High-density concrete and preparation method thereof

A dense concrete and ultra-fine cement technology, applied in the field of concrete, can solve the problems of easy erosion and freeze-thaw damage, low concrete density, etc., and achieve the effect of reducing water permeability coefficient, reducing porosity and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

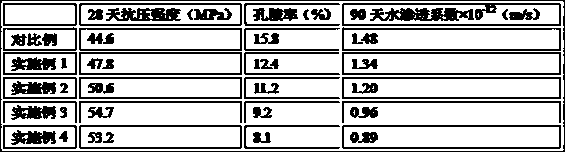

Examples

Embodiment 1

[0026] (1) Preparation of superfine cement: Mix 400 parts by weight of ordinary cement, 50 parts by weight of sericite powder, 5 parts by weight of sodium stearate and 40 parts by weight of beet pulp, and grind them in a ball mill for 20 minutes to obtain superfine cement. The fineness of cement is 600m 2 / kg. The cement used is Portland cement with a fineness of 320m 2 / kg. The pear pomace used is the dry residue left after extracting pear juice, with a fineness of 500m 2 / kg, the sugar content is 2%.

[0027] (2) Preparation of modified gangue: Grind the gangue to a fineness of 300m 2 / kg, soak in 30% sodium hydroxide solution for 8 hours, rinse and dry. Then calcined at 550° C. for 4 hours to obtain modified coal gangue.

[0028] (3) Preparation of pore blocking agent: Mix 300 parts by weight of water-soluble polyurethane, 60 parts by weight of ethyl acetate, 5 parts by weight of 2,4-dihydroxybenzamide and 55 parts by weight of carboxymethylcellulose.

[0029] (4) Pr...

Embodiment 2

[0031] (1) Preparation of superfine cement: Mix 450 parts by weight of ordinary cement, 30 parts by weight of sericite powder, 10 parts by weight of sodium stearate and 40 parts by weight of beet pulp, and grind them in a ball mill for 40 minutes to obtain superfine cement. The fineness of cement is 700m 2 / kg. The cement used is Portland cement with a fineness of 350m 2 / kg. The pear pomace used is the dry residue left after extracting pear juice, with a fineness of 600m 2 / kg, the sugar content is 5%.

[0032] (2) Preparation of modified gangue: Grind the gangue to a fineness of 345m 2 / kg, soak in 30% sodium hydroxide solution for 12 hours, rinse and dry. Then calcined at 750° C. for 2 hours to obtain modified coal gangue.

[0033] (3) Preparation of pore blocking agent: Mix 340 parts by weight of water-soluble polyurethane, 85 parts by weight of ethyl acetate, 10 parts by weight of 2,4-dihydroxybenzamide and 40 parts by weight of carboxymethyl cellulose.

[0034] (4...

Embodiment 3

[0036] (1) Preparation of ultra-fine cement: Mix 410 parts by weight of ordinary cement, 35 parts by weight of sericite powder, 7 parts by weight of sodium stearate and 50 parts by weight of beet pulp, and grind them in a ball mill for 25 minutes to obtain superfine cement. The fineness of cement is 677m 2 / kg. The cement used is Portland cement with a fineness of 321m 2 / kg. The pear pomace used is the dry residue left after extracting the pear juice, with a fineness of 550m 2 / kg, the sugar content is 3%.

[0037] (2) Preparation of modified gangue: Grind the gangue to a fineness of 320m 2 / kg, soak in 30% sodium hydroxide solution for 9 hours, rinse and dry. Then calcined at 590° C. for 2.5 hours to obtain modified coal gangue.

[0038] (3) Preparation of pore blocking agent: Mix 320 parts by weight of water-soluble polyurethane, 70 parts by weight of ethyl acetate, 7 parts by weight of 2,4-dihydroxybenzamide and 45 parts by weight of carboxymethyl cellulose.

[0039...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com