Patents

Literature

93results about How to "Play a role in dust suppression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rapid outburst elimination method for cross cut coal uncovering in coal mine underground

InactiveCN102242640ASolve the outstanding riskSpeed up coal removalUnderground miningFluid removalDrill holeElimination method

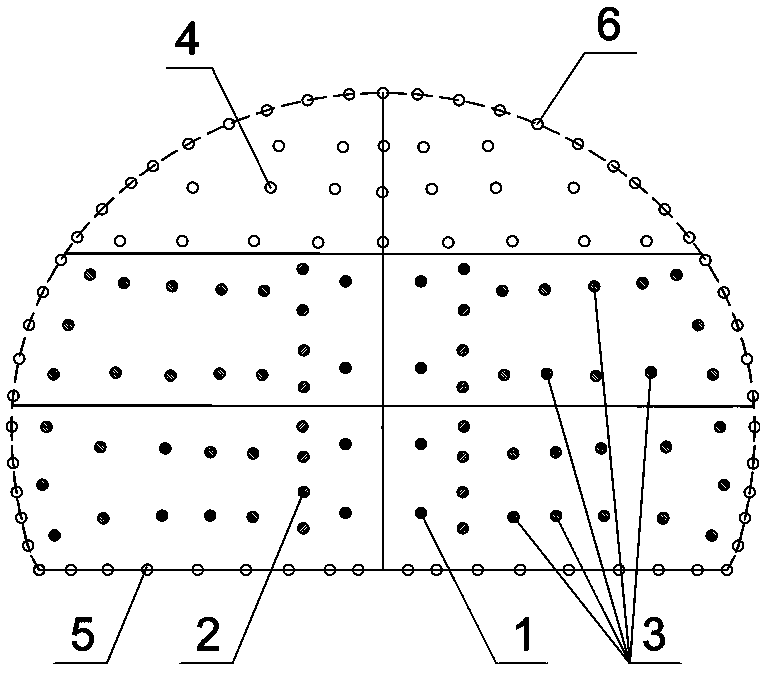

The invention provides a rapid outburst elimination method for cross cut coal uncovering in coal mine underground. The method comprises the following steps: before an outburst coal layer is uncovered by a cross cut, arranging hydraulic fracturing drill holes at the part, the normal distance of which is 5-7m with a coal layer, on a cross cut coal uncovering work face; sealing the fracturing drill holes; fracturing the fracturing drill holes with clear water the injection amount of which is determined according to an outburst elimination range; after fracture is finished, constructing deslagging blowholes, injecting high-pressure water into the fracturing drill holes for punching, and discharging coal and rocks generated from fracturing to the outside through the deslagging blowholes; carrying out gas extraction and drilling on the cross cut coal uncovering work face, sealing the drill holes by use of polyurethane and carrying out gas extraction, wherein the holes are sealed to the top plate / bottom plate of the coal layer; injecting high-pressure nitrogen or air into the fracturing holes, observing the gas flow and concentration change in gas extraction holes, and stopping gas injection if flow increases; if the gas extraction effect reaches the standard, and uncovering the rock cross cut when no outburst danger occurs to the cross cut work face; and if the gas extraction effectis not good, implementing fracturing once again and injecting high-pressure gas to expel and exchange methane. The method has the advantages of accelerating the coal uncovering speed of the cross cutwork face, playing a role in dust suppression, and improving the work conditions of a tunneling work face.

Owner:HENAN COAL CHEM IND GROUP INST +1

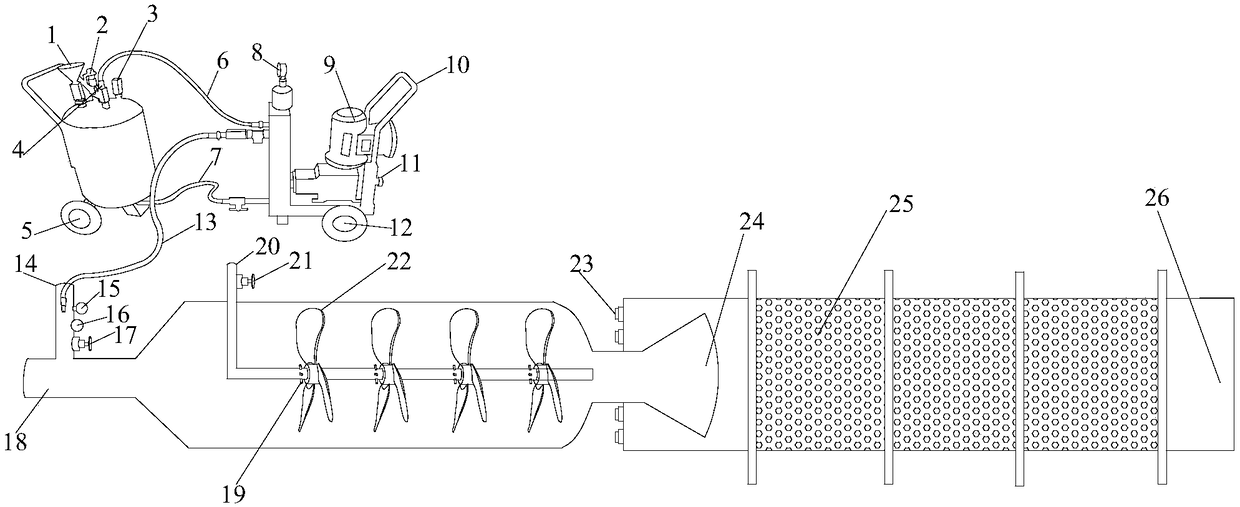

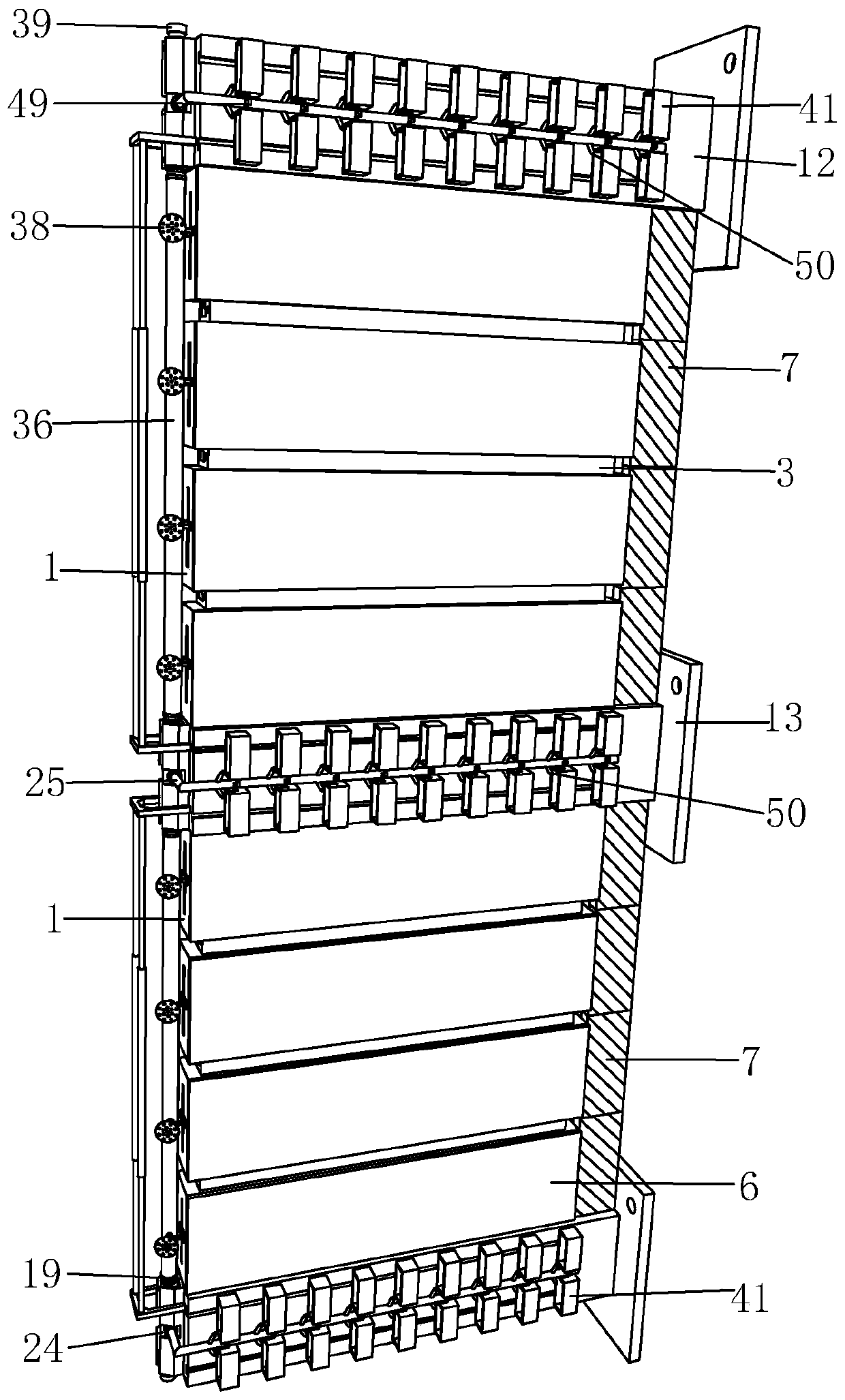

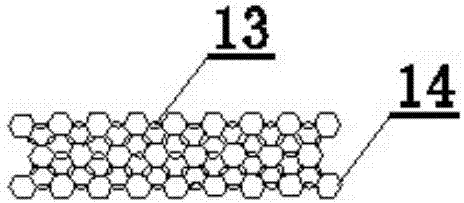

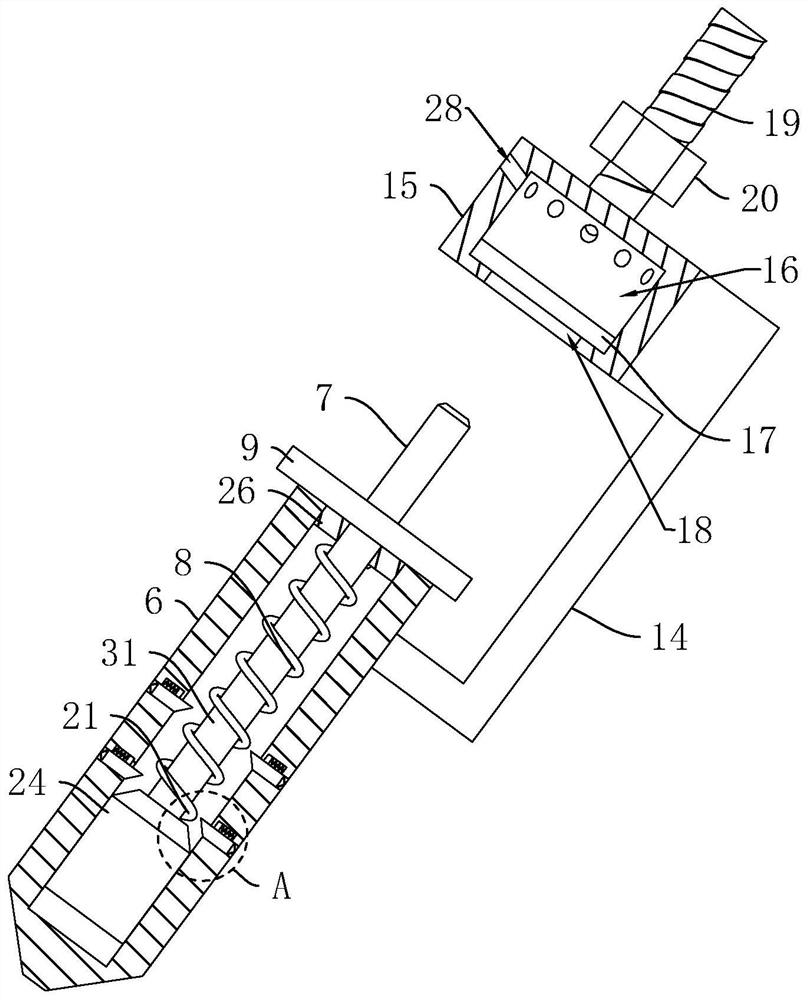

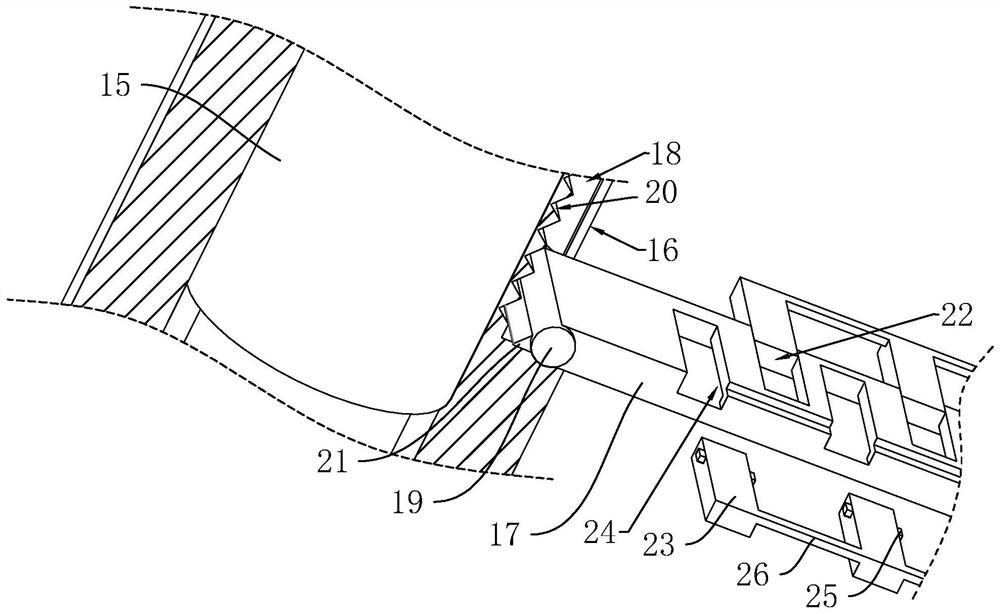

Foam generating device used for dust fall

ActiveCN104533501AImprove stabilityPlay a role in dust suppressionTransportation and packagingDust removalMouth shapeDust fall

The invention discloses a foam generating device used for dust fall. The foam generating device comprises an air inlet main pipe, one end of the air inlet main pipe is communicated with a foaming shell through a Venturi diffusion mechanism, the other end of the foaming shell is communicated with a foam output pipe, a longitudinal hollow air supply rod is arranged in the foaming shell, the air supply rod is sequentially provided with rotary power blades and a net type swirler, the air supply rod is provided with multiple air supply rod air outlet pipes which are evenly distributed in the circumferential direction of the air supply rod, an air supply rod air outlet is formed in the end, close to the foam output pipe, of the air supply rod and is of a horn mouth shape, the air supply rod air outlet corresponds to the foam output pipe, and an air supply rod air inlet pipe is arranged on the air supply rod and is communicated with the air supply rod air outlet and the air supply rod air outlet pipes. Foaming is performed on a foam dedusting agent solution three times, the foaming rate is greatly increased, and operation stability of the foam generating device is improved.

Owner:SHANDONG UNIV OF SCI & TECH

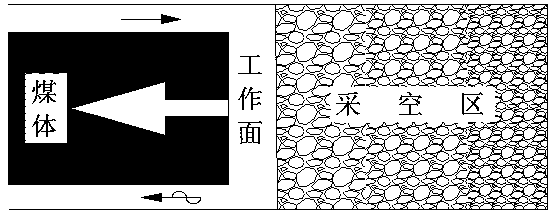

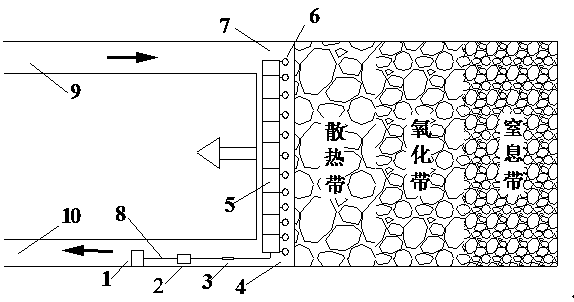

Method for preventing goaf spontaneous combustion through superfine inhibitor water mist

InactiveCN108843373ANo pollution in the processImprove fire extinguishing efficiencyDust removalFire preventionPorositySpontaneous combustion

The invention discloses a new method for preventing goaf spontaneous combustion, which is characterized in that: at first, an easy self-ignition area of a goaf is determined, since the influence of the mine pressure to coal and rock mass in an oxidizing zone area of the goaf is greater than that to a heat dissipation zone, and the coal and rock mass is further compressed and crushed, so that the porosity of the area is reduced, air leakage channels are reduced, and the heat generated through oxidization of the coal mass is easily accumulated; the oxygen supply condition of the area is more sufficient compared with a suffocative zone, so that the coal and rock mass form high-temperature point spontaneous combustion with sufficient oxidization; and then, a goaf superfine inhibitor water mistspraying system is established, and the goaf superfine inhibitor water mist spraying system comprises a movable pump station, a liquid storage tank, a hydraulic bracket, a nozzle, a pipeline and thelike. According to the new method for preventing goaf spontaneous combustion, a water retention film is formed on the surface of residual coal of the goaf, the inhibitor enters a coal fracture to realize the cooling and oxygen isolating effect, and finally, the purpose of preventing the goaf from spontaneous combustion is realized.

Owner:LIAONING TECHNICAL UNIVERSITY

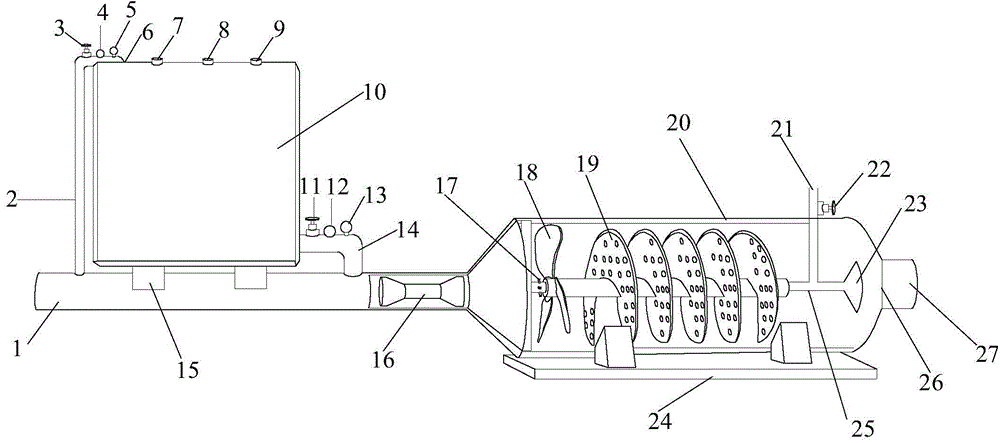

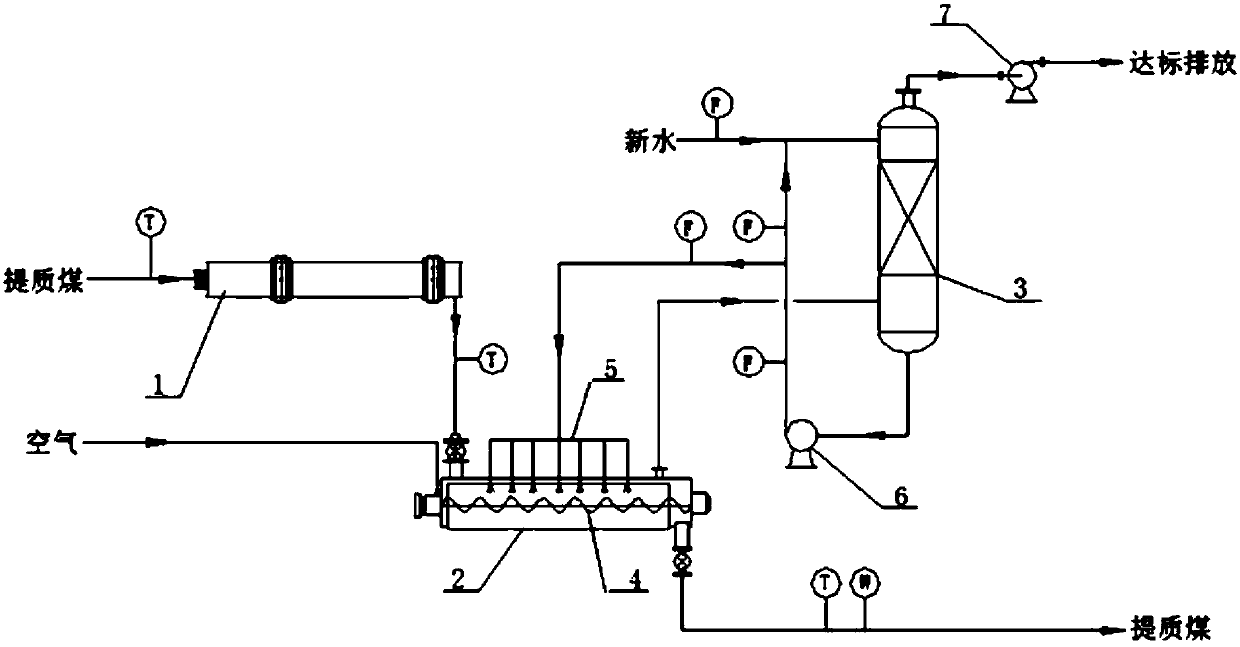

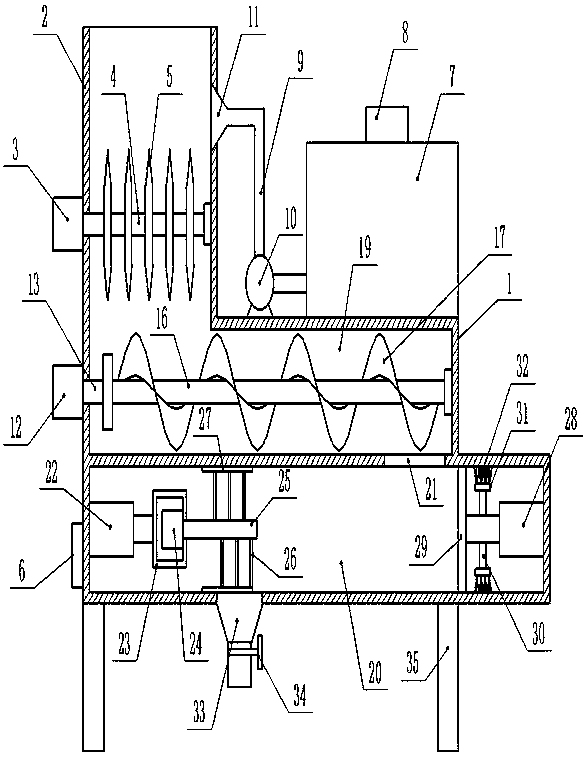

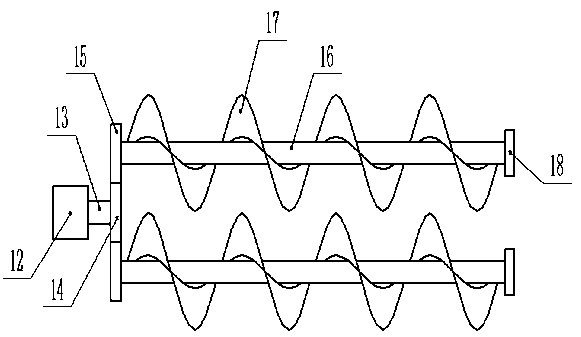

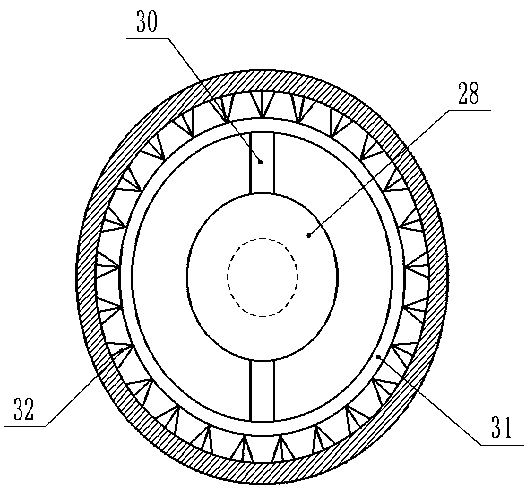

Upgraded coal cooling and humidifying device

PendingCN107937008AMeet the requirements of subsequent processesReduce loadCoke ovensUsing liquid separation agentTowerCirculating pump

