Rotational flow plate glycerinum chlorination bubbling reaction tower and device for producing epichlorohydrin

A technology of bubbling reaction tower and swirl plate glycerin is applied in the chemical method, organic chemistry, chemical instrument and method of reacting liquid and gas medium, etc. It can not meet the requirements of multi-stage contact of gas and liquid, etc., so as to achieve the effect of improving mass transfer efficiency and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

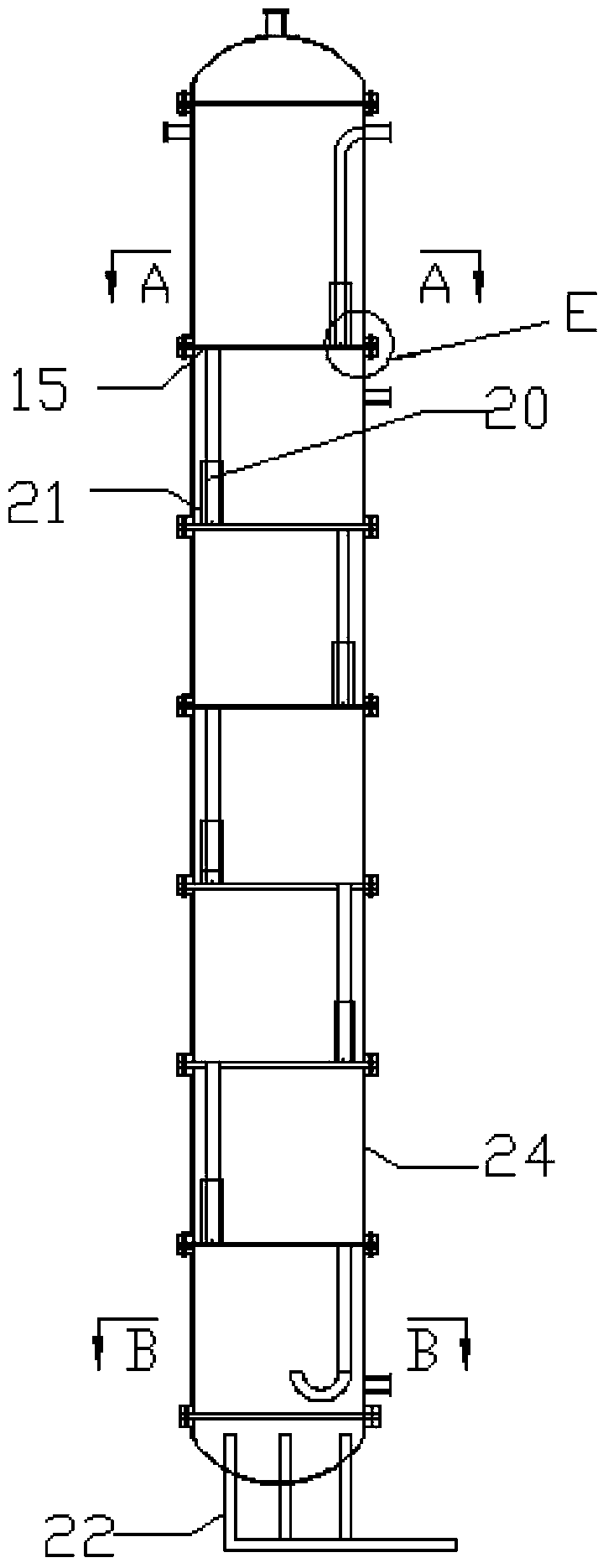

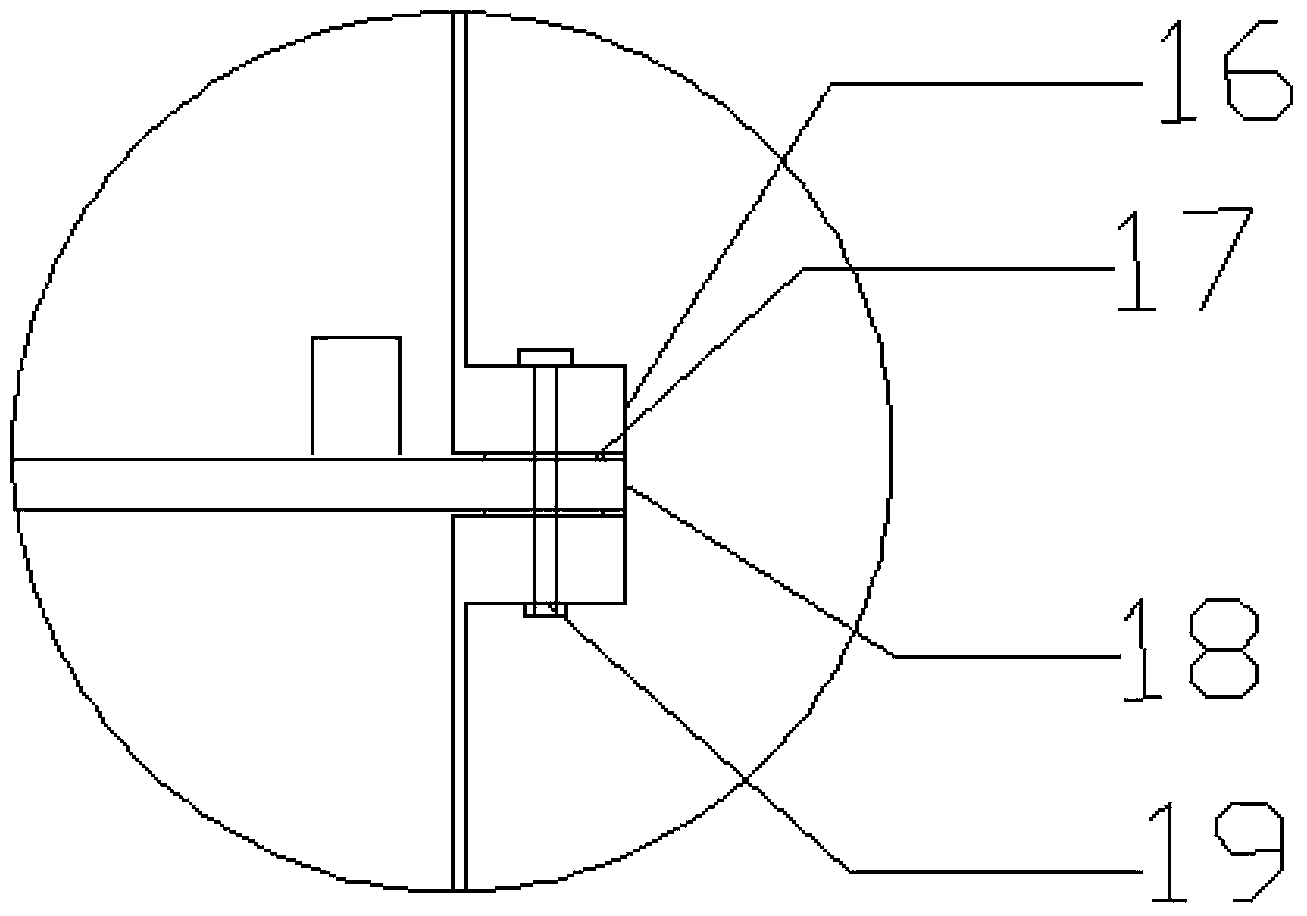

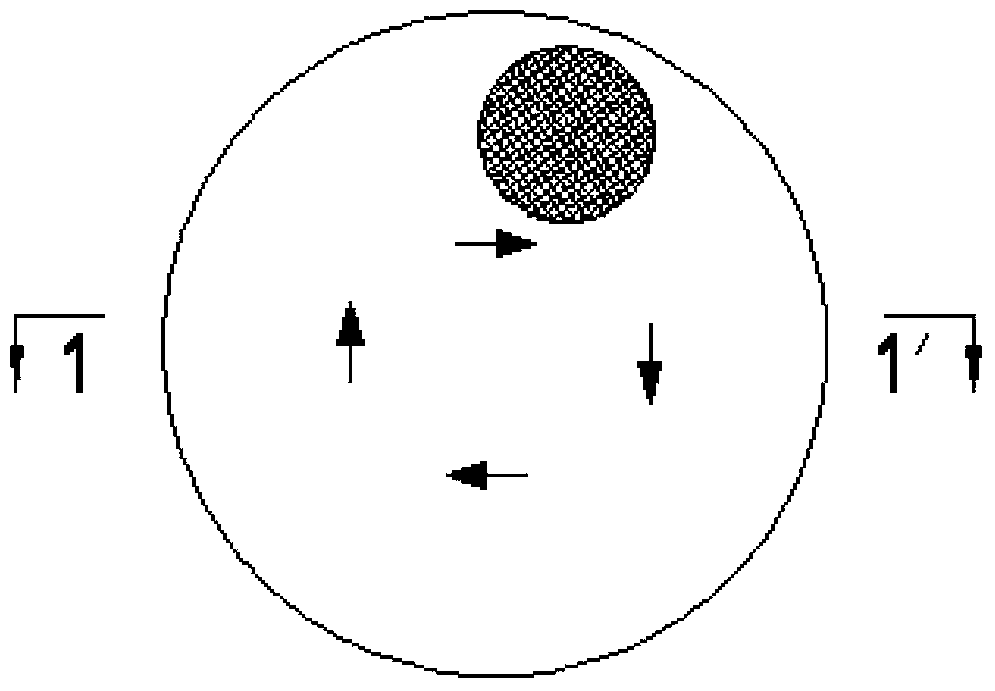

[0038] Such as Figure 1 to Figure 7 As shown, a kind of swirl plate glycerin bubbling reaction tower of the present invention is characterized in that: comprise tower body 24, tower body 24 is combined by several swirl plates 15, and swirl plate 15 is provided with sieve hole , the diameter of the sieve hole is 8mm, the top opening of the sieve hole and the horizontal line form the upper opening angle of the sieve hole 25 is 15°, the direction of the top opening of the sieve hole rotates clockwise, and the sieve holes on the swirl plate 15 are divided into four partitions distribution, such