Micro-reaction system and method for continuous synthesis of rubber anti-scorch agent CTP

A scorch inhibitor, micro-reaction technology, applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, chemical/physical/physical-chemical stationary reactors, etc., can solve the problem of low total reaction yield, imine The problem of high concentration can achieve the effect of remarkable technology, reducing imine residue and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

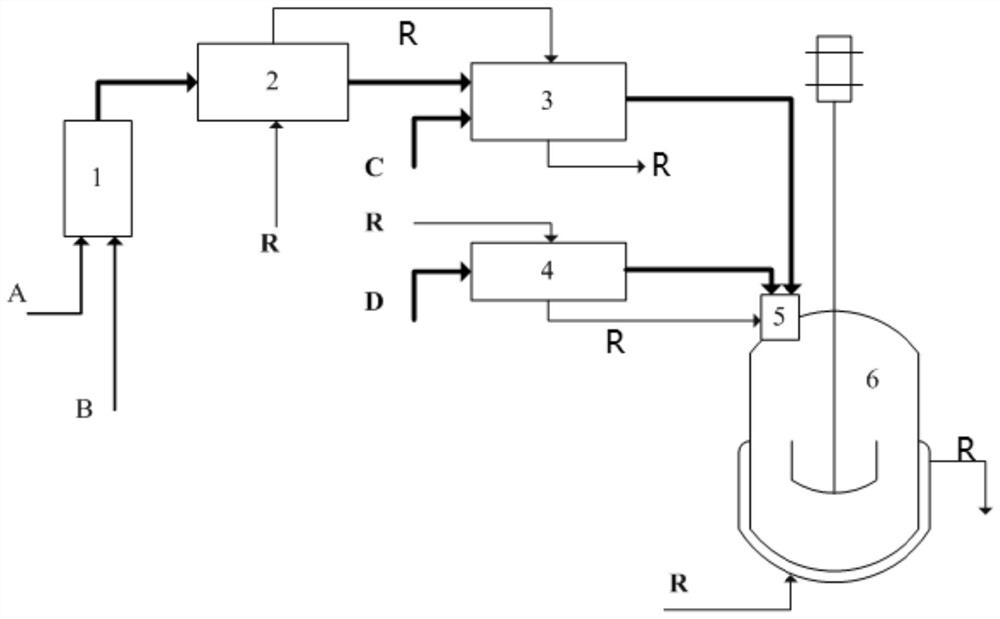

[0035] Microreactor systems such as figure 1 Shown, wherein, the effective volume of the internal microchannel of the chlorination microreactor 3 is 2.7 milliliters, and the volume of the stirred tank reactor is 1 liter, equipped with stirring paddles. Pre-prepared dicyclohexyl disulfide solution, the solvent is n-heptane and isoheptane mixed alkanes, wherein the mass concentration of dicyclohexyl disulfide is 11.9%, delivered by a metering pump, the volume flow rate is 40.0ml / min, enter Micro-heat exchanger 2 is cooled to subzero 5 ℃, enters chlorination micro-reactor 3 after cooling and mixes with the chlorine gas of 330ml / min (standard condition), and control reaction temperature in micro-reactor 3 is subzero 15 ℃, and reaction time (in liquid Disulfide solution meter) is 4 seconds, and reaction generates cyclohexyl sulfenyl chloride, and cyclohexyl sulfenyl chloride enters in the condensation microreactor 5, and enters the phthalimide sodium salt solution of this microreac...

Embodiment 2

[0037] Microreactor systems such as figure 1 Show, wherein, chlorination microreactor 3 internal microchannel effective volume is 0.3 milliliters (obtained by reducing channel number and number of layers), stirred tank reactor volume 2 liters, is equipped with stirring paddle. Pre-prepared dicyclohexyl disulfide solution, the solvent is n-heptane and isoheptane mixed alkanes, wherein the mass concentration of dicyclohexyl disulfide is 30%, transported by a metering pump, the volume flow rate is 50.0ml / min, enter Micro heat exchanger 2 is cooled to subzero 5 ℃, enters chlorination microreactor 3 after cooling and mixes with the chlorine gas of 1.16L / min (standard condition), controls the reaction temperature in microreactor 3 to be-5 ℃, and reaction time (with Liquid disulfide solution) is 0.36 seconds, and the reaction generates cyclohexylsulfenyl chloride, and cyclohexylsulfenyl chloride enters in the condensation microreactor 5, and enters the phthalimide sodium salt solutio...

Embodiment 3

[0039] Microreactor systems such as figure 1 Shown, wherein, the effective volume of the internal microchannel of the chlorination microreactor 3 is 2.7 milliliters, and the volume of the stirred tank reactor is 10 liters, equipped with stirring paddles. Dicyclohexyl disulfide is delivered by pump 1 with a volume flow rate of 46ml / min. The mixed alkanes of solvent n-heptane and isoheptane are delivered by pump 2 with a volume flow rate of 67.1ml / min. No heat exchange) mixed to form a dicyclohexyl disulfide solution (the mass concentration of the dicyclohexyl disulfide reaction solution can be calculated to be 50%), enter the micro heat exchanger 2 and cool down to minus 5°C, and enter the chlorination after cooling The microreactor 3 is mixed with chlorine gas of 4.7L / min (standard condition), and the reaction temperature in the microreactor 3 is controlled to be minus 5°C, and the reaction time (in terms of liquid disulfide solution) is 1.4 seconds, and the reaction generates...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com