Patents

Literature

103results about How to "Good mixability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fruit sweetener and application thereof

The invention relates to a fruit sweetener and an application thereof, and belongs to the field of fertilizers. The technical problem to be solved in the invention is to provide the fruit sweetener and the application thereof. The active ingredient of the fruit sweetener provided by the invention is composed of potassium, phosphorus, nitrogen, boron, molybdenum, magnesium, calcium, zinc, iron, and copper elements at a molar ratio of (31-66): (22-35): (14-83): (0.8-7): (0.05-0.26): (1.4-5.8): (0.5-3.3): (0.1-1): (0.1-1): (0.05-0.25). The fruit sweetener can increase the sugar contents of fruits by about 20%, has a good sweetening effect on various kinds of plant fruits and contains no hormone, so that the fruit sweetener is free of toxic or side effect on plants.

Owner:CHENGDU NEWSUN CROPSCI

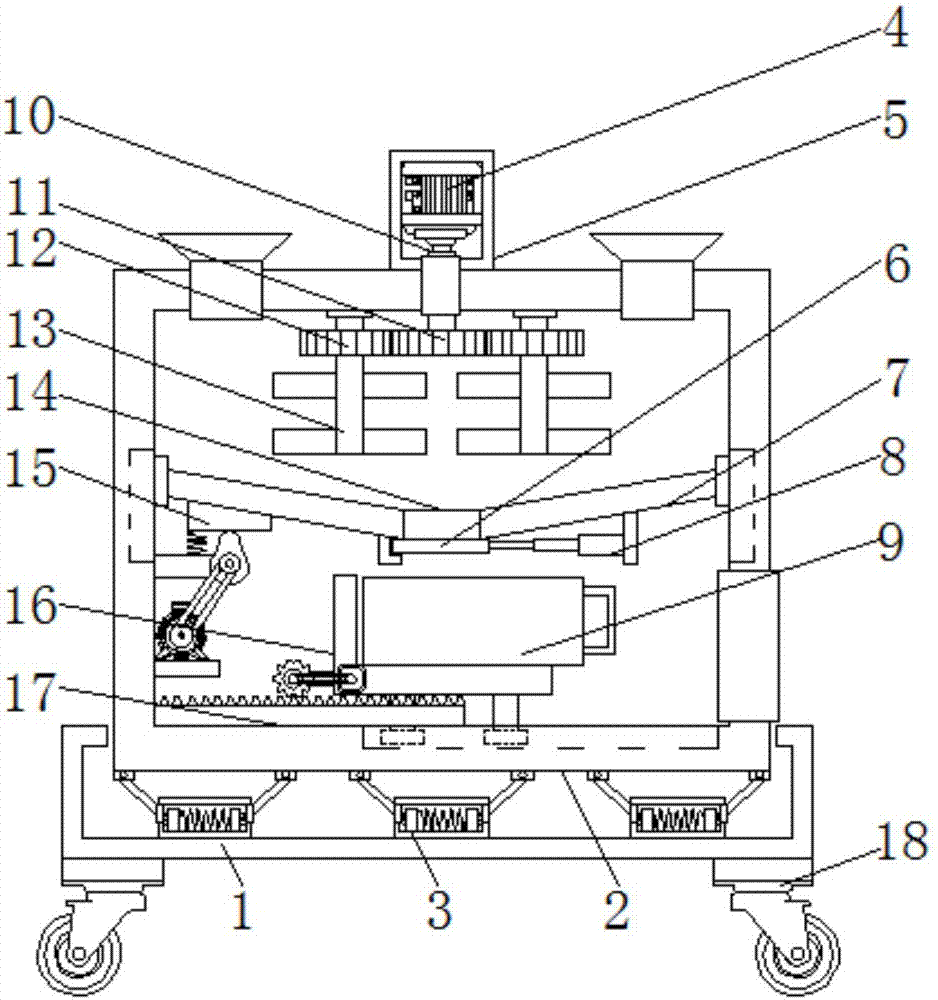

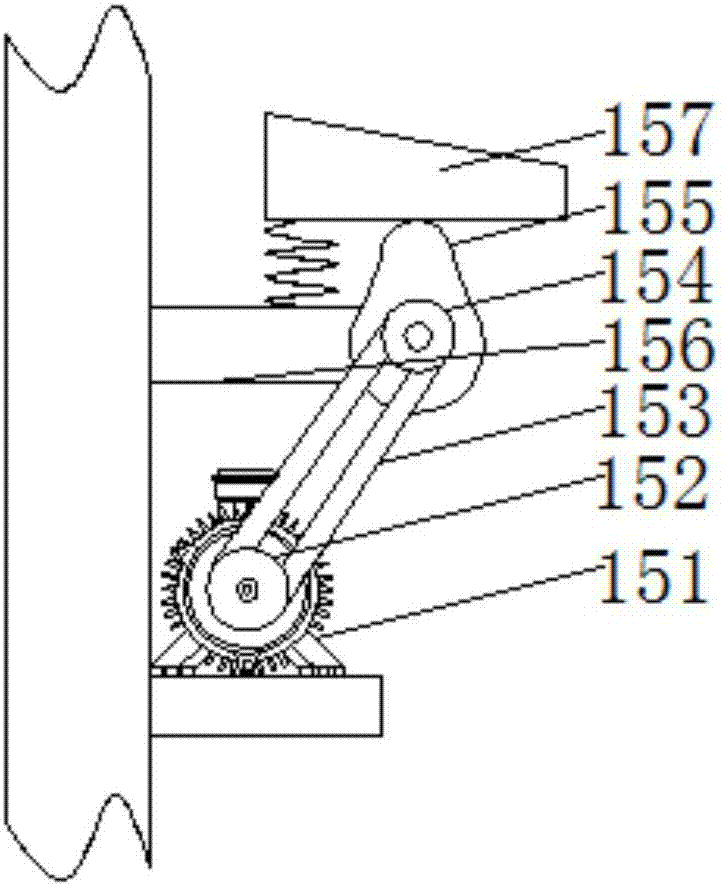

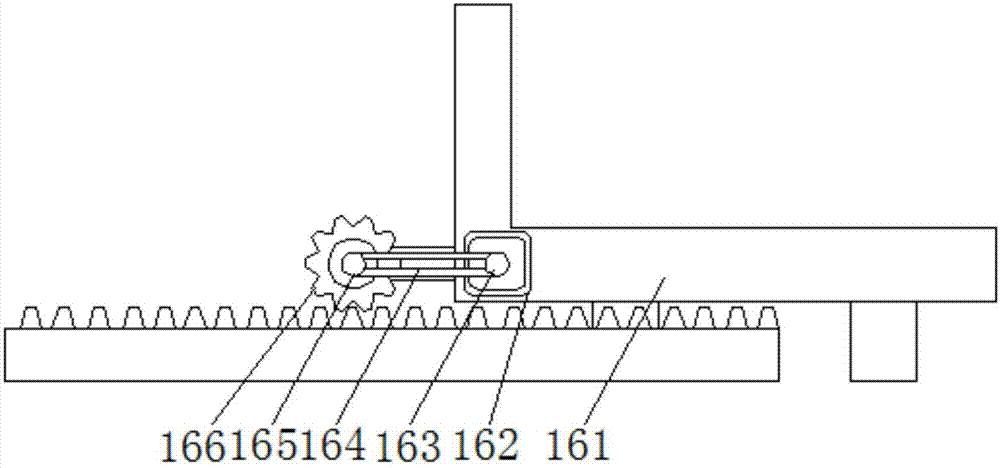

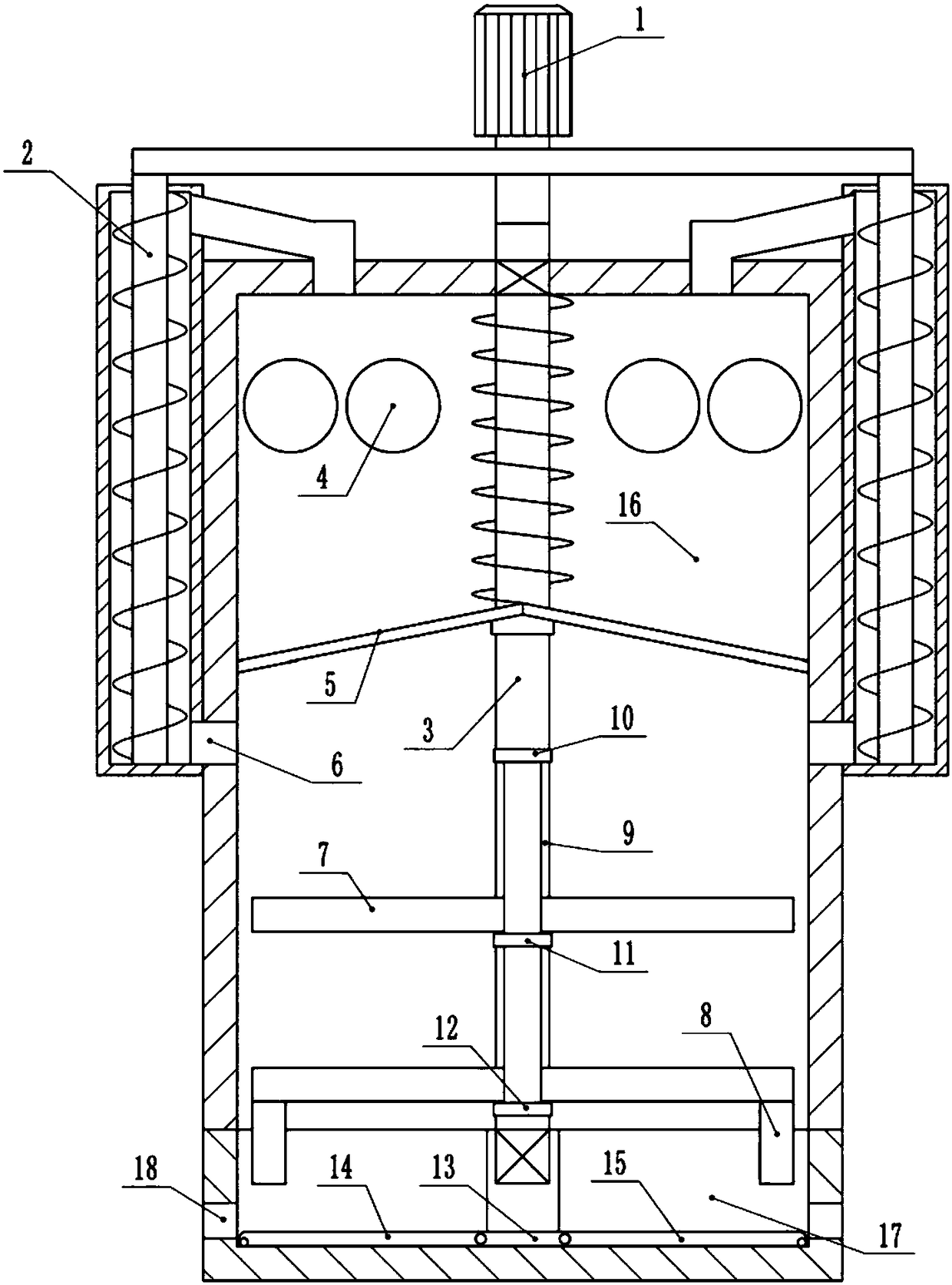

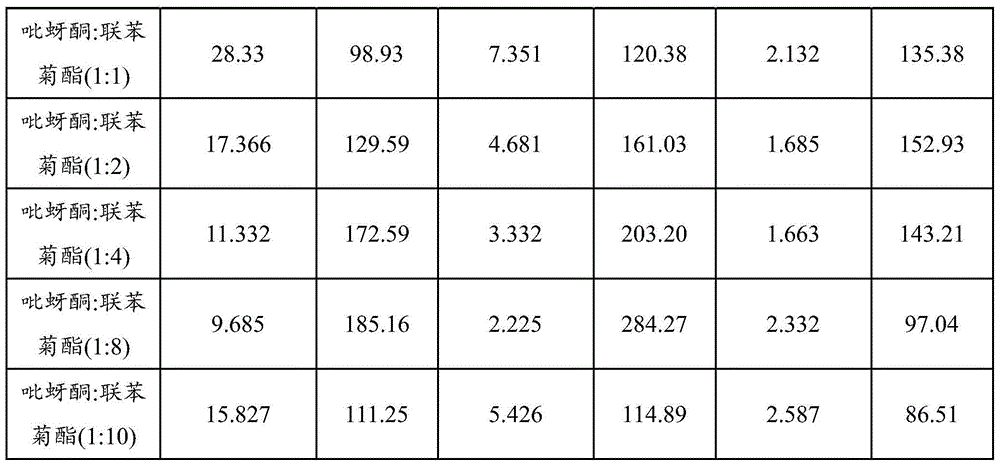

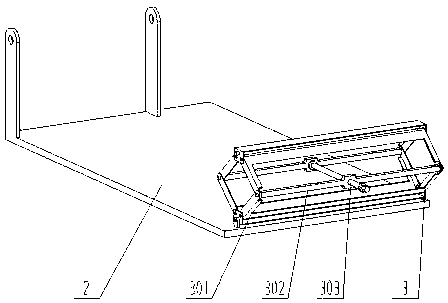

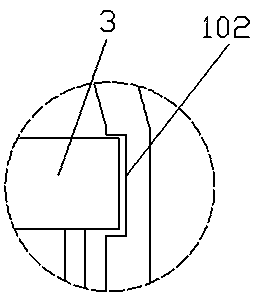

Glue preparation device for processing bamboo products

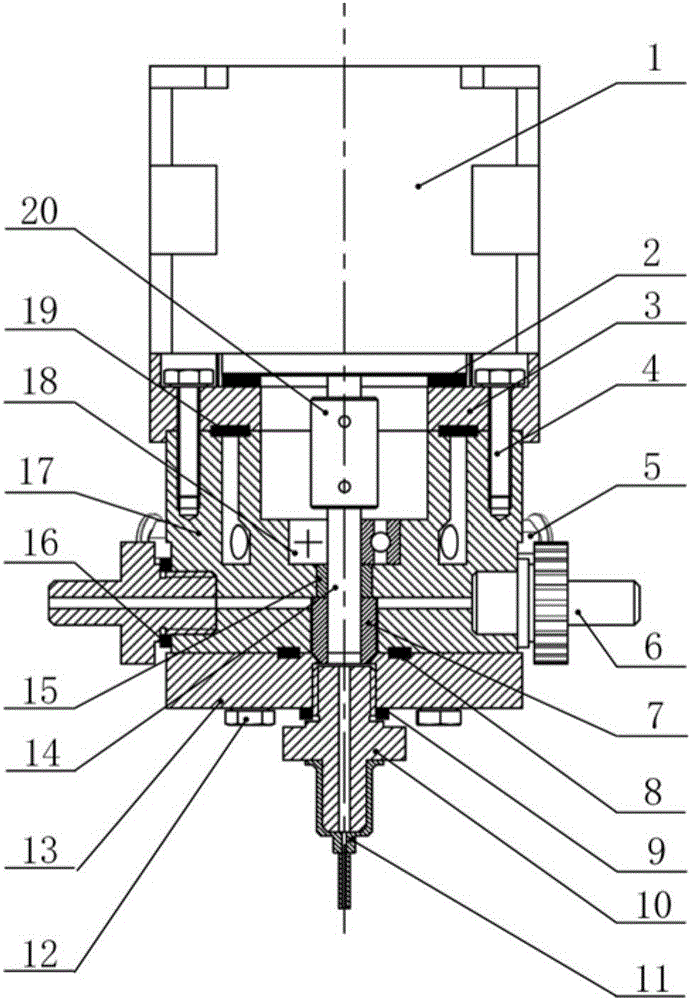

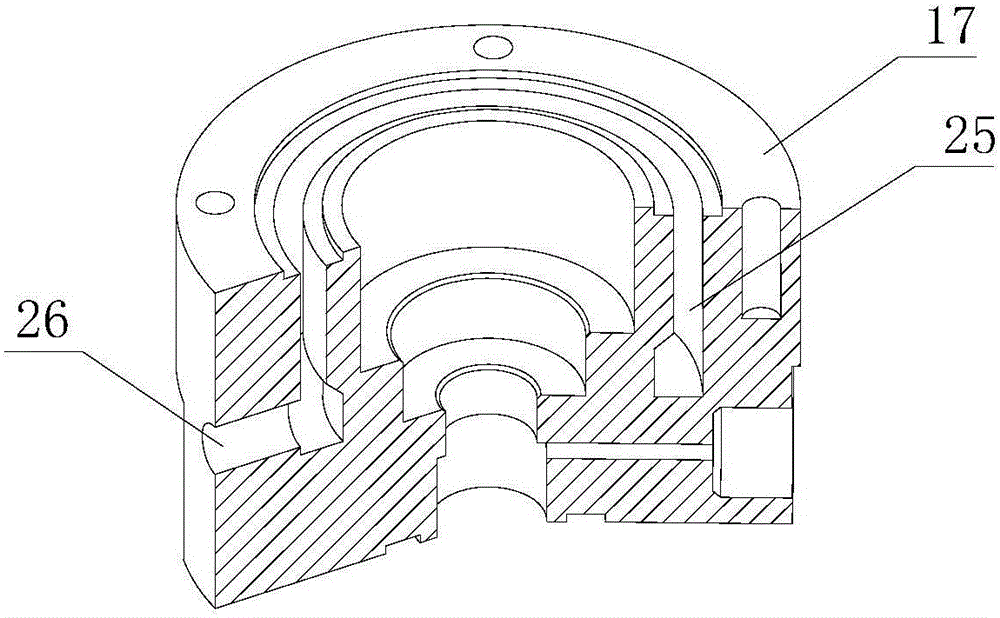

InactiveCN107414993AGood mixabilityImprove efficiencyTransportation and packagingRotary stirring mixersCouplingBiochemical engineering

The invention discloses a glue preparation device for processing bamboo products. The glue preparation device comprises bases, wherein a box body is arranged on the tops of the bases in a penetrated manner, and a damping device is fixedly connected between the bottom of the box body and the bottom of the inner cavity of each base; the top of the box body is fixedly connected with a motor box, and the interior of the motor box is fixedly connected with a first motor; and the output shaft of the first motor is fixedly connected with a rotating shaft through a coupler. The invention relates to the technical field of bamboo product processing. According to the glue preparation device for processing bamboo products, raw materials are shaken while the raw materials are stirred and mixed, so that the stirring and mixing effect of the raw materials is better, and the efficiency is higher; the raw materials are shaken during discharging, the raw materials are prevented from remaining inside the device, after the raw materials are stirred and mixed, the raw materials are automatically fallen into a material storage box, and the material storage box is sent out by a moving device, so that the workload of workers is alleviated, the device can be moved freely, the device is convenient to use, and the work efficiency is improved.

