CTP synthesis technology of rubber scorch retarder and device thereof

A technology of anti-scorch agent and rubber, which is applied in the field of CTP synthesis process of rubber anti-scorch agent, can solve the problems of unstable cyclohexylthio chloride, long time required for mixing, affecting the efficiency of the reaction, etc., so as to reduce the chance of decomposition. , The effect of promoting mixing and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

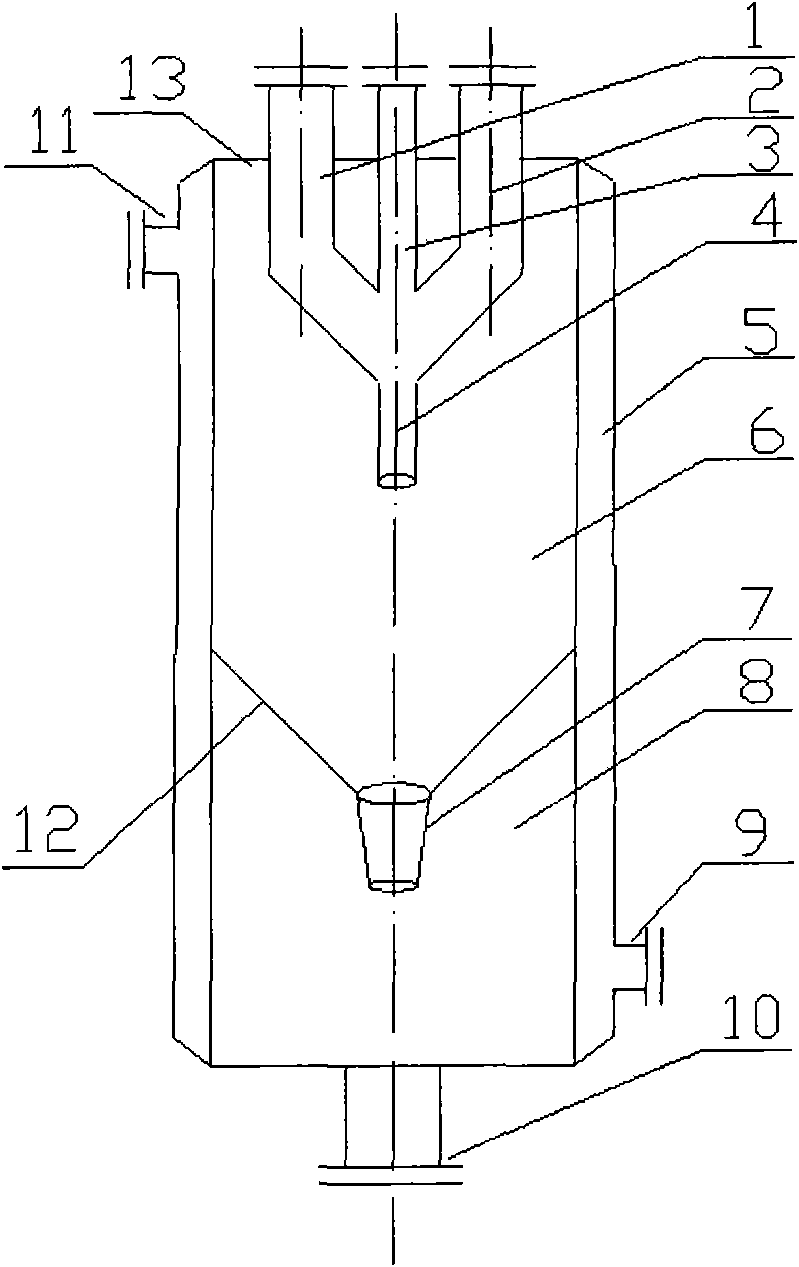

[0023] Embodiment 1: tubular reactor

[0024] The tubular reactor structure is as figure 1 shown. The size of the cylindrical chamber 13 is φ200mm×800mm. Two material feeding pipes 1, 2 and a nitrogen gas inlet pipe 3 are passed into the chamber from the upper side outside the chamber. The three pipes merge and communicate with a mixing vertical pipe 4. Material standpipe 4 is long 30mm. The nitrogen inlet pipe 3 is located at the center between the two material feeding pipes 1 and 2, and the two material feeding pipes 1 and 2 are arranged symmetrically. A funnel-shaped mixing pipe 7 is arranged at the center of the lower part of the chamber, and the length of the funnel-shaped mixing pipe 7 is 80 mm. The outer wall of the cavity is provided with a thermal insulation jacket 5, and the thermal insulation jacket 5 is provided with thermal insulation medium inlets and outlets 9, 11. There is a material outlet 10 at the bottom of the cavity directly leading to the condensation...

Embodiment 2

[0025] Embodiment 2: Synthesis of rubber anti-scorch agent CTP

[0026] (1) prepare cyclohexyl sulfenyl chloride with chlorine, dicyclohexyl disulfide and organic solvent in a reaction still (also become chlorination still) according to prior art, simultaneously in another reaction still, use phthalo Phthalimide sodium salt was prepared from imide and sodium hydroxide solution.

[0027] (2) Feed nitrogen into the tubular reactor for 4min to replace the mixture of organic solvent vapor and air inside. The tubular reactor size is φ 200mm × 600mm, and its structure is as described in Example 1. In the insulation jacket 5 The insulation medium used is ethylene glycol.

[0028] (3) then the cyclohexylsulfenyl chloride prepared by above-mentioned steps (1) and phthalimide sodium salt are continuously added in the tubular reactor by two material feeding pipes respectively with 1: 1 molar ratio, The feed rate is controlled to be 75-90 mol / min. The reaction temperature is 0-5°C, and...

Embodiment 3

[0032] Embodiment 3: rubber anti-scorch agent CTP is synthesized, as described in embodiment 2, difference is:

[0033] Cyclohexylsulfanyl chloride and phthalimide sodium salt are continuously added to the tubular reactor through two material feed pipes at a molar ratio of 1:1.1, and the heat preservation medium used in the heat preservation jacket 5 is ethanol , the reaction temperature is -5 ~ 3 ° C, and nitrogen is continuously fed, and the pressure is controlled at 0.2 ~ 0.3Mpa. After the initial reaction in the tubular reactor, the material reacted for 50 minutes under stirring at 5-10°C in the condensation kettle to obtain a mixture of rubber anti-scorch agent CTP, organic solvent and water, and then through water separation, crystallization, and pressure filtration and drying to obtain the finished rubber anti-scorch agent CTP. The CTP purity of the obtained rubber anti-scorch agent is increased from 96.6% in the existing traditional process to 98.5%, and the product y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com