The invention relates to an upgraded coal cooling and humidifying device which comprises a rotary cooler, a humidifier and a scrubbing tower, wherein an upgraded coal discharging hole of the rotary cooler is connected with an upgraded coal inlet in one side on the top of the humidifier; an upgraded coal outlet is formed in the other side at the bottom of the humidifier; a water spraying device isarranged on the top of the humidifier; an air inlet is formed in one end of the humidifier close to one side of the upgraded coal inlet; a tail gas outlet is formed in the top of the humidifier closeto the upgraded coal outlet; the tail gas outlet is connected with the tower column on the lower part of the scrubbing tower by virtue of a pipeline; at least two stages of spraying devices are arranged on the upper part of the scrubbing tower; a net gas outlet is formed in the top of the scrubbing tower; a washing water outlet is formed in the bottom of the scrubbing tower and connected with thespraying device by virtue of a washing water circulating pipeline; and a circulating pump and a washing water supply inlet are arranged on the washing water circulating pipeline. By virtue of a methodfor combining indirect cooling and humidification cooling, the temperature and moisture of the upgraded coal meet the requirements. Meanwhile, dust-containing steam produced in the humidification cooling process is effectively treated, and up-to-standard discharge is achieved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

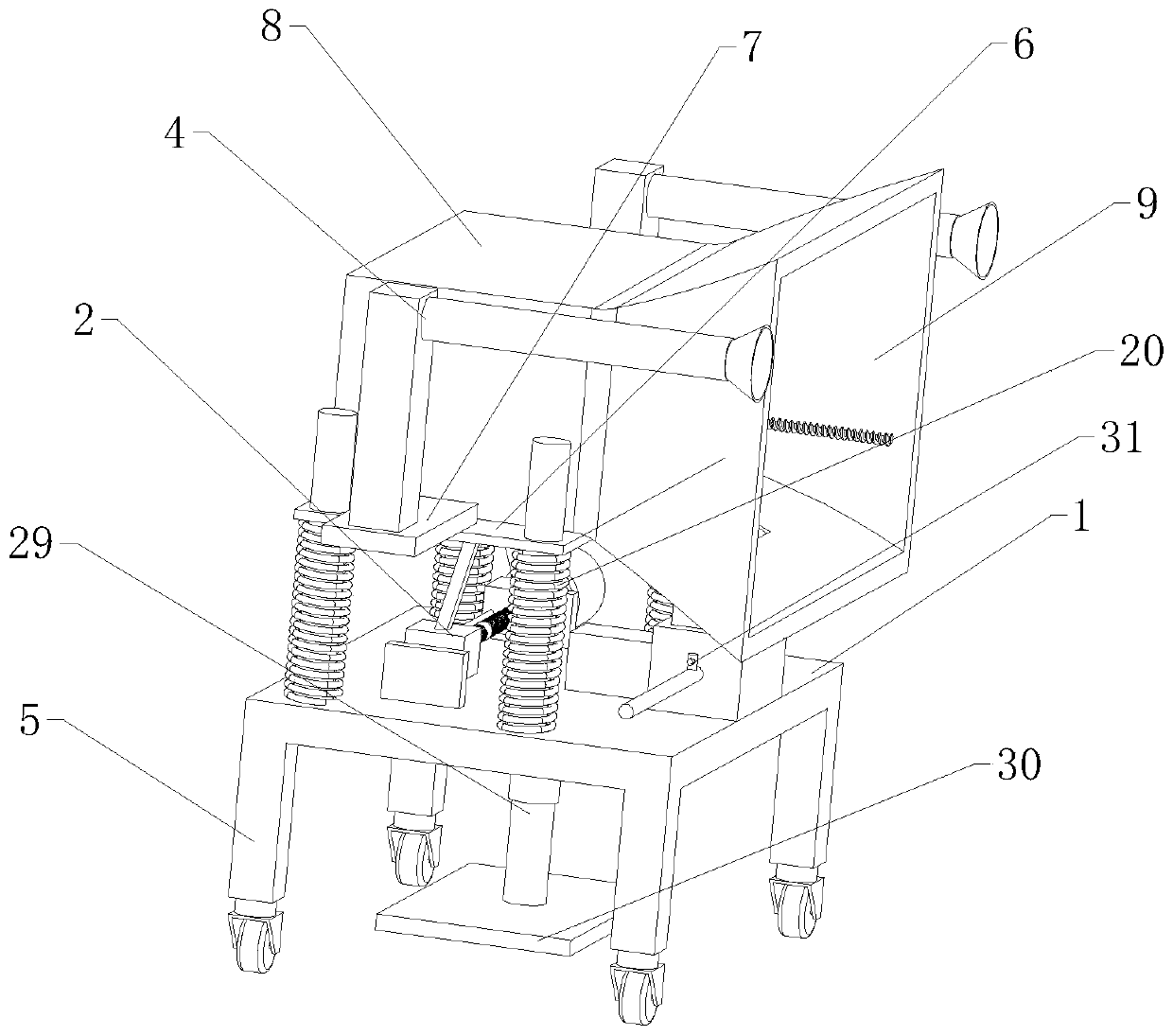

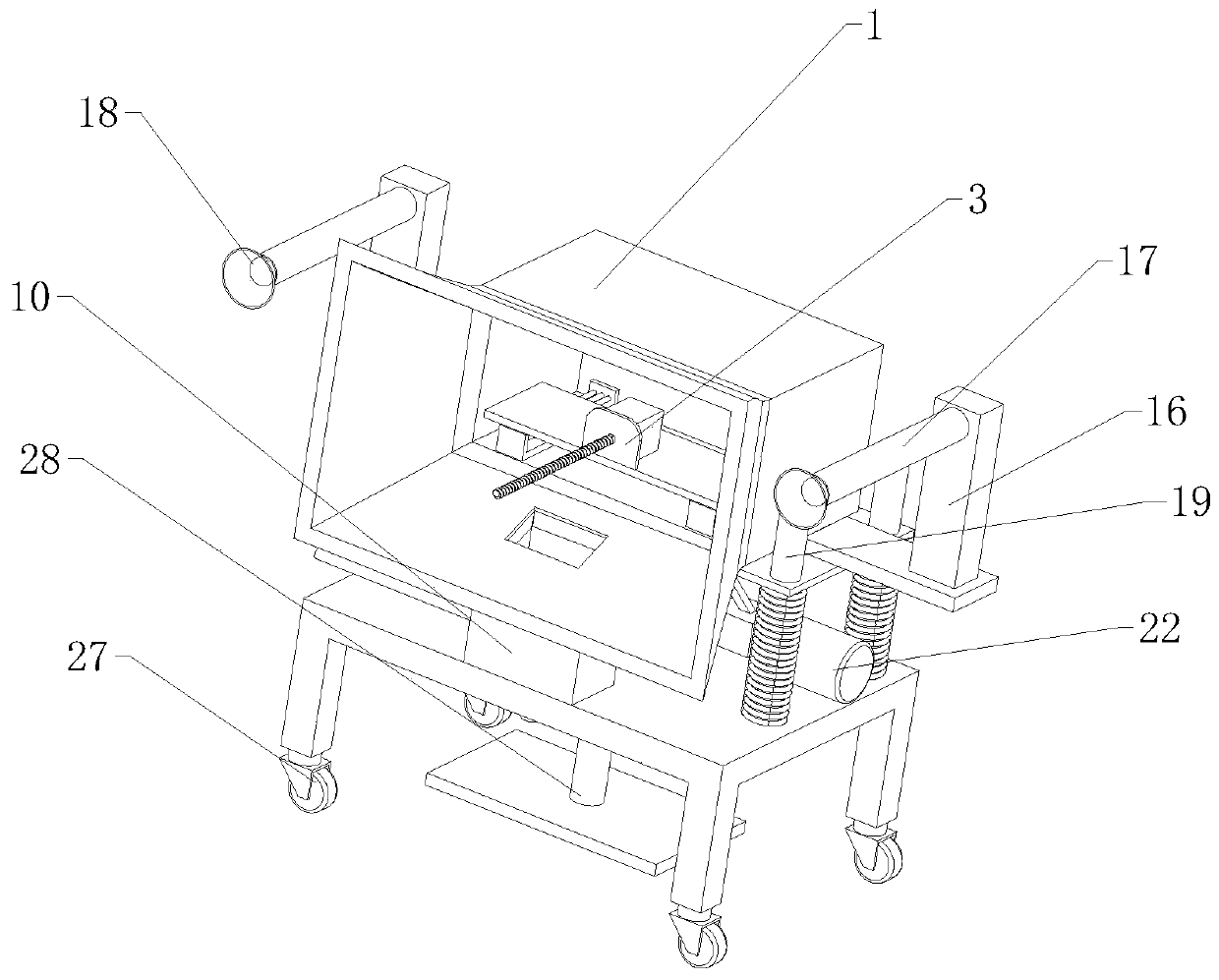

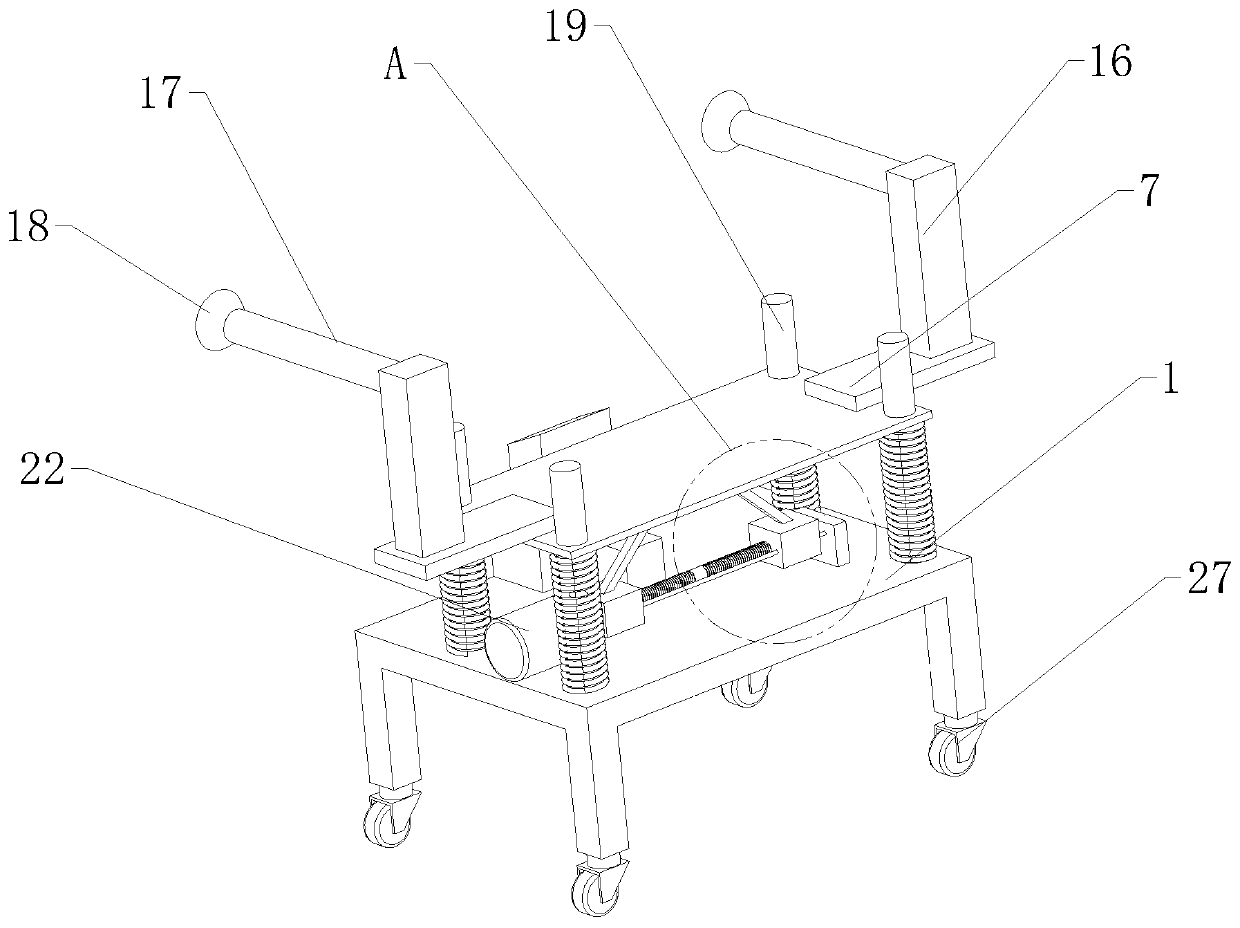

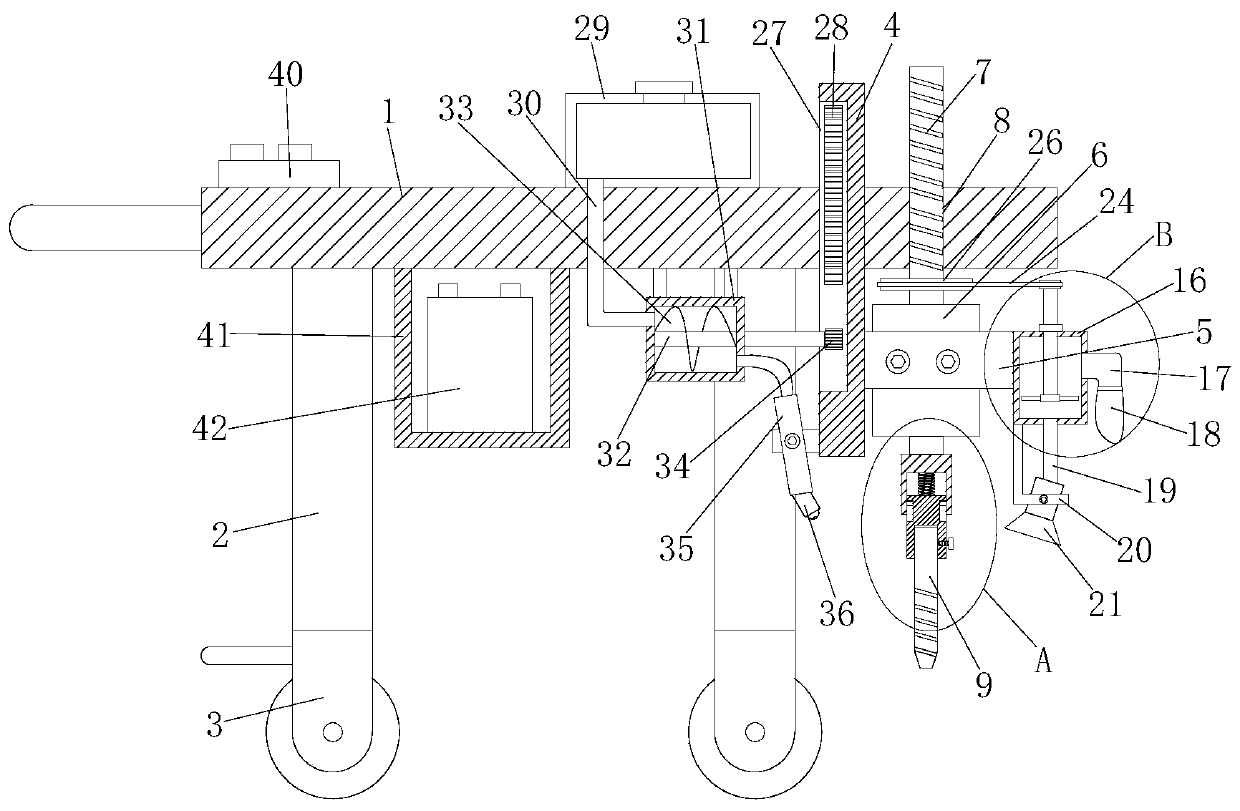

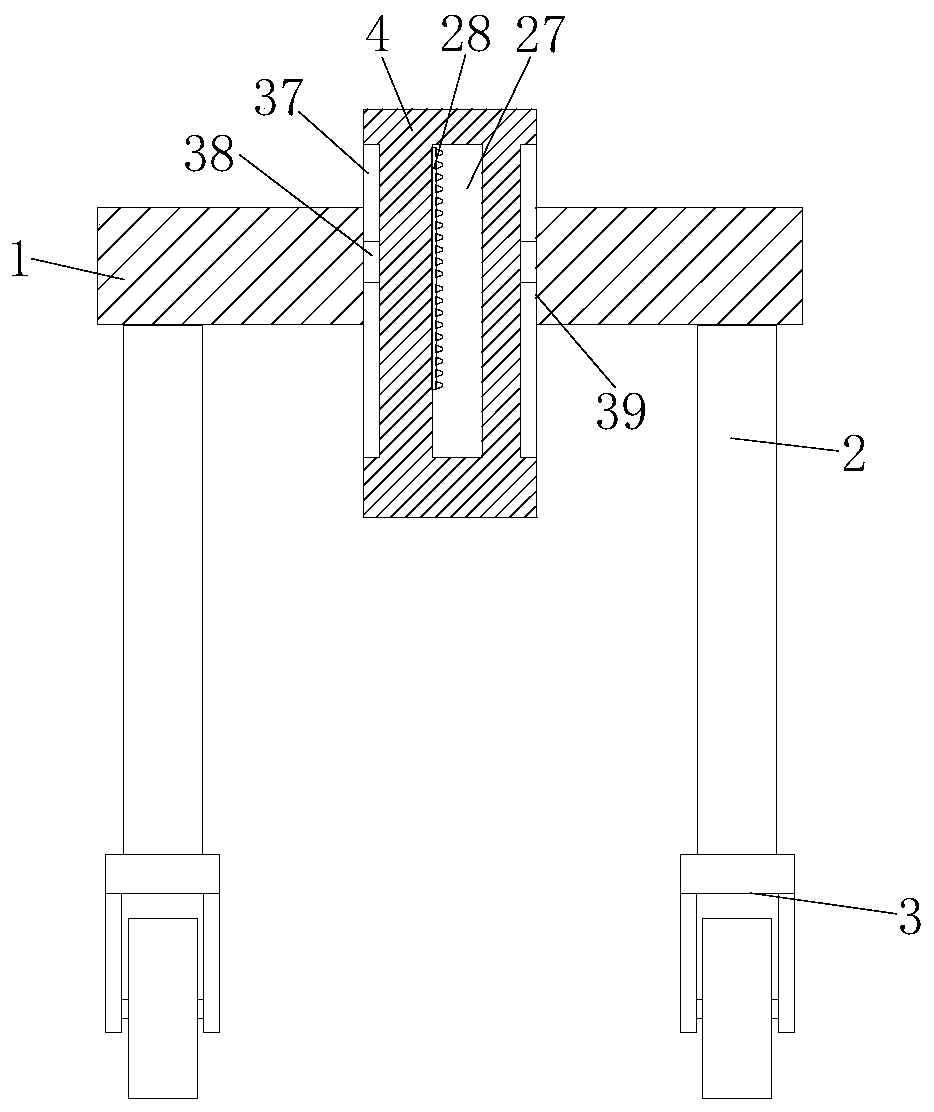

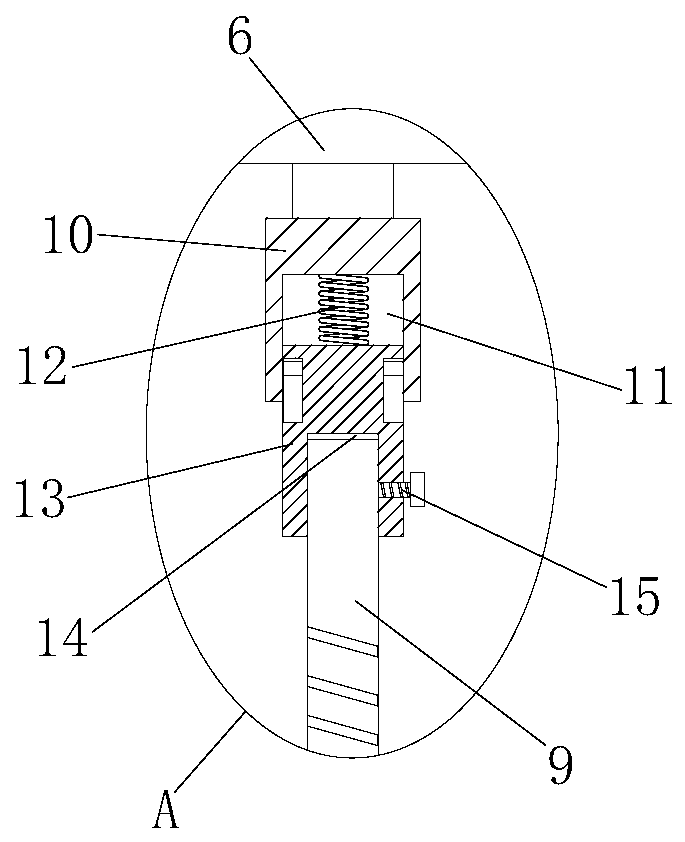

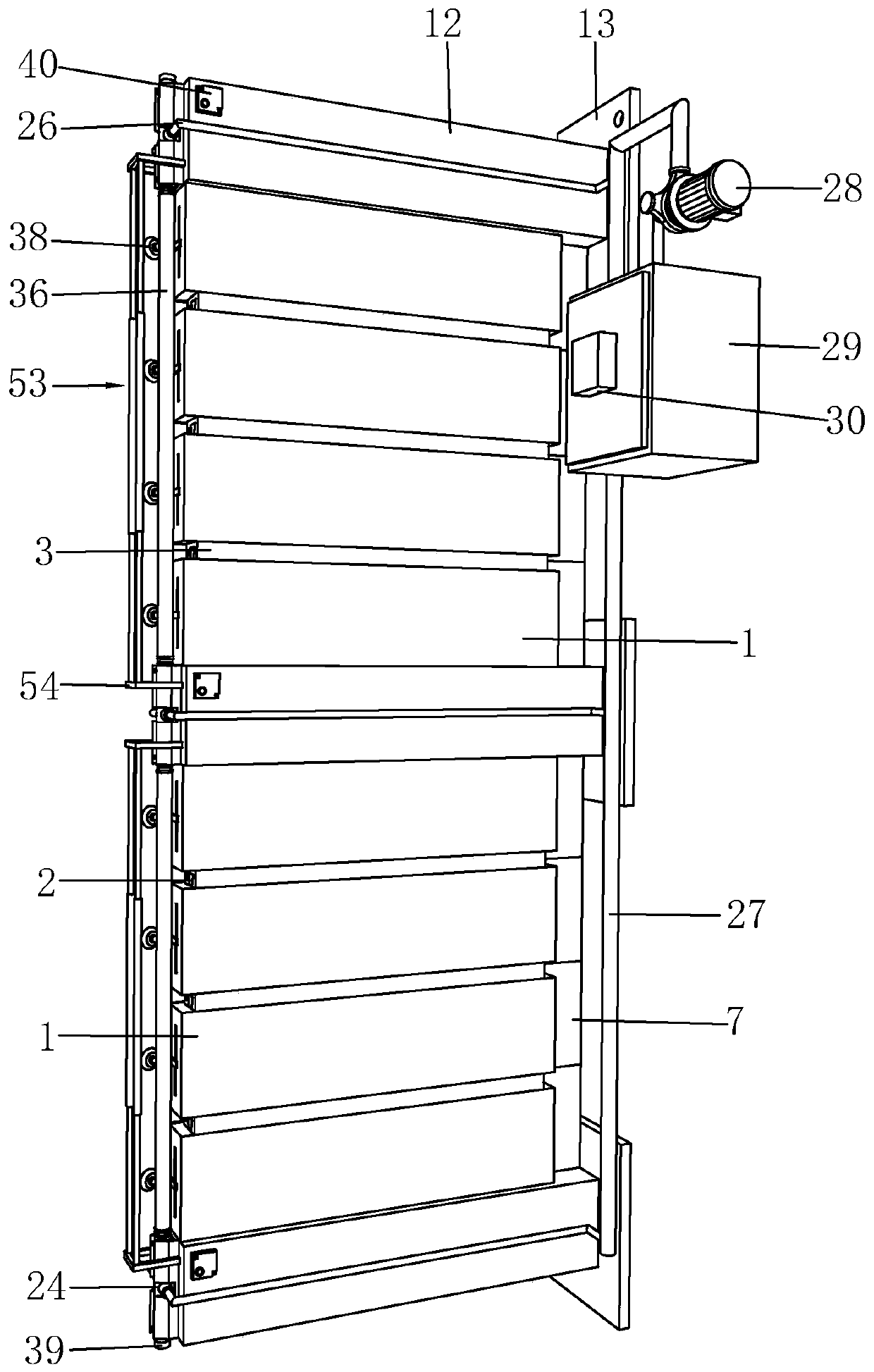

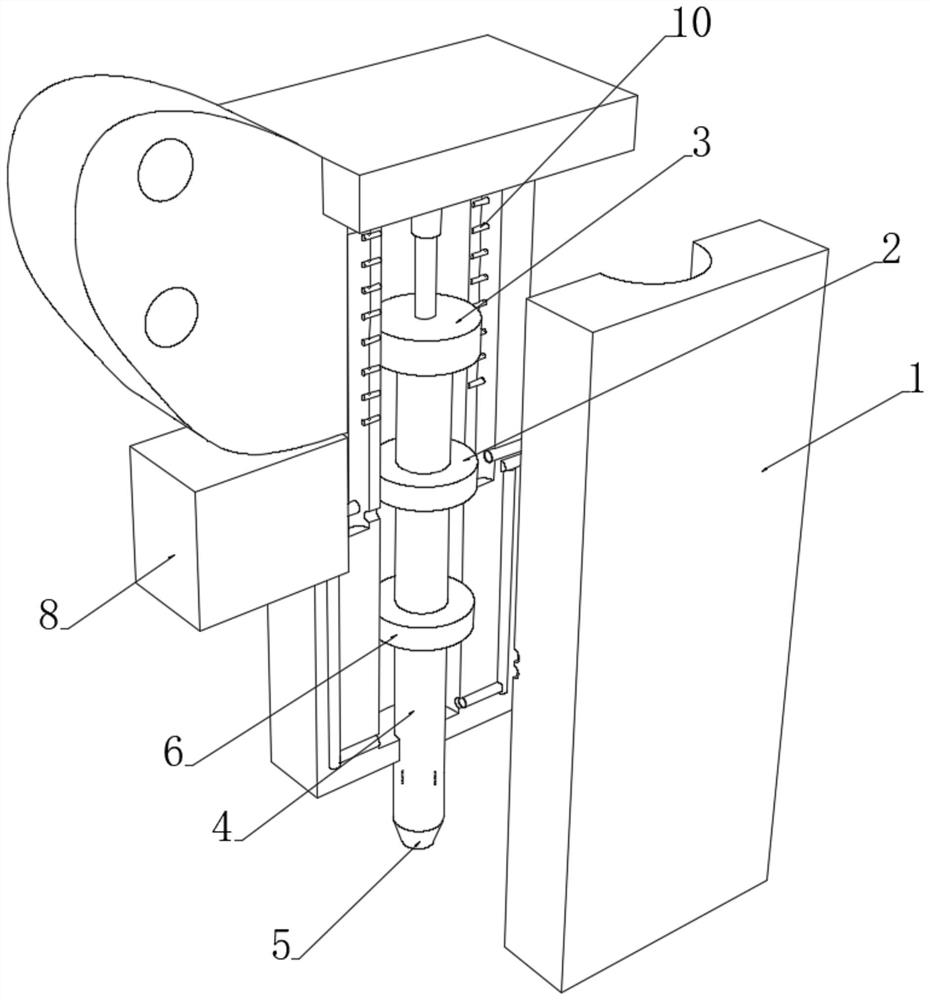

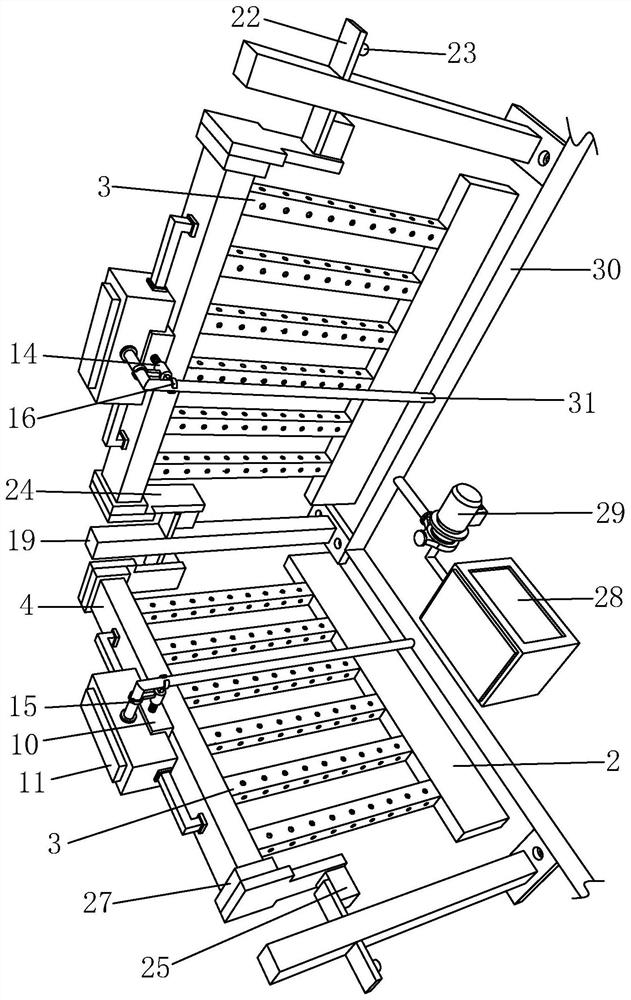

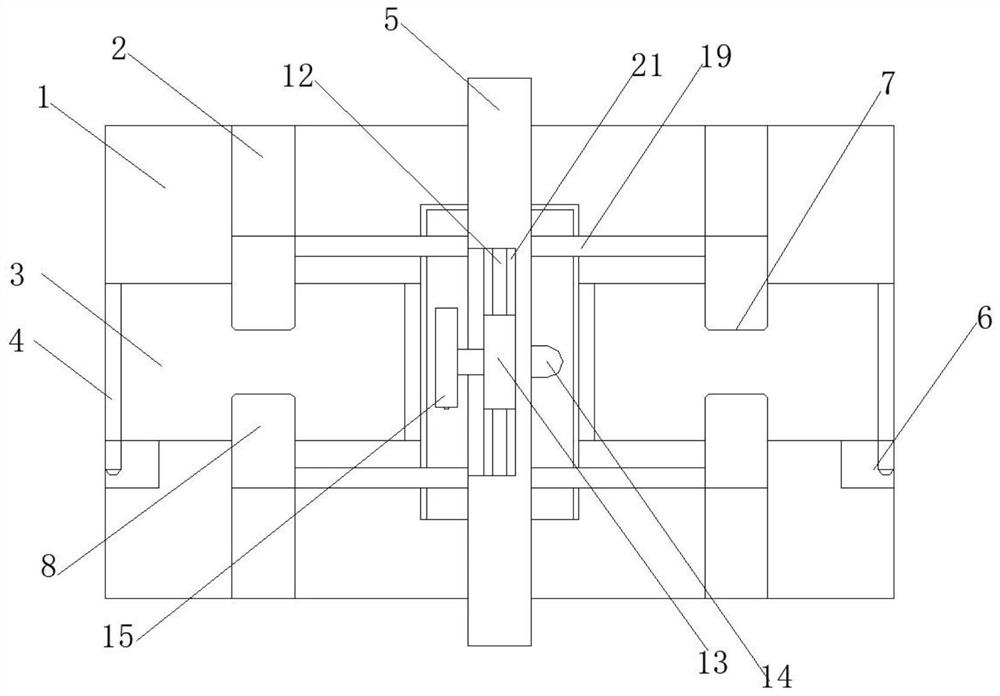