Owner:安吉县安信信息有限公司

Emulsified powder-like explosive

InactiveCN101024594ALow detonation velocityLow costExplosive working-up apparatusNon-explosive/non-thermic compositionsEmulsionDiluent

The invention relates to an emulsion powder explosive that has low detonation velocity. The feature is that it has 80-95 portions emulsion powder explosive, 5-20 portions diluents agent, and 0-10 portions density regulator. It could gain emulsion powder explosive that has 2000-2800m / s low detonation velocity, and density at 0.5-1.0g / cm3. The invention could lower the cost to 10-15% and has no adverse effect to explosive.

Owner:宜兴市阳生化工有限公司

Stirring device

ActiveCN108310995AAvoid cloggingAvoid mixingShaking/oscillating/vibrating mixersRotary stirring mixersEngineeringElectromagnet

The invention belongs to the technical field of stirring equipment and in particular discloses a stirring device. The stirring device comprises a stirring barrel and a charging basket, wherein a motoris arranged on the stirring barrel; a rotating shaft is connected onto an output shaft of the motor; the lower end of the rotating shaft is rotationally connected into the charging basket; two feeding holes are formed in top walls of the stirring barrel; two grinding roller groups are arranged in the stirring barrel; a spring is arranged on the rotating shaft in a sleeving manner; the upper end of the spring is fixed on the top wall of the stirring barrel; a screen is arranged at the lower end of the spring and connected onto the inner wall of the stirring barrel in a sliding manner; a chuteis formed in a side wall of the rotating shaft; two upper and lower layers of stirring paddles are connected onto the chute in a sliding manner; a first electromagnet, a second electromagnet and a third electromagnet are sequentially arranged at the top end, in the middle and at the lower end of the chute; permanent magnets are arranged on the screen and the two groups of stirring paddles; the left and right sides of the screen are downwards inclined; circulating orifices are formed in side walls on two sides of the stirring barrel; screw feed mechanisms are arranged outside the circulating orifices; orifices in the upper ends of the two screw feed mechanisms are respectively communicated with the two feeding holes.

Owner:青岛泰富科技有限公司

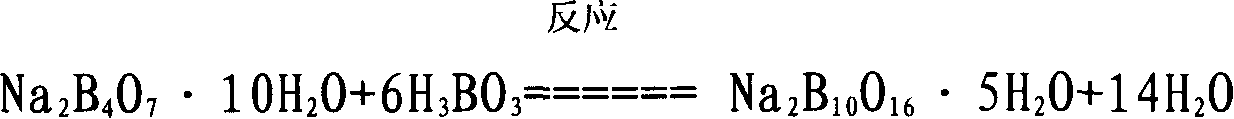

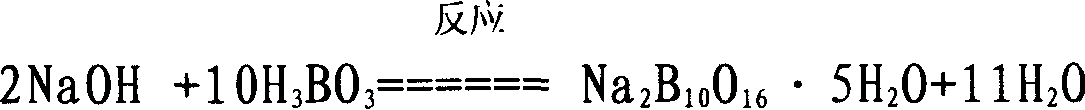

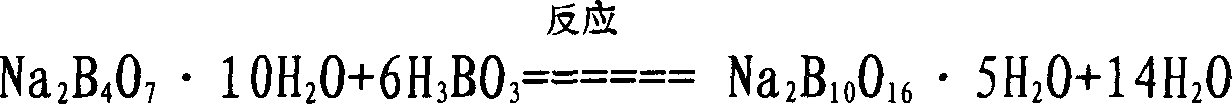

Instant soluble leaf-surface sprayed boric fertilizer and its production method

InactiveCN1789209ALow temperature dissolves quicklyPromote absorptionFertilizer mixturesPotassium hydroxideBoron

Disclosed is an instant dissolving type foliage-spraying boron fertilizer and its preparing process, wherein the fertilizer is prepared from borax, potassium hydroxide and boracic acid, the obtained sodium tetraborate can be widely used for various agronomic crops.

Owner:安徽省农望农业科技开发有限公司

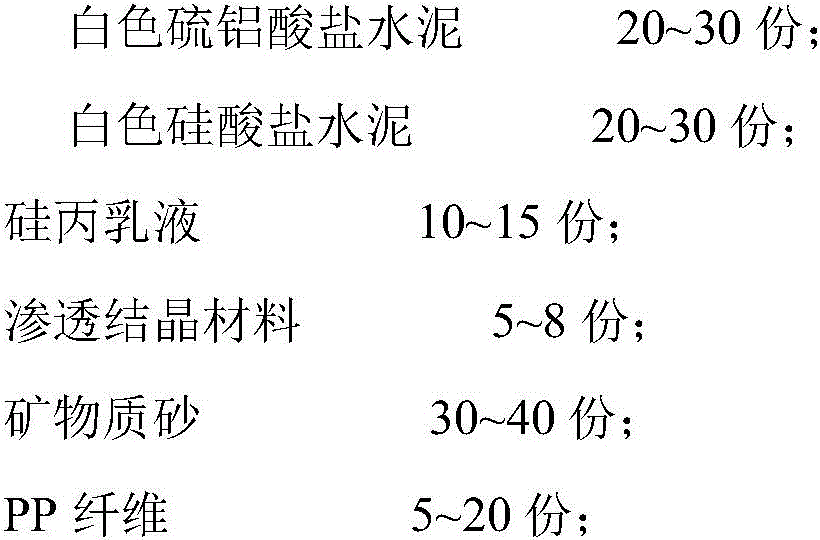

Waterproof early-strength decoration mortar and preparation method thereof

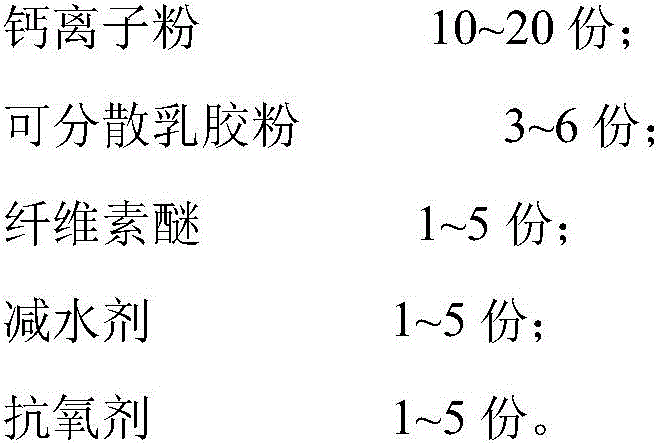

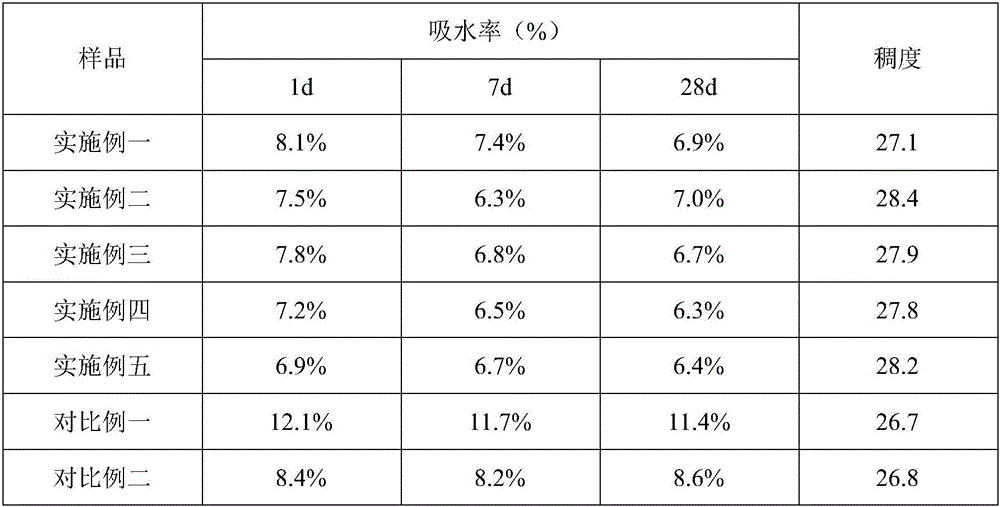

The invention discloses waterproof early-strength decoration mortar. The defect that traditional mortar cannot have both advantages of bright color and excellent waterproof early-strength effect at the same time is solved. According to main points of the technical scheme, the waterproof early-strength decoration mortar comprises the following ingredients (by weight): 20-30 parts of white sulphate aluminium cement, 20-30 parts of white portland cement, 10-15 parts of a silicon-acrylate emulsion, 5-8 parts of a permeable crystalline material, 30-40 parts of mineral sand, 5-20 parts of PP fiber, 10-20 parts of calcium ion powder, 3-6 parts of dispersible latex powder, 1-5 parts of cellulose ether, 1-5 parts of a water reducer and 1-5 parts of an antioxidant. The prepared mortar has excellent waterproofness and high strength, and has a decoration effect. According to the invention, defects of decoration mortar in the market, such as poor waterproofness and low early-strength, are compensated; and the waterproof early-strength decoration mortar with excellent properties is prepared.

