CTP synthesis technology of rubber scorch retarder and device thereof

A technology of anti-scorching agent and rubber, which is applied in the field of rubber anti-scorching agent CTP synthesis process, can solve the problems of unstable cyclohexylsulfenyl chloride, affecting the efficiency of reaction, and long time required for mixing, so as to reduce the chance of decomposition , Promote mixing and improve yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: tubular reactor

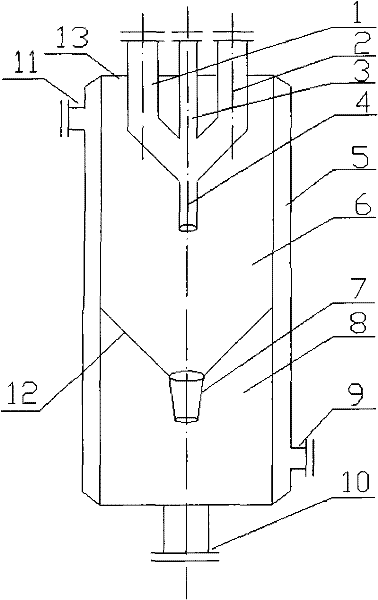

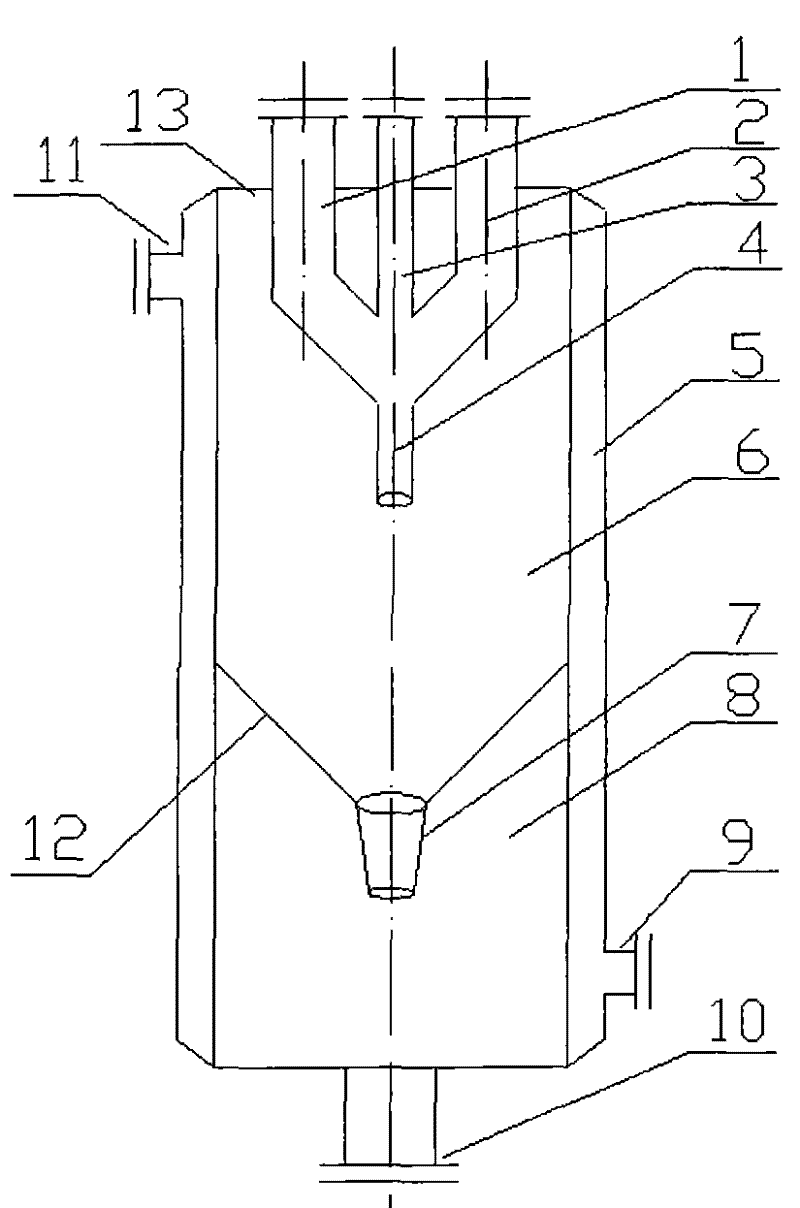

[0024] The tubular reactor structure is as figure 1 shown. The size of the cylindrical chamber 13 is φ200mm×800mm. Two material feeding pipes 1, 2 and a nitrogen gas inlet pipe 3 are passed into the chamber from the upper side outside the chamber. The three pipes merge and communicate with a mixing vertical pipe 4. Material standpipe 4 is long 30mm. The nitrogen inlet pipe 3 is located at the center between the two material feeding pipes 1 and 2, and the two material feeding pipes 1 and 2 are arranged symmetrically. A funnel-shaped mixing pipe 7 is arranged at the center of the lower part of the chamber, and the length of the funnel-shaped mixing pipe 7 is 80 mm. The outer wall of the cavity is provided with a thermal insulation jacket 5, and the thermal insulation jacket 5 is provided with thermal insulation medium inlets and outlets 9, 11. There is a material outlet 10 at the bottom of the cavity directly leading to the condensation...

Embodiment 2

[0025] Embodiment 2: Synthesis of rubber anti-scorch agent CTP

[0026] (1) prepare cyclohexyl sulfenyl chloride with chlorine, dicyclohexyl disulfide and organic solvent in a reaction still (also become chlorination still) according to prior art, simultaneously in another reaction still, use phthalo Phthalimide sodium salt was prepared from imide and sodium hydroxide solution.

[0027] (2) Feed nitrogen into the tubular reactor for 4min to replace the mixture of organic solvent vapor and air inside. The tubular reactor size is φ 200mm × 600mm, and its structure is as described in Example 1. In the insulation jacket 5 The insulation medium used is ethylene glycol.

[0028] (3) then the cyclohexylsulfenyl chloride prepared by above-mentioned steps (1) and phthalimide sodium salt are continuously added in the tubular reactor by two material feeding pipes respectively with 1: 1 molar ratio, The feed rate is controlled to be 75-90 mol / min. The reaction temperature is 0-5°C, and...

Embodiment 3

[0032] Embodiment 3: rubber anti-scorch agent CTP is synthesized, as described in embodiment 2, difference is:

[0033] Cyclohexylsulfanyl chloride and phthalimide sodium salt are continuously added to the tubular reactor through two material feed pipes at a molar ratio of 1:1.1, and the heat preservation medium used in the heat preservation jacket 5 is ethanol , the reaction temperature is -5 ~ 3 ° C, and nitrogen is continuously fed, and the pressure is controlled at 0.2 ~ 0.3Mpa. After the first reaction in the tubular reactor, the material reacted for 50 minutes under stirring at 5-10°C in the condensation kettle to obtain a mixture of rubber anti-scorch agent CTP, organic solvent and water, and then through water separation, crystallization, and pressure filtration and drying to obtain the finished rubber anti-scorch agent CTP. The CTP purity of the obtained rubber anti-scorch agent is increased from 96.6% in the existing traditional process to 98.5%, and the product yie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com