Expansive soil tunnel supporting structure and method

A support structure and expansive soil technology, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as expansion, contraction, deformation, damage, etc., to prevent excessive grouting pressure, low economic cost, and reduce water and mud gushing The effect of the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

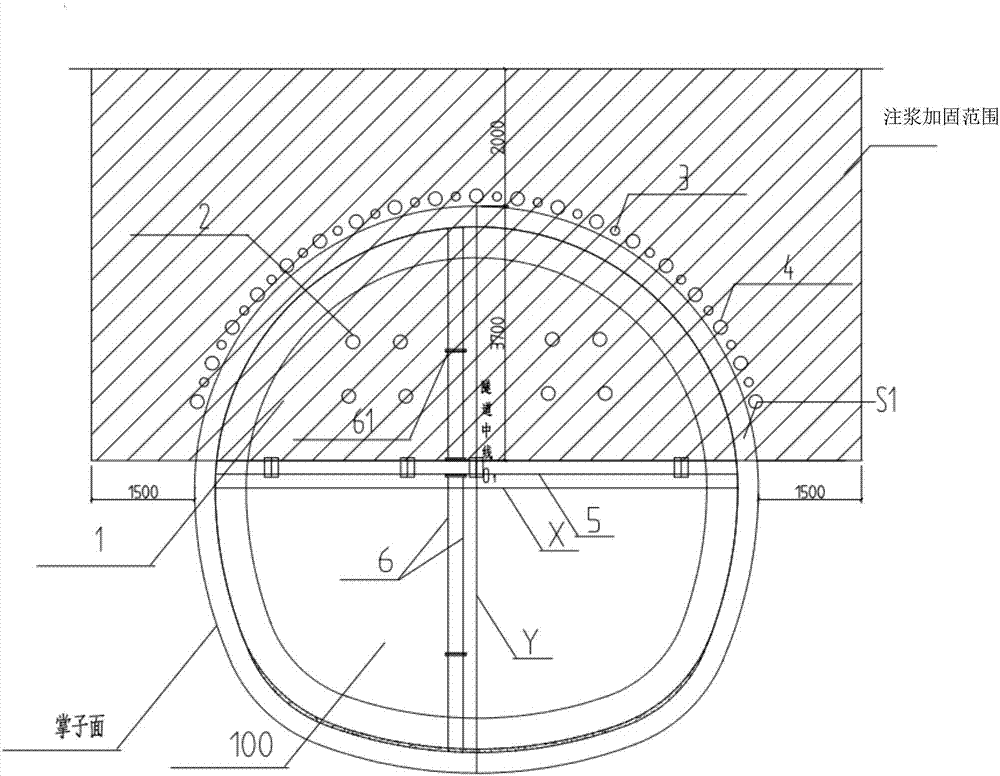

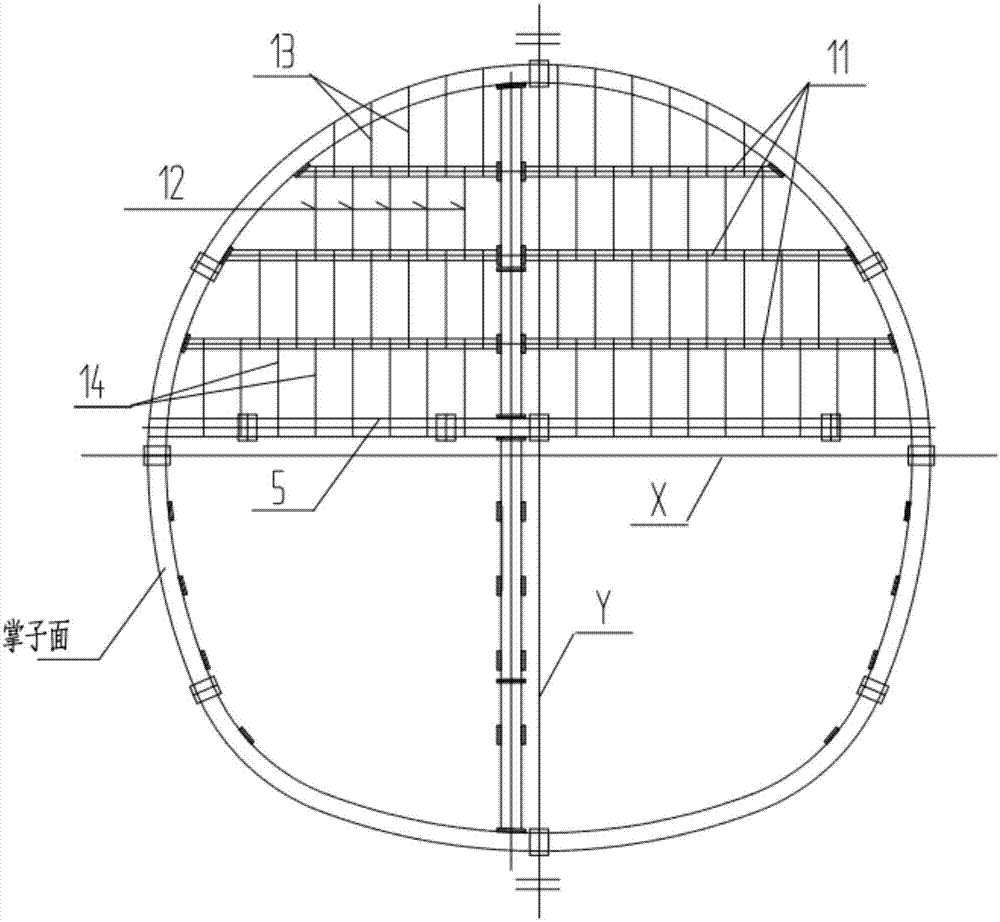

[0038] figure 1 Shown is the expansive soil tunnel support structure of the present invention, which includes:

[0039] A grout stop wall 1, which is arranged on the upper half-section S1 of the tunnel face of the expansive soil tunnel 100;

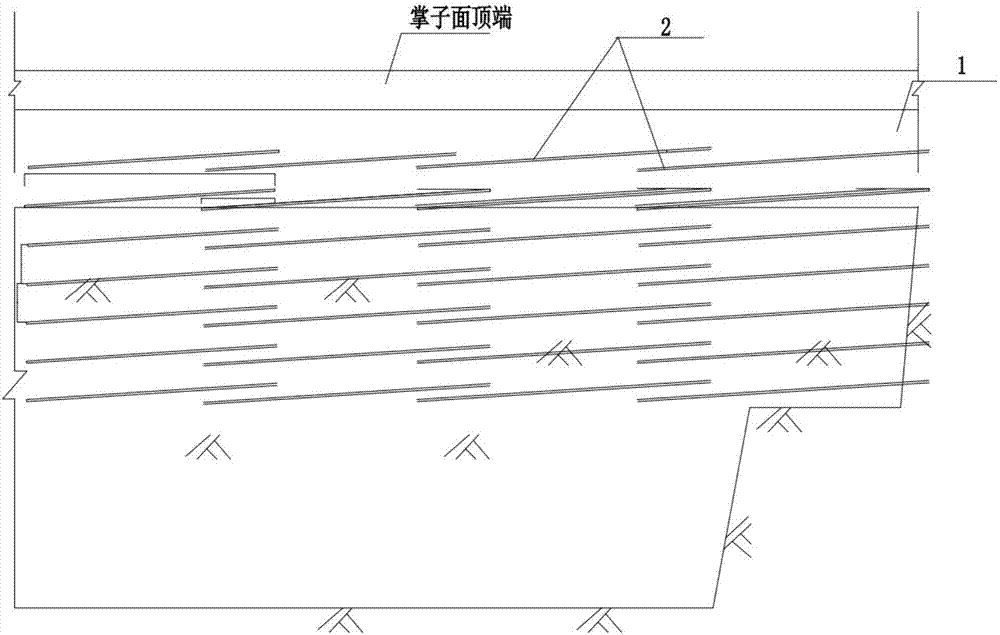

[0040] A plurality of grouting pipes 2, which are pre-embedded in the grout-stop wall 1, are used for advanced grouting of the expansive soil surrounding rock around the upper half-section S1 of the face of the expansive soil tunnel 100 to form a grouting Reinforcement range (in this embodiment, the size of the grouting reinforcement range is 1-1.5m extending outward from both sides of the tunnel surface, and 1.5-2m upwards from the top of the tunnel surface, i.e. figure 1 The rectangular area shown in the oblique box); the grouting pipes 2 are all arranged along the extension direction of the expansive soil tunnel 100 (that is, the direction perpendicular to the paper surface), and the cross-sections are all facing the tunnel face. Upp...

Embodiment 2

[0063] Such as Figure 5-6 Shown, the present invention also shows a kind of expansive soil tunnel support method, and it comprises the steps:

[0064] S1. Install a grout stop wall 1 on the upper half section S1 of the tunnel face of the expansive soil tunnel 100;

[0065] S2. A plurality of grouting boreholes 21 are drilled in the grout stop wall 1, and expansive soil surrounding the upper half section of the expansive soil tunnel 100 is embedded in each of the grouting boreholes 21. Grouting pipes 2 for advanced grouting; the grouting pipes 2 are arranged along the extension direction of the expansive soil tunnel, and the cross-sections are all facing the upper half-section S1 of the tunnel face;

[0066] S3. Perform advanced grouting through the grouting pipe 2 .

[0067] Preferably, before the step S1, the method further includes: S1a, setting an advance support structure.

[0068] Specifically, the step S3 includes:

[0069] S31. Configure the grouting material: In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com