Outburst prevention method in rock cross-cut coal uncovering and gas outburst coal seam double-curtain grouting

A technology of coal excavation and curtain grouting in Shimen, which is used in earth-moving drilling, wellbore/well components, sealing/packing, etc., can solve the problems of coal seam gas content and pressure difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Implementation of the present invention will be further described below in conjunction with accompanying drawing:

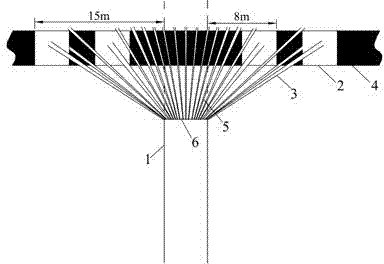

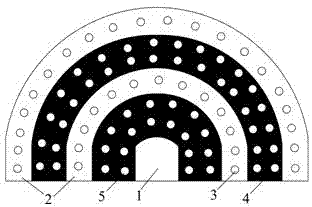

[0016] like figure 1 and figure 2 As shown, the steps of the double curtain grouting anti-outburst method of Shimen coal and gas outburst coal seam of the present invention are as follows:

[0017] a. When the Shimen coal uncovering working face 6 in the Shimen coal uncovering roadway 1 is excavated until the minimum normal distance from the coal seam 4 is greater than and close to 7m, firstly along the Shimen coal uncovering roadway 1 in the direction of the Shimen coal uncovering working face 6 facing the coal seam 4 The outer edge is drilled with two circles of layer-crossing grouting holes 3 inclined outwards, and the distance L between the layer-crossing grouting holes 3 passing through the roof of the coal seam 4 and the coal mining roadway 1 in Shimen 1 is 15m, the distance L between the layer-crossing grouting drill hole 3 passing through the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com