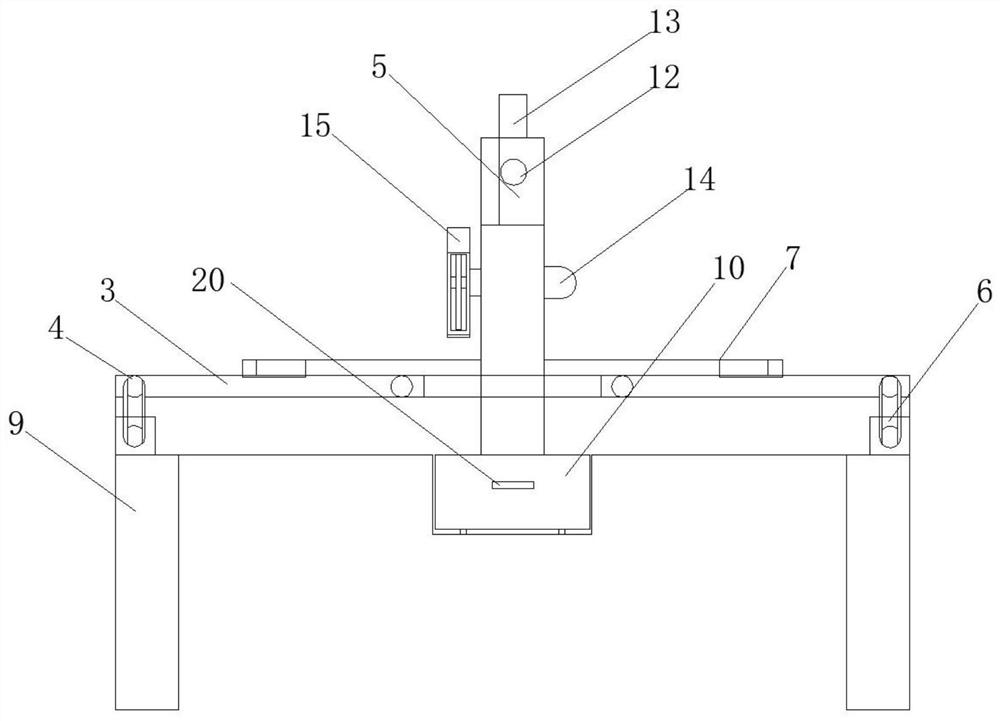

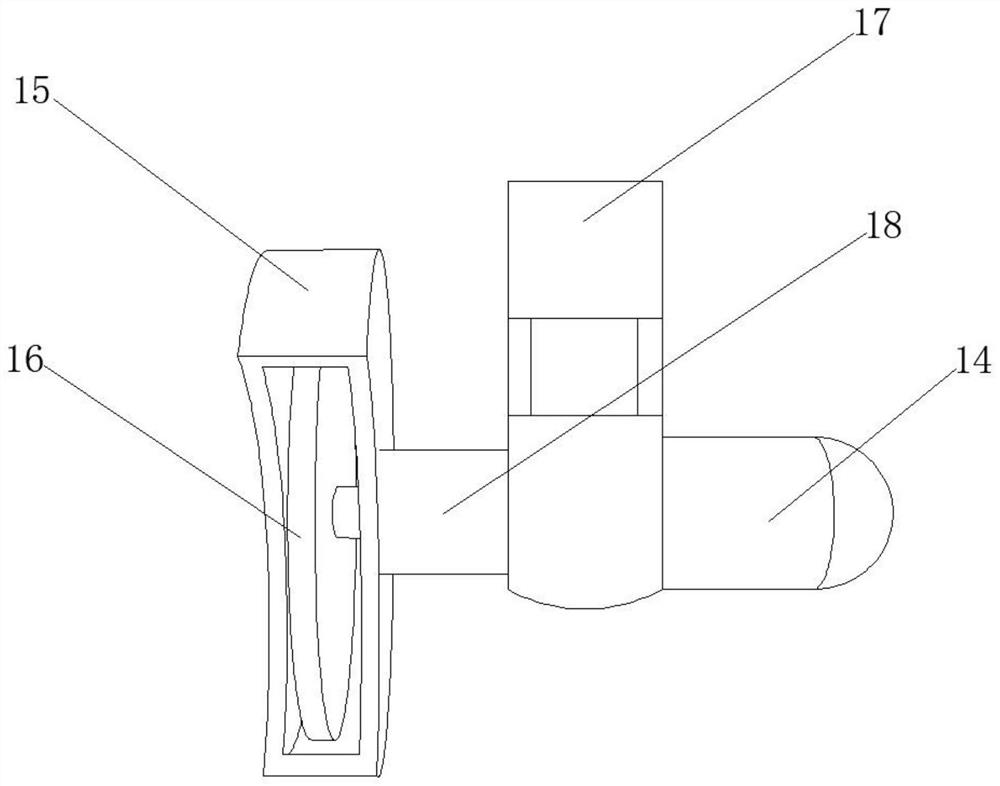

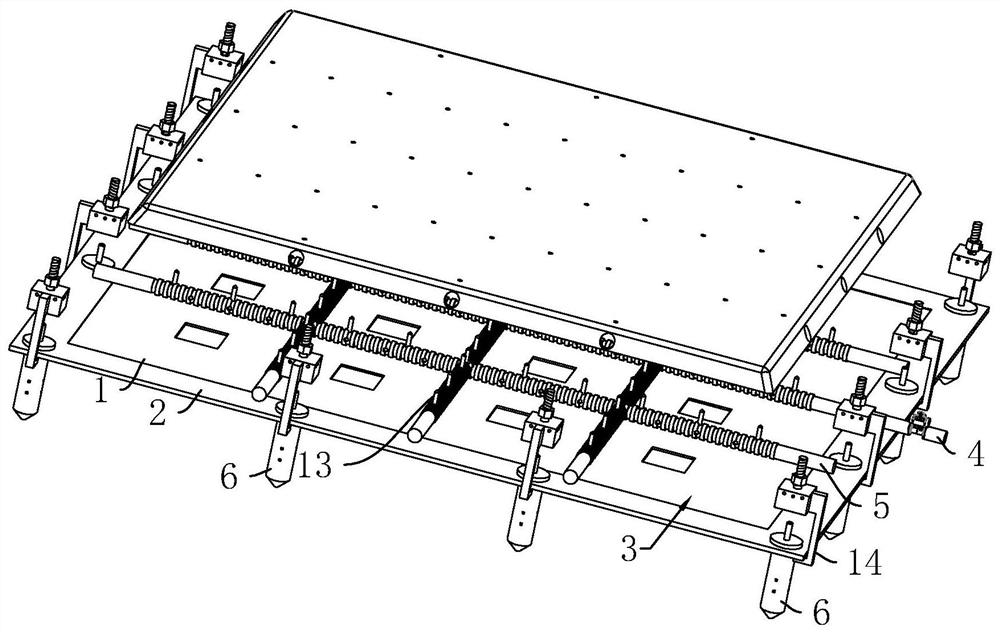

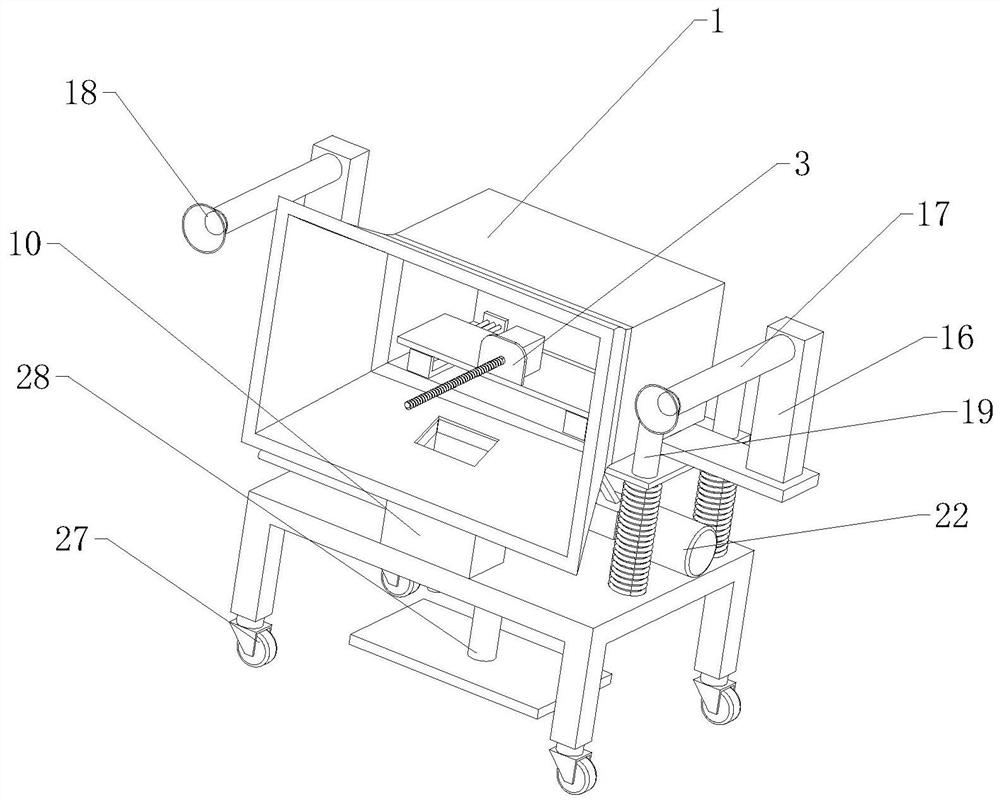

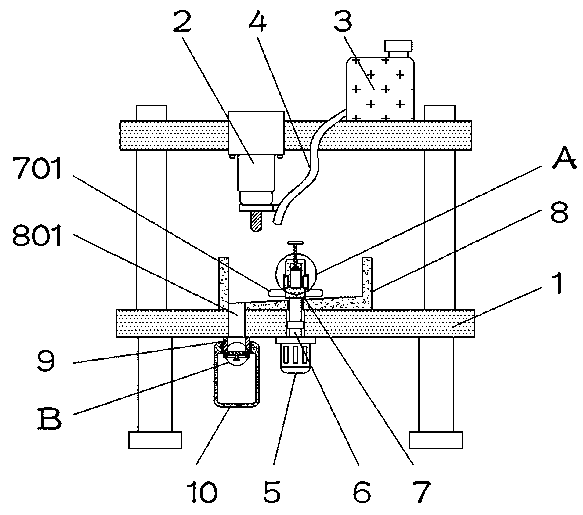

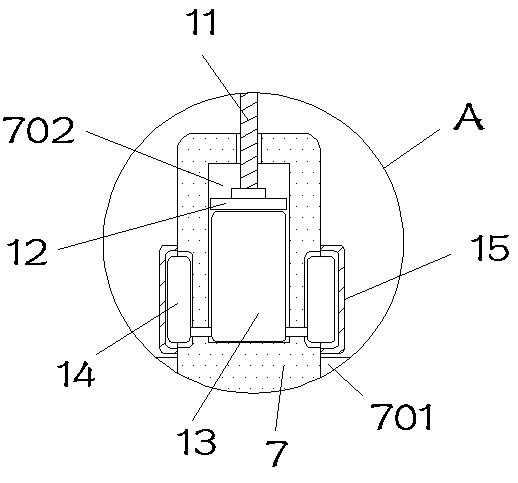

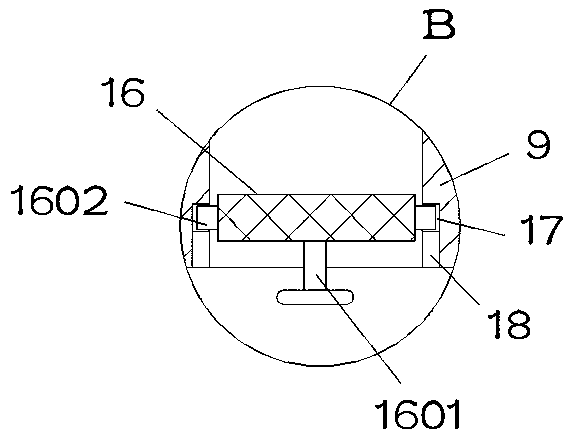

Wall perforating device with dust collection function

InactiveCN110154247AAchieve protectionRealize adsorption recoveryWorking accessoriesStone-like material working toolsSprayerEngineering

The invention relates to the technical field of building devices, in particular to a wall perforating device with a dust collection function. The wall perforating device comprises a workbench, a lifting mechanism, a perforating machine and a stabilizing mechanism. The lifting mechanism is fixedly mounted on the workbench. A mounting plate is fixedly arranged at the output end of the lifting mechanism. Connecting plates are further fixedly arranged on the two sides of the mounting plate correspondingly. The stabilizing mechanism is fixedly mounted on the connecting plates. A mounting box is fixedly arranged on the mounting plate. An opening is formed in the left side of the mounting box. A hood is fixedly arranged on the opening. The perforating machine is fixedly mounted in the mounting box. A dust collection box is further arranged on the workbench. A suction blower is mounted on the side portion of the dust collection box. A dust suction hose communicating with the hood is arranged on the dust collection box. The side portion of the dust collection box is further provided with a water conveying pipeline stretching into the dust collection box. A universal sprayer is mounted at the end, located in the dust collection box, of the water conveying pipeline. The wall perforating device can be used for suppressing dust during perforating, the environment is purified, and the humanhealth is protected.