as Image 6 As shown, the opening direction of the sieve openings of the four partitions "1", "2", "3" and "4" on the cross-sectional projection plane of the reaction tower is set perpendicular to the radius of the reactor cross-section circle , each partition is designed in a clockwise or counterclockwise direction; there is a chamfer at the bottom of the screen hole on the swirl plate 1...

Embodiment 2

[0041] Such as Figure 1 to Figure 7 As shown, a kind of swirl plate glycerin bubbling reaction tower of the present invention is characterized in that: comprise tower body 24, tower body 24 is combined by several swirl plates 15, and swirl plate 15 is provided with sieve hole , the diameter of the sieve hole is 5mm, the upper opening of the sieve hole and the horizontal line form an angle 25 of the upper opening of the sieve hole is 45°, the direction of the upper opening of the sieve hole is clockwise or counterclockwise, and the sieve hole on the swirl plate 15 is in accordance with " 1" area, "2" area, and "3" area are distributed, and each partition is designed in a counterclockwise direction; there is a chamfer at the bottom of the screen hole on the swirl plate 15, and the chamfer angle 26 is 45°. There is a downcomer 20 between the two swirl plates 15, the downcomer 20 is covered with a liquid seal tube 21, and the bottom of the tower body 24 is provided with several g...

Embodiment 3

[0043] Such as Figure 1 to Figure 7 As shown, a kind of swirl plate glycerin bubbling reaction tower of the present invention is characterized in that: comprise tower body 24, tower body 24 is combined by several swirl plates 15, and swirl plate 15 is provided with sieve hole , the diameter of the sieve hole is 3mm, the upper opening of the sieve hole and the horizontal line form the upper opening angle of the sieve hole 25 is 85°, the direction of the upper opening of the sieve hole rotates clockwise, and the sieve hole on the swirl plate 15 follows the "1" area , "Zone 2", "Zone 3", "Zone 4" and "Zone 5" are distributed in five partitions, and each partition is designed in a clockwise or counterclockwise direction; at the bottom of the screen hole on the swirl plate 15 There are chamfers, and the chamfer angle 26 is 85°. There is a downcomer 20 in the middle of the two adjacent swirl plates 15. The downcomer 20 is covered with a liquid seal tube 21. The bottom of the tower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com