Instant soluble leaf-surface sprayed boric fertilizer and its production method

A technology of foliar spraying and production method, which is applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of inappropriate pH, inconvenient agricultural production, low absorption rate, etc., and achieves green, safe solubility and good mixability , the effect of high absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

[0026] 1, powder process of the present invention:

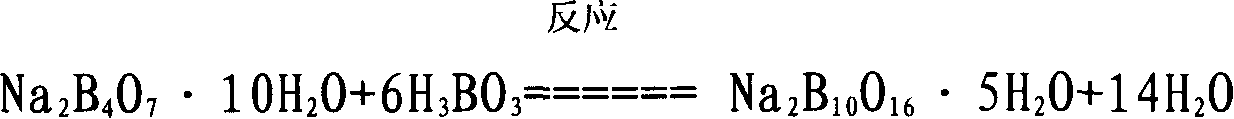

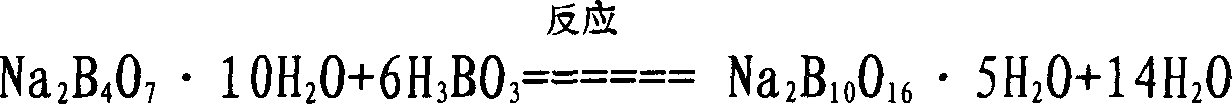

[0027] Take 50 parts by weight of borax and 50 parts by weight of boric acid and mix them evenly, add 20 parts by weight of water, heat at 150 degrees centigrade and react for 30 minutes. Cool the product to 70 degrees Celsius, add 0.1 parts by weight of dodecylbenzenesulfonic acid, stir evenly, keep the temperature at 90 degrees Celsius, send the liquid into a high-speed centrifugal dryer for drying through a suction pump, and control the inlet temperature to 400 degrees Celsius. The outlet temperature is 170 degrees centigrade, and after cooling, a powder product is obtained, and the pure boron content is greater than 20%.

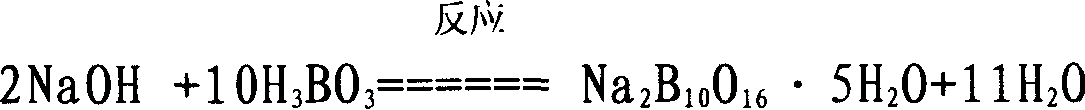

[0028] Alternatively, mix 11 parts by weight of sodium hydroxide and 89 parts by weight of boric acid, add 20 parts by weight of water, and heat at 130 degrees Celsius for 30 minutes. Cool the product to 70 degrees Celsius, add 0.1 parts by weight of calcium dodecylbenzenesulfonate, stir evenly, keep ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com