Method for preventing goaf spontaneous combustion through superfine inhibitor water mist

A goaf and water mist technology, applied in fire prevention, dust prevention, mining equipment, etc., can solve the problems of prevention and control effects and economic benefits to achieve better results, and achieve high fire prevention and extinguishing efficiency, low cost, and good flow sexual and diffuse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

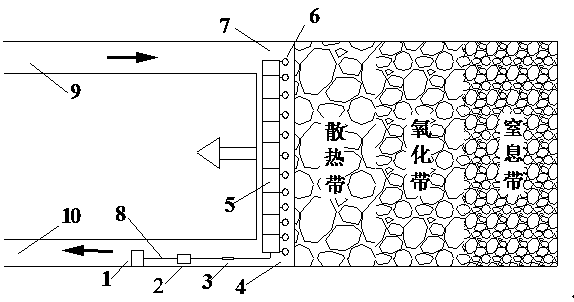

[0017] General situation of the working face, there are 9, 12, 16, 18 and 20 coal seams that have been mined in a certain mine, and the 12 and 16 coal seams are currently being mined. Among the above-mentioned coal seams, 9 and 16 are Class II (spontaneous combustion) coal seams, 12 and 18 , 20 are Class I (easy to spontaneous combustion) coal seams, and all coal seams are explosive. There is currently 1 hydrostatic pool on the ground with a total capacity of 200m3. The pool has been antifreeze (insulation boards were installed around the pool when it was constructed) and protective measures have been taken. The dust-proof main road is a six-inch seamless steel pipe, with a total length of 2,480 meters, and the branch pipeline is a two-inch seamless steel pipe, with a total length of 18,280 meters. The main water supply route is the auxiliary well shaft—level 155—return air inclined shaft in the south area—the bottom of the shaft is negative 440 north wing return air lane, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com