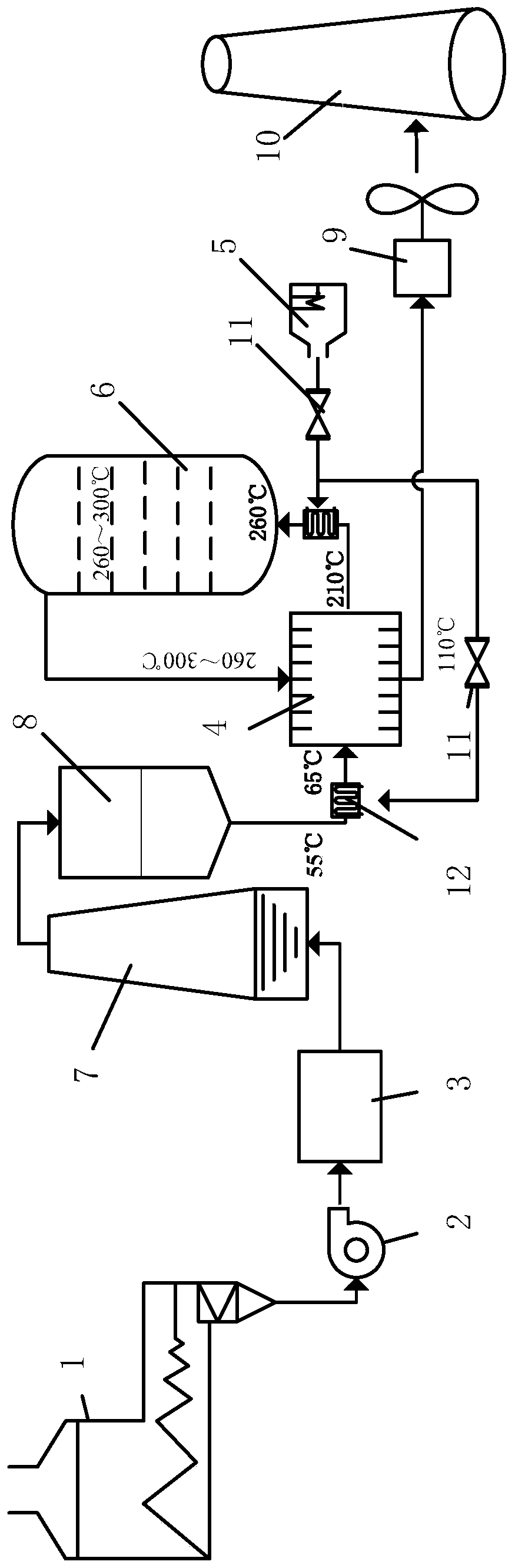

[0046] The present invention provides a preferred embodiment, such as image 3 As shown, the sintering flue gas dual-heating SCR denitrification system includes the main exhaust fan 2, the head electrostatic precipitator 3, the desulfurization tower 7, the wet electrostatic precipitator 8, the GGH flue gas heat exchanger 4, and the SCR denitrification reactor. 6. The outlet of the SCR denitrification reactor 6 enters the GGH flue gas heat exchanger 4, and then connects the induced draft fan 9 and the chimney 10 in sequence;

[0047] The first flue gas mixer 12 is set at the entrance of the desulfurization side of the GG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com