Upgraded coal cooling and humidifying device

A humidification device and coal upgrading technology, which is applied in the petroleum industry, the separation of dispersed particles, coking ovens, etc., can solve the problems of high dust removal pressure, harsh production environment, and high cost, so as to improve the operating environment, reduce the risk of spontaneous combustion, and reduce equipment effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

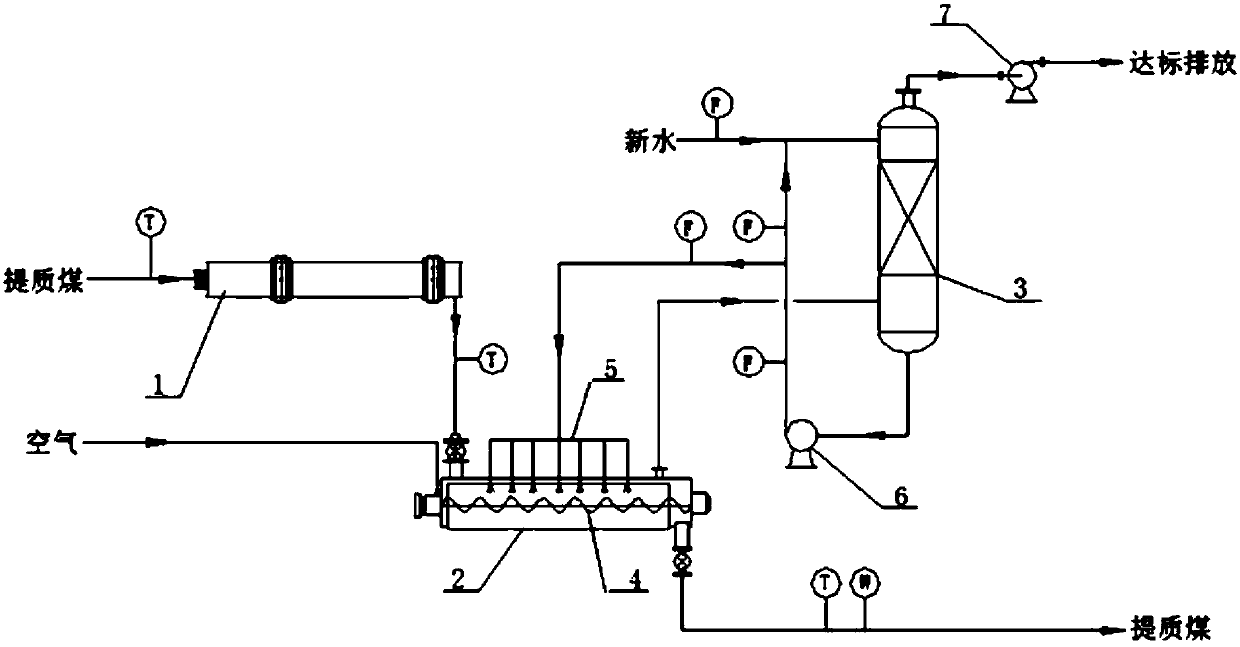

[0016] Such as figure 1 As shown, a cooling and humidifying device for upgrading coal in the present invention includes a rotary cooler 1, a humidifier 2 and a washing tower 3; the rotary cooler 1 is provided with a water cooling jacket, and the upgraded coal of the rotary cooler 1 is discharged The feed port is connected to the upgraded coal inlet on one side of the top side of the humidifier 2, and the upgraded coal outlet is arranged on the other side of the bottom of the humidifier 2, and a screw conveying mechanism 4 is arranged between the upgraded coal inlet and the upgraded coal outlet; Sprinkler device 5, an air inlet is provided at one end of the humidifier 2 near the inlet of the upgraded coal, and an exhaust gas outlet is installed at the top of the humidifier 2 near the outlet of the upgraded coal, and the outlet of the exhaust gas is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com