Water-cooling-type tail gas cleanup device of explosion-proof diesel engine

A technology of exhaust gas purification device and explosion-proof diesel engine, which is applied to exhaust devices, mufflers, mechanical equipment, etc., can solve problems such as affecting conversion efficiency, achieve uniform heating, avoid shell cracking, and prolong life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

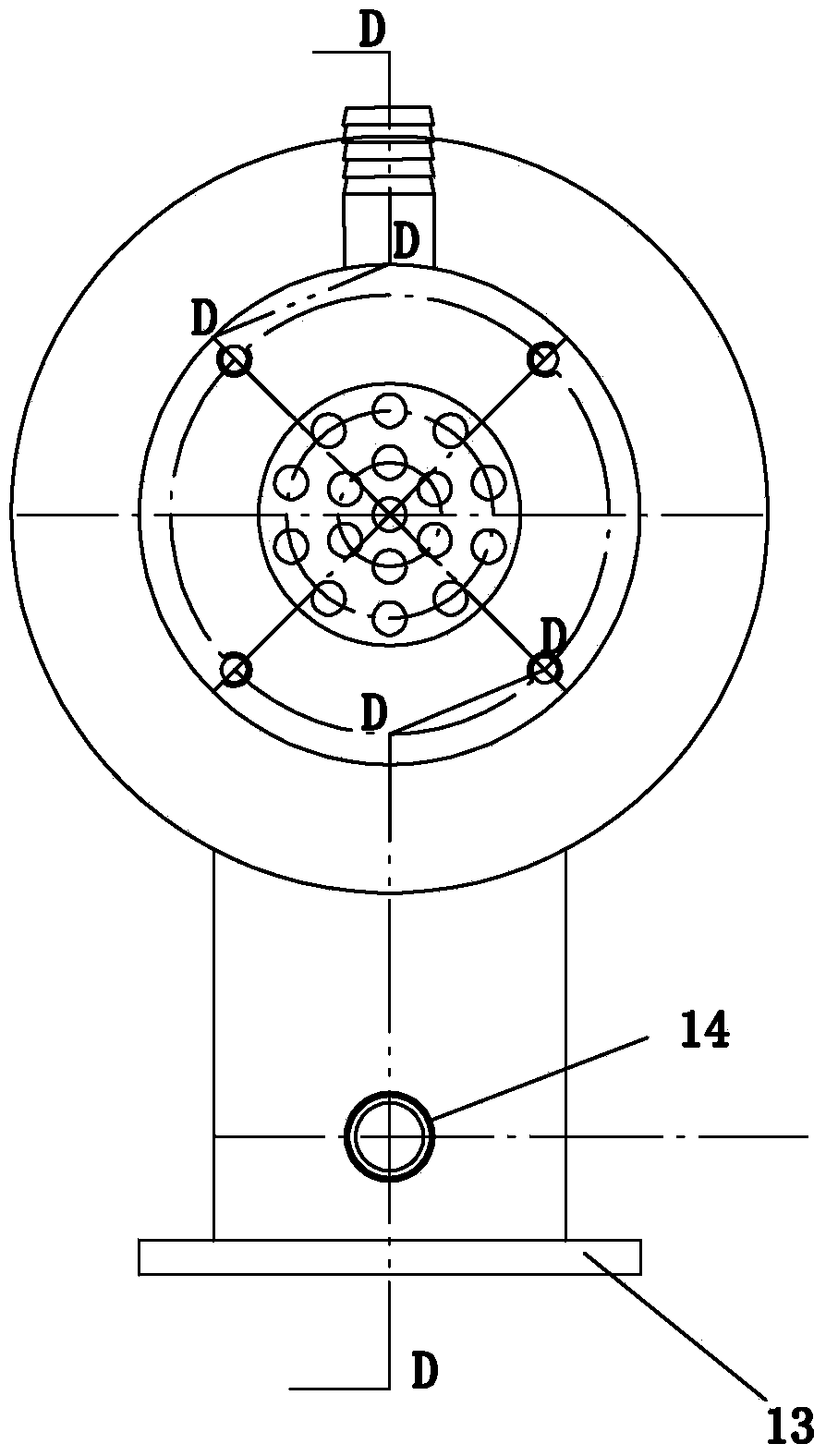

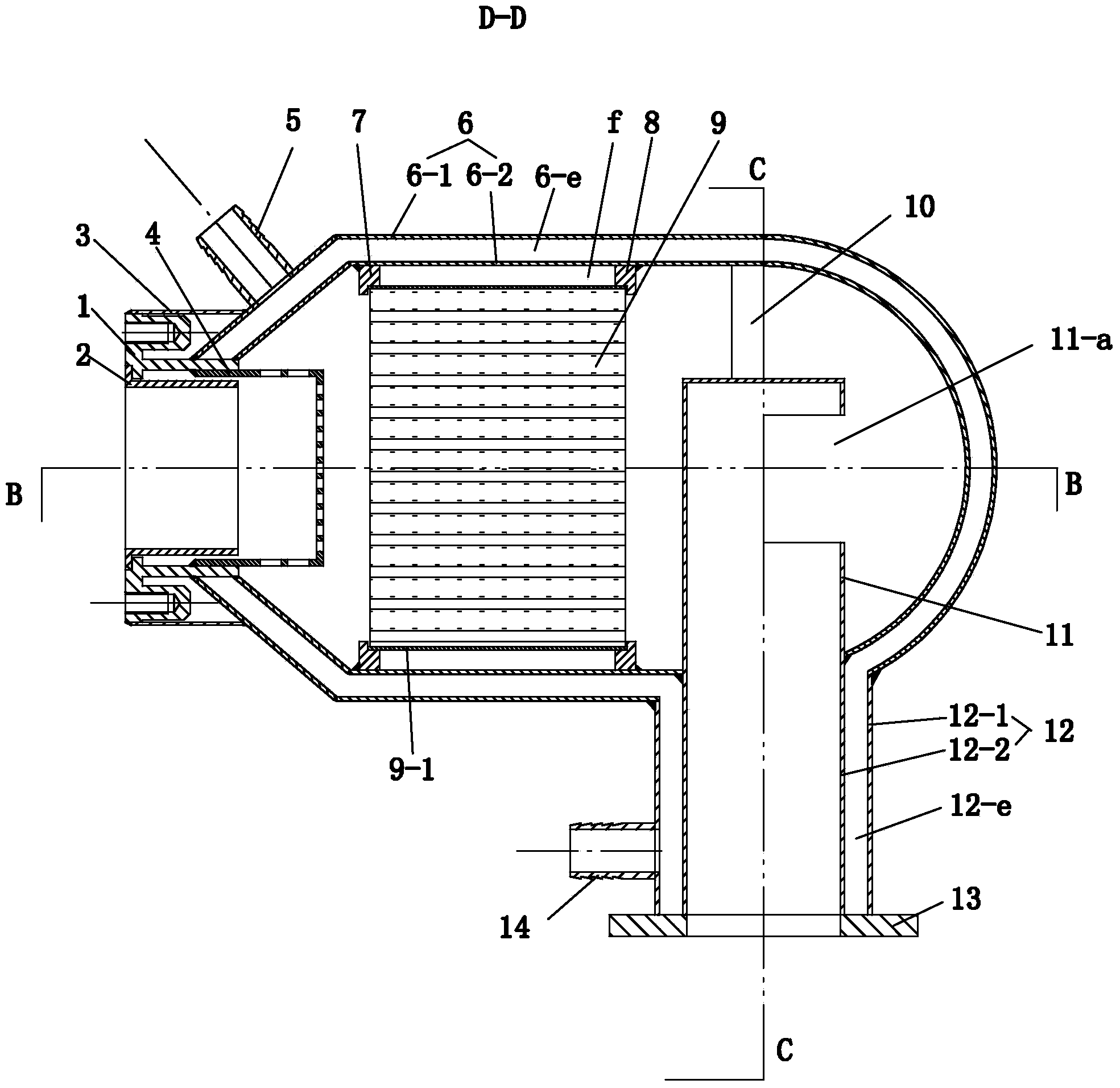

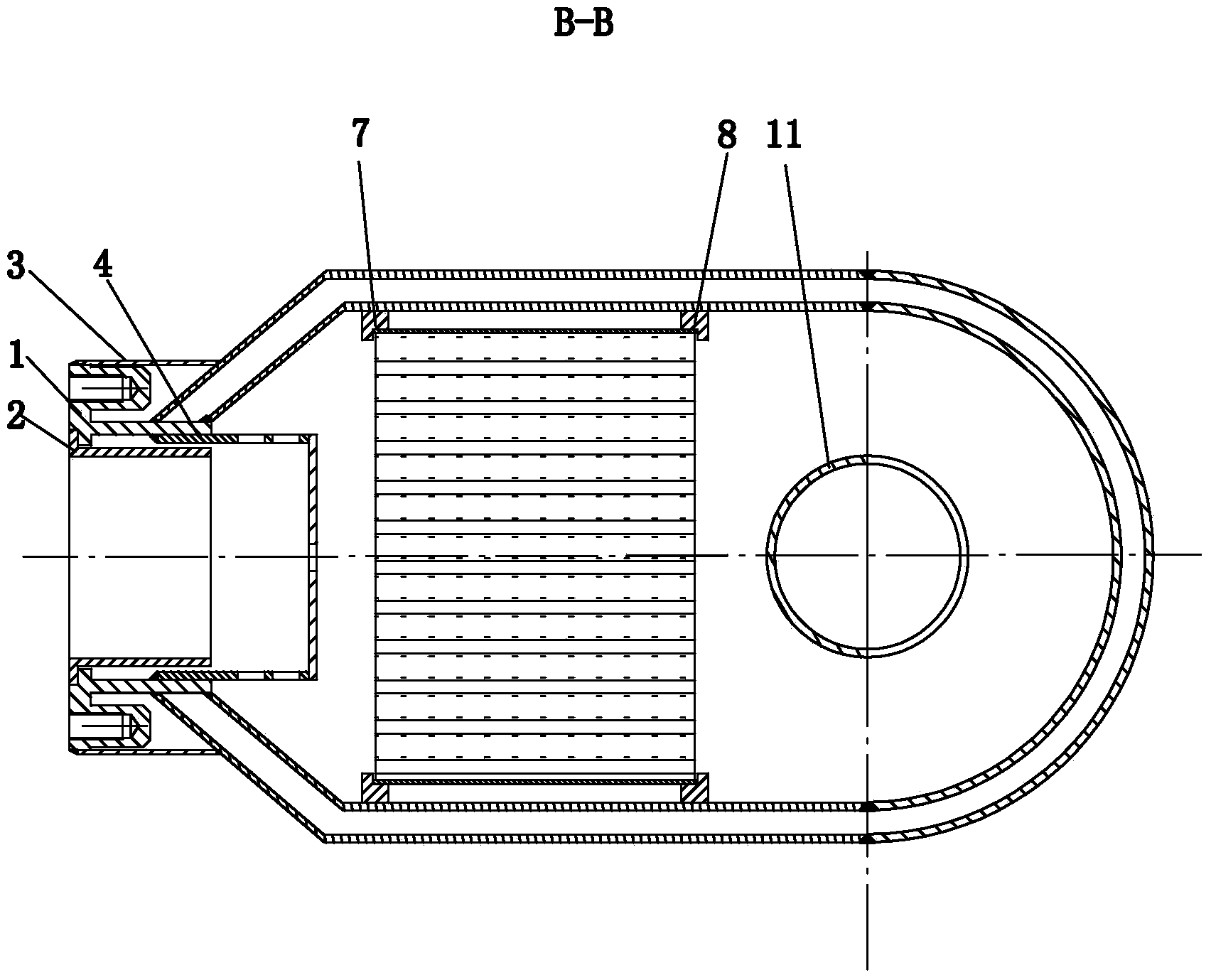

[0017] See Figure 1 to Figure 4 , the present embodiment has a front flange 1, a rear flange 13, a shell and a DOC core 9, the shell has a main body shell 6 and a lower shell 12, and the front part of the main body shell 6 is a cone with an air inlet Body, the rear portion of the main body housing 6 is a hemisphere. The DOC core 7 is coated with a catalyst coating mainly composed of precious metals platinum and rhodium. The outer cylindrical surface of the DOC core 9 is covered with a thin iron sheet 9-1 with a thickness not exceeding 1.8mm.

[0018] Main body shell 6 and lower shell 12 are respectively made up of inner and outer shells, and between inner and outer shells is a water jacket, that is, main body shell 6 is made up of main body outer shell 6-1, main body inner shell 6-2, and lower shell The body 12 is composed of a lower shell outer shell 12-1 and a lower shell inner shell 12-2. The water jacket 6-e of the main body shell 6 and the water jacket 12-e of the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com