Owner:JIANGSU NANTONG NO 2 CONSTR ENG GRP

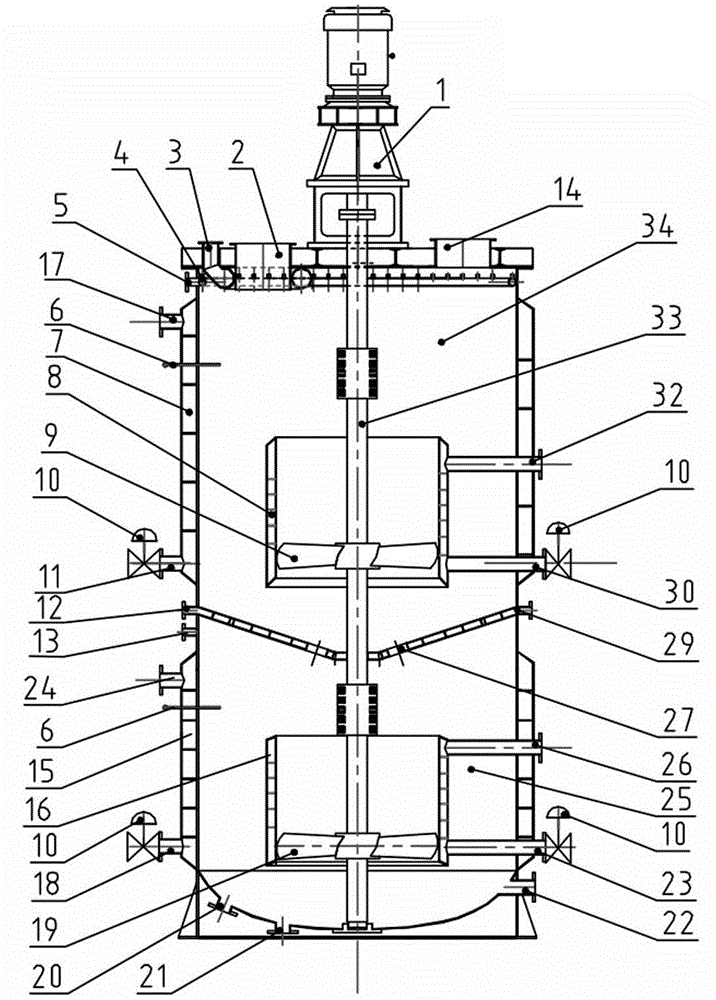

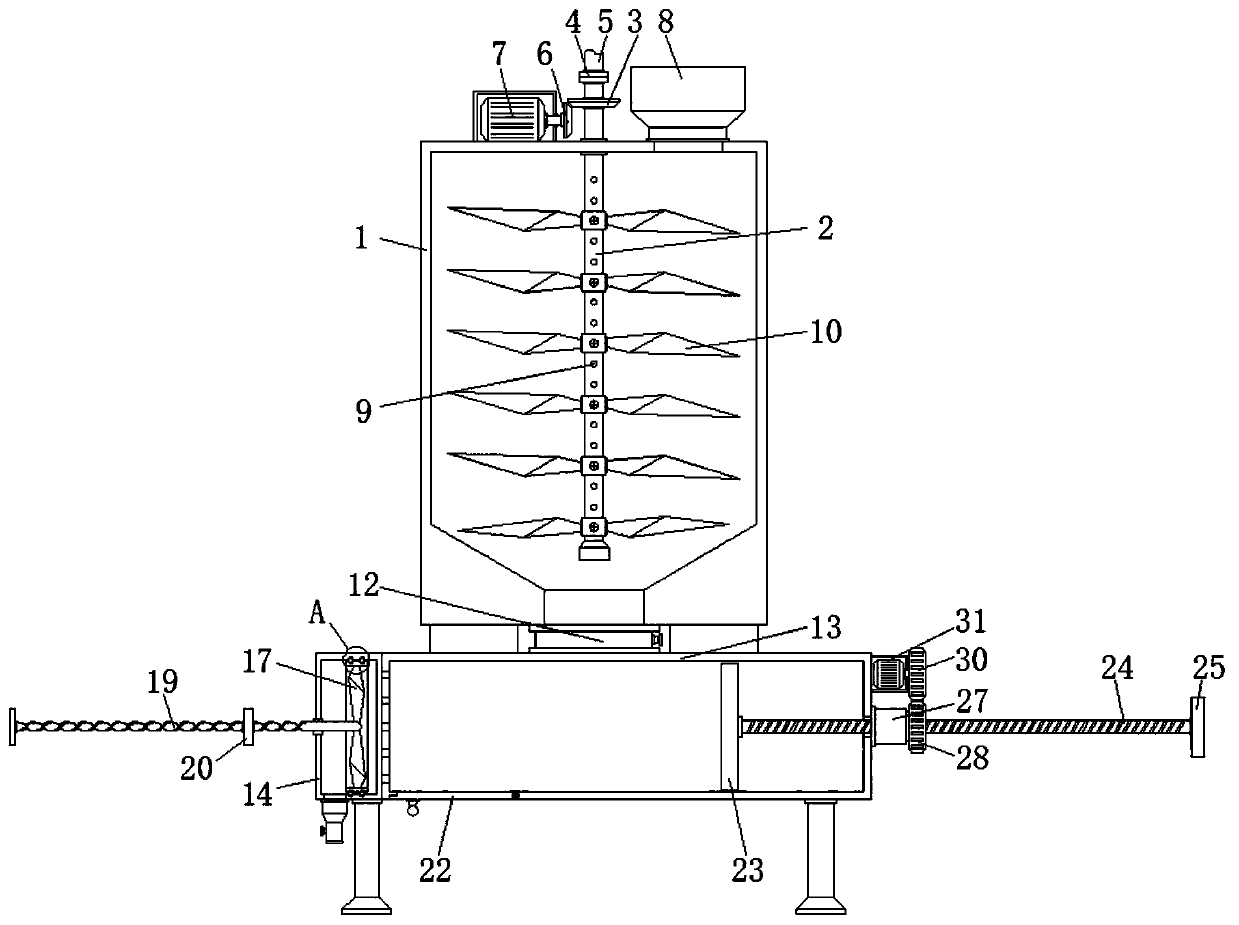

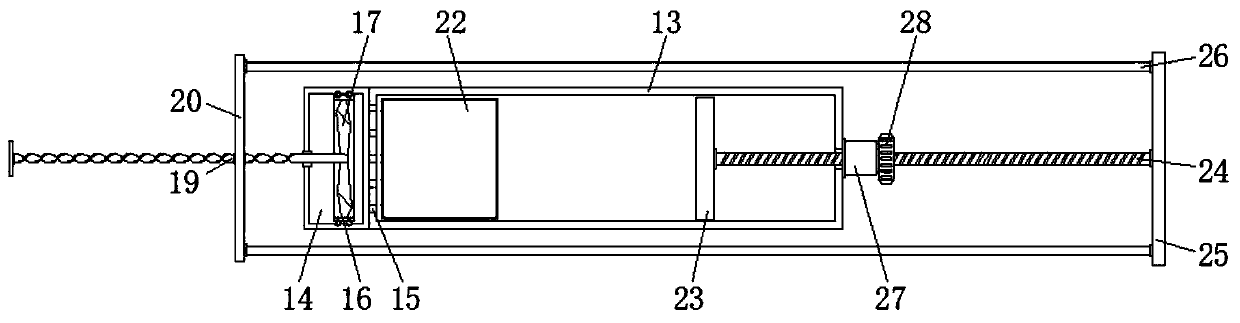

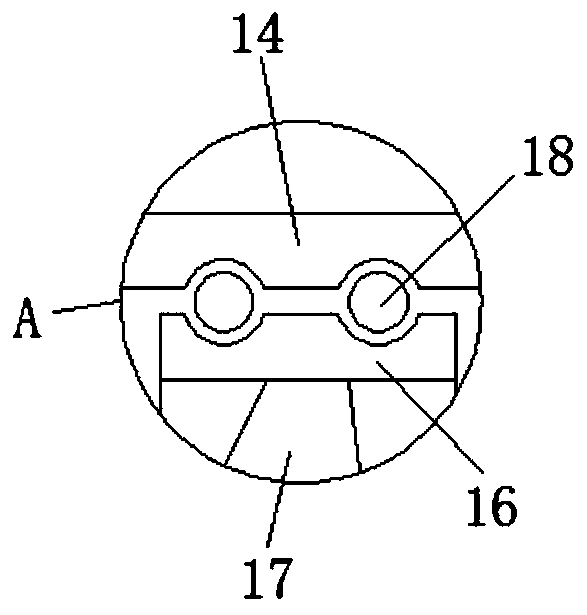

Novel high efficiency reactor

ActiveCN104941554AUniform temperatureQuality improvementMixer accessoriesChemical/physical/physico-chemical stationary reactorsAutomatic controlNuclear engineering

The invention discloses a novel high efficiency reactor, which comprises a reactor body, the reactor body comprises an upper reaction zone and a bottom reaction zone, an intermediate heat exchange separator plate is arranged between the upper reaction zone and the lower reaction zone, a mixer shaft passes through the reactor body, the mixer shaft is connected to a speed reducer arranged on the upper part of the reactor body, an upper heat exchange jacket and an upper inner heat exchange guide shell are respectively arranged on the upper reaction zone; a lower heat exchange jacket and an lower inner heat exchange guide shell are respectively arranged on the lower reaction zone; a temperature sensor arranged on the reactor body and an automatic regulating valve are respectively connected to an automatic control device, and automatic accurate control of the reaction of the materials in the reactor body can be realized. Compared with prior art, a structure of the high efficiency reactor is simple, accurate automatic control can be realized, continuous high efficiency operation of the high efficiency reactor can be carried out, material reaction effect is ensured, effect of the large-scale reactor is more protruding, and a novel development of the novel reactor can be provided.

Owner:吴巴特尔 +2

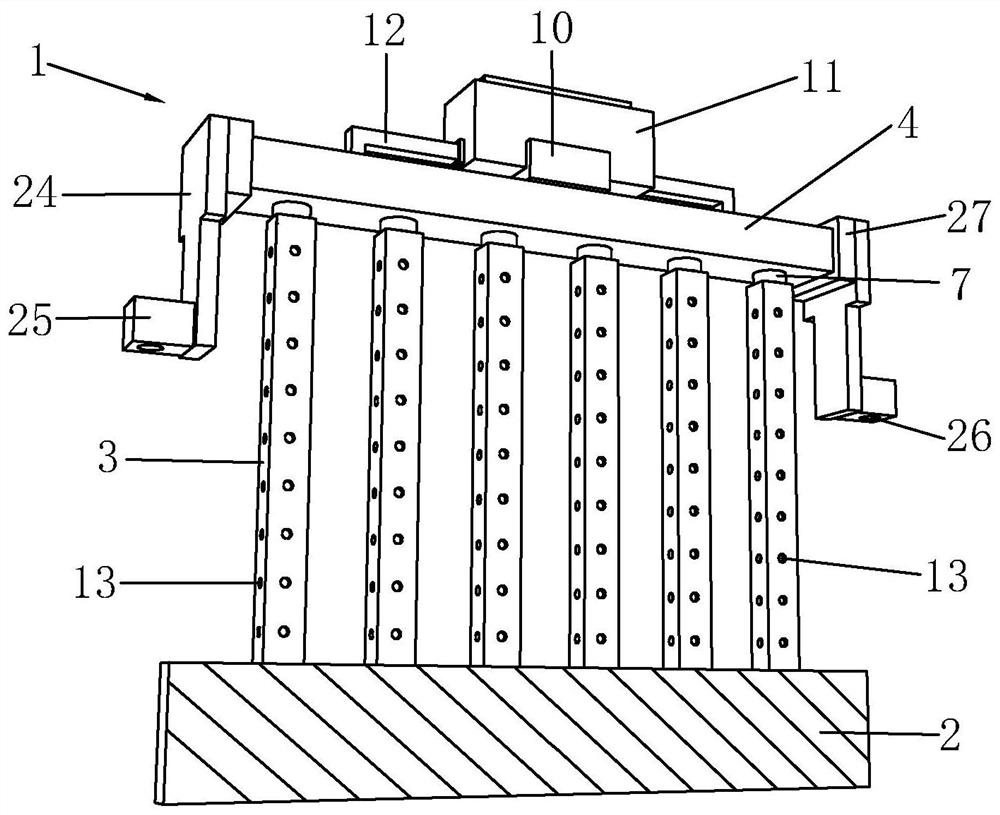

Punching equipment for bridge construction site

InactiveCN111425135AEasy to installEasy to disassembleEarth drilling toolsDrilling rodsPunchingArchitectural engineering

The invention belongs to the technical field of bridge construction, and particularly relates to punching equipment for a bridge construction site. The punching equipment is put forward to solve the problems that existing punching equipment for bridge construction is inconvenient to use, the time and labor are wasted, the working efficiency is low, a drill rod cannot be cooled, the service life ofthe drill rod is affected, and job schedule is influenced. The punching equipment comprises a top plate, wherein four supporting legs are fixedly installed at the bottom of the top plate, universal wheels are arranged at the bottoms of the four supporting legs, a perpendicular plate is vertically and slidably installed on the top plate, a motor installing plate is fixedly installed at one side ofthe perpendicular plate, a double-end motor is arranged on the motor installing plate, a lifting screw rod is fixedly installed on an output shaft of the double-end motor, a lifting screw hole is formed in the top plate, and the lifting screw rod is in threaded connection with the lifting screw hole. The punching equipment is convenient to operate, manual punching is avoided, the labor is saved,and the working efficiency is improved; and meanwhile, the punching equipment has the effects of collecting dust and cooling the drill rod, so that the situation that the temperature rise of the drillrod influences the service life of the drill rod is avoided.

Owner:罗峰

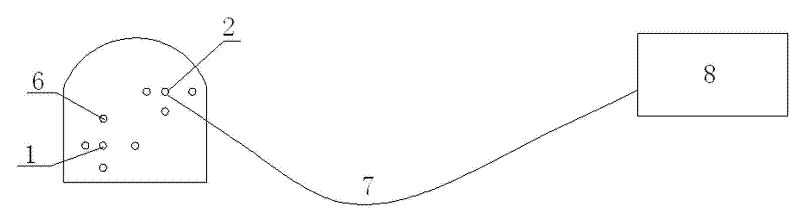

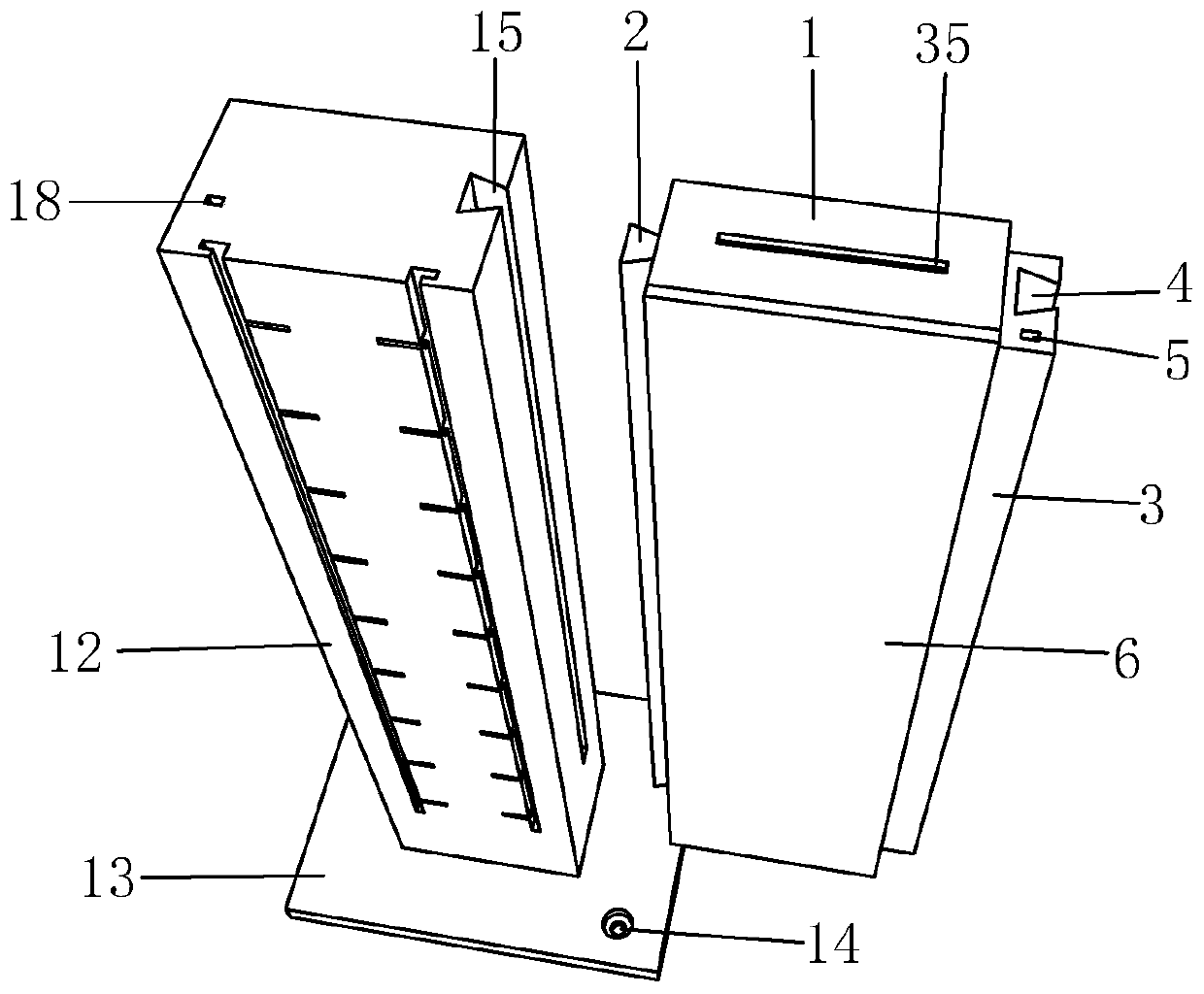

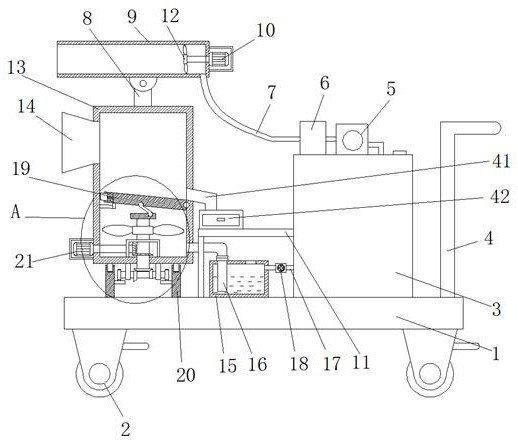

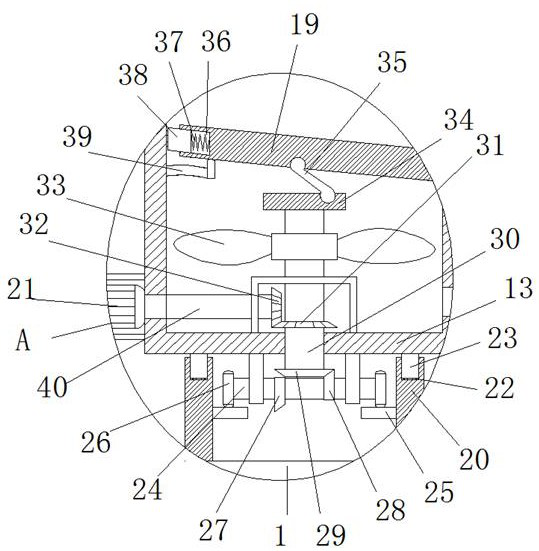

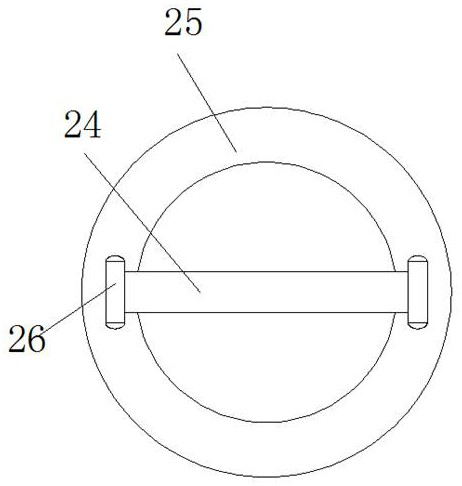

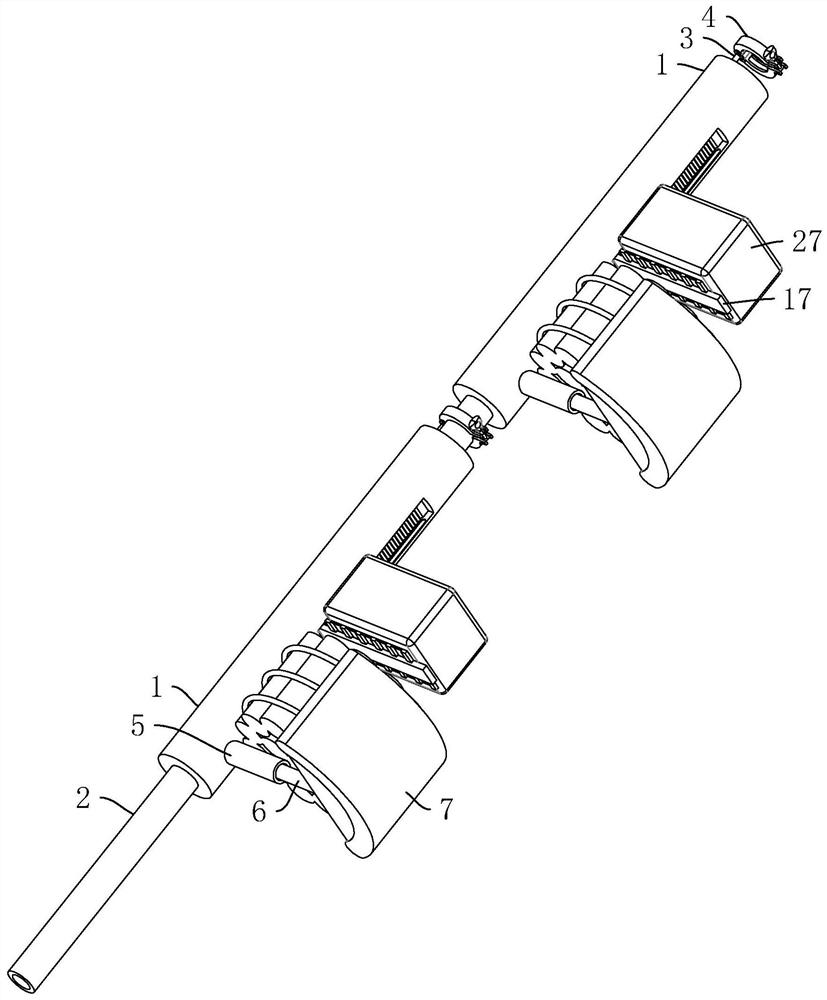

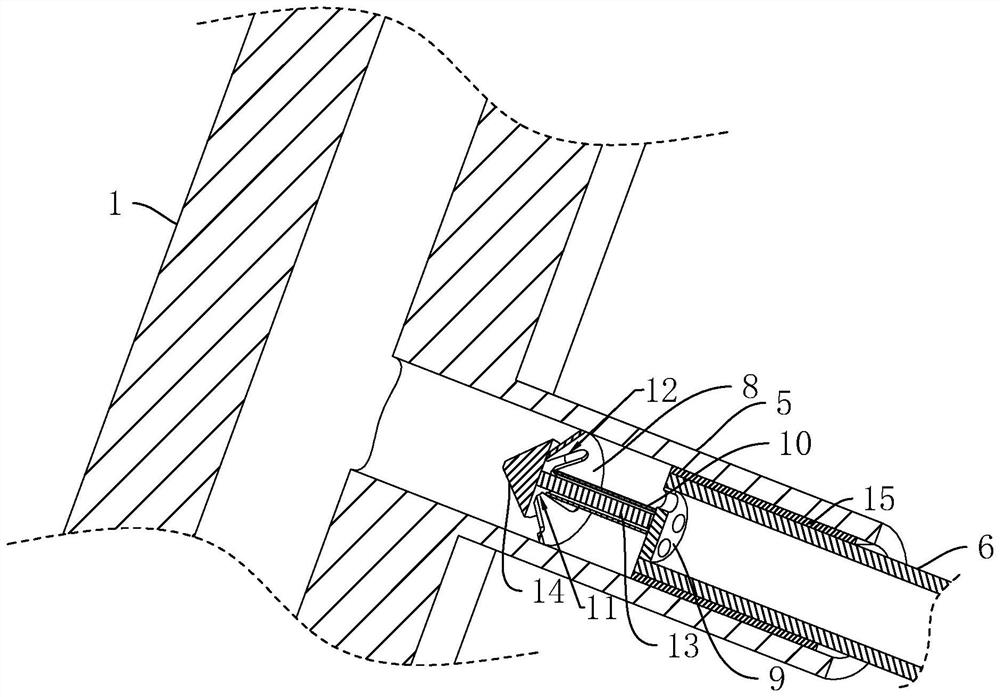

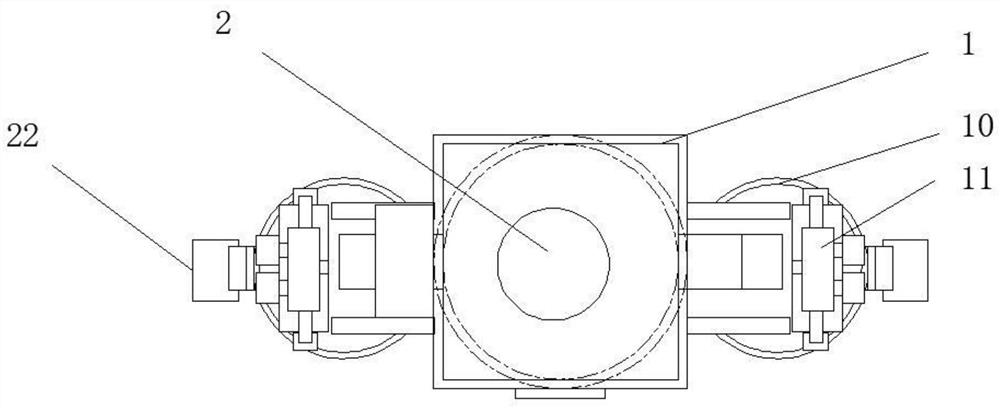

Electric addition-type filled pore foaming device and foaming method for mine dust removal

