Standing pouch tube sealing machine pouch protecting frame

A technology of stand-up pouch and tube sealing machine, which is applied in packaging and other directions, can solve the problems of stand-up pouch deviation, affect bagging accuracy, and affect the appearance of stand-up pouches, and achieve the effect of improving the quality of finished products and reducing the rate of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

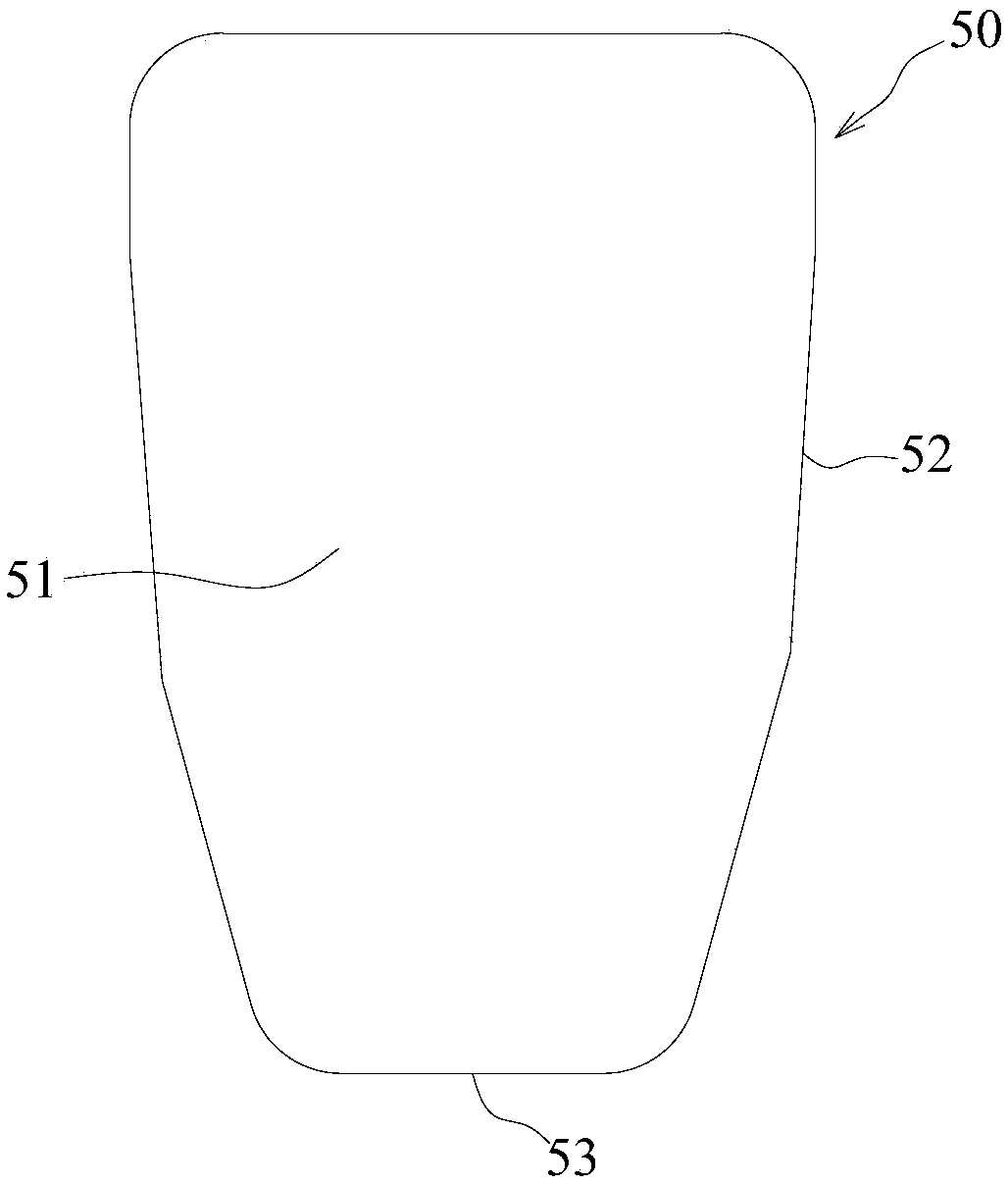

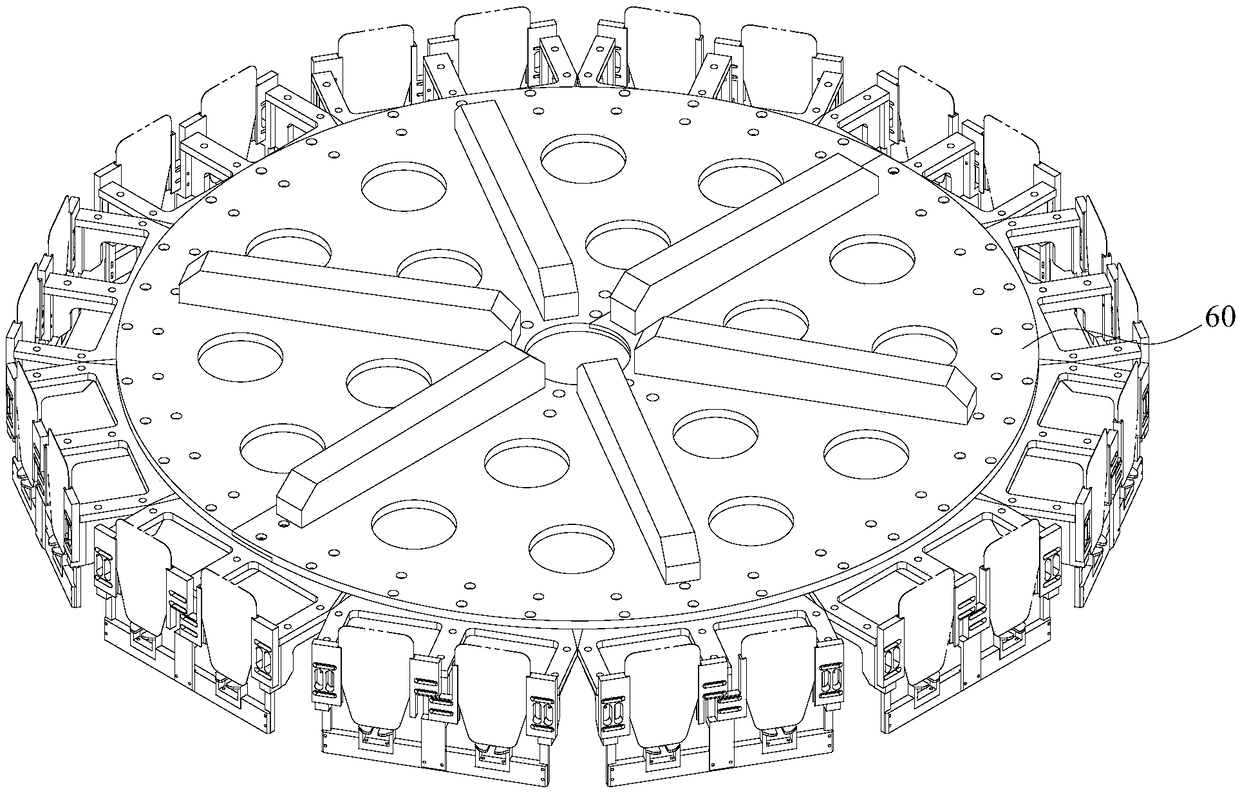

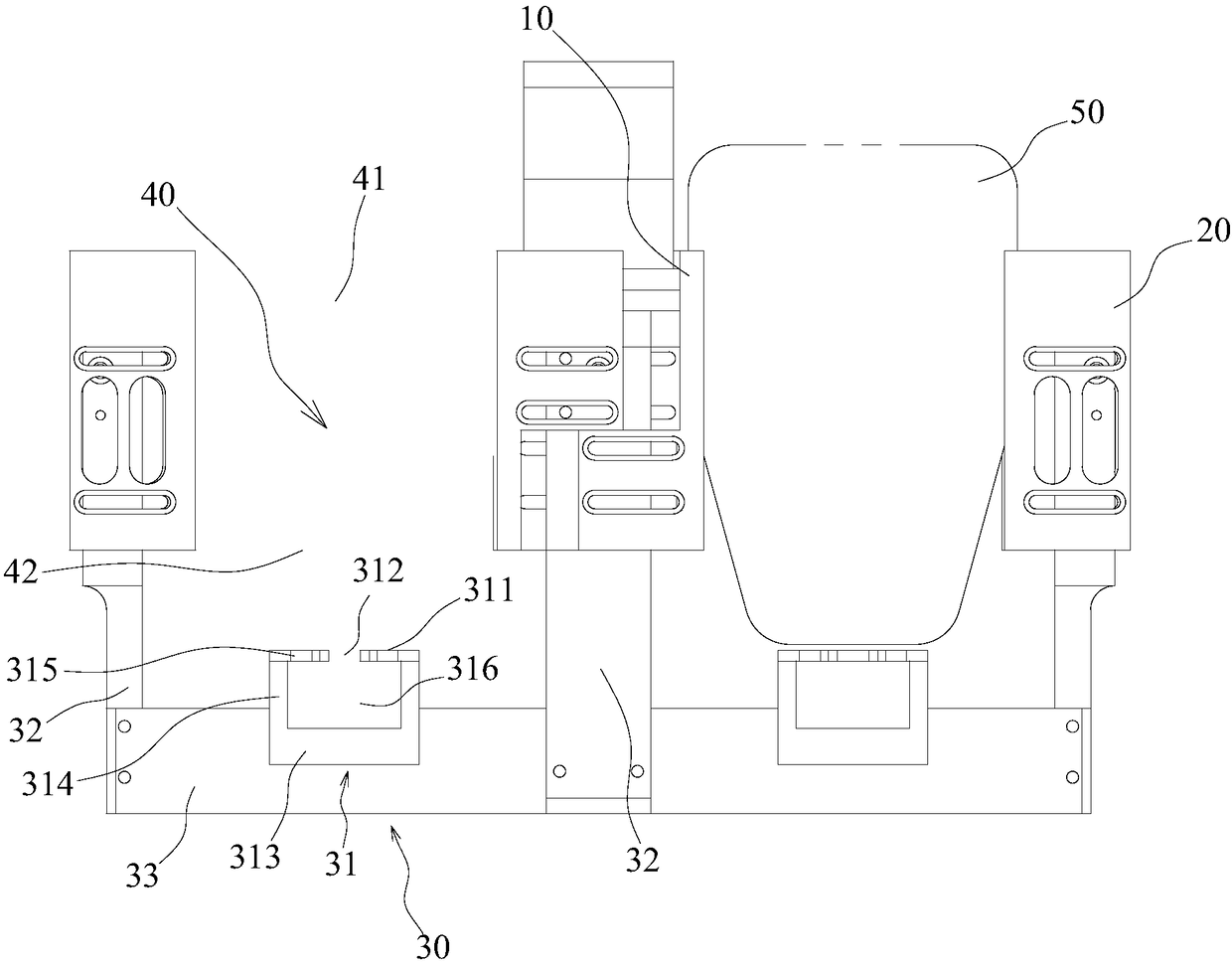

[0044] Embodiment 1: as Figure 1~4 As shown, the first guide groove 11 and the second guide groove 21 are parallel to each other, and both are perpendicular to the horizontal plane.

