Blasting dust purification treatment equipment

A treatment equipment and dust purification technology, which is applied in the fields of dust removal, chemical instruments and methods, and separation of dispersed particles, etc., can solve the problems of limited effective dust absorption range and low reliability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

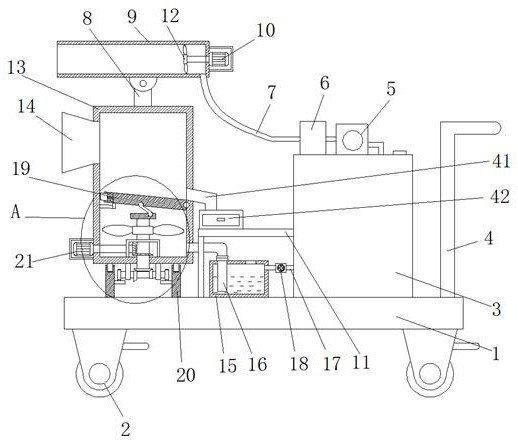

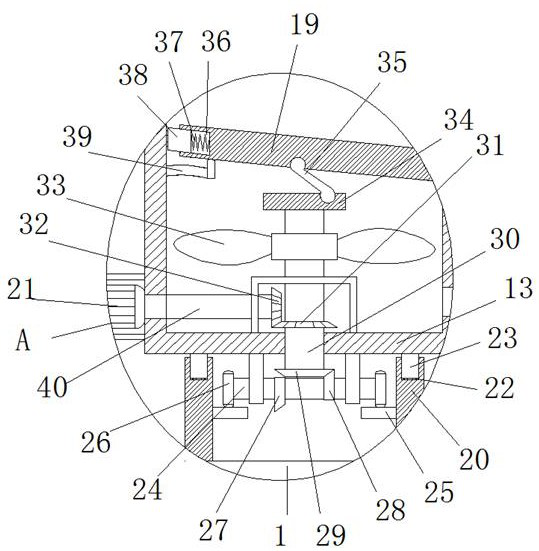

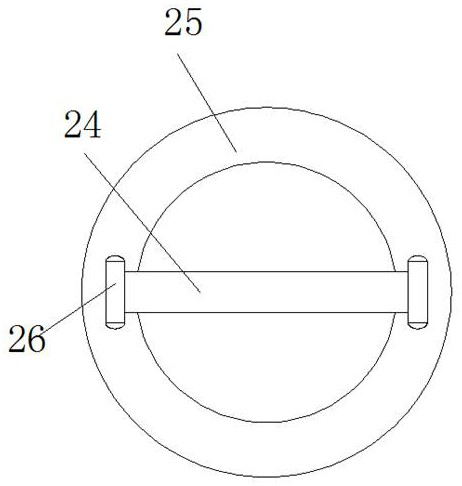

[0030] refer to Figure 1-5 , a blasting dust purification treatment equipment, comprising a base plate 1, four universal wheels 2 are arranged on the bottom of the base plate 1, brake pads are arranged on the four universal wheels 2, and the top of the base plate 1 is fixedly connected with an annular block 20, The liquid tank 15, the water tank 3 and two push handles 4, the top of the annular block 20 is rotated and installed with a rectangular box 13, and one side of the rectangular box 13 is connected with a dust suction port 14, the dust suction port 14 is a horn structure, and the rectangular box 13 The top of the support rod 8 is fixedly installed, and the top of the support rod 8 is rotated and installed with an atomizing cylinder 9, which is connected with an air blowing structure. The top of the water tank 3 is connected with a water pump 5, and the water outlet of the water pump 5 is connected with a fog The atomizer 6, the same hose 7 is connected between the atomi...

Embodiment 2

[0041] refer to Figure 1-5 , a blasting dust purification treatment equipment, comprising a base plate 1, four universal wheels 2 are arranged on the bottom of the base plate 1, brake pads are arranged on the four universal wheels 2, the brake pads can be fixed to the universal wheels 2, the base plate The top of 1 is fixedly connected with an annular block 20, a liquid tank 15, a water tank 3 and two push handles 4 by screws, and the top of the annular block 20 is rotated to install a rectangular box 13, and one side of the rectangular box 13 is connected with a dust suction port 14, The dust suction port 14 is a trumpet structure, the top of the rectangular box 13 is fixedly installed with a support rod 8 by welding, and the top of the support rod 8 is rotatably installed with an atomizing tube 9, and the atomizing tube 9 and the support rod 8 are connected by screw rotation, which can be adjusted The inclination angle of the atomizing cylinder 9, the atomizing cylinder 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com