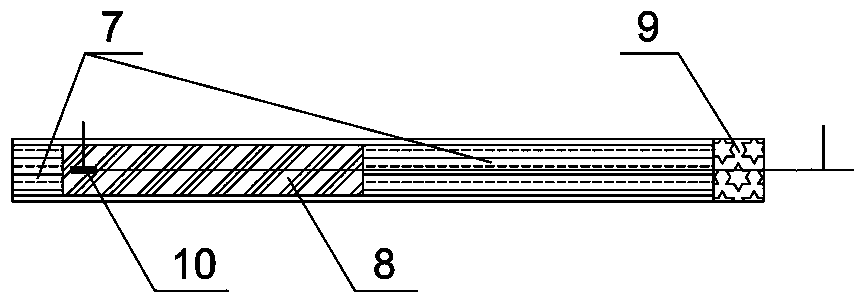

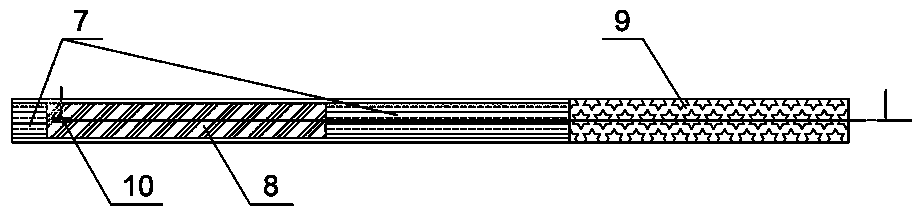

PendingCN108386221AIncrease productionPlay a role in dust suppressionTransportation and packagingMixing methodsGlass ballEngineering

The invention discloses an electric addition-type filled pore foaming device and a foaming method for mine dust removal. A bell-mouthed liquid outlet pipe is arranged at the other end of a first barrel; the bell-mouthed liquid outlet pipe is communicated with a second barrel; the middle part of the second barrel is uniformly filled with a plurality of glass balls to form a glass ball filled pore foaming section; a foam outlet is formed in the tail end of the second barrel; the second barrel in front of the glass ball filled pore foaming section is a primary foaming section; the bell-mouthed liquid outlet pipe is arranged inside the primary foaming section; a plurality of airflow inlets are formed in positions, corresponding to the primary foaming section, of the second barrel. A foam solution after primary foaming is secondarily foamed through the glass ball filled pore foaming section under the action of an airflow to generate a large amount of foam, and the foam is discharged througha foam discharging pipe and is finally sprayed out from a foam nozzle to cover a dust source so as to achieve a dust reducing effect; under the same condition, the yield of the foam is greatly increased, which is 10% higher than that of the conventional foam generating device.

Owner:BINZHOU UNIV

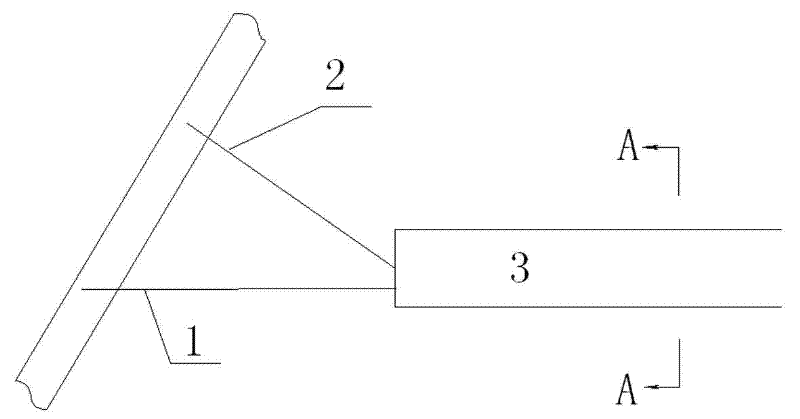

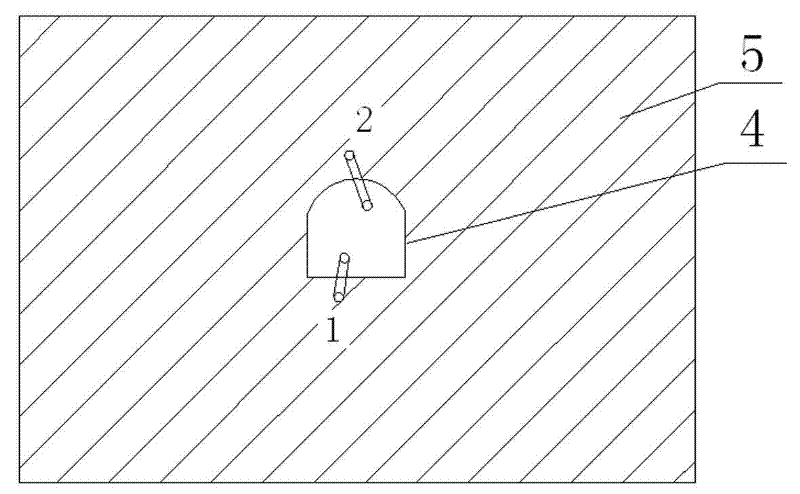

Blasting construction method suitable for hydraulic pressure smooth surface of granitic geological III-grade surrounding rock

The invention discloses a blasting construction method suitable for a hydraulic pressure smooth surface of a granitic geological III-grade surrounding rock. The blasting construction method comprisesthe following steps: (1) excavating each shot hole including a center breaking-in hole, an inclined breaking-in hole, an auxiliary hole, a coping hole, a bottom plate hole and a peripheral hole; (2) blowing out residues in each blast hole through high-pressure air; (3) mounting an explosive roll clamped between water bags into each shot hole according to blasting design requirements, adopting a stemming material for sealing an opening end of the shot hole, and connecting the explosive roll to an electronic detonator initiation system; (4) checking safety of the electronic detonator initiationsystem, and detonating according to a sequence of blasting the inclined breaking-in hole, the center breaking-in hole, the auxiliary hole, the coping hole, the bottom plate hole and the peripheral hole; and (5) after no squib is checked, performing deslagging operation to accomplish construction. The blasting construction method uses hydraulic pressure blasting to improve drilling depth of the surrounding rock, saves usage amount of explosives, saves conventional blasting ventilation time, controls back break, improves construction efficiency, and greatly saves comprehensive cost by 8.9% in comparison with that in the prior art.

Owner:CHINA RAILWAY SEVENTH GRP CO LTD +1

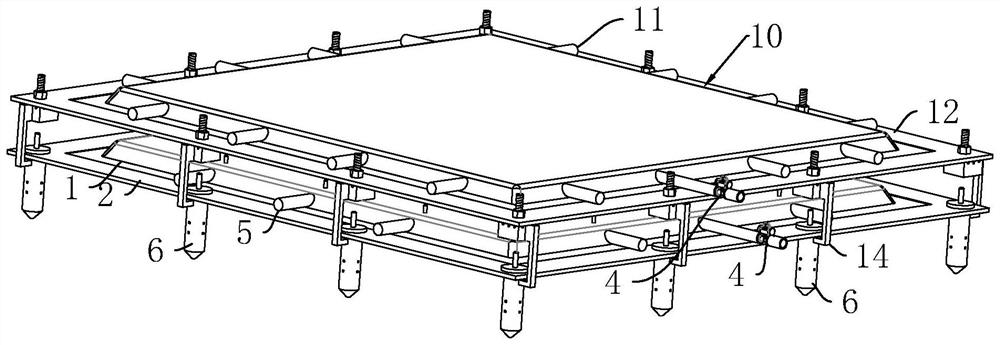

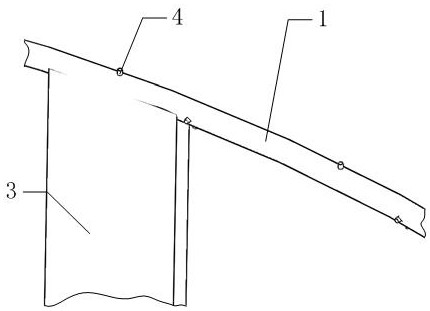

Construction method of drip irrigation type ecological fence

ActiveCN111101746AStable structureVariable lengthSelf-acting watering devicesFencingEnvironmental resource managementDrip irrigation

The invention discloses a construction method of a drip irrigation type ecological fence. The construction method comprises the following steps that (a) baffles are assembled; (b) a warning board is assembled; (c) assembling is carried out to form a wall; (d) supporting piles are placed in place; (e) the supporting piles are fixed; (f) a pipeline is mounted; and (g) a planting basket is installed.The construction method is simple to operate, easy to construct, low in difficulty, high in construction efficiency, labor-saving, convenient and fast, high in construction quality, stable in ecological fence structure, variable in length, high in adaptability, large in shielding range, good in effect, reusable after being disassembled, high in resource utilization rate and cost-saving; and a three-dimensional greening mode is adopted, attractiveness can be improved, raised dust can be adsorbed, and the dust reduction effect is achieved.

Owner:浙江恒山建设有限公司

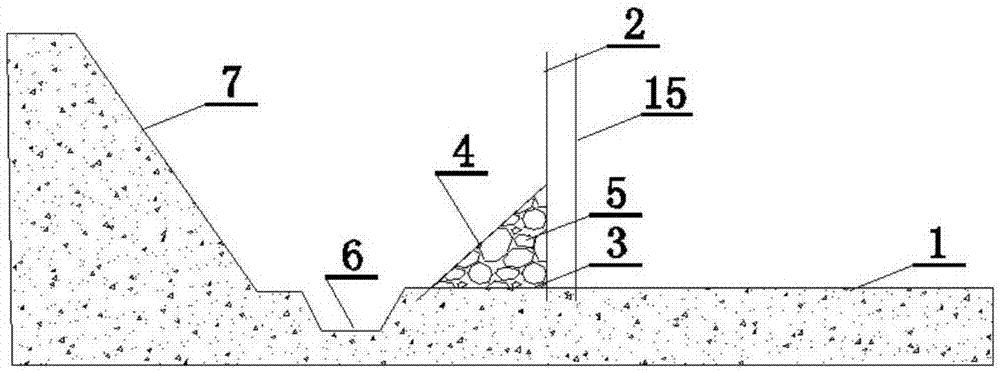

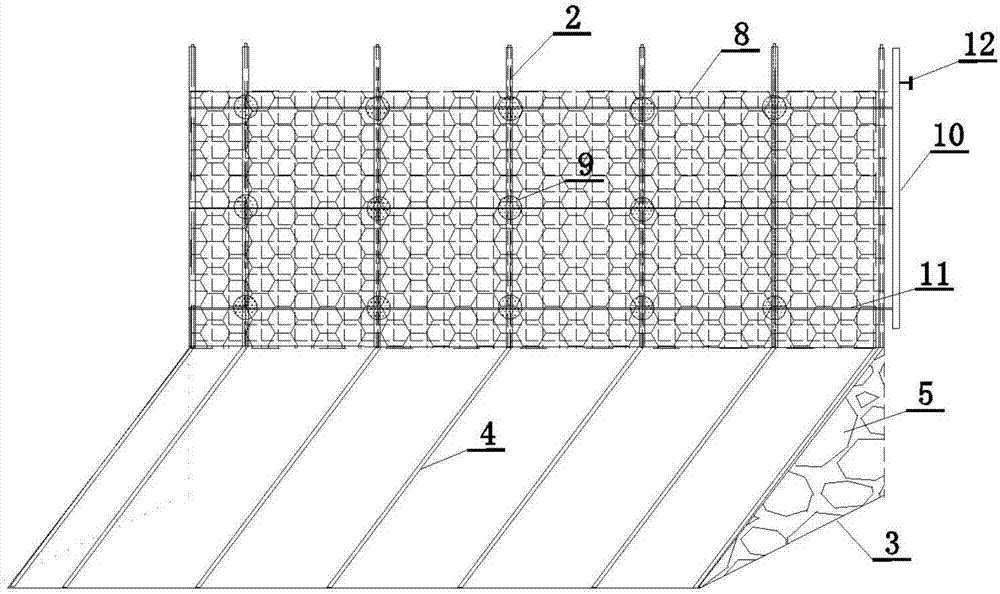

High and steep slope blasting comprehensive protection device and method

ActiveCN107421405AAvoid harmEasy to cleanClimate change adaptationBlastingSocial benefitsEconomic benefits

The invention relates to the technical field of engineering blasting, in particular to a high and steep slope blasting comprehensive protection device and method. The device comprises a first protection device body, a second protection device body and a spraying dust preventing device; the first protection device body comprises a first fixed supporting frame, a steel channel bottom frame and an inclined supporting frame; a triangular space is formed among the first fixed supporting frame, the steel channel bottom frame and the inclined supporting frame; the triangular space is filled with a protective bag; the second protection device body comprises a second fixed supporting frame and a protective net; and the spraying dust preventing device comprises a spraying pipe and a spraying head. The high and steep slope blasting comprehensive protection device is simple in structure, easy to operate, low in cost and convenient to construct, guarantees that blasting of a high and steep slope is fast and effectively performed, economic construction is accelerated, and an important role is achieved for creating good economic benefits, environmental benefits and social benefits.

Owner:中铁十九局集团矿业投资有限公司

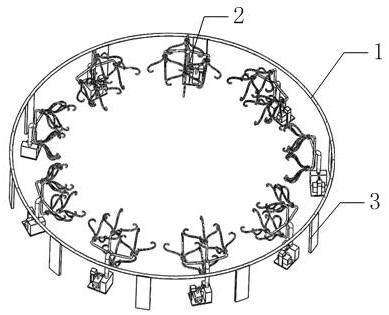

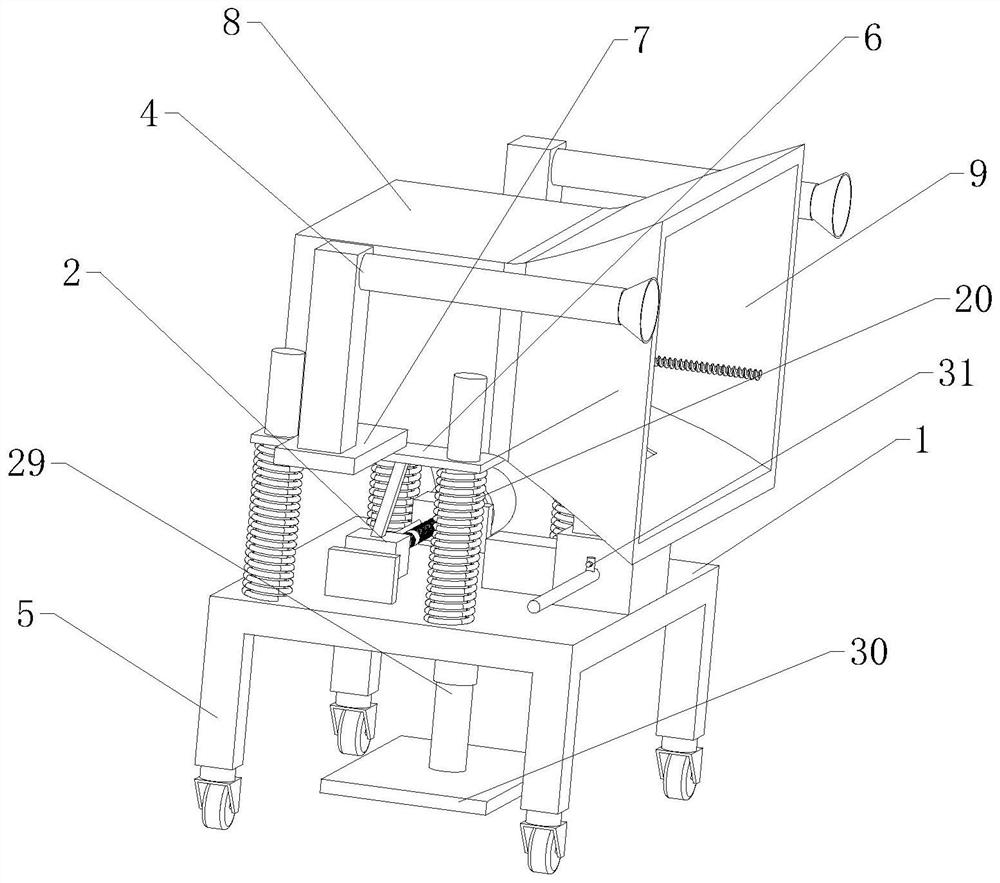

Blasting dust purification treatment equipment

InactiveCN111841226AExpand the spraying rangePlay a role in dust suppressionCombination devicesDirt cleaningArchitectural engineeringLiquid tank

The invention belongs to the technical field of dust treatment and especially relates to blasting dust purification treatment equipment. The invention aims to overcome the problem that an existing engineering blasting dust degradation treatment device is limited in effective dust absorption range and is thus low in use reliability. The blasting dust purification treatment equipment comprises a bottom plate, wherein four universal wheels are arranged at the bottom of the bottom plate; brake pads are arranged on the four universal wheels; an annular block, a liquid tank, a water tank and two push handles are fixedly connected to the top of the bottom plate; a rectangular box is rotationally installed at the top of the annular block; one side of the rectangular box communicates with a dust suction port; the dust suction port is of a horn structure; a supporting rod is fixedly installed at the top of the rectangular box; an atomizing cylinder is rotationally installed at the top of the supporting rod; the atomizing cylinder is connected with an air blowing structure; the top of the water tank communicates with a water pump; and a water outlet of the water pump communicates with an atomizer. The blasting dust purification treatment equipment is simple in structure and convenient to operate, a dust collection and dust suppression range can be expanded, and use performance is improved.

