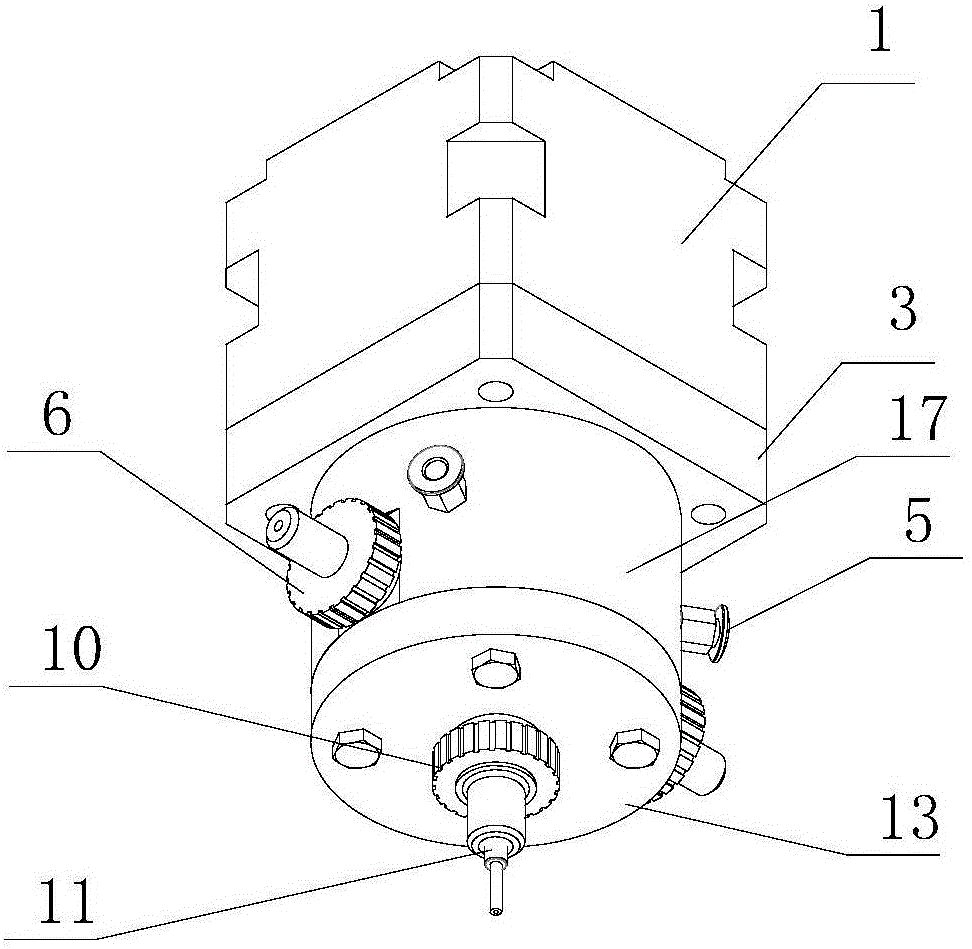

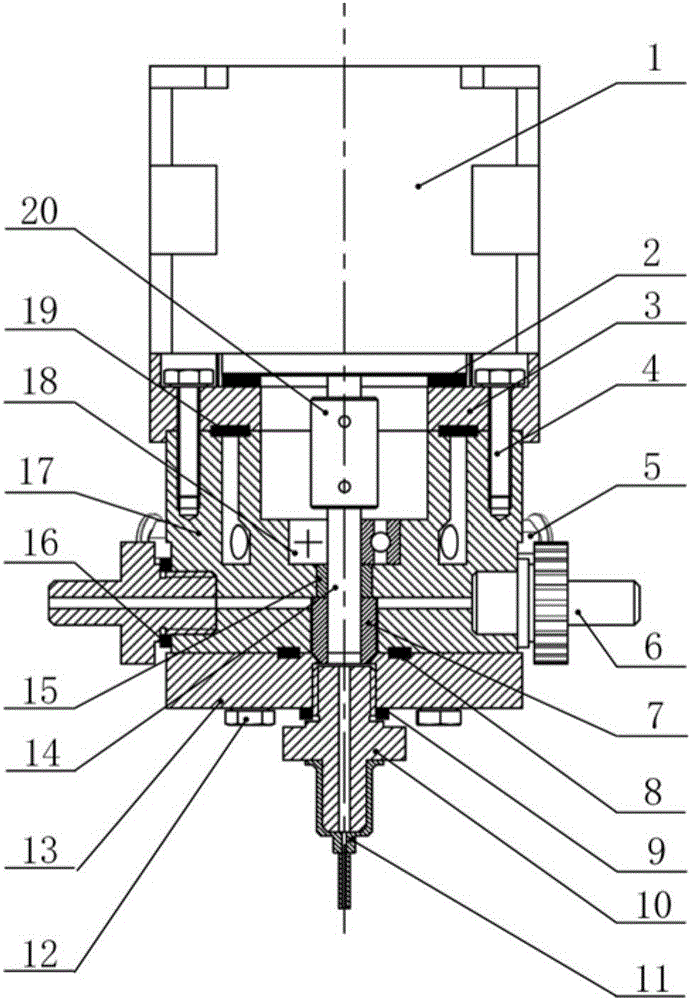

Dynamic cell printing micromixer

A cell printing and micro-mixer technology, which is applied to animal cells, vertebrate cells, mixers, etc., can solve the problems of physical damage of the mixed liquid, inability to be used as cells, and print a micro-mixer, so as to reduce the complexity of mechanism design, The mixing effect is obvious and the volume of the mixer cavity is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0062] The dynamic cell printing micro-mixer of the present invention was used to study the effects of the concentration of various growth factors and their gradient distribution on the growth of mouse epidermal fibroblasts.

[0063] Step 1. Prepare all the components. Disinfect the motor fixing block, upper and lower chambers, stirrer, rotating shaft, adjustable speed motor installation surface and its main shaft with 75% alcohol. Luer connector, quick connector, syringe, feed Tubes and other equipment are sterilized at high temperature, and finally all equipment that comes into contact with cells is sterilized by ultraviolet light.

[0064] Step 2: Assemble the components on the clean bench, and connect the feed hoses and quick connectors of the two input channels. Pass clean water at a constant temperature of 37 degrees from the quick connector, and preheat for 5 to 10 minutes. Start the stirring bar and keep the rotation speed of 7r / s, use 37°C PBS to pass through the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com