Owner:苏州大乘环保新材有限公司

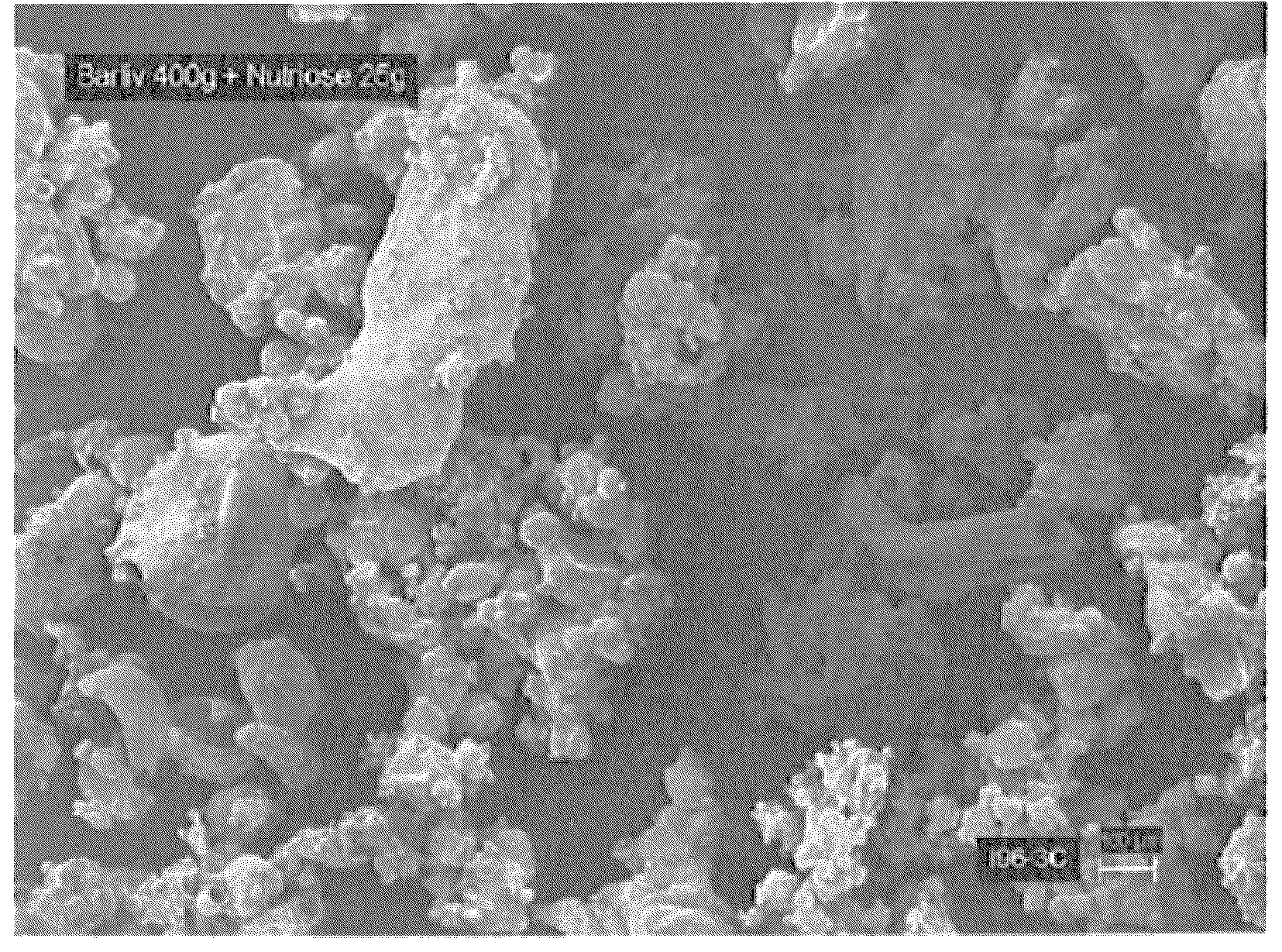

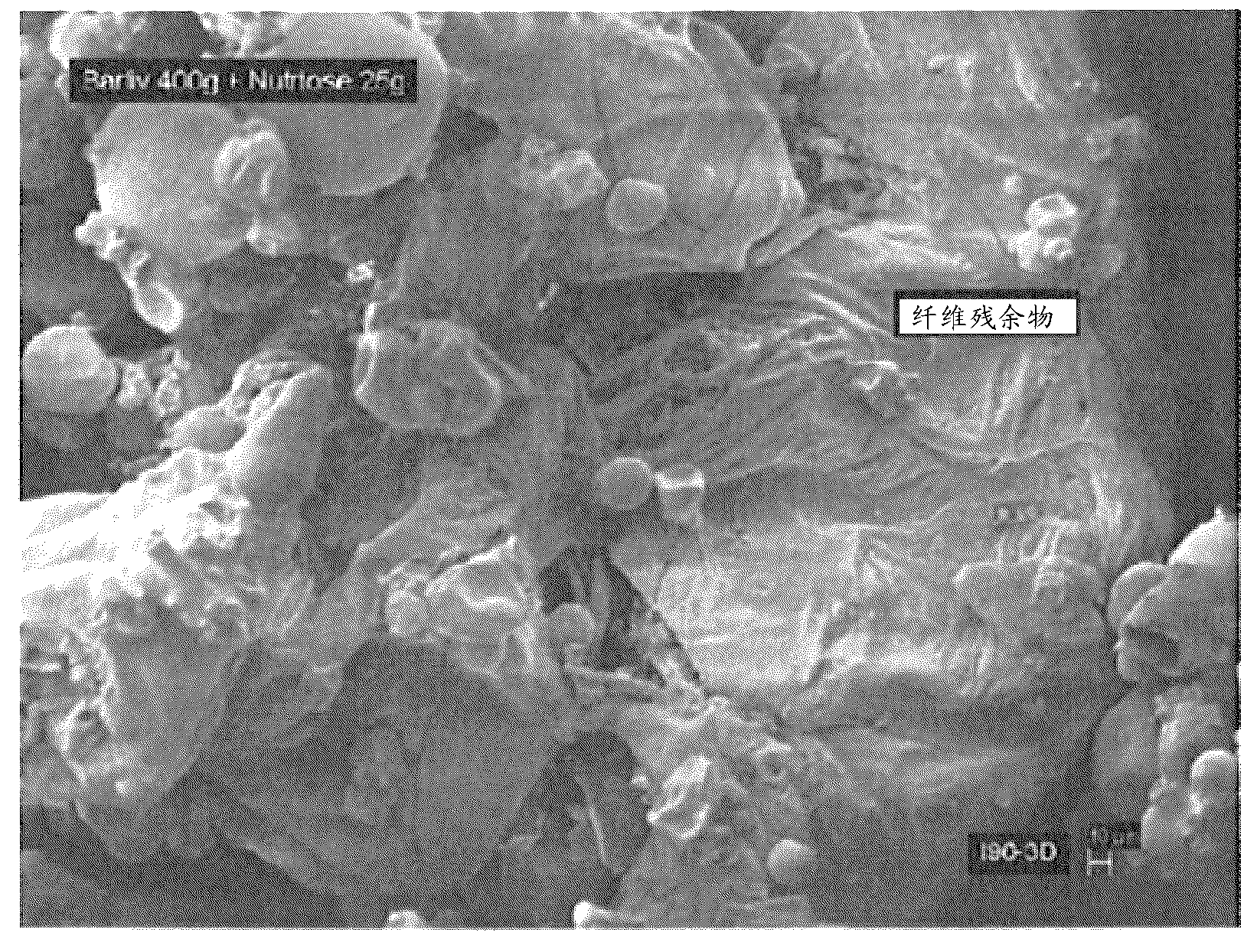

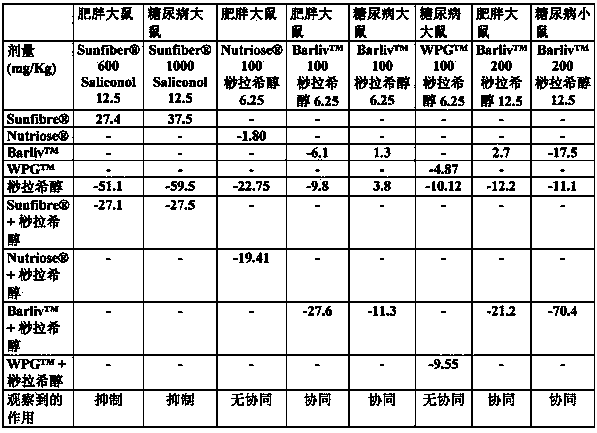

Water soluble nutritional compositions comprising cereal beta-glucan and resistant starch

InactiveCN103354719AImprove cold water solubilityImprove wettabilityOrganic active ingredientsMetabolism disorderSolubilityBeta-glucan

Disclosed are nutritional compositions comprising agglomerated and / or co-dried particles comprising a cereal beta-glucan and a resistant starch. The agglomerated and / or co-dried particles improve the cold water solubility of the nutritional compositions. The nutritional compositions may be dryblended powdered nutritional compositions including the agglomerated and / or co-dried particles and optionally a Salacia extract.

Owner:ABBOTT LAB INC

Disinsection emulsion in water containing avermectin

The present invention discloses an insecticidal aqueous emulsion containing abamectin. Its composition contains (by wt%) abamectin 0.1-5%, emulsifier 5-25%, antifreezing agent 1-5%, defoaming agent 0.05-0.2%, solvent 3-35%, thickening agent 0.5-1% and the rest is water. It can be extensively used for killing antagonistical pests of cabbage moth, leaf miner and red mite, etc. on the vegetables, tangerine and cotton, etc.

Owner:HEBEI VEYONG BIO CHEM

High purity glyphosate ammonium salt raw powder and its production method

InactiveCN1394483ANo pollution in the processPollution meetsBiocideAnimal repellantsAdjuvantGlyphosate

The present invention discloses a high-purity glyphosate ammonium salt raw powder and its production method. It is characterized by that the glyphosate ammonium salt contnet is 95-99%, the decrement due to drying is less than or equal to 1.0% and glyphosate acid content is above 88%. Its production method incldues the following steps: making glyphosate raw material and ammonia produce reaction, adding natural adjuvant to form salt, filtering and drying so as to obtain high-purity glyphosate ammonium salt raw powder whose purity is 95-99%. It is high in content, good in weeding effect, low-toxic and low in cost, etc.

Owner:张鸿秀

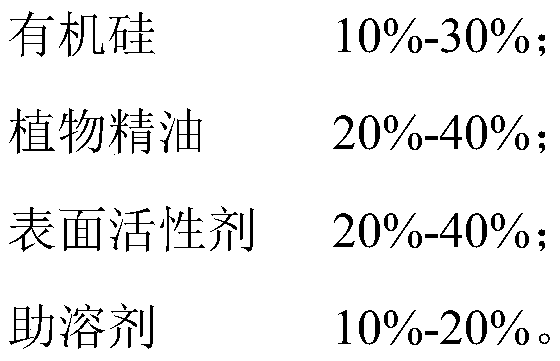

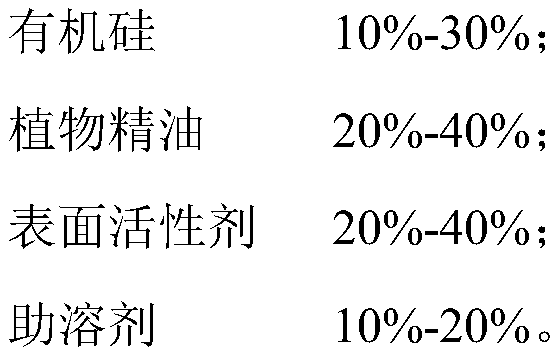

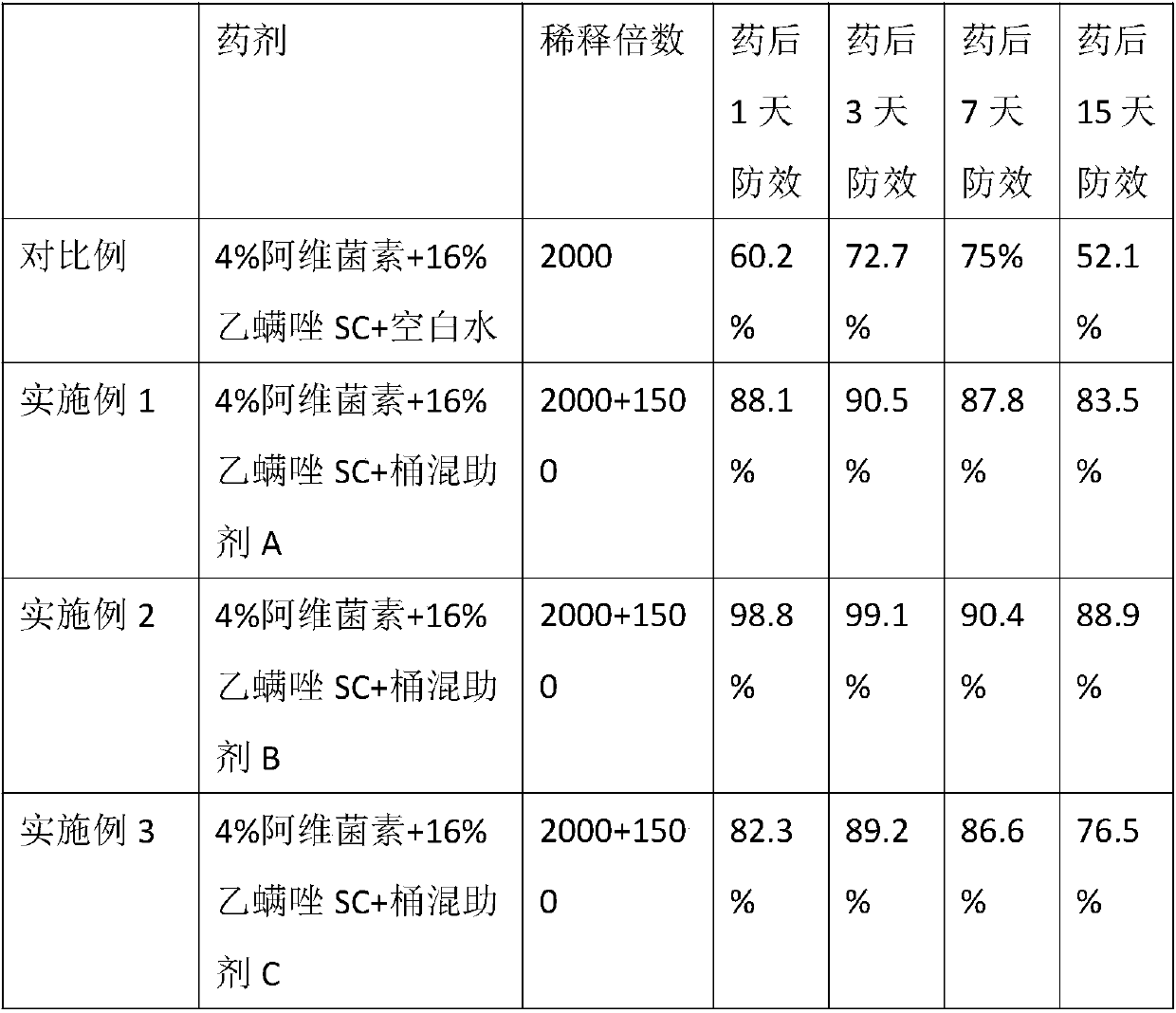

Barrel blending aid and preparation method and application thereof

The invention discloses a barrel blending aid, which is characterized by comprising the following components in percentage by weight: 10-30% of organic silicon, 20%-40% of plant essential oil, 20%-40%of a surfactant, and 10%-20% of a cosolvent. The barrel blending aid can be used for preventing and treating citrus red mites, has good compatibility with missible oil, microemulsion, a water suspending agent, an oil suspending agent and a water dispersing agent, has wide universality, can improve the utilization rate of medicaments, reduces the use amount of pesticides, and reduces environmentalpollution.

Owner:GUANGZHOU FANGZHONG CHEM CO LTD

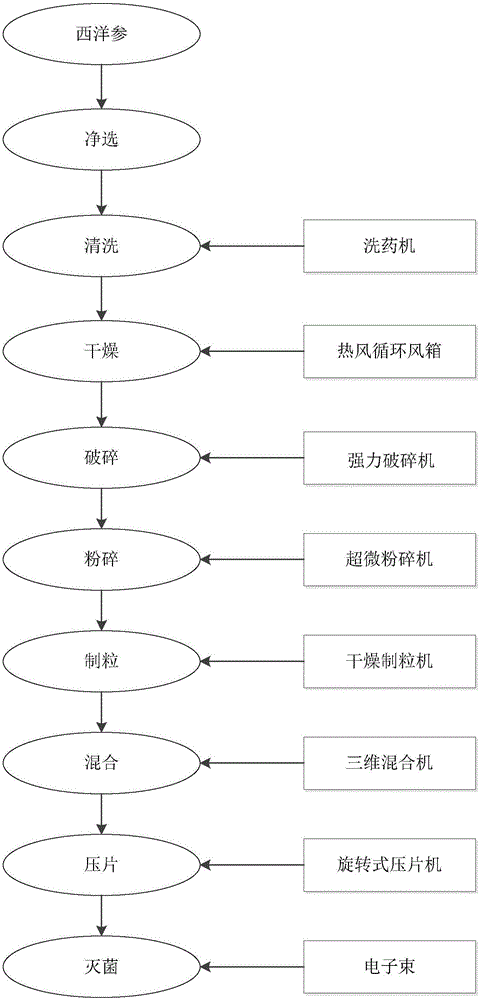

Preparation method of panax quinquefolius raw powder tablets

InactiveCN105902587ADisintegrates quicklySpeed up entryNervous disorderPill deliveryBioavailabilityProcessing cost

The invention discloses a preparation method of panax quinquefolius raw powder tablets, and belongs to the technical field of health care products. The method comprises nine steps: sorting, cleaning, drying, crushing, grinding, granulating, mixing, tabletting and sterilizing. The panax quinquefolius raw powder tablets do not contain any auxiliary materials; the bioavailability of product is increased; the product is more convenient to use, with longer guarantee period, lower processing cost, good dispersibility, miscibility and absorbability, thus the effective constituents of panax quinquefolius enter human body quickly; the original taste is reserved, and the health care function is increased; moreover, the dosage can be exponentially reduced, thereby effectively increasing utilization ratio of rare resources.