Owner:惠安县崇武镇栓锋广告设计中心

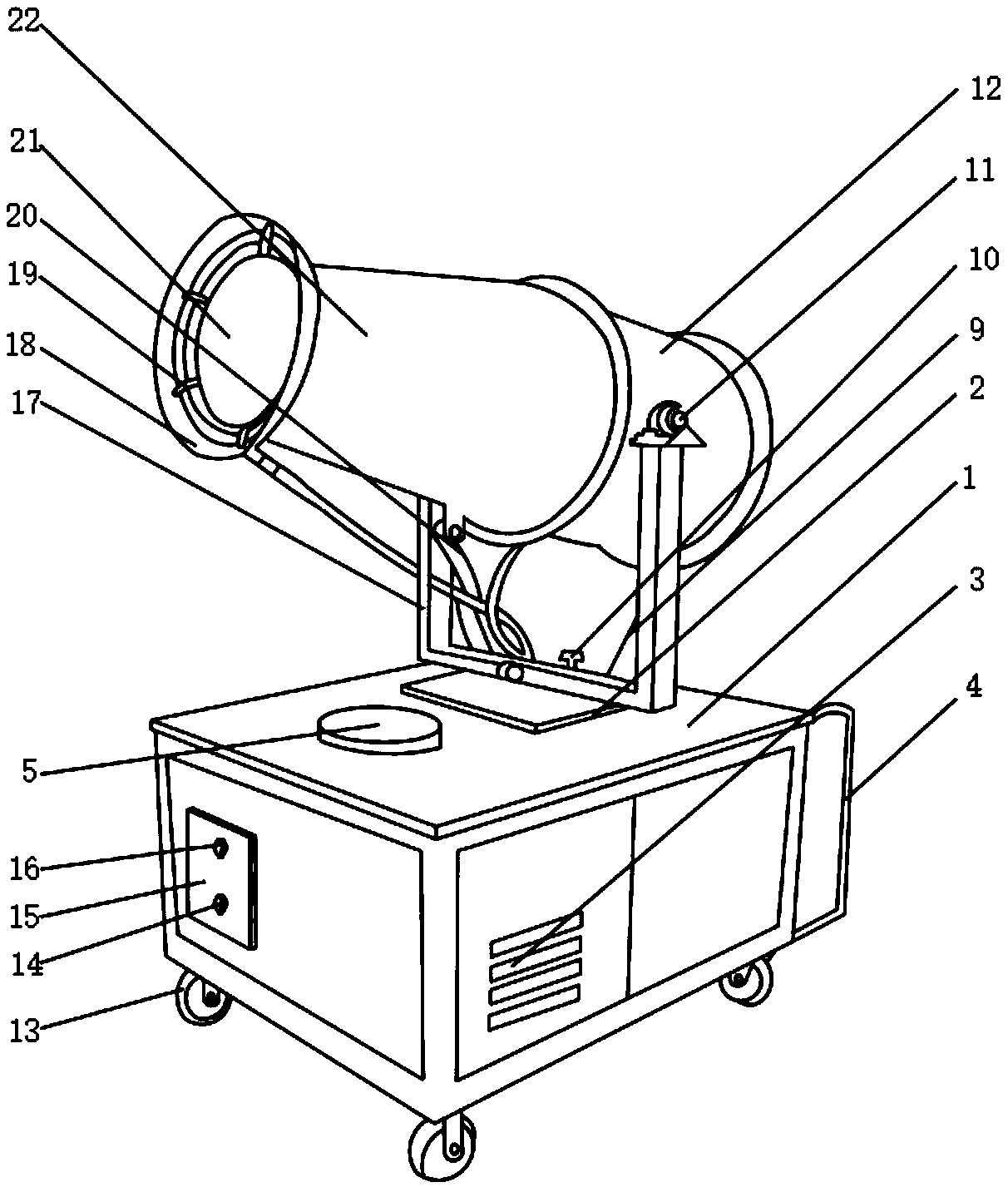

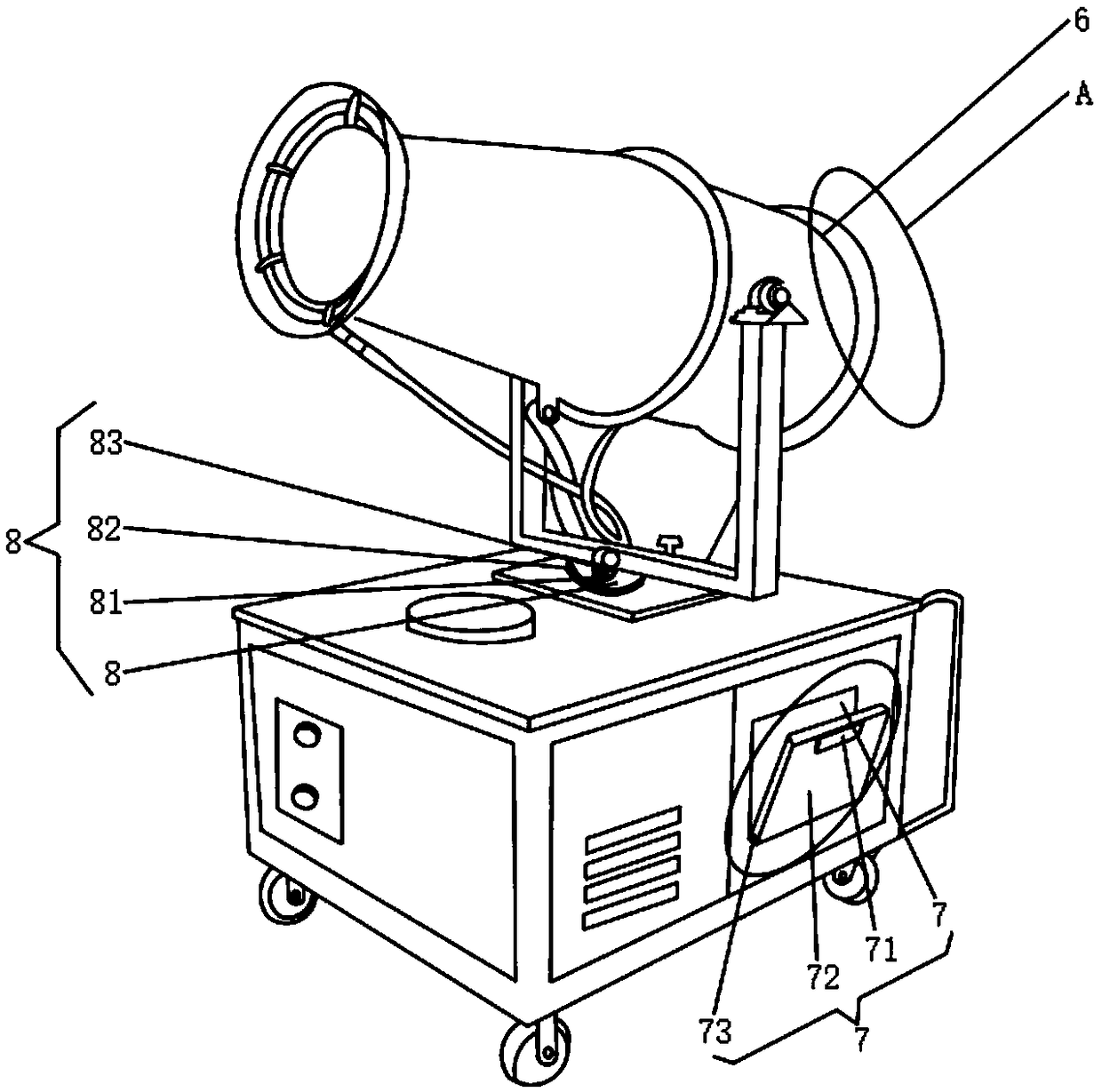

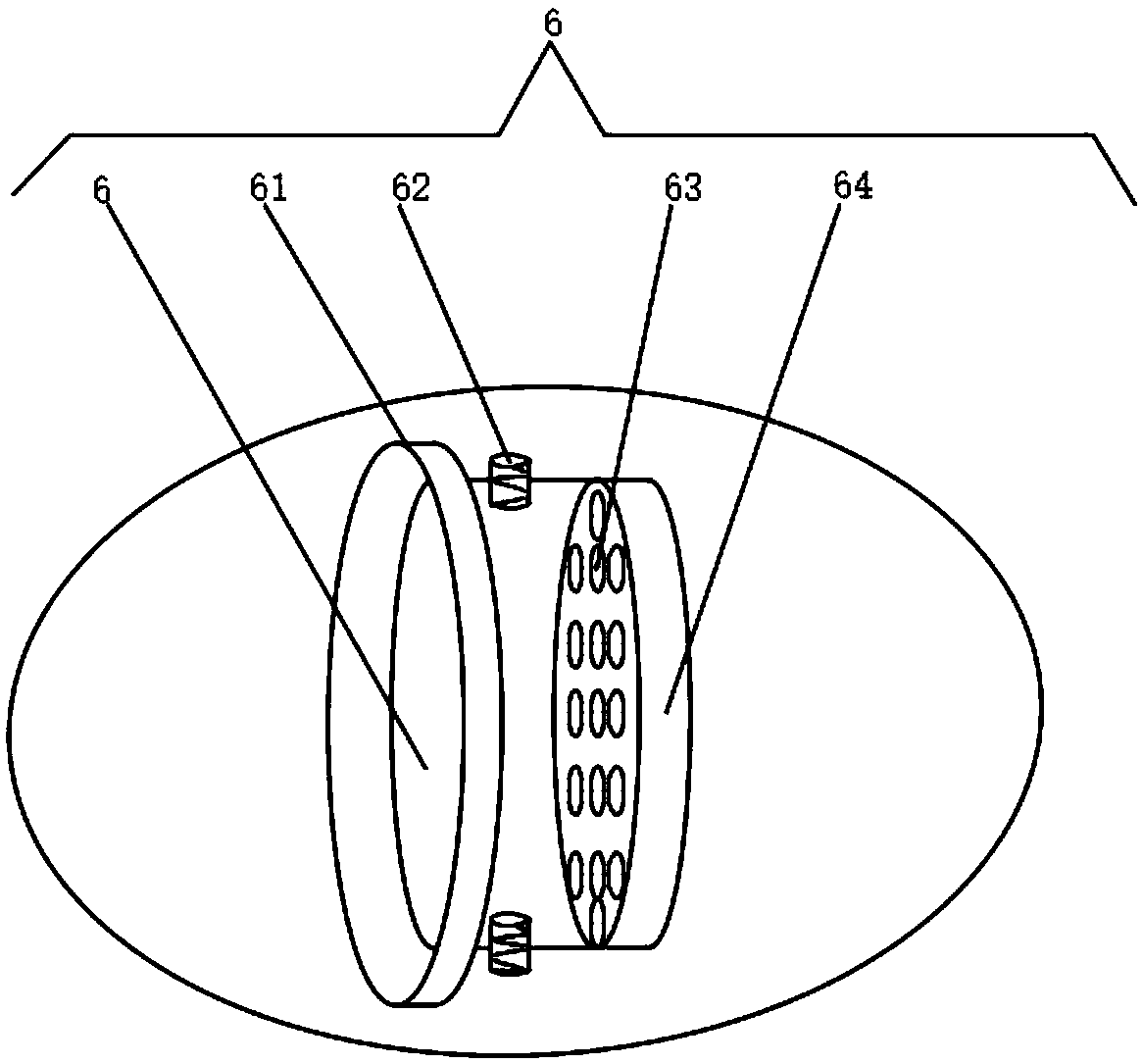

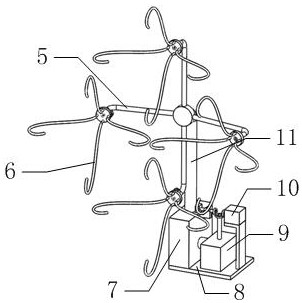

Highly-efficient dust-removing fog gun machine

InactiveCN108926937AAll-round sprayGood effect of dust suppressionUsing liquid separation agentForeign matterEngineering

The invention discloses a highly-efficient dust-removing fog gun machine. The highly-efficient dust-removing fog gun machine comprises a fog gun machine body, wherein the outer surface of one side ofthe upper end of the fog gun machine body is fixedly provided with a supporting panel; the outer surface of the upper end of the supporting panel is fixedly provided with a rotating disk; the outer surface of the upper end of the rotating disk is fixedly provided with a supporting column; and the outer surface of the upper end of the supporting panel is fixedly provided with a supporting frame. According to the invention, through the rotating disk, all-round spraying can be performed, so the effect of dust removal achieves the most ideal effect; through a maintenance toolbox, when the highly-efficient dust-removing fog gun machine encounters an outage or an emergency situation needing maintenance in the process of working, maintenance tools placed in the maintenance toolbox can be timely taken out for maintenance, so the working efficiency of the highly-efficient dust-removing fog gun machine is greatly improved; and through a foreign matter isolation cover, sticky foreign matters canbe directly adsorbed onto the foreign matter isolation cover, so the highly-efficient dust-removing fog gun machine can be conveniently disassembled and cleaned for cyclic use and is favorable for people to use.

Owner:FOSHAN QIANGWEI NEW ENERGY TECH CO LTD

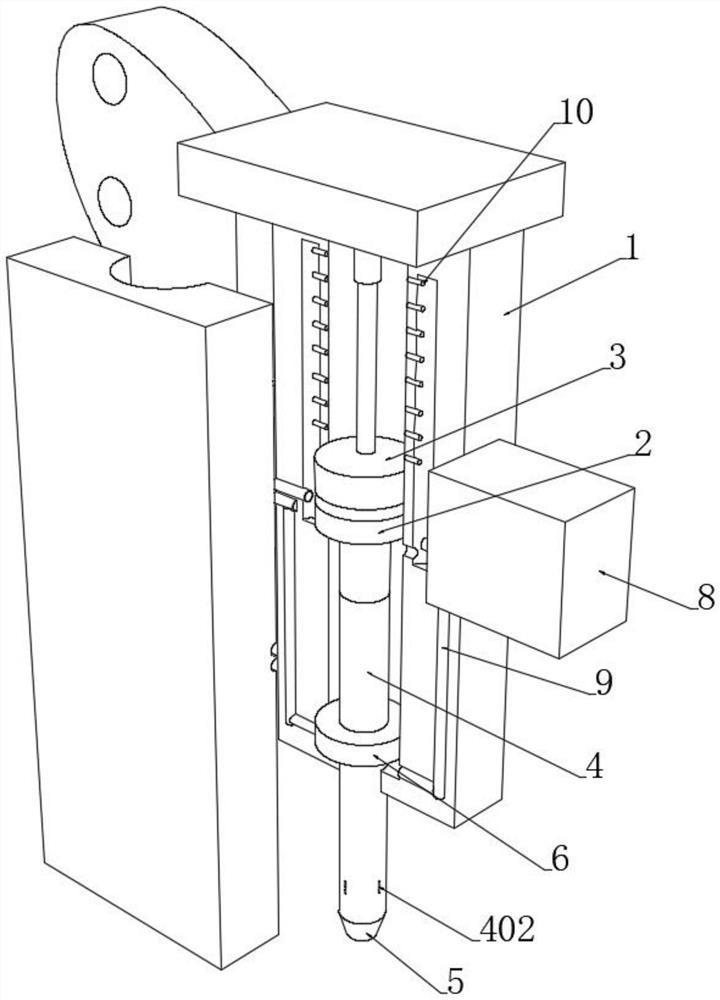

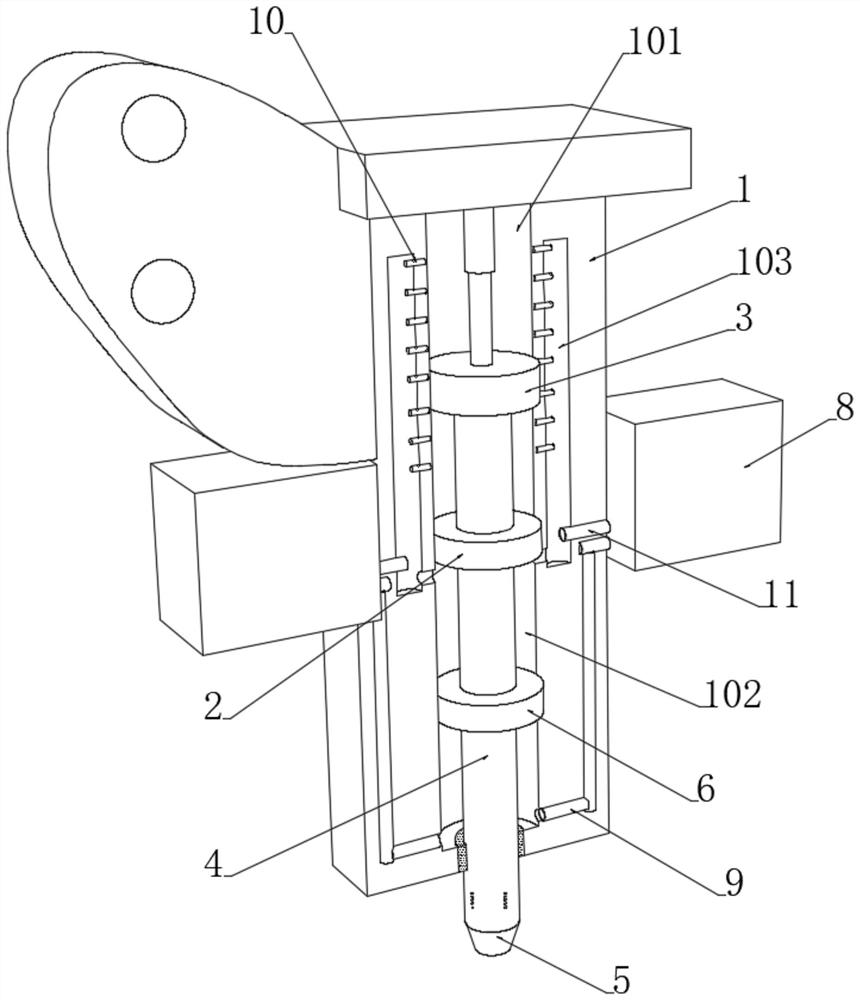

Hydraulic two-way recooling type heat dissipation type hydraulic hammer

InactiveCN113294400APlay a role in dust suppressionImprove the effect of dust suppressionReciprocating drilling machinesSoil-shifting machines/dredgersCooling effectEngineering

The invention discloses a hydraulic two-way recooling type heat dissipation type hydraulic hammer, and belongs to the technical field of heat dissipation treatment of hydraulic hammers. Cooling liquid is supplied to the upper end part and the lower end part of a liquid storage cavity through a water cooling box; and by utilizing the principle that a piston drives a drill rod and a movable sleeve to move up and down in a reciprocating mode, the cooling liquid supplied to the lower end part of the liquid storage cavity is extruded when the movable sleeve moves downwards, so that the cooling liquid is guided into a drainage cavity through a perfusion hole and flows through a connecting tenon body and overflows through a spraying hole, and therefore, on the one hand, a drill rod and a drill hammer head are cooled, and on the other hand, the sprayed cooling liquid plays a dust falling role; and when the movable sleeve moves upwards, on the one hand, the cooling liquid is supplied to the lower end part of the liquid storage cavity through a negative pressure, and on the other hand, the cooling liquid at the upper end part of the liquid storage cavity is pressed into a recooling cavity and wets multiple refrigeration bag rods, the cooling liquid and the recooling cavity cooperate with each other so that the cooling effect on the hydraulic cavity can be improved; after the movable sleeve retreats, the cooling liquid in the recooling cavity synchronously retreats; circulation is conducted in this way; and therefore, two-way water cooling is achieved through hydraulic reciprocating motion.

Owner:刘壮

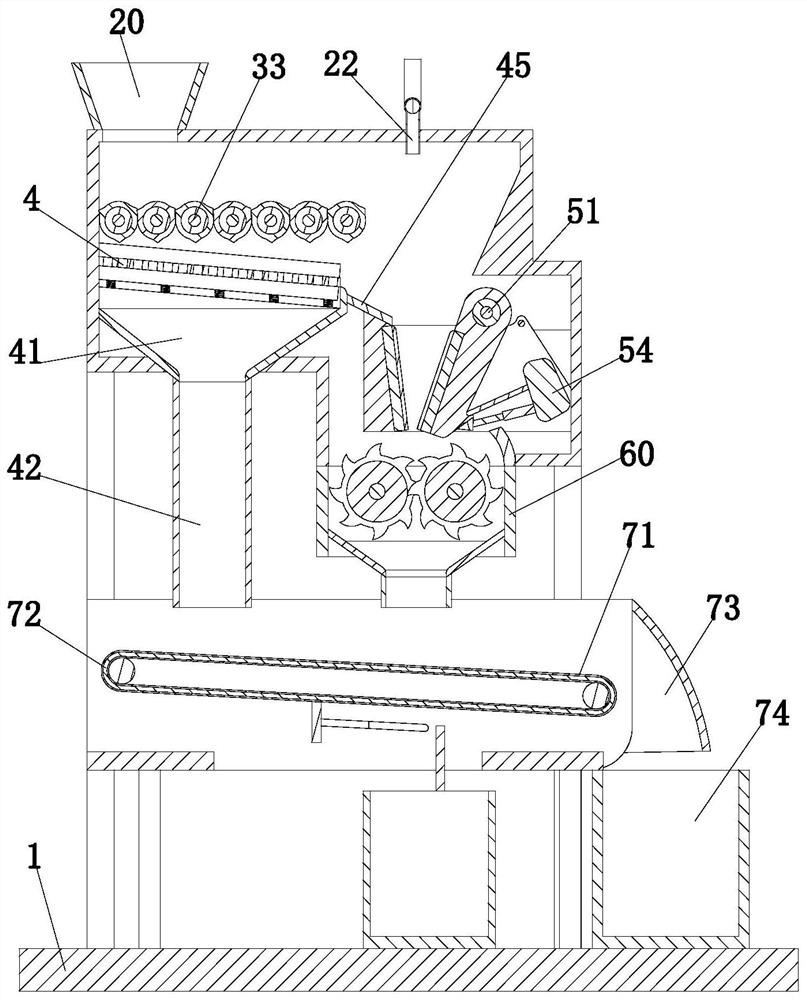

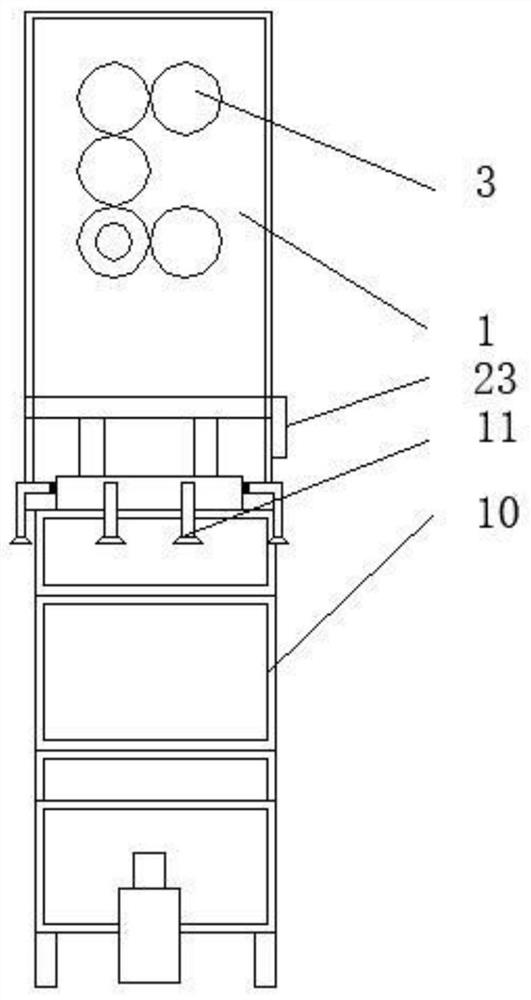

Waste sorting and screening device for waste disposal

InactiveCN112675948ANo need for manual secondary sortingImprove efficiencyCleaning using toolsMagnetic separationEnvironmental engineeringRefuse Disposals

The invention relates to the technical field of waste screening, in particular to a waste sorting and screening device for waste disposal. The device comprises a bottom plate, a sorting box, a feeding device, a screening device, a jaw crushing device, a smashing device and an adsorption device, wherein four support columns are arranged on the bottom plate, the classification box is arranged on the four support columns, inclined installation grooves are formed in the two inner walls of the classification box, a feeding port is formed in the sorting box, a water inlet pipe is arranged above the classification box, a plurality of nozzles are arranged on the water inlet pipe and all communicates with the interior of the sorting box, the feeding device is arranged in the sorting box, the screening device is arranged in the sorting box of the jaw crushing device below the feeding device, the smashing device is arranged below the jaw crushing device, and the adsorption device is arranged on the bottom plate. According to the waste sorting and screening device for waste disposal, through mutual cooperation operation of all the devices, construction waste can be automatically sorted and screened, manual secondary sorting is not needed, and sorting and screening effect and efficiency are improved.

Owner:王子腾

Edge ecological protective fence for building engineering construction and construction method thereof

InactiveCN113073899ANot easy to break awayPrevent disengagementUsing liquid separation agentFencingArchitectural engineeringBaluster

The invention discloses an edge ecological protective fence for building engineering construction and a construction method thereof. The protective fence comprises a fence body, wherein the fence body comprises a warning bottom plate, hollow handrails and a hollow top pipe, the hollow handrails are uniformly distributed between the warning bottom plate and the hollow top pipe, a water distribution box is arranged on the hollow top pipe, the water distribution box communicates with an inner cavity of the hollow top pipe through a liquid guide pipe, the hollow handrails communicate with the inner cavity of the hollow top pipe, fixed through holes are formed in the side surfaces of the hollow handrails, and a fixed pile is connected between every two adjacent fence bodies. The construction method comprises the following steps of (a) assembling the fence body; (b) arranging the fence body; (c) arranging a pipeline; and (d) arranging plants. The edge ecological protective fence has the advantages of the novel structure, reliability in connection and high applicability, water can be sprayed to fall dust, and the use functions are enriched. The construction method has the advantages of simple process, positioning assembly, low operation intensity, low difficulty, high construction efficiency, short period and convenience in control over the construction quality and can be flexibly adjusted in the construction process, and the construction cost is reduced.

Owner:深川控股集团有限公司

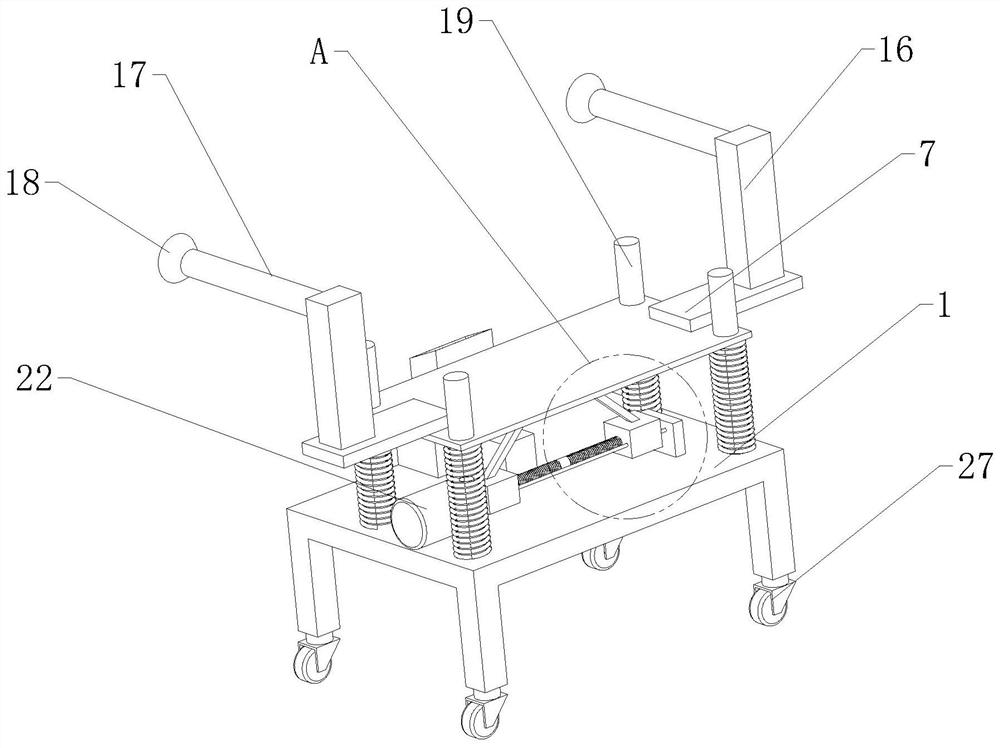

Steel pipe cutting device for rotating shaft production

InactiveCN111822773APlay a role in dust suppressionReduce workloadTube shearing machinesMaintainance and safety accessoriesWaste materialWorkbench

The invention discloses a steel pipe cutting device for rotating shaft production, and relates to the field of rotating shaft production. The steel pipe cutting device aims at solving the problems that an existing steel pipe cutting device cannot move a steel pipe with a large size in the cutting process, and the angle of a cutting blade cannot be adjusted. According to the scheme, the steel pipecutting device comprises a workbench, wherein supporting legs are fixedly installed at the four corners of the bottom end of the workbench; two sets of sliding block moving grooves are formed in the upper surface of the workbench; the two sets of sliding block moving grooves are symmetrically distributed relative to the center line of the length direction of the workbench; sliding blocks are installed in the sliding block moving grooves in a sliding mode; and a connecting rod is fixedly connected between the two sliding blocks positioned on the same side. The steel pipe cutting device is novelin structure, the stability of the steel pipe is guaranteed in the cutting process of the steel pipe, the workload of workers is reduced to a certain extent by utilizing a conveying belt, and dust pollution in the air is reduced to a certain extent by collecting waste in the cutting process.