[0045] Preferably, the distances between the opening 312 and the first guiding groove 11 and the second guiding groove 21 are equal. This embodiment is mostly used for the stand-up pouch 50 structure in which the straw is located in the middle of the sealing edge 53 of the stand-up pouch 50, and the distance between the opening 312 and the first guide groove 11 is equal to the distance between the opening 312 and the second guide groove 21. When the bag 50 enters the positioning space 40 from the bag-entry end 41, it is vertically displaced in the direction of the opening 312 along the setting direction of the first guide groove 11 and the second guide groove 21, so that both sides 52 of the stand-up bag 50 are vertical after the straw is nested. On a horizontal plane, the suction pipe can also...

Embodiment 2

[0046] Embodiment 2: as figure 1 , Figure 5-7 As shown, the first guide groove 11 is inclined relative to the horizontal plane, so that the extension line of the first guide groove 11 intersects the extension line of the second guide groove 21 and forms a positioning point (not shown);

[0047] The positioning point is located between the first guide groove 11 and the second guide groove 21, and is located below the first guide groove 11 and the second guide groove 21; here, since the first guide groove 11 is inclined relative to the horizontal plane, the stand-up bag 50 When entering the positioning space 40 from the bag-entry end 41, the side edge 52 of the stand-up bag 50 close to the first guide groove 11 is also inclined together with the first guide groove 11, so the extension line of the first guide groove 11 is aligned with the second guide groove. The intersection point of the extension line of 21 becomes the supporting end of the stand-up bag 50, so that the sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com