Owner:HEBEI LIN YITANG MEDICAL CO LTD

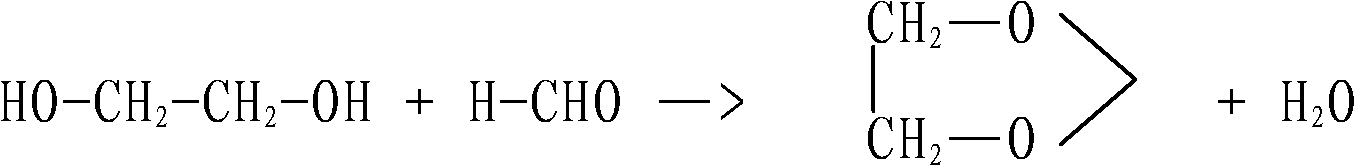

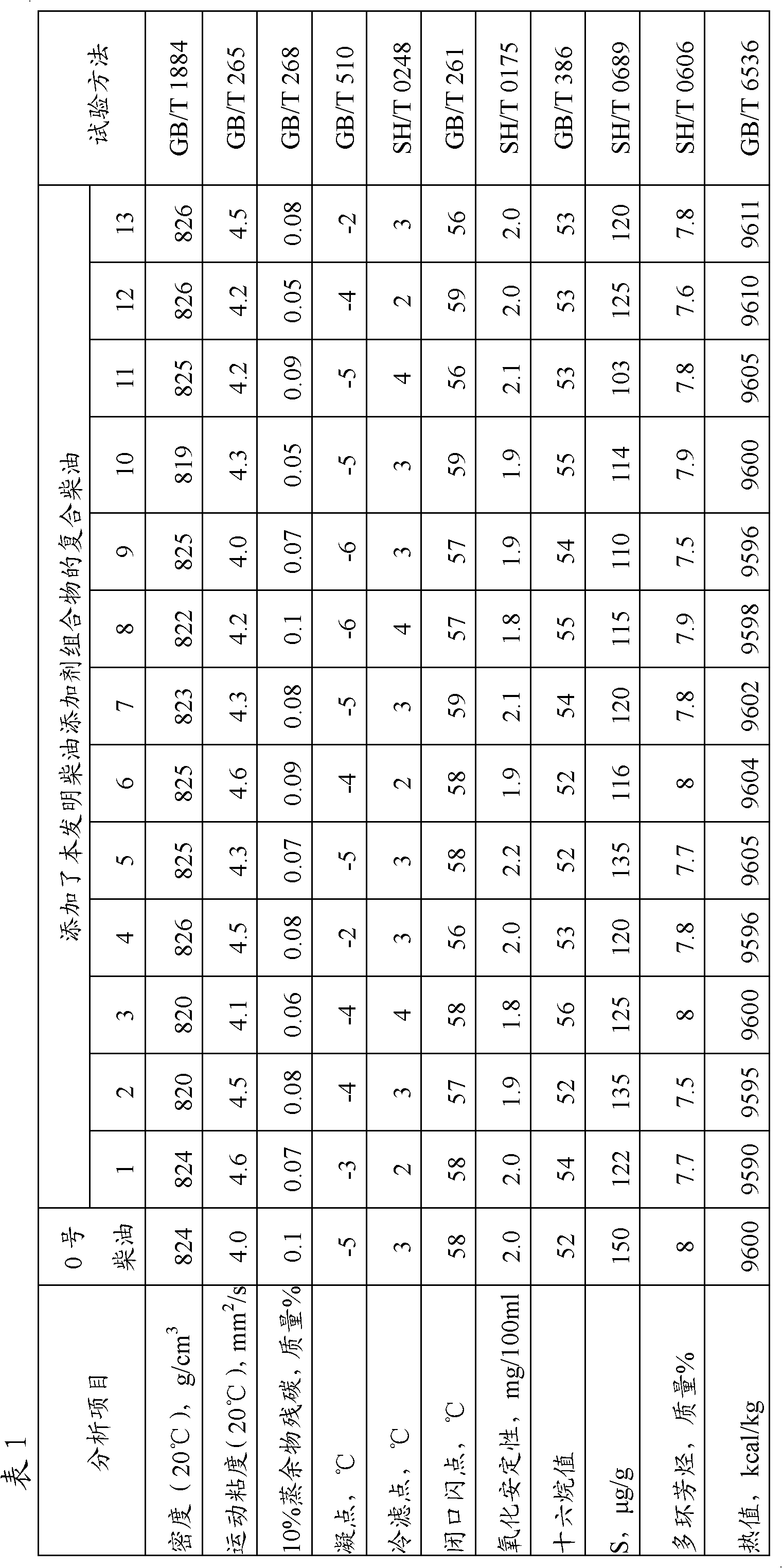

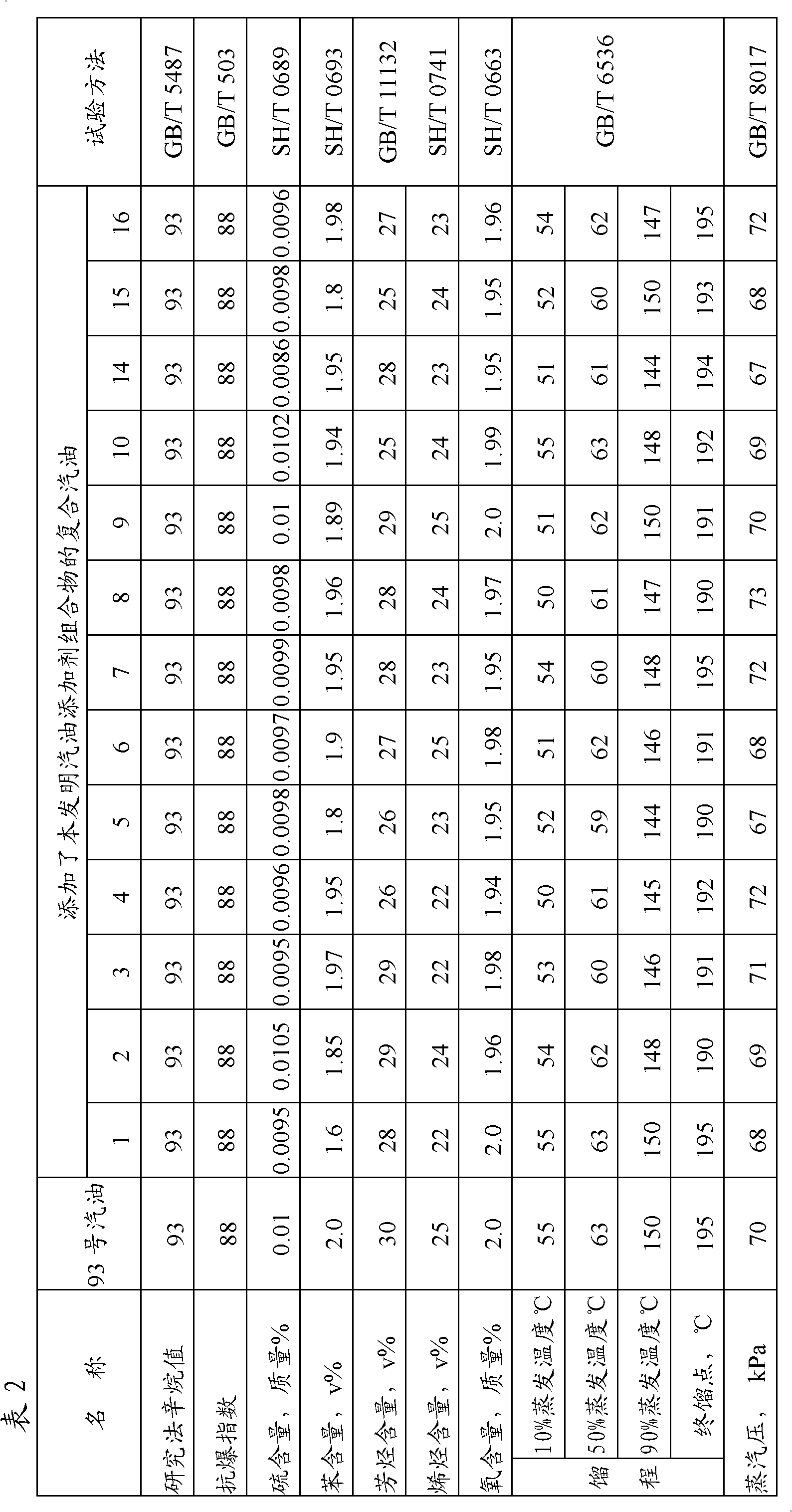

Gasoline and diesel oil additive composition and preparation method and application thereof

ActiveCN102627985AGood miscibilityHigh flash pointLiquid carbonaceous fuelsOil additiveReaction temperature

The invention provides a method for preparing a gasoline and diesel oil additive composition. The method comprises the following steps of: performing addition and dehydration reaction on glycol, trioxymethylene and methanol in the mole ratio of 1: (0.5-3.5): (1.0-6.0) under the action of an acidic ionic liquid catalyst for 2 to 8 hours at the temperature of 65 to 140 DEG C to generate a mixture containing dimethoxymethane and bidimethoxyethane; and separating the mixture, wherein the dimethoxymethane-containing product with low boiling point is a gasoline additive composition, and the bidimethoxyethane-containing product with high boiling point is a diesel oil additive composition. The reaction process is high in controllability, reaction equipment is readily available, the operation is simple, the applicability of the reaction products is relatively good in distribution, the total yield of the products is high, and the economic benefit is good. The invention also provides a composite oil product prepared from the gasoline and diesel oil additive composition, and the performance of the composite oil product meets the quality index requirement on commoditization of automotive fuels.

Owner:田强 +1

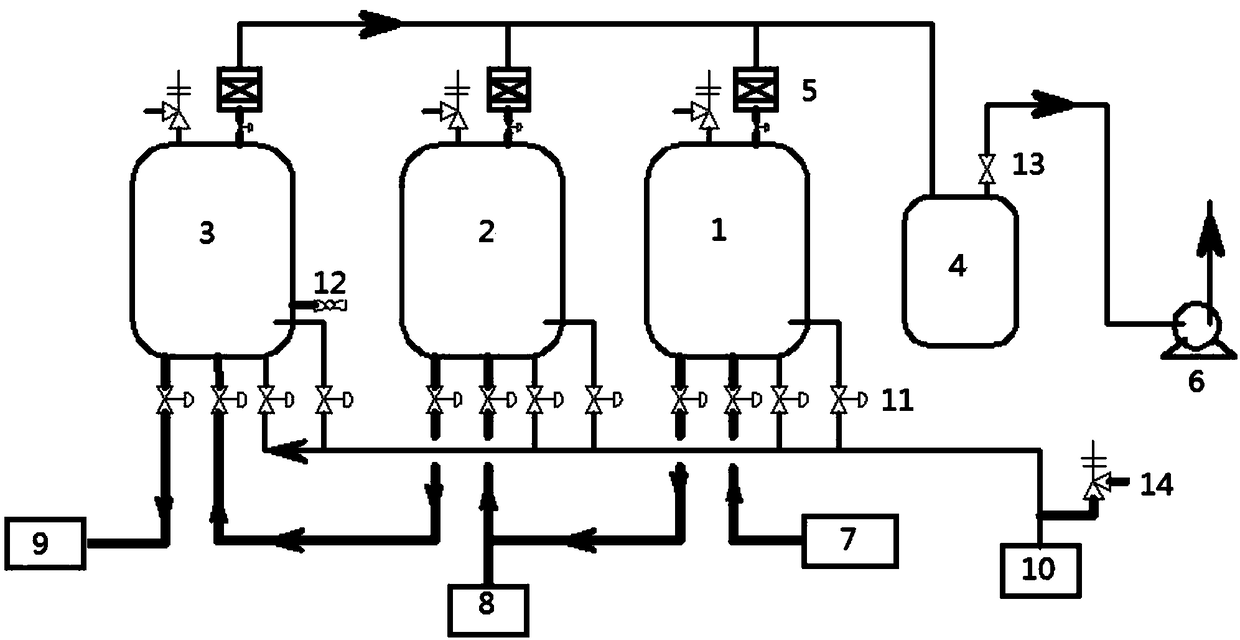

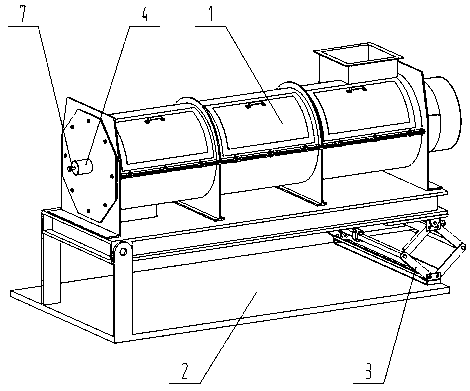

Device for blending pulverized fuel ash and cement

InactiveCN108274616AAvoid uneven mixingImprove sealingPretreatment controlIngredients weighing apparatusFuel tankPulverized fuel ash

The invention relates to a device for blending pulverized fuel ash and cement. The device for blending pulverized fuel ash and cement comprises a metering tank, a primary mixing tank, a batch mixing tank, a dust removing tank, dust removers, a fan, a pulverized fuel ash tank, a cement tank, a fished product bin, a pressure air tank, pneumatic adjusting valves, a sampling ball valve, a stop valve and a safety valve, wherein the pressure air tank is connected with the bottoms and lateral portions of the metering tank, the primary mixing tank and the batch mixing tank; the pulverized fuel ash tank is connected with the bottom of the metering tank, the bottom of the cement tank and the bottom of the metering tank are connected with the bottom of the primary mixing tank, and the bottom of the finished product bin and the bottom of the primary mixing tank are connected with the bottom of the batch mixing tank; the top of the metering tank, the top of the primary mixing tank and the top of the batch mixing tank are each connected with one dust remover and then connected with the top of the dust removing tank, and the top of the dust removing tank is connected with the fan; and pipeline connection is used as the connection mode. By means of the device for blending pulverized fuel ash and cement, the problem that pulverized fuel ash and cement are not mixed evenly is solved.

Owner:THE 404 COMPANY LIMITED CHINA NAT NUCLEAR

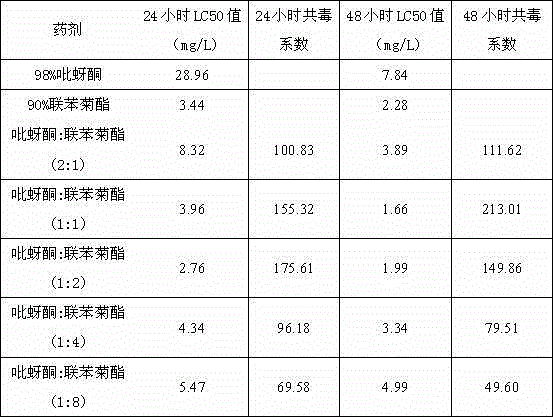

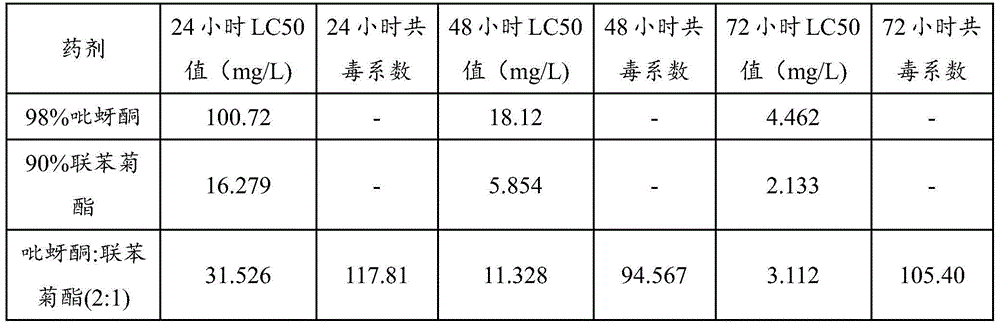

Compound pesticide for preventing and treating lygus lucorum and preparation method of compound pesticide

InactiveCN105028460AReduce pollutionImprove efficacyBiocideAnimal repellantsPesticide residueToxicology

The invention belongs to the technical field of compound pesticides, and in particular relates to a compound pesticide for preventing and treating lygus lucorum and a preparation method of the compound pesticide. The compound pesticide is prepared from effective constituents of pymetrozine and bifenthrin, aiming at the problems that at present, the selection of pesticide is not proper, the dosage of the pesticide is not accurate, the pesticide application is not timely, and the pesticide application method is not accurate, so as to cause the severe results that labor, time and pesticide are wasted, the pollution is heavy, the insects have strong resistance to pesticides, and the pesticide residue of the crop is serious. The compound pesticide is prepared from effective constituents of pymetrozine and bifenthrin, the pesticide effects of pymetrozine and bifenthrin are increased, the spray times is reduced, the resistance is delayed, the life of the crop is prolonged, and the environment pollution is reduced.

Owner:INST OF PLANT PROTECTION SHANDONG ACAD OF AGRI SCI

Stirring mixer

A stirring mixer comprises a shell with a material inlet and a material outlet, and a stirring shaft. The shell consists of a barrel and an end cover arranged on the barrel end. Lines of vertically and horizontally neatly arranged teeth are provided on the inner wall of the barrel evenly, and the tooth width for each line of teeth is the same. Lines of teeth are also provided at the stagger positions of lines of teeth on the stirring shaft and the barrel inner wall. The barrel inner wall and the lines of teeth on the barrel inner wall are manufactured as a whole, and the stirring shaft and the lines of teeth arranged on the stirring shaft are also manufactured as a whole. The invention is characterized in that the barrel is spliced by two or more barrel units, and a gasket is provided at the splicing part of two adjacent barrel units. Compared with the prior art, the invention has the advantages that continuous stirring and mixing can be conducted, and meanwhile the stirring and mixing effect is ideal.

Owner:黎泽荣

Mixing device for preparation of artworks by re-processing of solid wastes

ActiveCN108970457AImprove uniformityQuality improvementShaking/oscillating/vibrating mixersTransportation and packagingEngineeringMaterial distribution

The invention discloses a mixing device for preparation of artworks by re-processing of solid wastes. The mixing device comprises a mixing chamber, a stirring shaft, a stirring peddle, a material distribution part, an opening and closing part and a resetting part, wherein the stirring shaft is rotationally arranged in the mixing chamber; the stirring paddle is arranged on the stirring shaft; the material distribution part is used for conveying the material at the lower part of the mixing chamber to the upper part of the mixing chamber, and comprises a material conveying cavity, a material inlet, a material outlet, a piston part and a drive part, the material conveying cavity is arranged in the stirring shaft, the material inlet is arranged at the lower part of the stirring shaft, and the material outlet is arranged at the upper part of the stirring shaft; the opening and closing part is arranged in the material conveying cavity, and is used for controlling the opening or closing of thematerial inlet; the resetting part is used for driving the opening and closing part to reset to the closing state of the material inlet after the opening and closing part is moved. The mixing devicehas the advantages that by arranging the resetting part, after the opening and closing part leaves the material inlet, the opening and closing part can be quickly and stably reset to the closing position of the material inlet, thereby avoiding the condition of the opening and closing part failing to close the material inlet, and reducing the fault rate.

