Mixing device for preparation of artworks by re-processing of solid wastes

A solid waste and mixing device technology, which is applied to mixers with rotating stirring devices, mixers, shaking/oscillating/vibrating mixers, etc., can solve problems such as difficult recovery, reduce equipment energy consumption, and improve quality , Improve the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

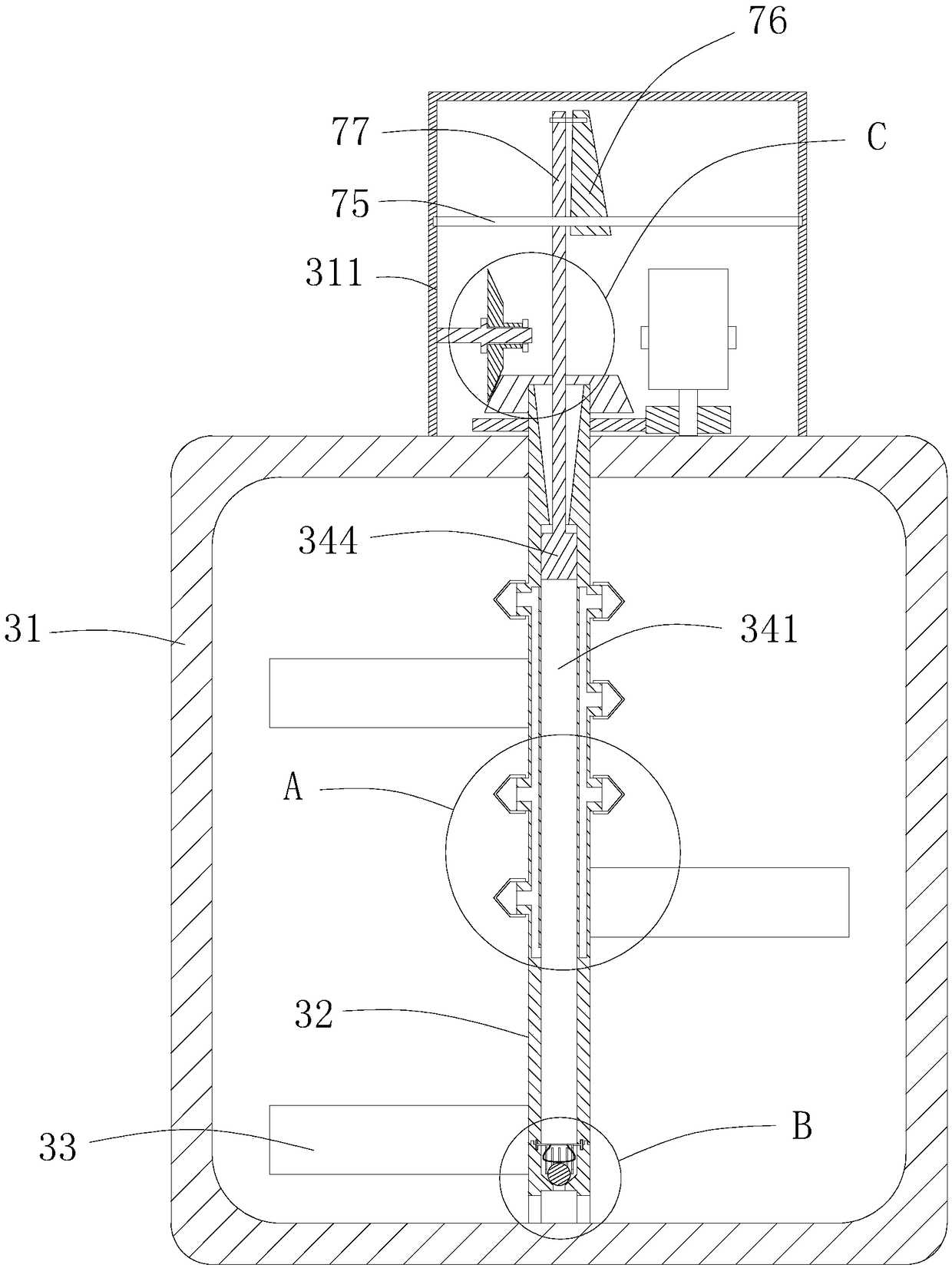

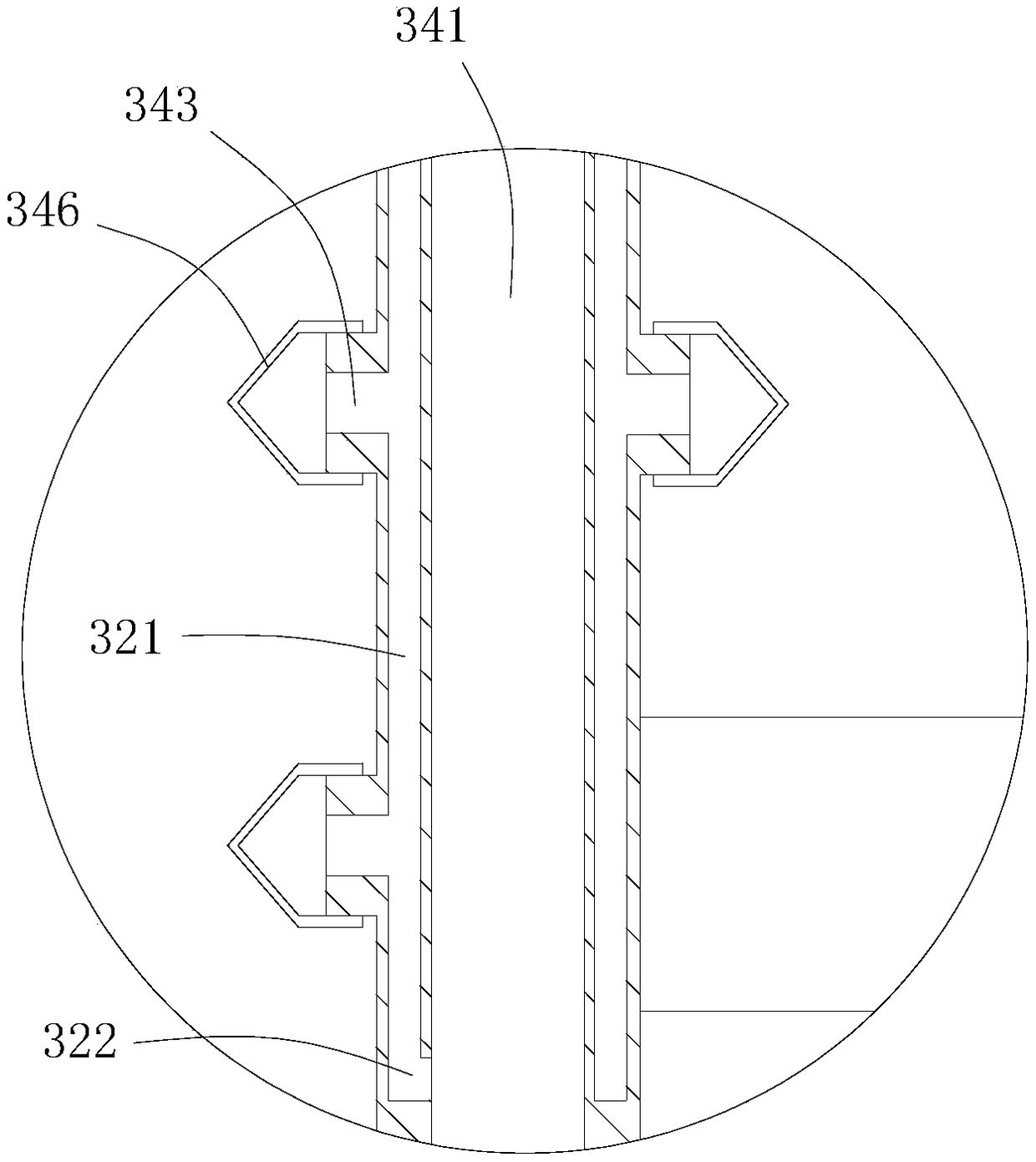

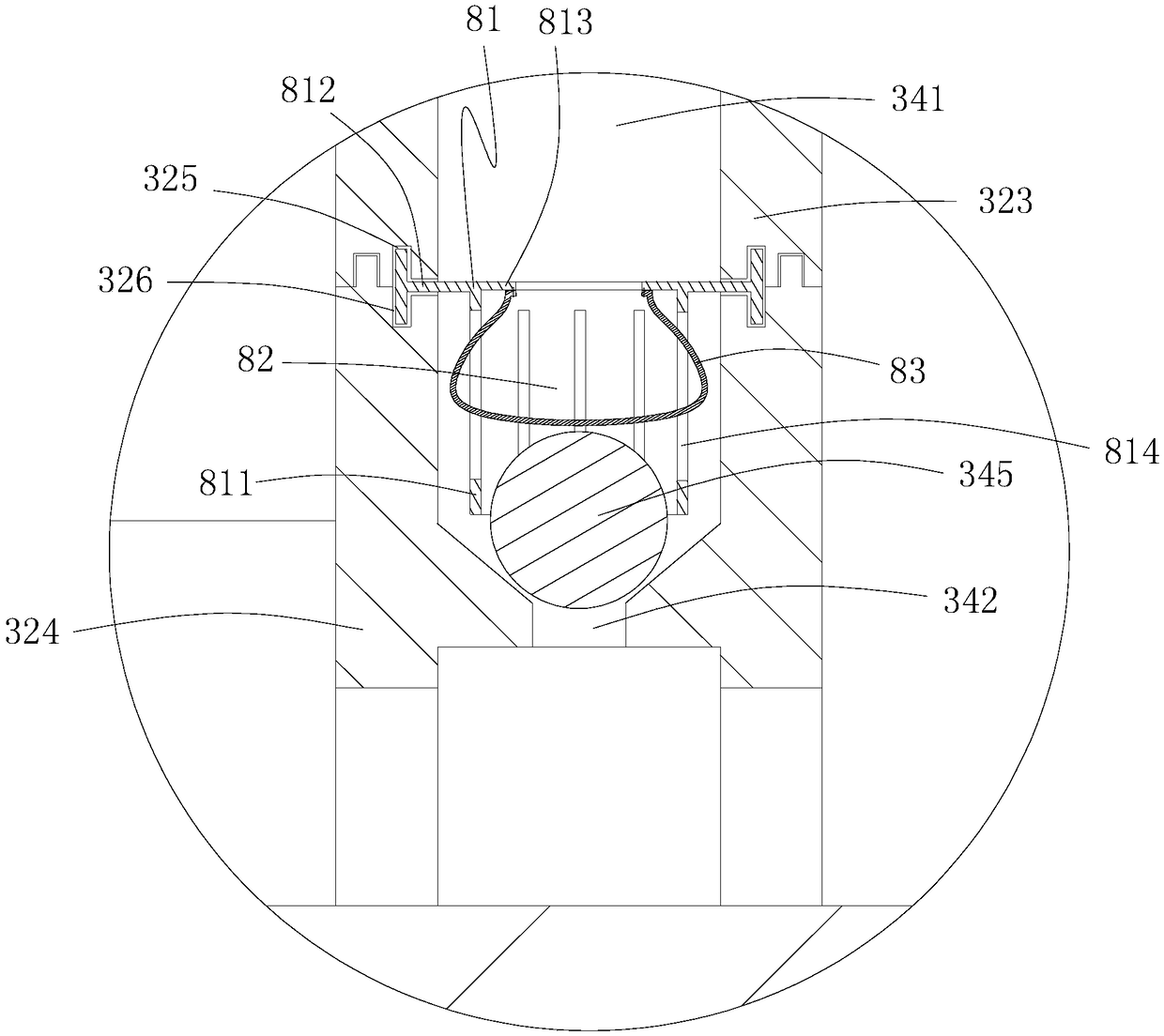

[0026] Such as Figure 1-5 As shown, a mixing device for reprocessing solid waste to prepare handicrafts is used to mix powdered materials obtained by crushing and grinding solid waste with kaolin and porcelain stone powder to prepare porcelain clay; specifically, it includes a mixing chamber 31 , a rotatable stirring shaft 32 disposed in the mixing chamber, a stirring paddle 33 disposed on the stirring shaft, a drive member for driving the stirring shaft to rotate, a material transported to the top of the mixing chamber 31 for transporting the material in the mixing chamber 31 bottom A homogenizing part and a reset part; the driving part is a motor arranged on the upper oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com