Owner:惠州市福昌盛五金制品有限公司

Blasting dust-proof device

ActiveCN113899273APlay a role in dust suppressionGeneral water supply conservationBlastingArchitectural engineeringMechanical engineering

Owner:浙江秦核环境建设有限公司

Efficient dust removal environment-friendly equipment for green buildings

PendingCN113713537AReduce energy consumptionPlay a role in dust suppressionUsing liquid separation agentDirt cleaningAtomizer nozzleEnvironmental engineering

The invention belongs to the technical field of machine-made sand powder removal, and particularly relates to efficient dust removal environment-friendly equipment for green buildings, wherein the efficient dust removal environment-friendly equipment comprises a water pipe and a dust collection unit. Firstly, a part of dust enclosed in the middle is firstly absorbed by the dust collection unit; and after the residual dust which is not absorbed is blown out of the periphery of the dust collection unit, atomized gas is sprayed out through an atomizing nozzle in the water pipe, the residual dust is settled, and the dust collection effect can be greatly improved through double-layer absorption. A dust collection layer is not arranged in the middle of traditional equipment, dust collection is conducted through a traditional single dust collection pipe even if the dust collection layer is arranged, the dust collection range is small, and energy consumption is high. Compared with traditional dust collection equipment, the designed dust collection unit does not use a small-hole filter screen for blocking a channel to filter dust, so that the dust collection resistance is relatively small, a part of power of the dust is absorbed after the dust passes through a turbine, and the relative resistance borne by the dust in the subsequent moving process is relatively small.

Owner:三亚城投众辉新型建材有限公司

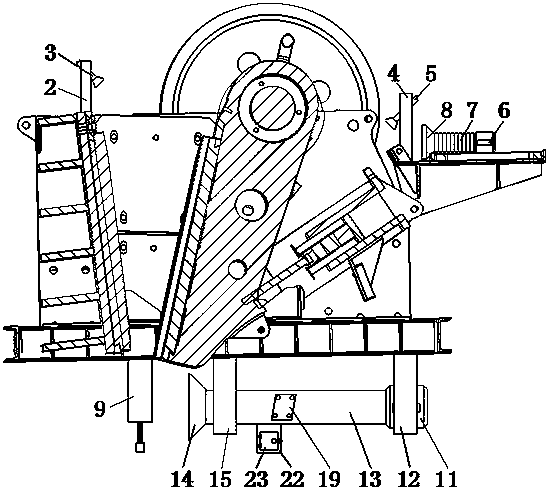

Jaw crusher with functions of spray dust suppression and dust collection dust removal

The invention discloses a jaw crusher with functions of spray dust suppression and dust collection dust removal, the jaw crusher comprises a jaw crusher body, the front side and the rear side of the left side of the top of the jaw crusher body both are fixedly connected with a first fixing plate. The jaw crusher body, a first nozzle, a second nozzle, a first dust collector, a telescopic tube, a first dust collection cover, an adjusting mechanism, a third nozzle, a second dust collector, a connecting tube, a second dust collection cover, a clamping block, a filter plate, an opening, a baffle plate, a fixing mechanism, a through opening, a storage box, a box door, a fixing column, a fixing block, a pull ring, a clamping rod and a clamping groove are matched for use, so that the problem the most existing jaw crushers do not have the function of inhibiting dust generation is solved. In the process of working, dust may inevitably be generated at a feeding port, a discharging port and a crushing cavity, and especially when in crushing of materials such as limestone, a large amount of dust will be generated, and not only pollutes the environment, but also damages the health of workers.

Owner:SHANDONG SHANKUANG MACHINERY

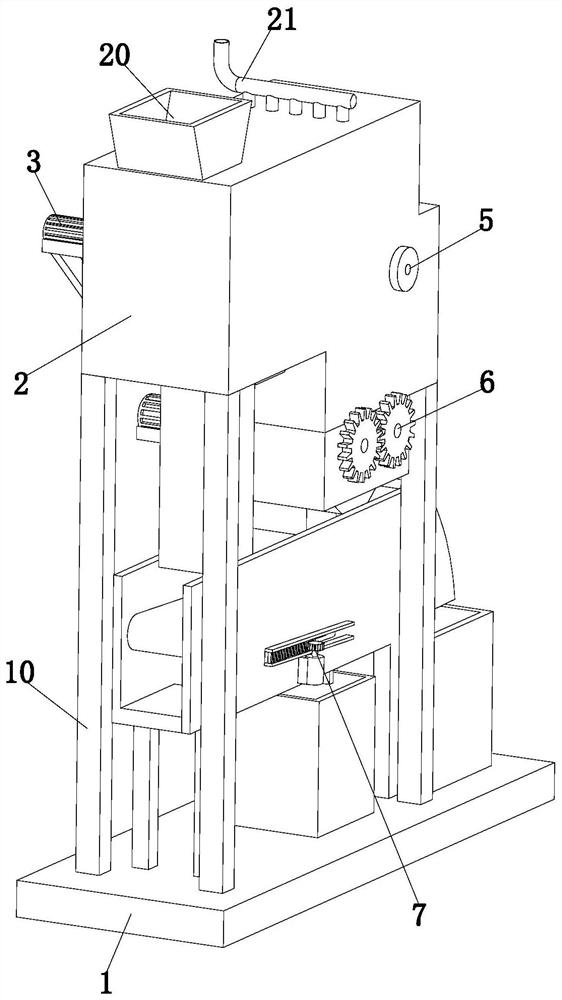

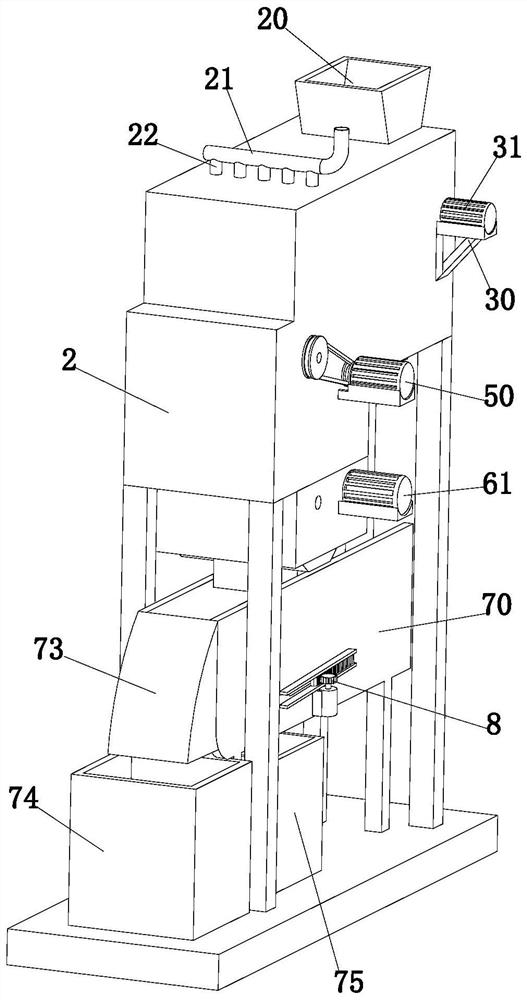

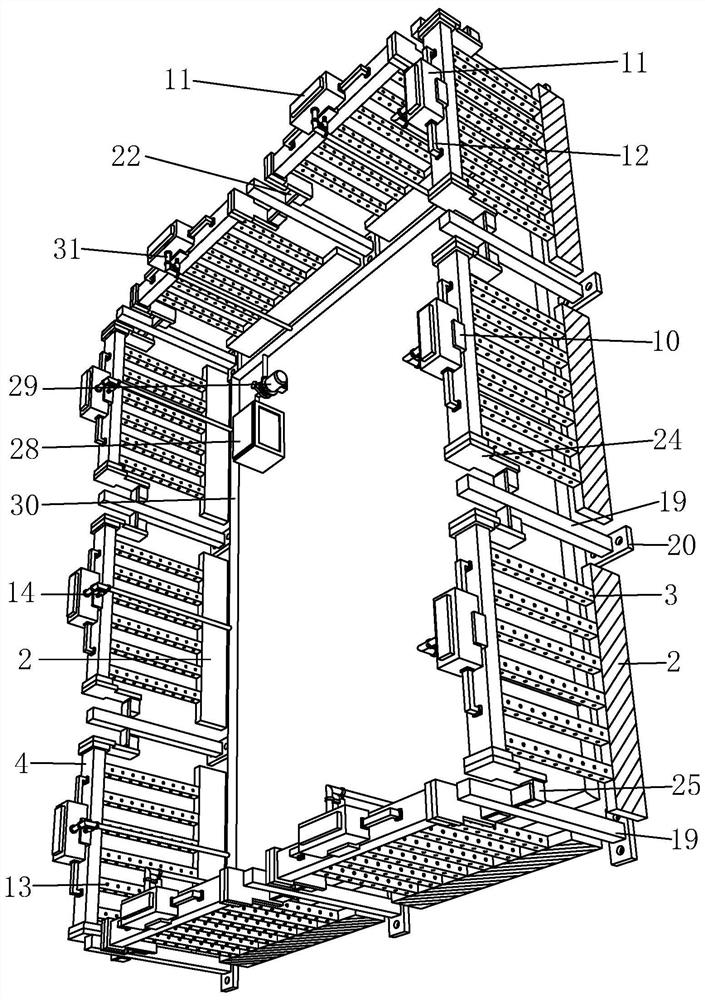

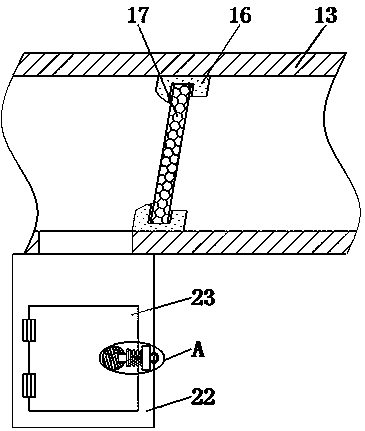

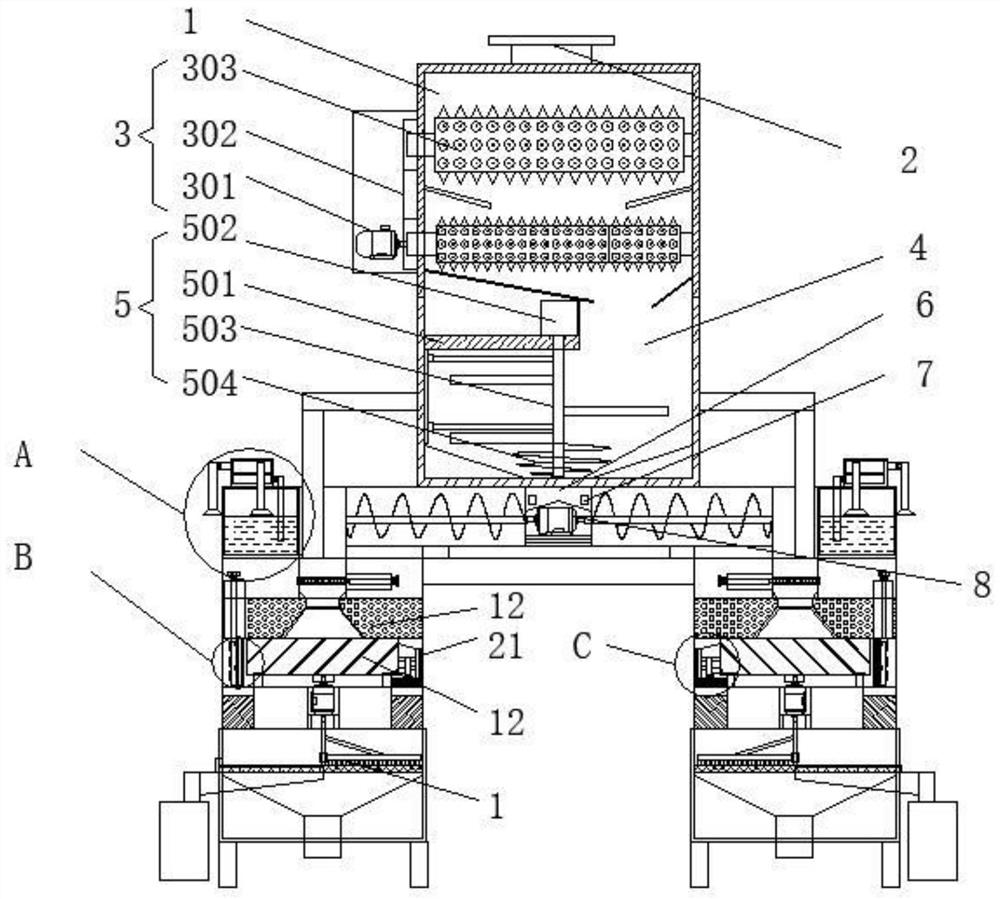

Straw briquetting equipment with dust settling function

ActiveCN111543190AWith dust suppression functionConvenient briquette processingBalingCuttersAgricultural engineeringEnvironmental geology

The invention discloses straw briquetting equipment with a dust settling function. The straw briquetting equipment comprises a smashing tank, a sealing bearing, a servo electric motor and a servo motor, wherein a dust settling vertical shaft is arranged in the smashing tank, a first bevel gear and the sealing bearing are mounted at the upper end of the dust settling vertical shaft respectively, the first bevel gear and the sealing bearing are both located above the smashing tank, the dust settling vertical shaft and an exhaust column are mutually connected through the sealing bearing, a drivegear is connected with the outer side of an adjusting gear, the servo motor is mounted on the drive gear, and the servo motor is fixedly mounted at the right end of an extruded square pipe. Accordingto the straw briquetting equipment with the dust settling function, the straw is subjected to pre-smashing treatment by the smashing tank, the dust settling vertical shaft and smashing blades, so thatsubsequent briquetting processing is convenient, and when the straw is subjected to pre-smashing treatment by the dust settling vertical shaft and the smashing blades, the exhaust column can suck andabsorb raising dust in the smashing tank through the hollow dust settling vertical shaft and through holes, and the dust settling effect is realized.

Owner:海阔农业科技股份有限公司

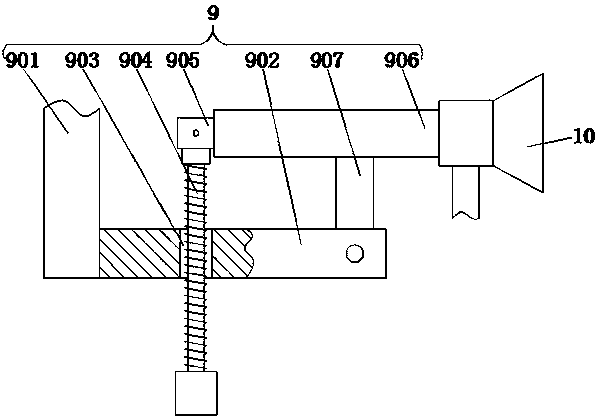

Anti-freezing dust suppression device for belt

PendingCN109230372APlay a role in dust suppressionSolve the problem of dust suppressionCleaningPackagingAnti freezingAutomatic control

The invention relates to an anti-freezing dust suppression device for a belt. The anti-freezing dust suppression device for the belt comprises a heating assembly, a conveying assembly and a spraying assembly; one end of the conveying assembly is connected with the heating assembly, the other end of the conveying assembly is connected with the spraying assembly, and the spraying assembly is locatedabove the belt. The device solves the problem of influence of sticking of coal on production during belt operation in winter from the source, a great anti-freezing effect is achieved, the returned belt after coal transportation is clean, automatic control over a machine to prevent freezing is achieved, manpower and material resources are saved, and all kinds of potential safety hazards brought bymanual cleaning are avoided; at the same time, the device solves the problem of dust suppression of the outdoor belt in winter, and flying of coal dust is effectively suppressed, so that environmental protection requirements for a production environment are met, and the gap in the field is filled up; investment of equipment is small, small space is occupied, and convenience is provided for popularization.

Owner:浙江弗戈科技发展有限公司

Efficient feed stirring machine for livestock breeding

The invention discloses an efficient feed stirring machine for livestock breeding, and belongs to the field of livestock breeding. The efficient feed stirring machine comprises a machine shell, crushing blades, a water pump, a second gear, a pre-stirring chamber, a stirring rod, a material pushing plate and cleaning brushes, wherein a feeding cylinder is arranged above the left side of the machineshell, the crushing blades are uniformly distributed and installed on a first rotating shaft, and the pre-stirring chamber is arranged below the feeding cylinder; a second motor is installed on the left side of the pre-stirring chamber, and an auger is installed on a third rotating shaft; and a stirring chamber is arranged below the pre-stirring chamber, a second telescopic rod is installed on the right side of the interior of the stirring chamber, the cleaning brushes are uniformly distributed on the side, far away from the second telescopic rod, of an installation plate, and a PLC is installed below the left side of the machine shell. According to the efficient feed stirring machine, the first motor, the first rotating shaft and the crushing blades cooperate, so that added feed can be crushed, the caked feed is scattered into powder, and the stirring and mixing effect is better.

Owner:安徽省快乐农牧科技股份有限公司

Mine blasting charging device

ActiveCN113932672AMeet the needs of blastingReduce generationBlastingClassical mechanicsStructural engineering

Owner:浙江秦核环境建设有限公司

Dye raw material grinding device with dust suppression function

ActiveCN113231136AShorten processing timeImprove processing efficiencyRotary stirring mixersTransportation and packagingSodium carbonateProcess engineering

The invention discloses a dye raw material grinding device with a dust suppression function. The dye raw material grinding device comprises a dyeing box, a sodium carbonate powder quantifying assembly and a cleaning box, wherein material conveying rollers are fixed on the inner walls of the dyeing box, the cleaning box and the cleaning box; a liquid quantifying assembly and a first cleaning assembly are fixed on the upper sides of the dyeing box and the cleaning box; a second water discharging pipe is located on the upper side of a precipitation box; electric heating wires are embedded into the dyeing box and the cleaning box; the sodium carbonate powder quantifying assembly is used for quantifying sodium carbonate powder; a feeding pipe penetrates through the upper side of the cleaning box; a second cleaning assembly is fixed on the upper side of the cleaning box; and a second hot air blower is fixed on the upper side of a drying box. The dye raw material grinding device with the dust suppression function, disclosed by the invention, can be used for carrying out cleaning operation in a dyeing process and can be used for carrying out quantitative treatment on a dyeing pigment and a cleaning raw material; the quality of cleaned tencel dyed blended yarns can be ensured and the tencel dyed blended yarns are dried; and the dye raw material grinding device has the advantage that the dyeing box and the cleaning box can be cleaned.

Owner:江苏嘉利精细化工有限公司

A wall punching device with dust suction function

InactiveCN110154247BPrevent spillageAchieve eliminationWorking accessoriesStone-like material working toolsPunchingClassical mechanics

The invention relates to the technical field of construction devices, in particular to a wall punching device with a dust-absorbing function, which includes a workbench, a lifting mechanism, a punching machine and a stabilizing mechanism. The lifting mechanism is fixedly installed on the workbench. A mounting plate is fixedly arranged on the output end, and connecting plates are fixedly arranged on both sides of the mounting plate, the stabilizing mechanism is fixedly mounted on the connecting plate, and a mounting box is fixedly mounted on the mounting plate, and the left side of the mounting box An opening is provided, a cover body is fixedly arranged on the opening, the punching machine is fixedly installed in the installation box, a dust collection box is also provided on the workbench, a suction fan is installed on the side of the dust collection box, and the dust collection box A dust suction hose connected to the cover is provided on the top, and a water delivery pipe extending into the dust collection box is also provided on the side of the dust collection box. One end of the water delivery pipeline located in the dust collection box is installed with a Universal nozzle, the device can suppress dust when drilling, purify the environment and protect human health.