Owner:磐安县宸熙工艺品有限公司

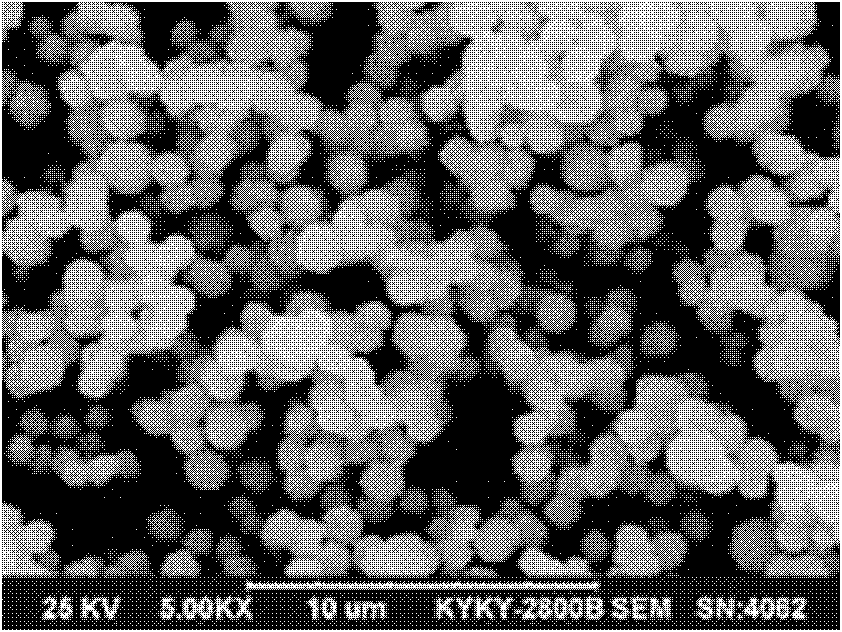

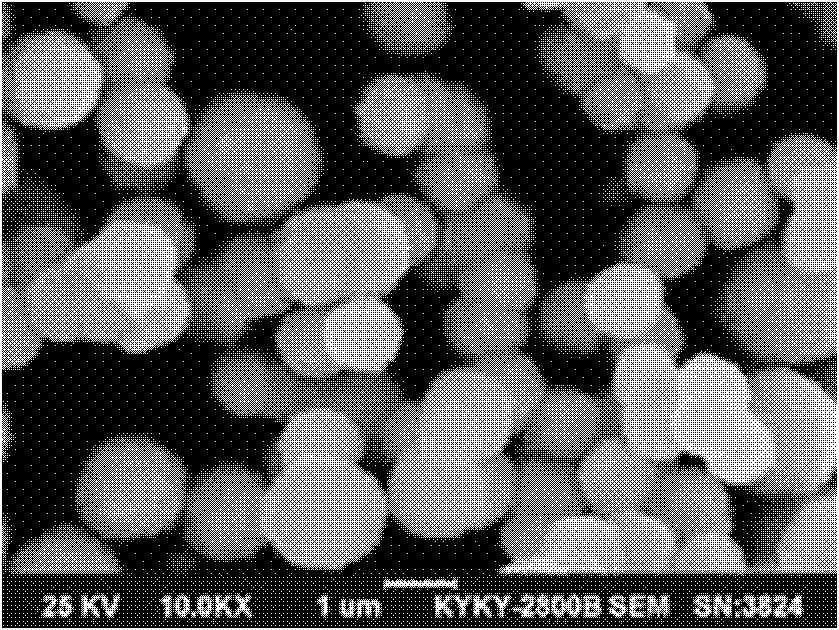

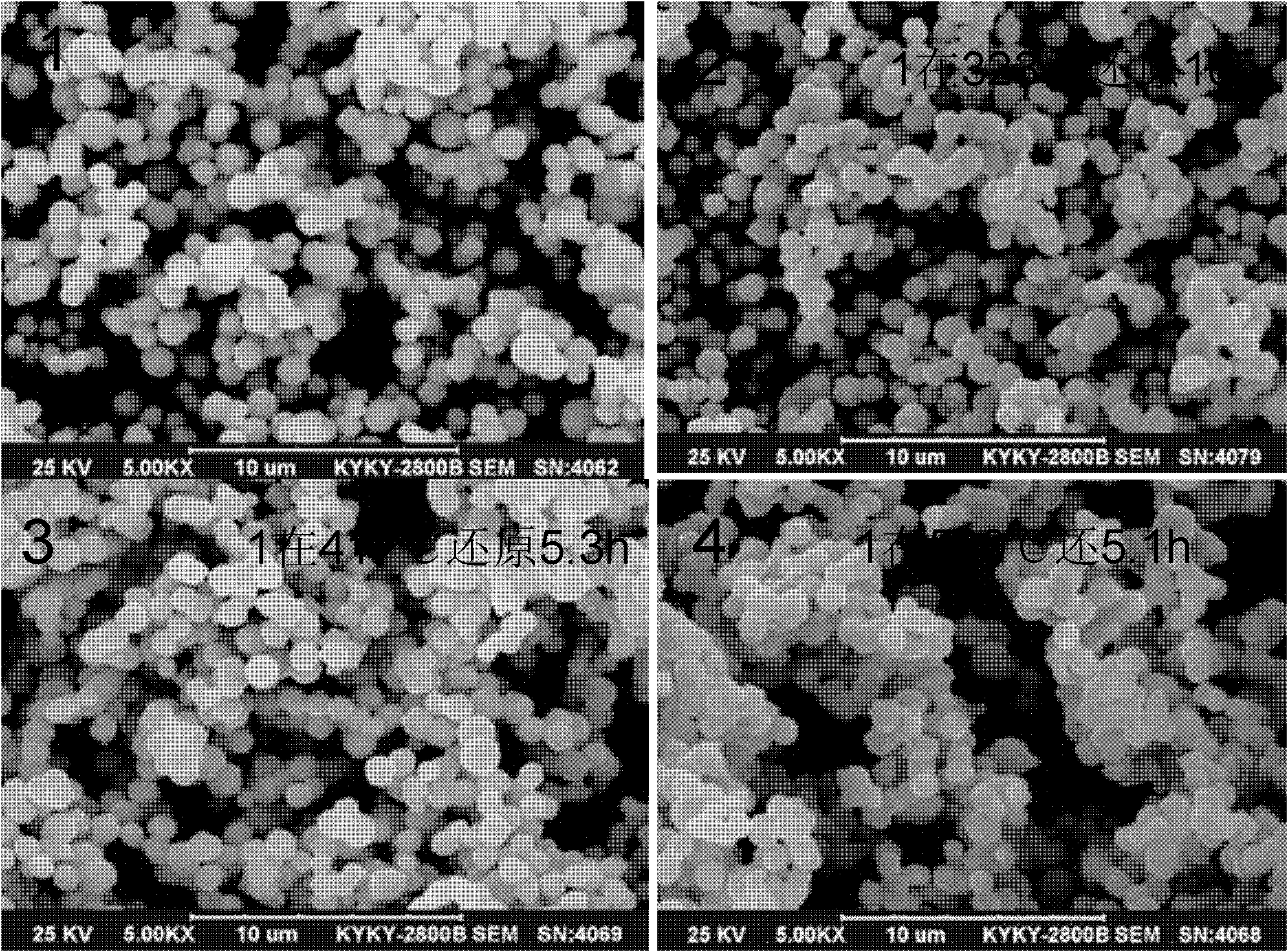

Method for preparing spherical cobalt powder

ActiveCN103128304AOmit the synthesis of Co(OH)

<sub>2</sub>

the process ofSimple processRefluxAlcohol reduction

The invention provides a method for preparing spherical cobalt powder. The method includes the following steps of mixing CoCL2.6H2O with polyhydric alcohols, adding alkali liquor, preparing mixed solutions with the cobalt concentration of 5-30g / L, heating for 196-198 DEG C, reflux carried out for 2-4 hours, suction filtration, washing, hydrogen drying and reduction under the temperature of 300-500 DEG C, and preparing the cobalt powder. According to the method, the cobalt salt CoCL2.6H2O is directly utilized to be reacted with the polyhydric alcohols to prepare the spherical cobalt powder, and consumed time is shortened by 40%-60% of the time of a traditional cobalt salt reduction method. According to the method, the polyhydric alcohols and the hydrogen drying and the reduction under a high temperature are adopted, not only is spherical appearance of the polyhydric alcohol reduction cobalt powder saved, but also purity of the cobalt powder is improved, under the condition that the cobalt concentration is up to 5-30g / L in an industrialized process, the prepared spherical cobalt powder has good appearance characteristics, the grain size of products can be controlled, and the cobalt conversion rate is up to more than 98%.

Owner:GEM CO LTD

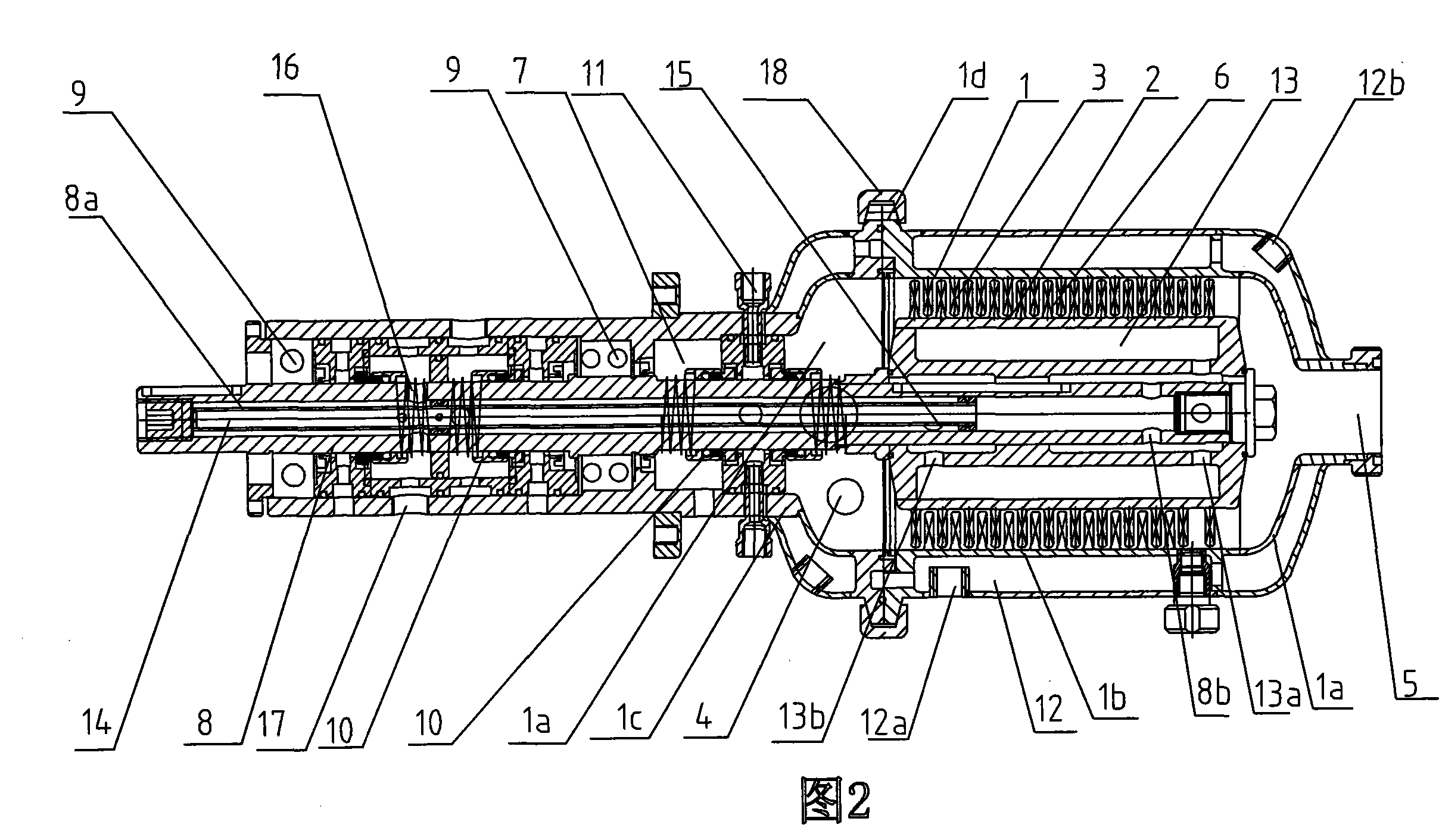

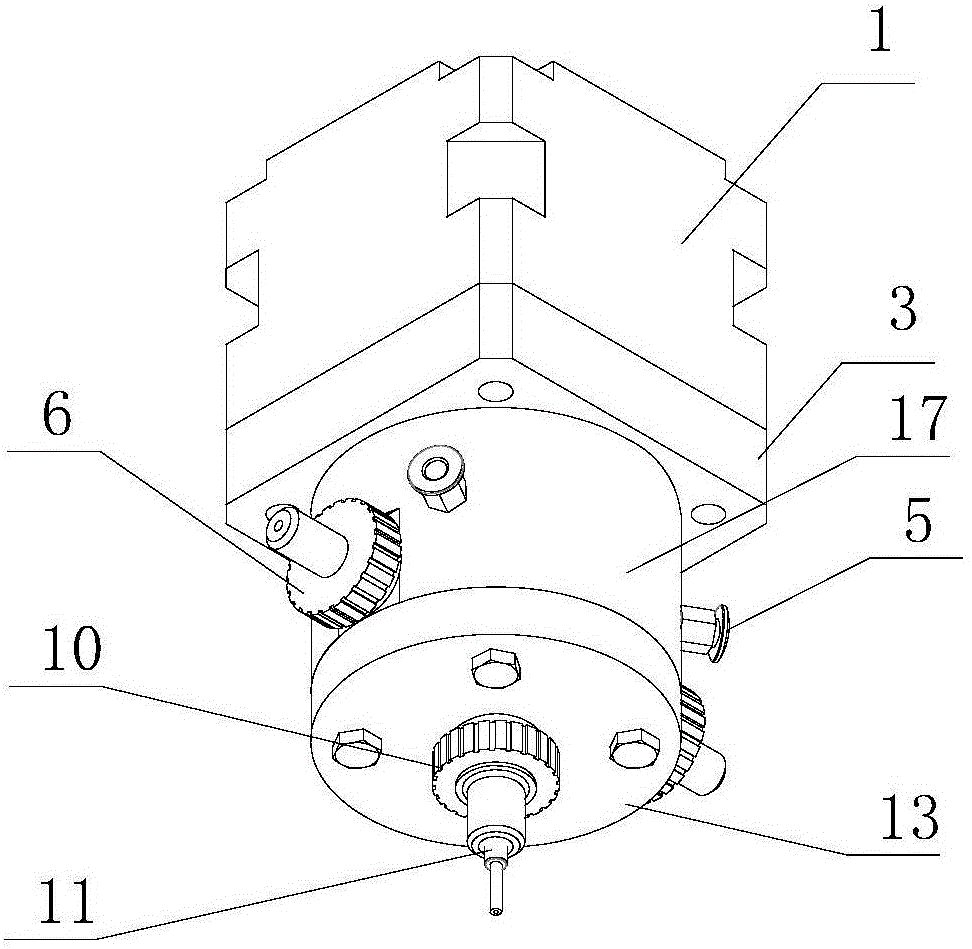

Dynamic cell printing micromixer

ActiveCN105854685AAvoid damageAccurate speed controlRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses a dynamic cell printing micromixer which comprises a mixer cavity with a discharge outlet in the bottom. The side wall of the mixer cavity is provided with at least two feed inlets. A stirrer is arranged in the mixer cavity. An adjustable-speed motor in linkage with the stirrer is installed outside the mixer cavity. Multiple guide grooves are formed in the periphery of the stirrer and attached to the inner side wall of the mixer cavity. The dynamic cell printing micromixer has the advantages of being good in biological compatibility, small in design size, easy to disassemble, assemble, sterilize and clean, convenient to integrate, high in mixing and response gradient, adjustable in stirring speed, small in damage to cell and the like, and has the wide prospect in the fields of medicine screening, gradient manufacturing, biological printing and the like.

Owner:ZHEJIANG UNIV

Complex formulation plant-growth regulator

InactiveCN107098776AEffective absorption and utilizationRich in nutrientsAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphateFlubendiamide

The invention provides a complex formulation plant-growth regulator. The complex formulation plant-growth regulator comprises the following components in parts by weight: 10-25 parts of urea, 20-30 parts of potassium chloride, 10-20 parts of potassium dihydrogen phosphate, 3-5 parts of brassinolide, 1-20 parts of vitamin, 0.2-0.5 parts of indole acetic acid, 0.5-10 parts of cloxyfonac, 5-20 parts of a cosolvent, 1-3 parts of flubendiamide, and the balance of water. The plant-growth regulator is prepared by the steps of burdening, mixing and concentrating, before application, water is used for diluting the plant-growth regulator, and a soil perfusion or leaves spraying method is employed for usage. The plant-growth regulator has the advantages of abundant nutrient composition and good mixing performance, can effectively adjust the growth of the crops, provides nutrient elements such as nitrogen, phosphor and potassium required by vegetation, increases the fruit setting rate, improves the fruit quality, increases the output, and has pesticides effect.

Owner:合肥龙滨化工科技有限公司

Organic titanium calcium fertilizer and preparation method thereof

InactiveCN102584485AHigh in calciumSimple and fast operationFertilizer mixturesDistilled waterTitanium

The invention discloses an organic titanium calcium fertilizer which is prepared by taking the following materials in proportion: 800-1200ml distilled water, 5-100g organic titanium chelate, 40-200g glucose, 0-80g humic acid, 900-1600g calcium acetate and 300-1000g EDDHA chelant. A preparation method thereof comprises the following steps: 1) adding all components in proportion into distilled water, and stirring, thereby obtaining a uniform solution; 2) heating the solution at 40-65 DEG C for 1-2 hours; 3) reacting for 2-4 hours at 40-50 DEG C; and 4) after completely reacting, cooling for 1-1.5 hours, thereby obtaining the organic titanium calcium fertilizer. According to the physiological chrematistics and calcium-absorbing chrematistics of crops, the organic titanium chelate and the matters containing calcium ions are mixed, and then organic matters are added, and the chelation is further performed, so as to form a water-soluble active calcium, so that the organic titanium calcium fertilizer is suitable for fruit trees, vegetables and calcium-loving crops for efficiently absorbing calcium and overcomes the acalcicosis.

