Rapid outburst elimination method for cross cut coal uncovering in coal mine underground

A technology for removing coal in Shimen and coal mines, which is applied in the field of rapid outburst removal in underground Shimen in coal mines. The speed of unraveling coal, the solution to the high risk of outburst, and the effect of improving working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

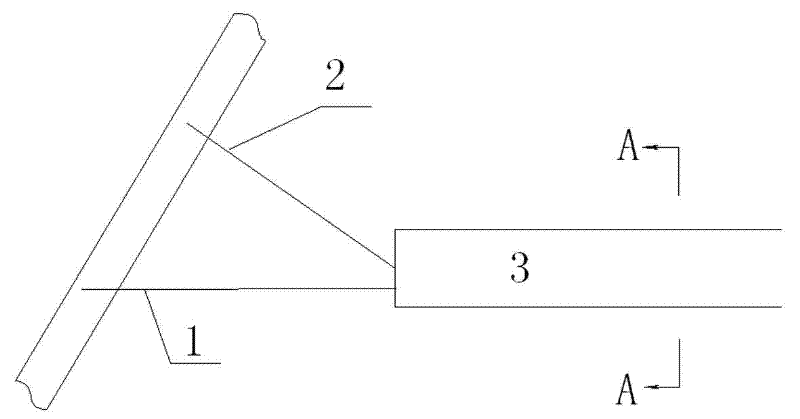

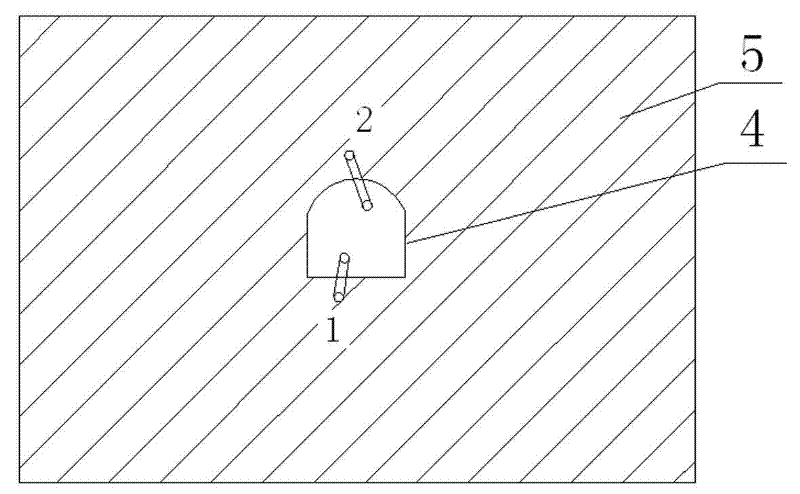

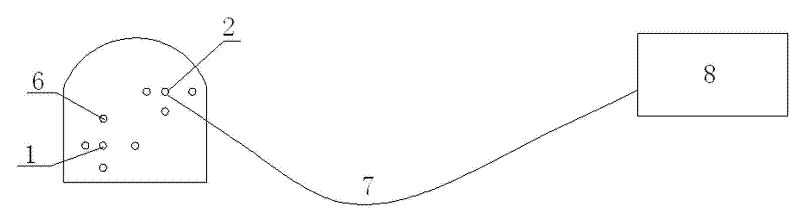

[0015] Example: such as Figure 1-5 As shown, a quick outburst elimination method for uncovering coal at an underground stone gate in a coal mine comprises the following steps:

[0016] (1) Before the outburst coal seam is uncovered in Shimen, hydraulic fracturing drilling holes (5m are used in this example) are arranged at a distance of 5-7 m (vertical distance) from the working face to the coal seam. The number of drilling holes depends on the impact of hydraulic fracturing drilling. The scope, section size of the roadway and the required outburst elimination range are determined; the final hole of the drill hole penetrates the roof (bottom) of the coal seam and is not less than 0.5m.

[0017] Article 82 of the "Regulations on the Prevention and Control of Coal and Gas Outburst" stipulates that "when the anti-outburst measures of pre-extraction and gas discharge drilling are adopted on the coal mining face in Shimen and vertical shafts, the diameter of the drilling hole is g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com