Owner:JIANGSU NANTONG NO 2 CONSTR ENG GRP

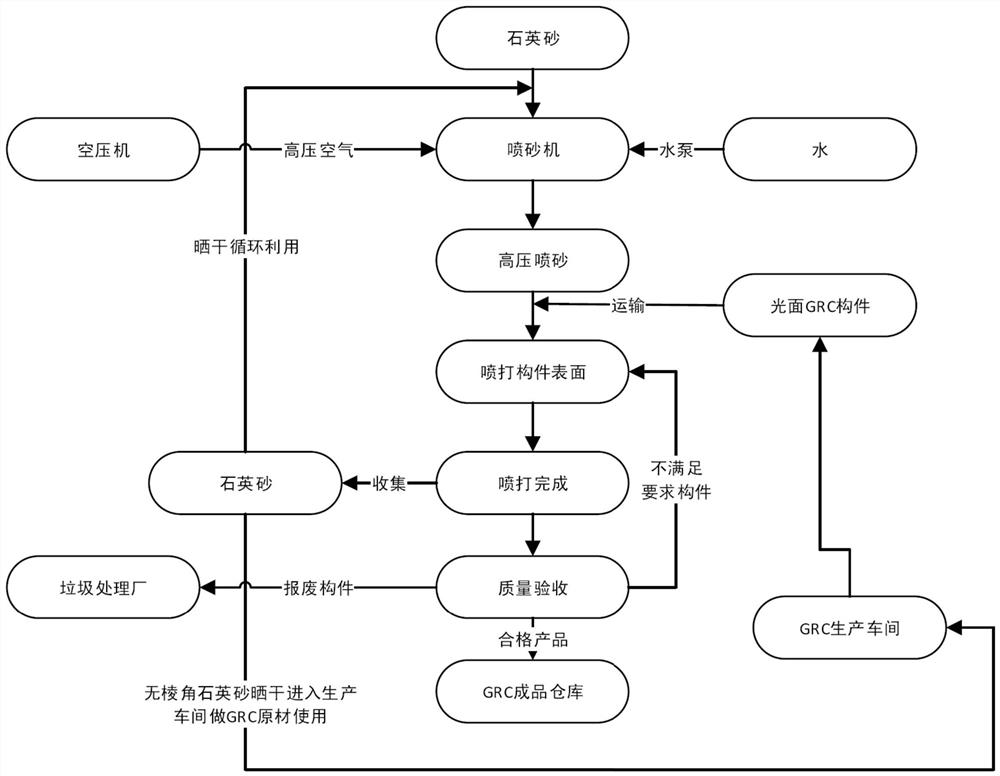

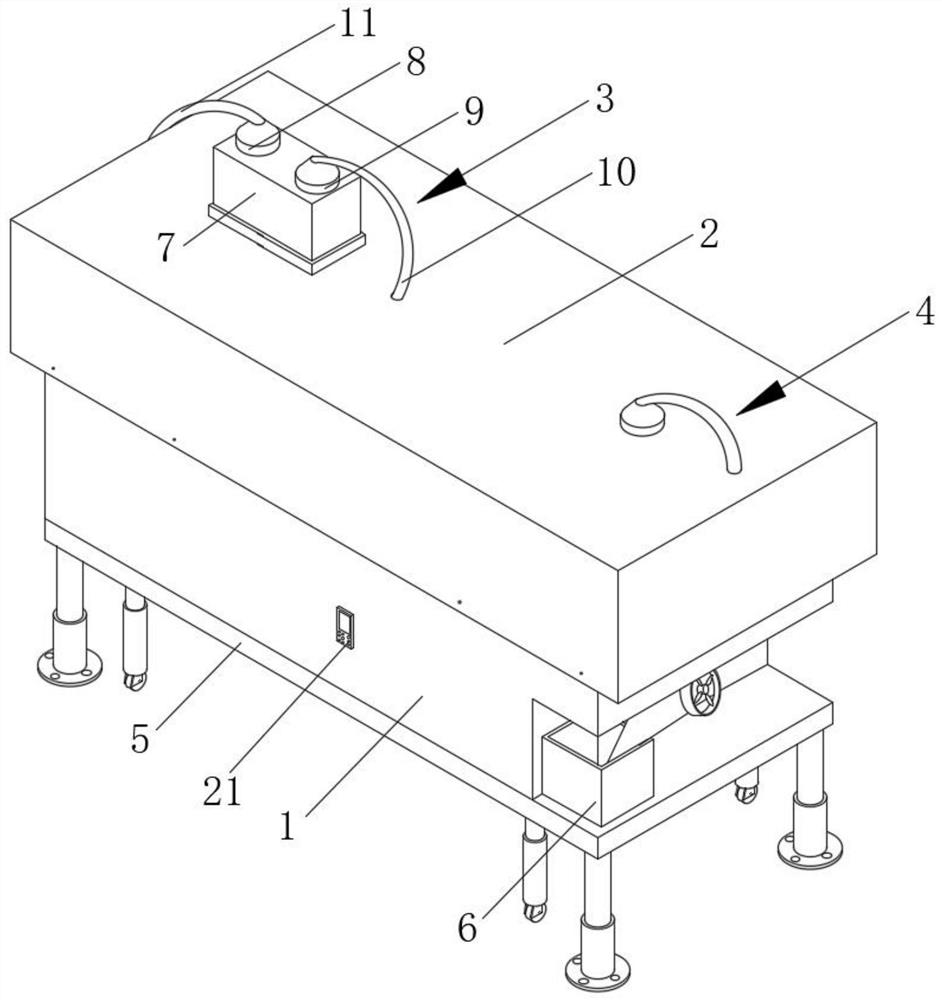

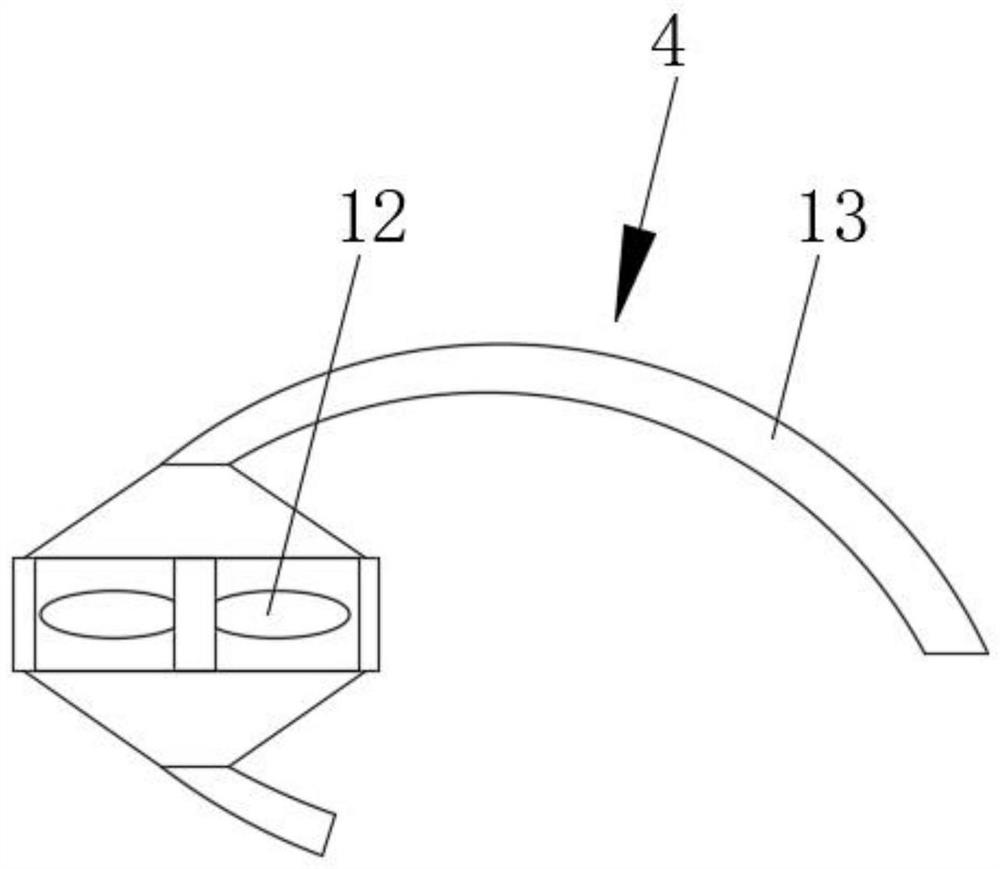

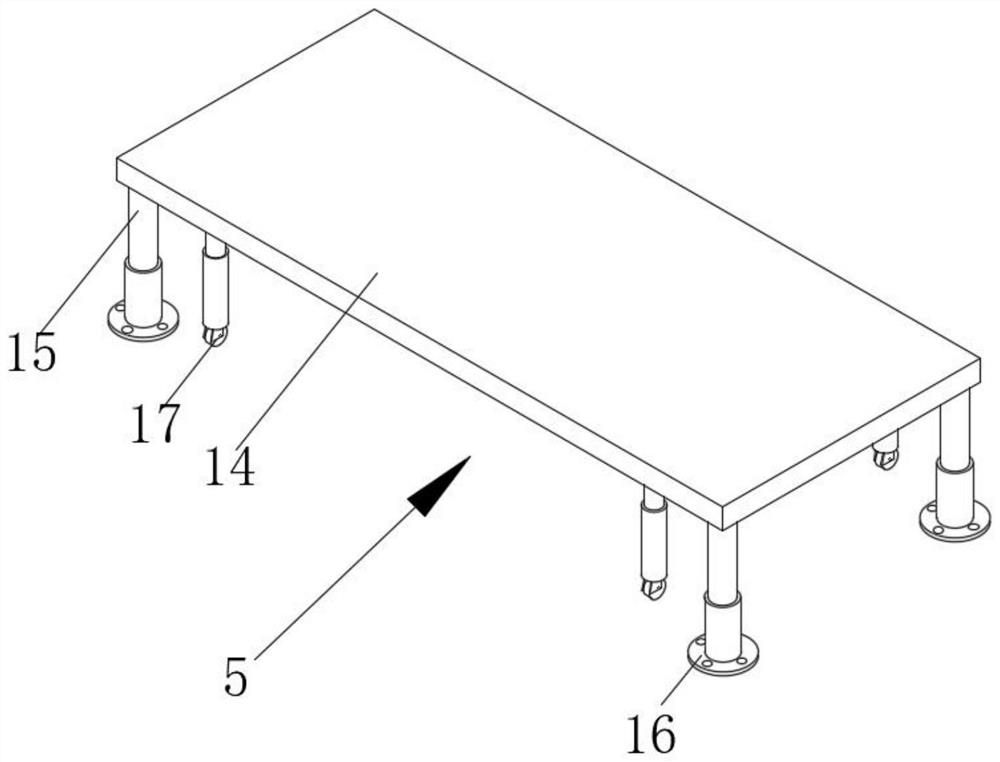

Production method of GRC component with stone-like effect

PendingCN114603488ALow costShorten the construction periodBlast gunsAbrasive machine appurtenancesSkin damageProcess engineering

The invention relates to a production method of a GRC component with a stone-like effect. The production method comprises the following steps: A, producing a glazed GRC component by using a mold; the member is regularly maintained after being demolded, the maintenance time is not less than 7 days, and the strength is ensured to reach 80% of the design strength; and B, quartz sand is sprayed out through a sand blasting machine, the smooth GRC component is impacted, the surface of the GRC component is subjected to skin damage, natural non-quality damage is caused, and a stone-like effect surface layer is formed. According to the production method of the GRC component with the stone-like effect, on the basis of ensuring the product quality and perfectly presenting the overall stone-like effect, the construction period can be greatly shortened, the cost can be saved, and the problems of environmental protection and the like can be avoided.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Protection device for offset press

The invention discloses a protection device for an offset press, comprising an offset press body, a protective shell, an air blowing mechanism and a drying mechanism. The periphery of the offset pressbody is connected with the protective shell of a box body structure through a plurality of screws; the top end of the protective shell is connected with the air blowing mechanism and the drying mechanism; the bottom end of the offset press body is connected with a movable support mechanism; an air treatment mechanism is arranged at the top end of the movable support mechanism; the air blowing mechanism comprises a liquid storage box, an exhaust fan, an ion fan and an air blowing pipe; the liquid storage box is arranged above the protective shell; two ventilation channels are formed in the topend of the liquid storage box; the inner walls of the two ventilation channels are connected with the exhaust fan and an ion fan for removing static electricity through a plurality of screws; funnel-shaped ventilation hoppers are welded to the two sides of the exhaust fan and the top end of the ion fan; and an air suction pipe is welded to the top end of each ventilation hopper above the exhaustfan. The protection device for the offset press not only can remove dust and static electricity, but also can treat air.

Owner:SHANGHAI XUANREN MACHINERY EQUIP

Gear machining cutting device with dust suction function and cutting method

PendingCN110653427AImprove practicality and environmental protectionIncrease cutting ratePositioning apparatusMaintainance and safety accessoriesElectric machineryDrive motor

The invention discloses a gear machining cutting device with a dust suction function and a cutting method. The gear machining cutting device comprises a workbench, a main cutting device body, a watertank and a driving motor, wherein the main cutting device body is arranged above the workbench, a water spraying hose is arranged at the right side of the main cutting device body, and the water tankis connected to the right side of the water spraying hose. The driving motor is installed on the lower surface of the workbench, a transmission shaft is connected to the upper portion of the driving motor, and a mounting pillar is fixed to the upper portion of the transmission shaft. The gear machining cutting device with the dust suction function is provided with the water spraying hose, a collection box and a liquid recycling chamber, and the surface of a gear can be subjected to water spraying treatment through the water spraying hose when the gear is cut. On one hand, a dust fall effect isachieved, and the harm of the dust and the like to the human body is reduced; on the other hand, a cutter can be cooled to a certain extent, and sprayed water enters a liquid recycling chamber through the collection box, and can be recycled after being filtered.

Owner:盐城永安科技有限公司

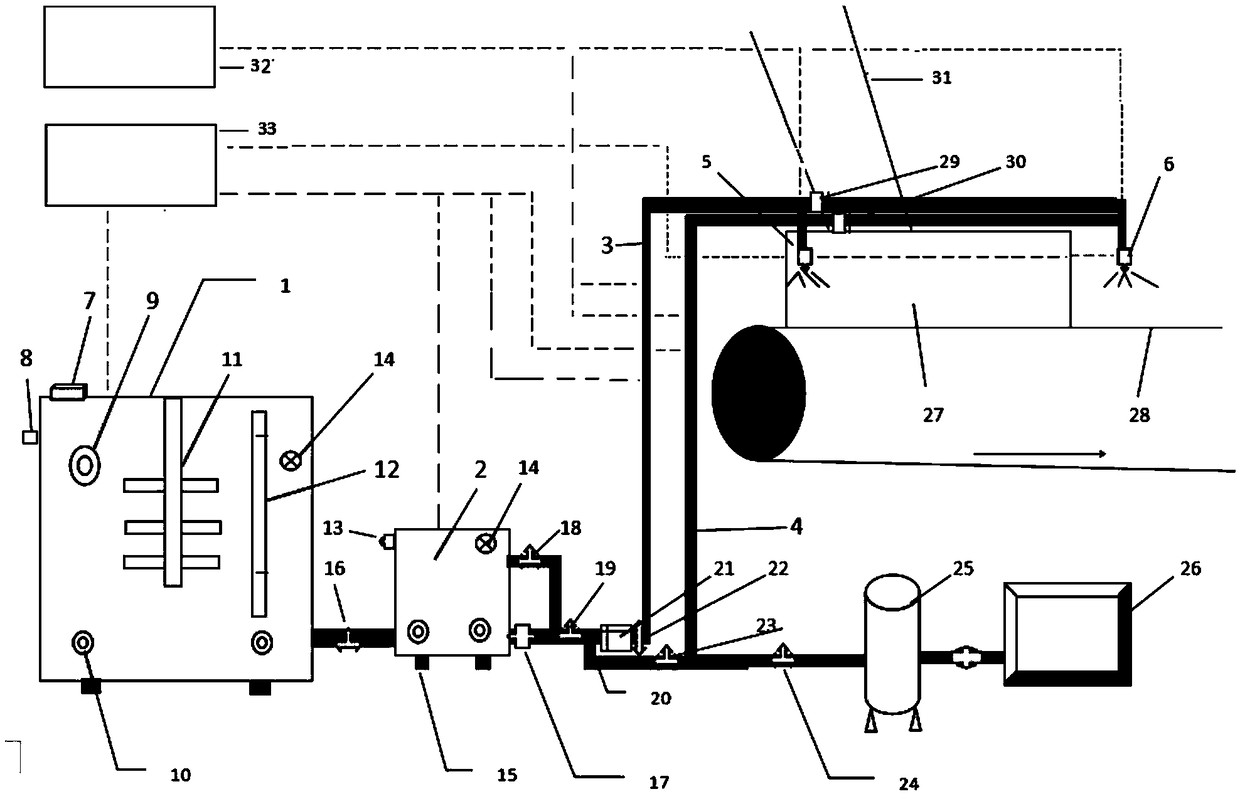

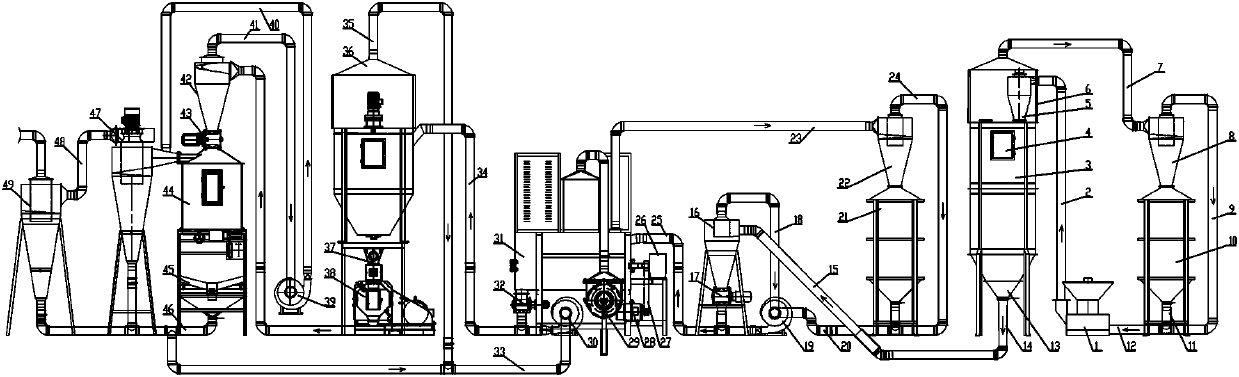

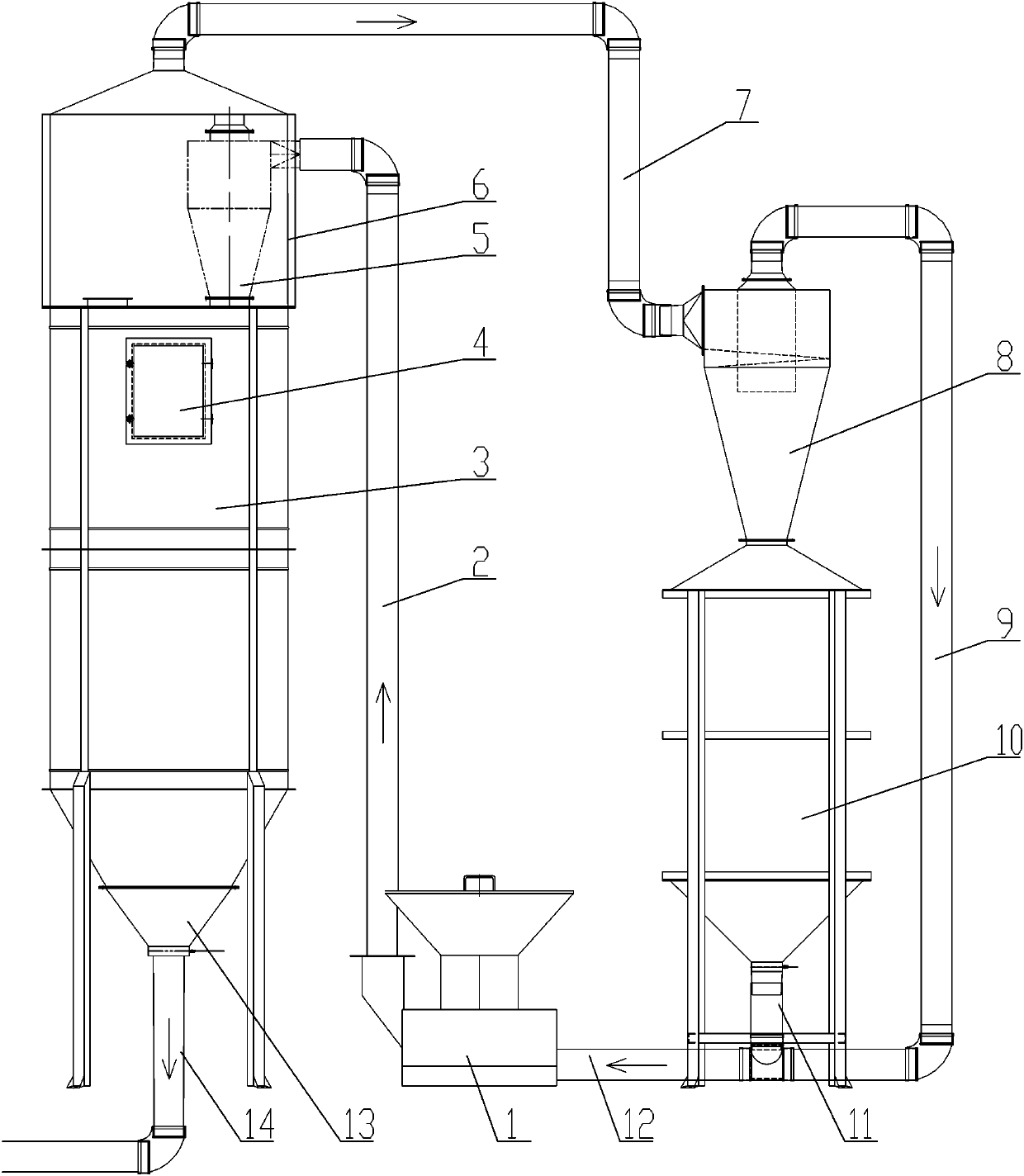

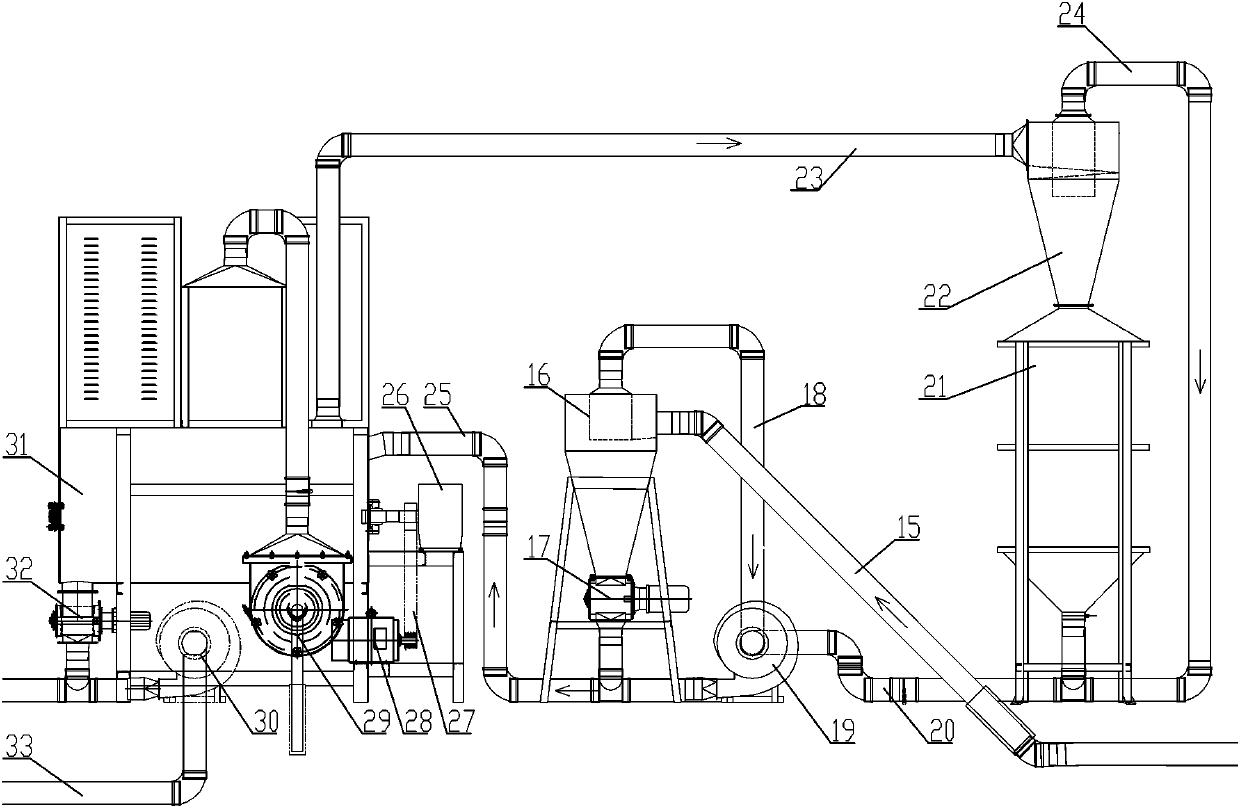

Totally-closed internal circulation self-dustfall granulation system, and method using same

ActiveCN109527628AIncrease profitEfficient purificationCombination devicesDispersed particle filtrationProcess engineeringTower

The invention provides a totally-closed internal circulation self-dustfall granulation system, and a method using the same. The powder output tube of a coarse material crushing system is connected with a first wind conveying system through a first conveying tube; the discharging port of the first wind conveying system is connected with a mixer through a second conveying tube; the mixer is providedwith a fine material crushing device for crushing a food grain material; the discharging port of the mixer is connected with a falling material tower through a second wind conveying system and a third conveying tube; the discharging port of the falling material tower is connected with a conditioner; the discharging port of the conditioner is connected with a granulator used for granulation; and the discharging port of the granulator is connected with a drying tower through a third wind conveying system through a third conveying tube. The system can be used for the fully automatic production of a feed in order to greatly improve the production efficiency of the feed, and adopts a totally-closed material circulation system to effectively improve the utilization rate of materials and preventdust pollution of workshop air.

Owner:DANGYANG CITY TIANGONG IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com