Owner:徐伟

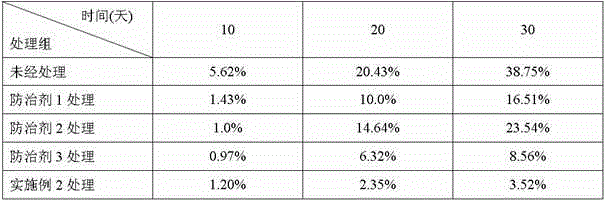

Export ficus microcarpa disease control agent and using method of export ficus microcarpa disease control agent

The invention discloses an export ficus microcarpa disease control agent and a using method of the export ficus microcarpa disease control agent. Aiming at the occurrence and development of ficus microcarpa diseases caused by fungi and bacteria, by taking mancozeb, alkali type copper sulfate and carbendazim as main raw materials of the disease control agent, ficus microcarpa is cleaned, diluted, soaked and packaged into cases for export. The export ficus microcarpa disease control agent disclosed by the invention adopts a simple formula and is convenient to use, and can kill bacteria and fungi, and also can enhance the resistance of plants to diseases, under the combined action of three raw materials, the sterilization effect is thorough, and the prevention effect is good; by utilizing the disease control agent disclosed by the invention for treating the export ficus microcarpa, the growth of harmful organisms in the ficus microcarpa can be effectively prevented, the occurrence of diseases can be reduced, and the success rate of export can be significantly increased.

