Heating cigarette smoking set gas path structure and heating cigarette smoking set

A technology for smoking sets and cigarettes, applied in tobacco, smoker's products, applications, etc., can solve the problems of high local temperature of the shell, non-uniform air temperature, and uneven heating of the air, so as to ensure the reaction temperature, improve the user experience, and improve the battery life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

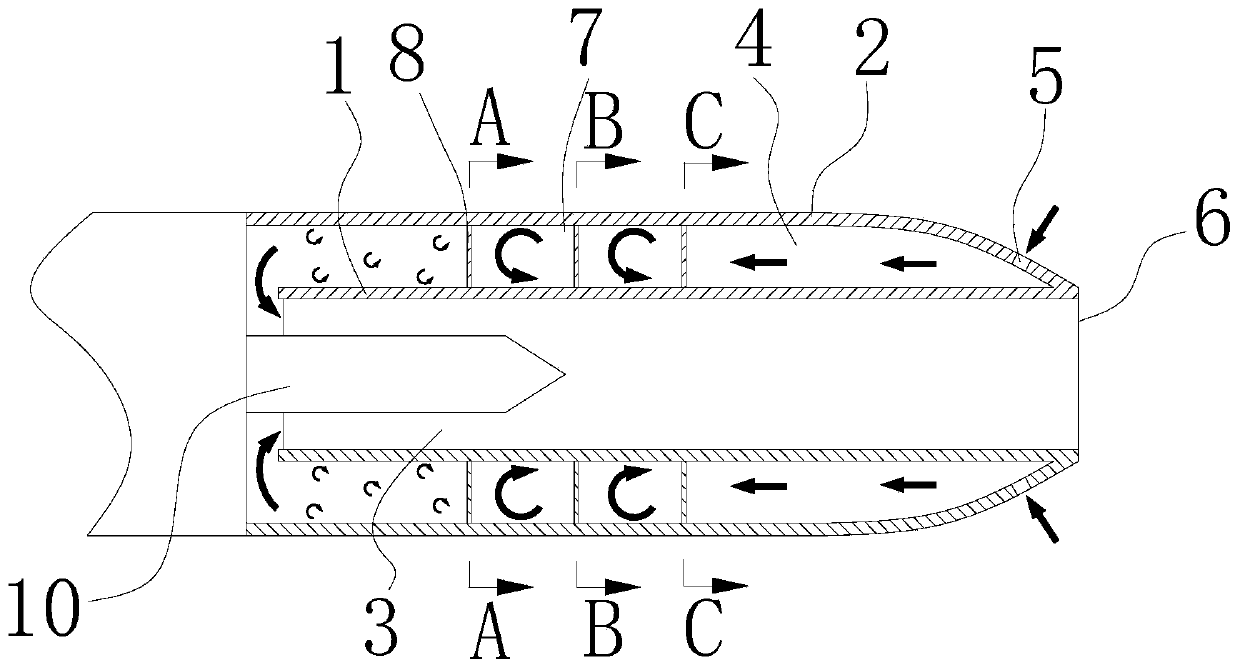

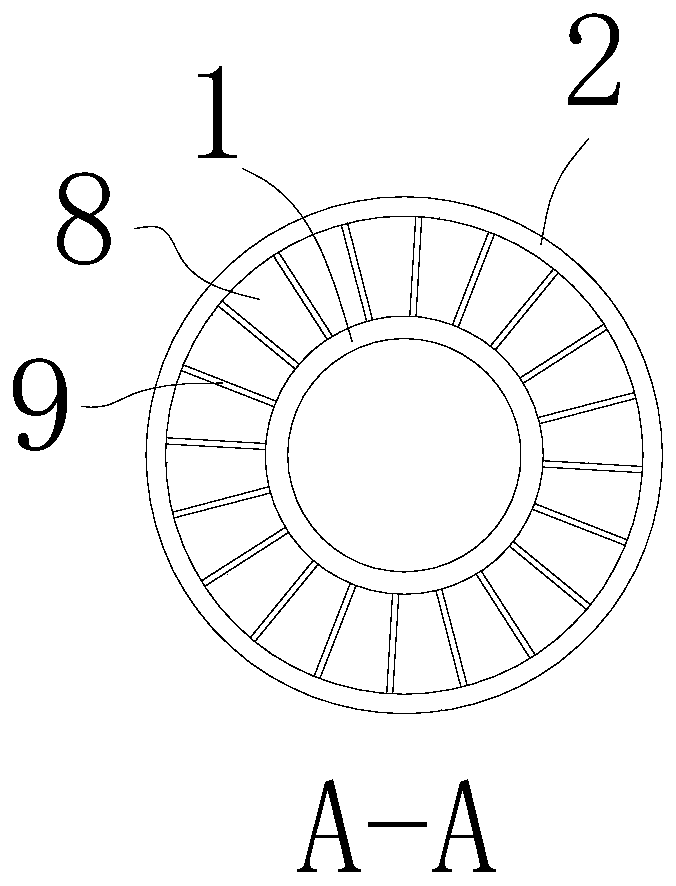

[0035] See figure 1 , figure 2 As shown, the heating cigarette smoking set is cylindrical as a whole, and is approximately truncated at the suction side 6 . The battery, power control module and temperature sensor are omitted in the figure, and only the heating head 10 is shown. In this example, a gap with a circular cross-section is formed between the outer wall 2 and the inner casing 1, and three partitions 8 are arranged in the air inlet passage 4 at intervals, and a section of the air inlet passage 4 is divided into two turbulence generation chambers . The shape of three partitions 8 is as follows: image 3 , Figure 4 and Figure 5 As shown, the ventilation holes on each partition 8 are thin stripes extending radially along the partition 8, the number of ventilation holes is not less than two, and the ventilation holes are distributed axially symmetrically on the partition 8; The ventilation hole of the partition 8 is different from the circumscribed angle of the in...

