Waterproof early-strength decoration mortar and preparation method thereof

A decorative mortar and cement technology, applied in the field of building materials, can solve the problems of low strength, single color, heavy self-weight of ordinary mortar, etc., and achieve the effects of excellent waterproofness, effective waterproofing, and enhanced strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

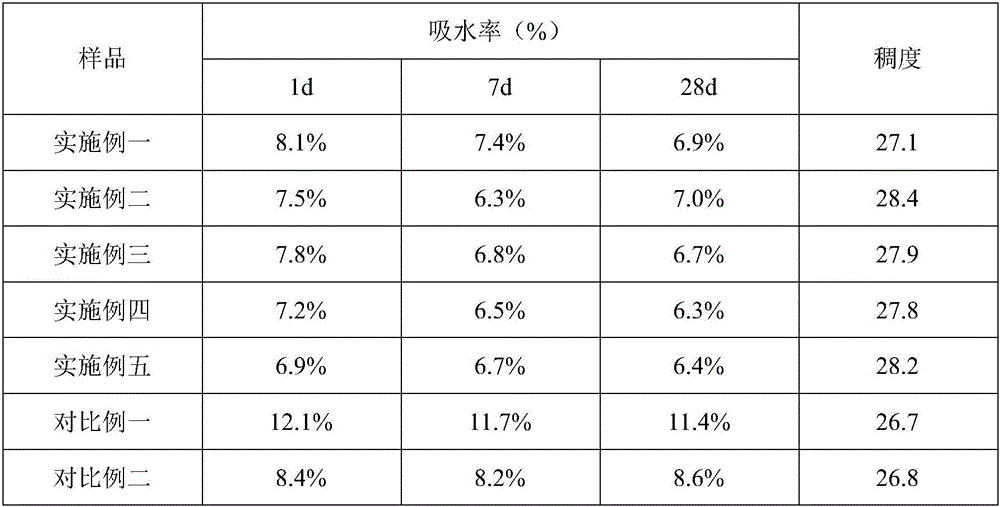

Embodiment 1

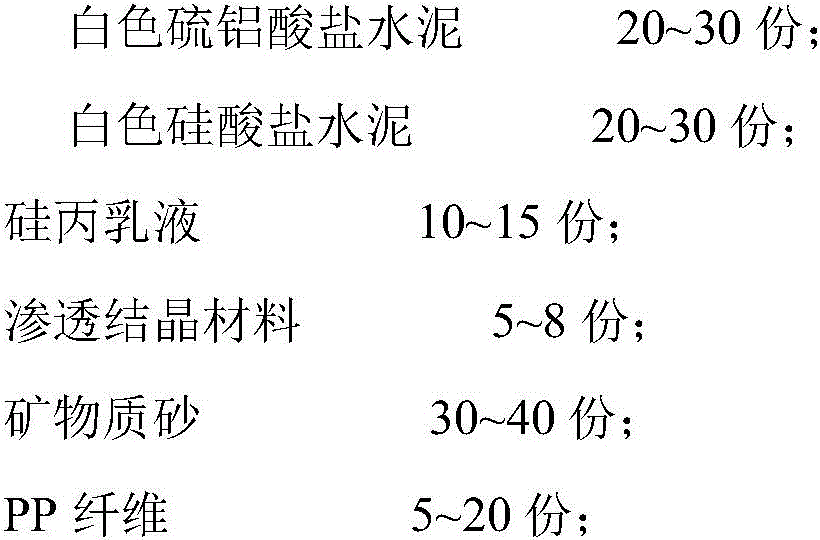

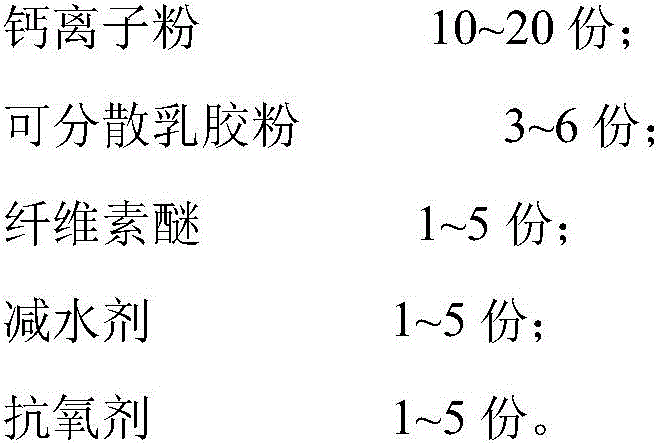

[0037] (1) According to 20 parts of white sulphoaluminate cement, 20 parts of white Portland cement, 10 parts of silicon-acrylic emulsion, 5 parts of osmotic crystallization material, 30 parts of mineral sand, 5 parts of PP fiber, and 3 parts of dispersible latex powder , 1 part of cellulose ether, 1 part of water reducing agent, and 1 part of antioxidant are mixed together, and stirred at a low speed for 30 seconds;

[0038] (2) Add 10 parts of water and stir rapidly for 90s.

Embodiment 2

[0040] (1) According to 20 parts of white sulphoaluminate cement, 20 parts of white Portland cement, 10 parts of silicon-acrylic emulsion, 5 parts of osmotic crystallization material, 30 parts of mineral sand, 5 parts of PP fiber, and 3 parts of dispersible latex powder , 10 parts of calcium ion powder, 1 part of cellulose ether, 1 part of water reducer, 1 part of antioxidant for batching, and stir at low speed for 30s;

[0041] (2) Add 10 parts of water and stir rapidly for 90s.

Embodiment 3

[0043] (1) According to 23 parts of white sulphoaluminate cement, 23 parts of white Portland cement, 12 parts of silicon-acrylic emulsion, 6 parts of osmotic crystallization material, 33 parts of mineral sand, 9 parts of PP fiber, and 4 parts of dispersible latex powder , 13 parts of calcium ion powder, 2 parts of cellulose ether, 2 parts of water reducer, 2 parts of antioxidant for batching, and stir at low speed for 30s;

[0044] (2) Add 10 parts of water and stir rapidly for 90s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com