Owner:FUJIAN AGRI & FORESTRY UNIV

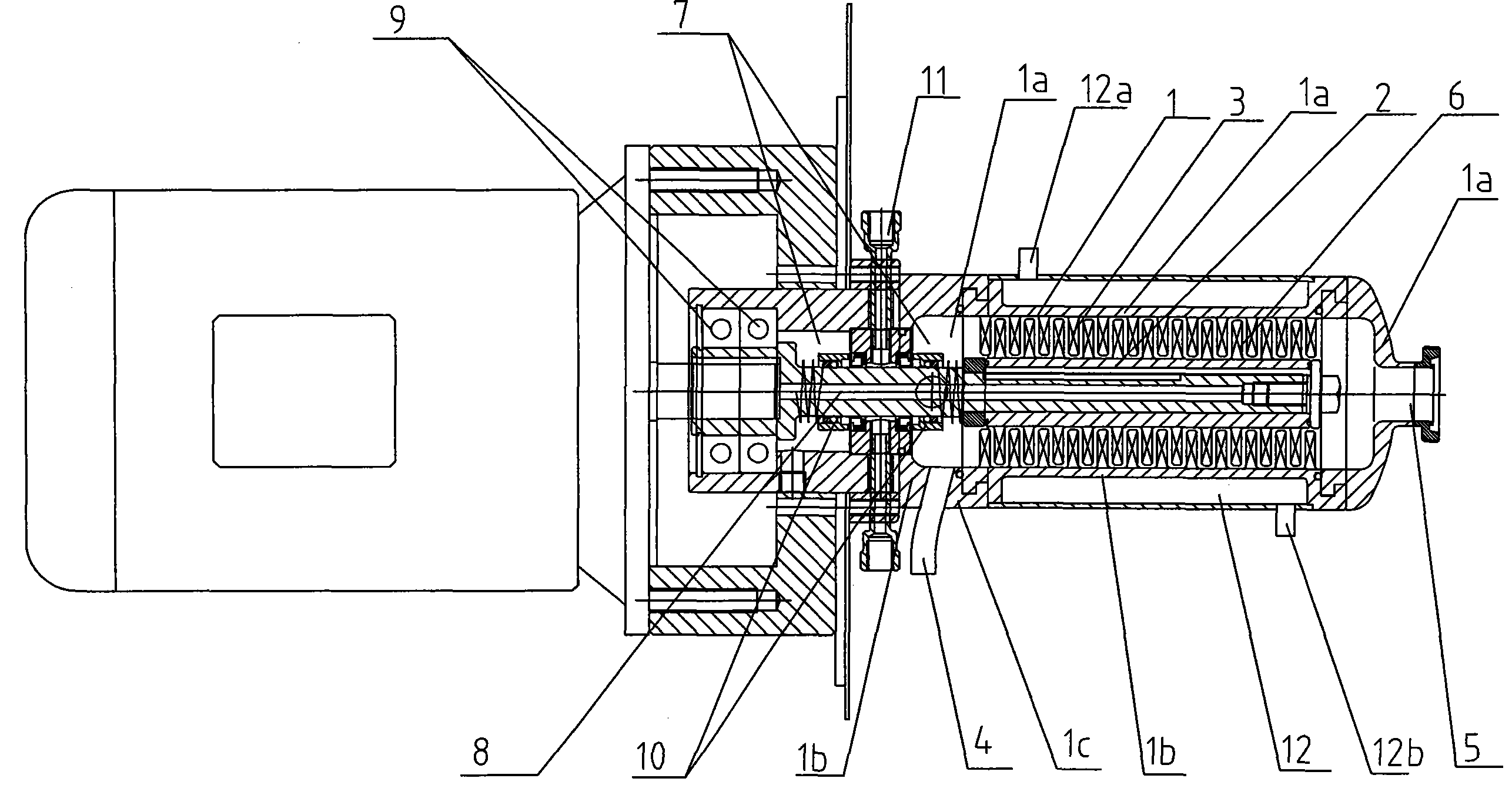

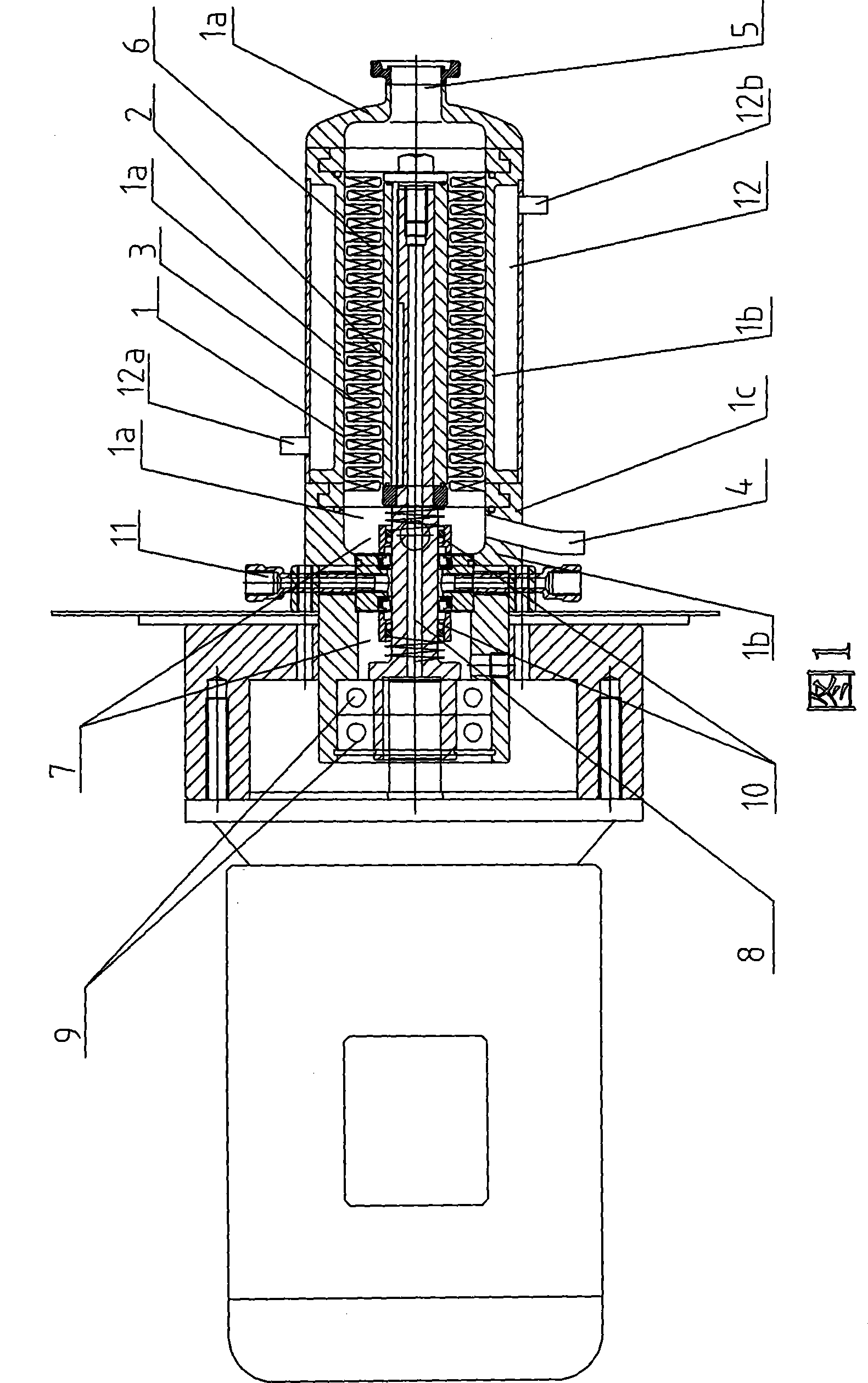

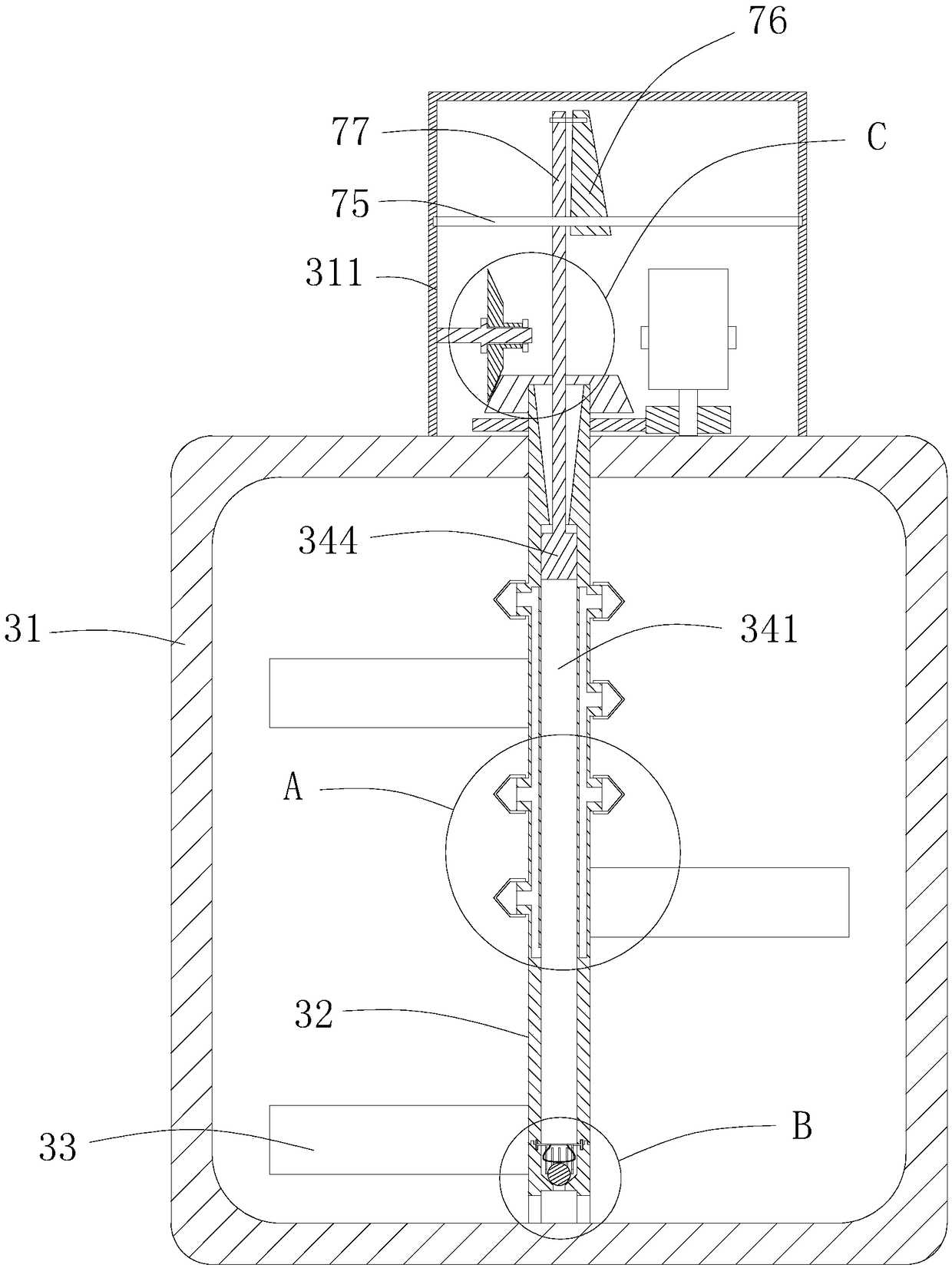

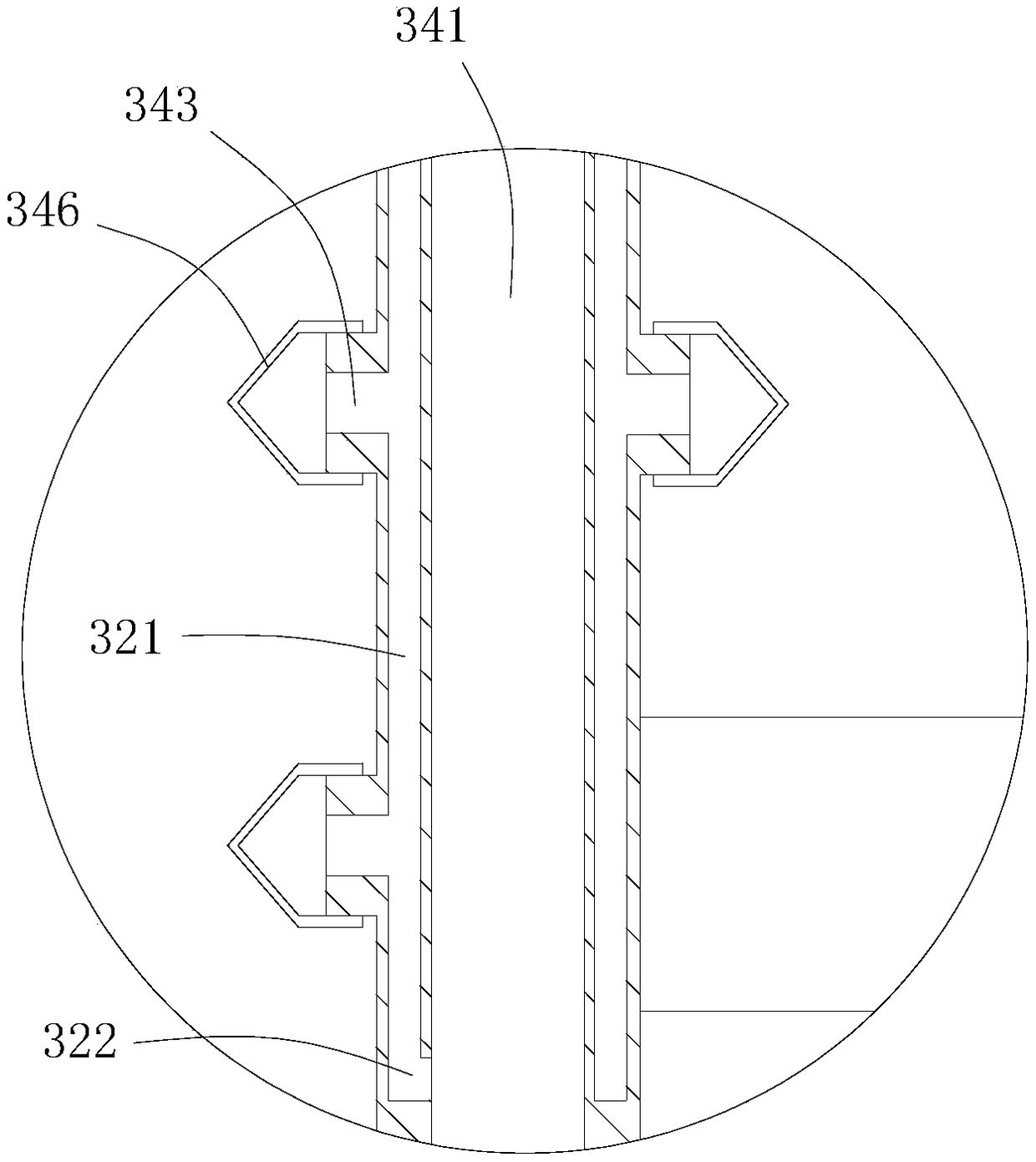

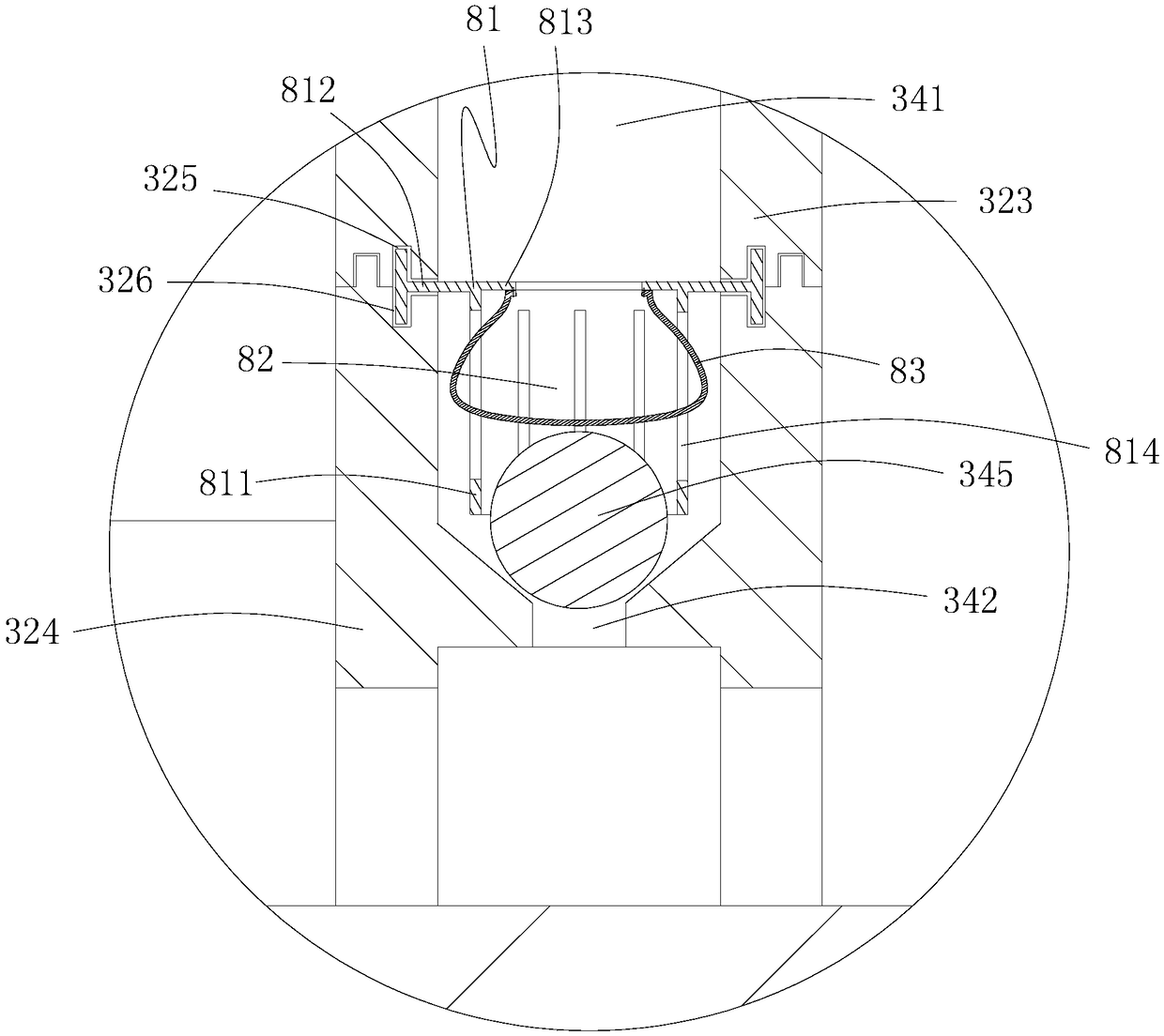

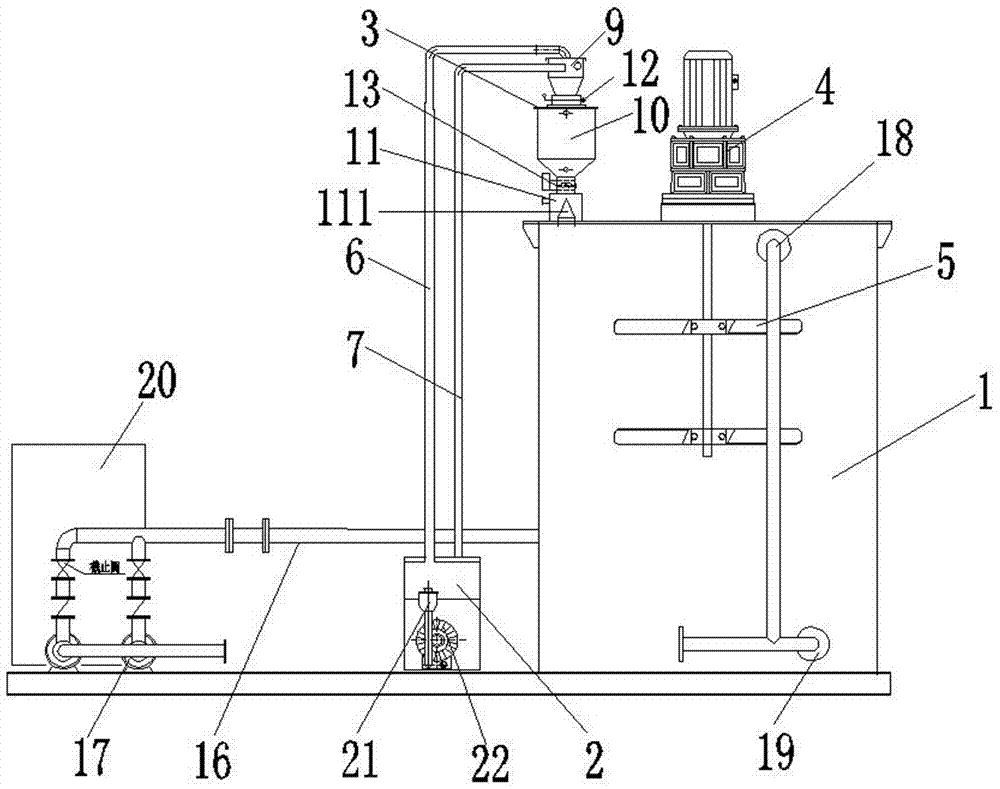

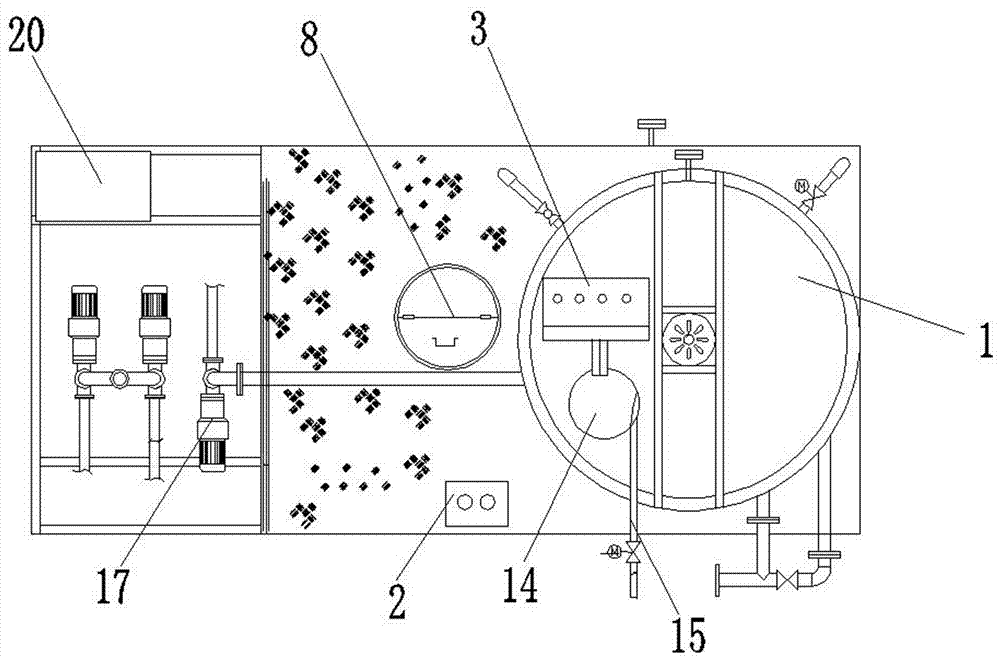

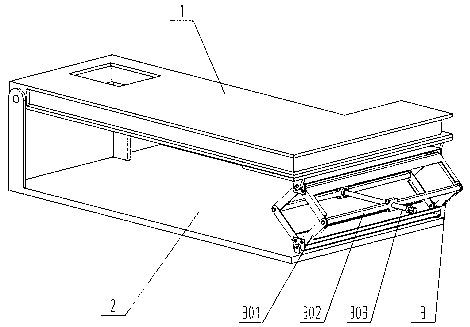

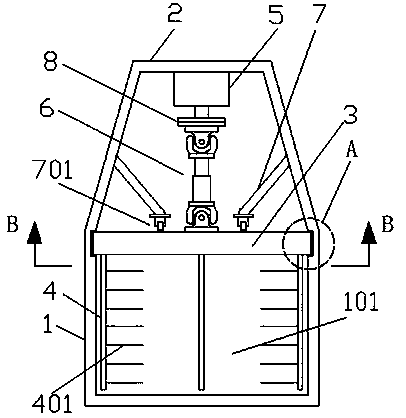

Smart PAM dosing device

PendingCN107963707AGood mixabilityReduce energy consumptionRotary stirring mixersTransportation and packagingFrequency conversionEngineering

The invention discloses a smart PAM dosing device. The device comprises a stirring barrel, a vacuum main machine and an automatic feeding machine, the center of the top of the stirring barrel is provided with a deceleration motor, the lower end of the deceleration motor is connected to a mixer blade inside the stirring barrel, the automatic feeding machine is arranged at the top of the stirring barrel, the automatic feeding machine is respectively connected to the vacuum main machine and a material cabin through a gas suction hose and a material suction hose, the automatic feeding machine is orderly provided with a feeding inlet, the material storage cabin and a feeding inlet from top to bottom, a vacuum controller is arranged between the feeding inlet and the material storage cabin, a frequency conversion speed regulating feeding valve is arranged between the material storage cabin and the feeding inlet, the bottom of the feeding inlet is communicated with the top of the stirring barrel, a feed diluting device is arranged at the top of the stirring barrel, the feed diluting device is connected to the automatic feeding machine, a water inlet pipe is arranged in one side of the feeddiluting device and the stirring barrel is connected to a PAM dosing screw pump through a discharge pipe.