Embodiment 2

[0038] The rest is the same as the embodiment except the partition 8, the partition 8 is divided into at least two fan blades by the air hole 9, the partition 8 has a fan blade shape, so that the passing air can be rotated.

Embodiment 3

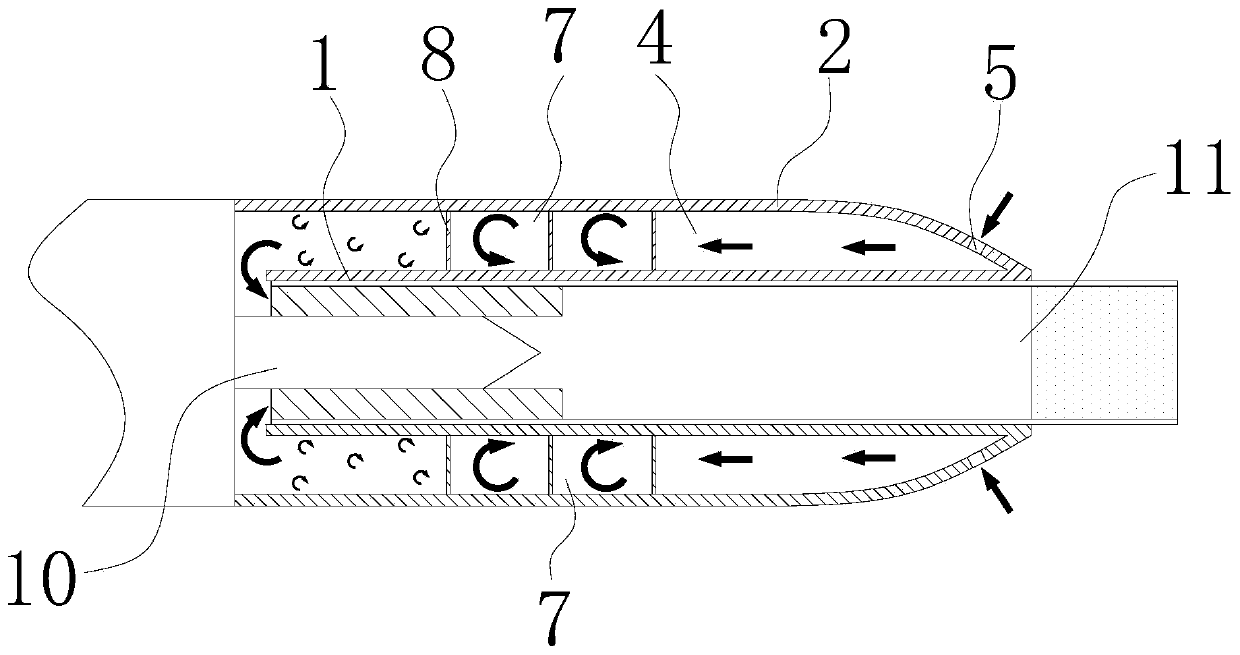

[0040] Such as Figure 6 As shown, the heating cigarette smoking set is in the shape of an ellipse as a whole, and its suction side 6 is located at Figure 6 the top of. Figure 7 It is a schematic diagram of the gas circuit structure of a heating cigarette smoking appliance. In this case, the outer wall 2 is oval, and the inner sleeve 1 is circular to match the smoking product 11 . The air inlet channel 4 is formed by the gap between the outer wall 2 and the inner casing 1, mainly on both sides, and three partitions 8 are provided, and two turbulence generation chambers are divided in the air inlet channel 4 . The feature of dividing plate 8 is that it is provided with bigger hole, and the shape of the hole on every dividing plate 8 is different, specifically as Figure 8 , Figure 9 and Figure 10 shown. When sucking, the air enters the air intake channel 4 from the air inlet 5, passes through the vent hole 9 on the partition plate 8, changes the path and speed, and thu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com