Owner:宜兴市江华环保科技有限公司

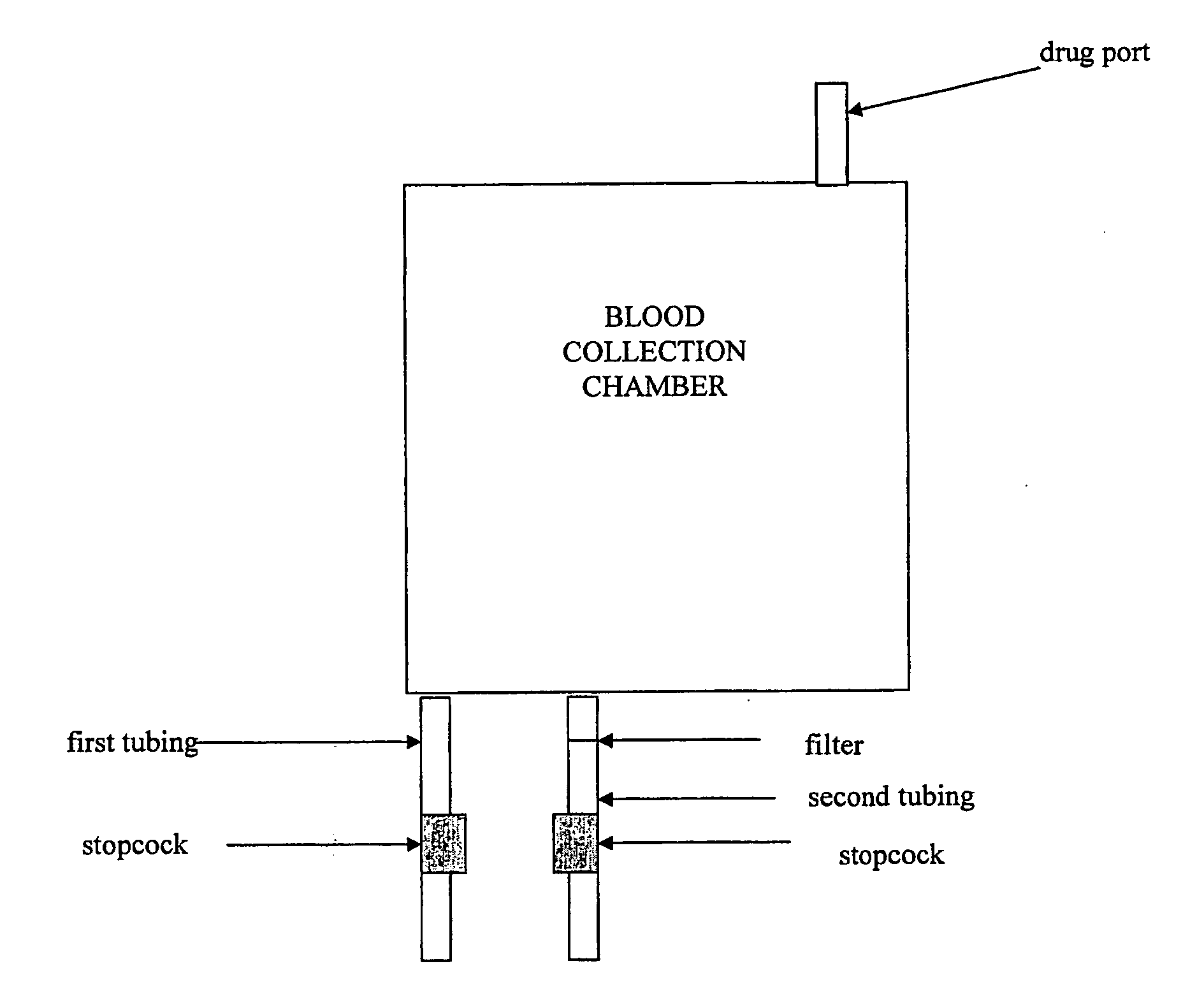

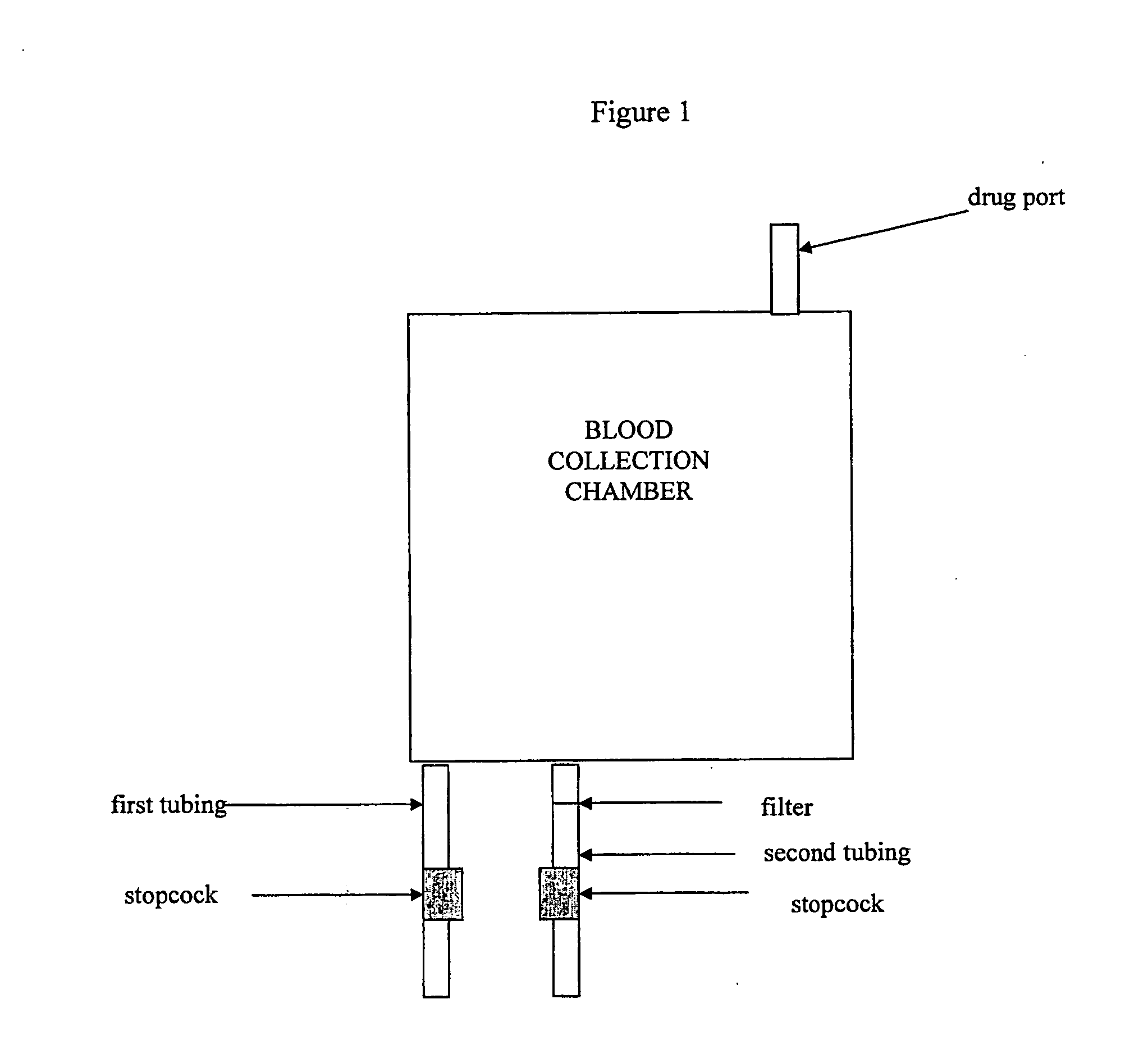

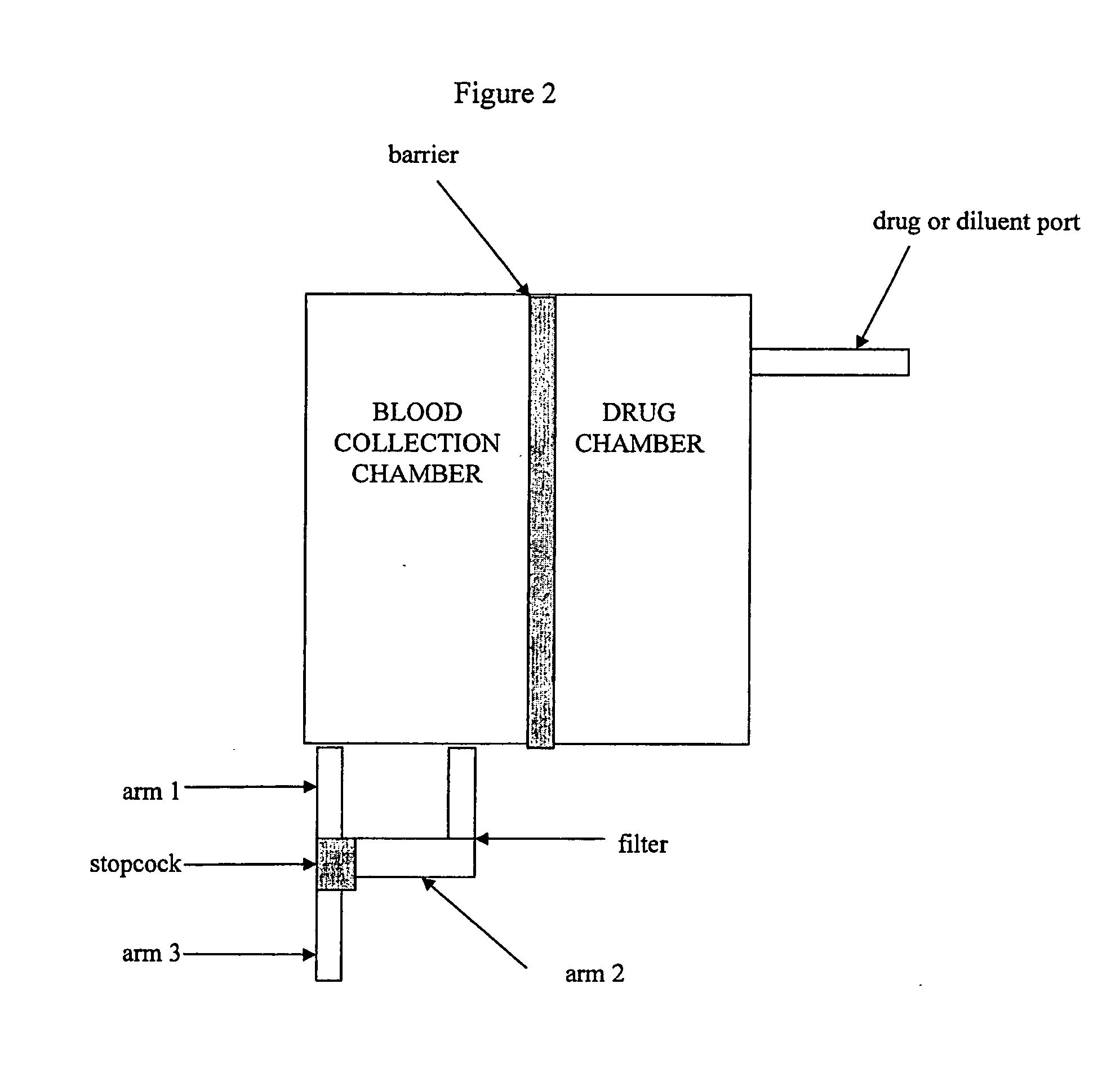

Device for using patient blood as diluent in administering pharmaceuticals

InactiveUS20050148991A1Less irritatingReduce painOther blood circulation devicesDiagnosticsDiluentSurgery

The subject invention comprises an apparatus and a method for administering a pharmaceutical to a patient by collecting the patient's blood in a collection chamber and adding the drug thereto, followed by re-infusing the blood admix to the patient. The administration may be carried out on a batch or continuous basis.

Owner:ALLOS THERAPEUTICS

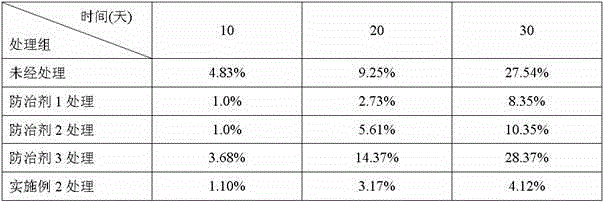

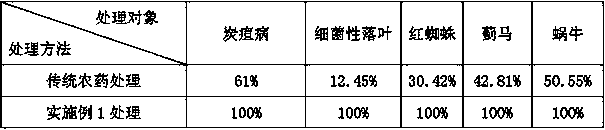

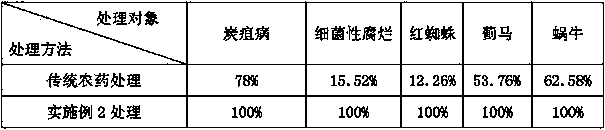

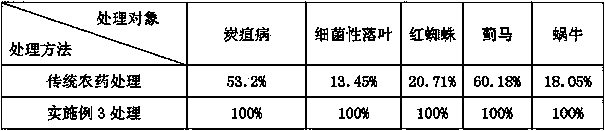

Pesticide preparation for removing diseases and insect pests of export pot flowers and application method of pesticide preparation

The invention discloses a pesticide preparation for removing diseases and insect pests of export pot flowers and an application method of the pesticide preparation. The pesticide preparation comprises the following raw material components: basic chrome sulphate, carbendazol, metalaxyl and dichlorvos; bare-root seedlings of the pot flowers are pre-processed, diluted, soaked and incased for export. The pesticide preparation has the effects of sterilization and deinsectization; the combined action of the four raw material components facilitates a relatively complete sterilization effect and a relatively good prevention effect; the pesticide preparation has wide applicable targets, can effectively remove quarantine diseases and insect pests of the export pot flowers, and remarkably improves the success rate for export.

Owner:FUJIAN AGRI & FORESTRY UNIV

Compound pesticide for preventing aphis pomi and preparation method thereof

InactiveCN104904740AOvercome the disadvantage of no systemicExtend your lifeBiocideAnimal repellantsAphis pomiBULK ACTIVE INGREDIENT

The invention belongs to the technical field of compound pesticide and in particular relates to a compound pesticide for preventing aphis pomi and a preparation method of the compound pesticide. Pymetrozine and bifenthrin are used as active ingredients to be prepared into the compound pesticide; the compound pesticide prepared from pymetrozine and bifenthrin which are used as active ingredients can overcome the situations that the existing pesticides for preventing aphis pomi are diverse, are used disorderedly, and have poor prevention effect; the pesticide effects of pymetrozine and bifenthrin are improved, the spraying frequency is reduced, the resistance is delayed, the variety life is prolonged and the environment pollution is relieved.

Owner:INST OF PLANT PROTECTION SHANDONG ACAD OF AGRI SCI

Mixing device for agricultural microbial fertilizer production

ActiveCN110479165AAdjustable installation angleImprove liquidityRotating receptacle mixersTransportation and packagingAgricultural engineeringMixing effect

The invention provides a mixing device for agricultural microbial fertilizer production. The mixing device comprises a mixer main body; a group of bases are hinged to the bottom of the mixer main body; and the left end surface of the stirring and mixing shaft is in threaded connection with a group of adjusting bolts. According to the device, the mixer main body is supported by adopting the telescopic angle adjusting device, so that the mounting angle of the mixer main body is convenient to adjust; during use, the mounting angle of the mixer main body can be adjusted according to material characteristics, so that good fluidity of the material is achieved and mixing effect is enhanced; meanwhile, a sliding shaft capable of sliding is adopted; and the gear rack transmission mechanism drives the stirring and mixing paddle to swing, so that the mounting angle of the stirring and mixing paddle can be adjusted according to material characteristics in use; the stirring capacity and the pushingcapacity of the stirring and mixing paddle to materials are changed, the stirring and mixing effect is improved, good fluidity of the materials is guaranteed, and the mixing effect and the mixing efficiency can be greatly improved.

Owner:INST OF SOIL FERTILIZER & ENVIRONMENT RESOURCE HEILONGJIANG ACADEMY OF AGRI SCI

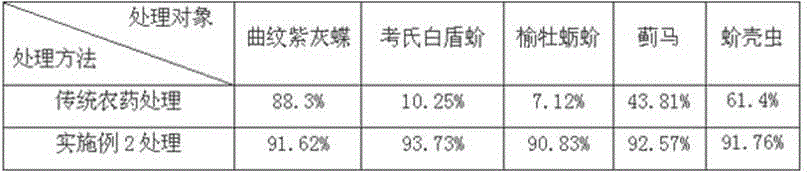

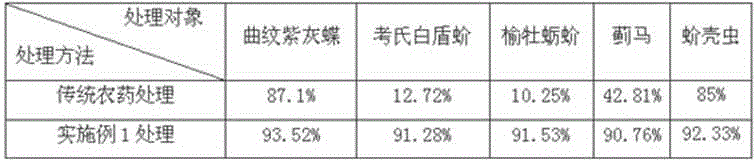

Major pest control agent for cycads

The invention discloses a major pest control agent for cycads and belongs to the field of agricultural production. The major pest control agent for cycads comprises effective active components: 4.5 to 7.5% carbofuran and 15 to 25% of imidacloprid. The agent is used for the cycads and can effectively control cycad pests such as chilades pandava, pseudaulacaspis cockerelli, lepidosaphesulmi linnaeus and thrips.

Owner:FUJIAN AGRI & FORESTRY UNIV

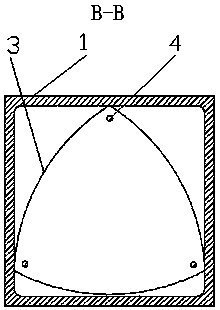

Material mixing device

PendingCN111013433AImprove effective utilizationReduce stirring dead angleRotary stirring mixersTransportation and packagingSquare cross sectionEngineering

The invention discloses a material mixing device, and belongs to the technical field of material processing equipment. The material mixing device is provided with a main body structure which is used for stirring and mixing, wherein the main body structure is of a rectangular tank body with a square cross section; compared with a traditional cylindrical stirring barrel, the material mixing device is larger in volume and single-time stirring amount when the occupied area with the same length and width is occupied; in order to stir the interior of the material mixing device more comprehensively,and avoid stirring blind angles, a Wankel rotor is arranged at the top of the rectangular tank body in a movably manner; the Wankel rotor can perform eccentric rotary motion in a square sliding groovewith the same shape of the rectangular tank body at the top of the rectangular tank body; therefore, the three corners can slide around the edge of a rectangular stirring and mixing chamber; stirringrods arranged at the three corners of the rectangular stirring and mixing chamber can be driven to slide in a square surrounding mode, the problems, that the stirring rods cannot be contacted with the four right-angle inner walls of the rectangular stirring and mixing chamber, and stirring blind angles are generated, are solved, and the stirring and mixing effect is still considerable while the space effective utilization rate is increased.

Owner:广州市浩恒建材科技有限公司

Disinsection emulsion in water containing avermectin

The present invention discloses an insecticidal aqueous emulsion containing abamectin. Its composition contains (by wt%) abamectin 0.1-5%, emulsifier 5-25%, antifreezing agent 1-5%, defoaming agent 0.05-0.2%, solvent 3-35%, thickening agent 0.5-1% and the rest is water. It can be extensively used for killing antagonistical pests of cabbage moth, leaf miner and red mite, etc. on the vegetables, tangerine and cotton, etc.

Owner:HEBEI VEYONG BIO CHEM

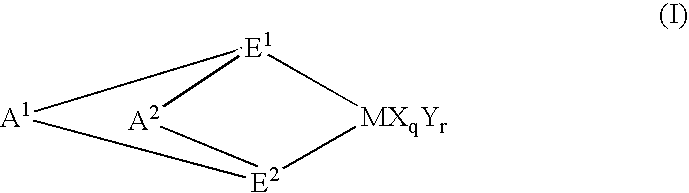

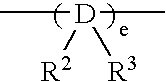

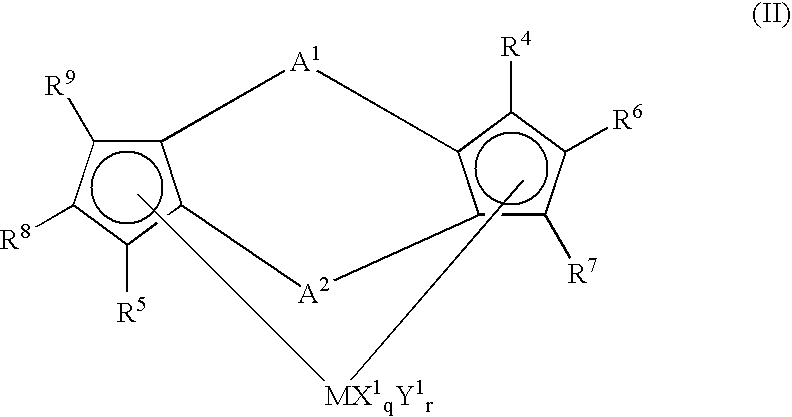

Higher olefin polymer having polar group and process for producing the same

A higher olefin polymer having a polar group which is produced by subjecting to an incorporation reaction of a polar compound or halogen compound into a higher α-olefin polymer satisfying the requirements of the following (1) and (2), which is obtained by polymerizing one or more higher α-olefins having 10 or more carbon atoms or copolymerizing one or more higher α-olefins having 10 or more carbon atoms with one or more other olefins and a method for producing a higher olefin polymer having a polar group which is obtained by polymerizing one or more higher α-olefins having 10 or more carbon atoms or copolymerizing one or more higher α-olefins having 10 or more carbon atoms with one or more other olefins to form a higher α-olefins polymer satisfying the requirements of the following (1) and (2) and subsequently subjecting to an incorporation reaction of a polar compound or halogen compound into the higher α-olefin polymer. (1) The content of units of a higher α-olefins having 10 or more carbon atoms is 50 mol % or more. (2) A single peak X1 which is ascribed to the side chain crystallization and observed at 15 deg<2θ<30 deg in a wide-angle X-ray scattering intensity distribution is observed.

Owner:IDEMITSU KOSAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com