Patents

Literature

98results about How to "Expand the vacuum range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

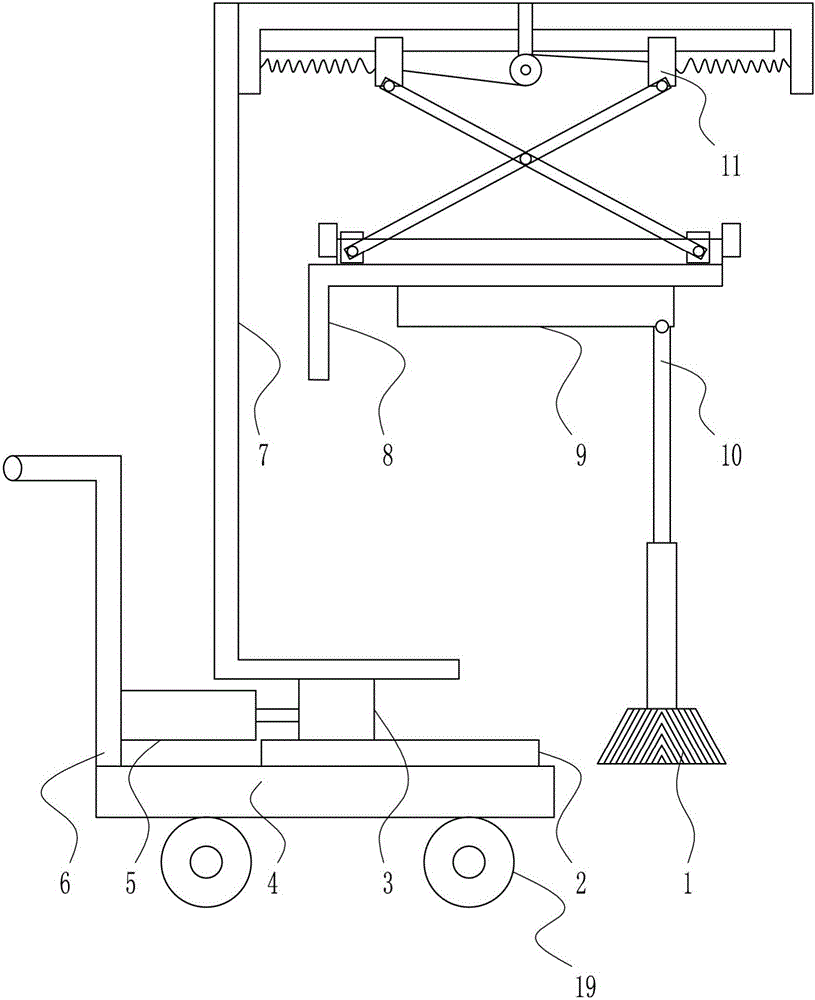

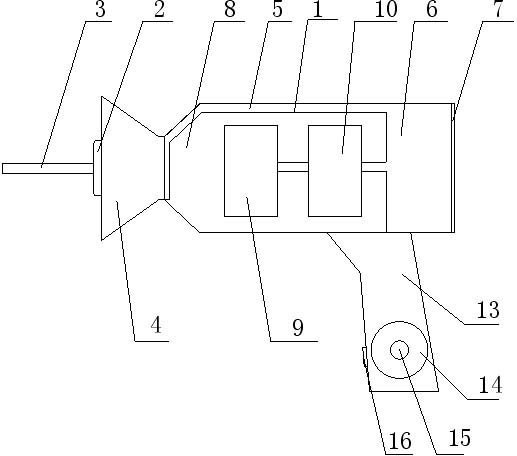

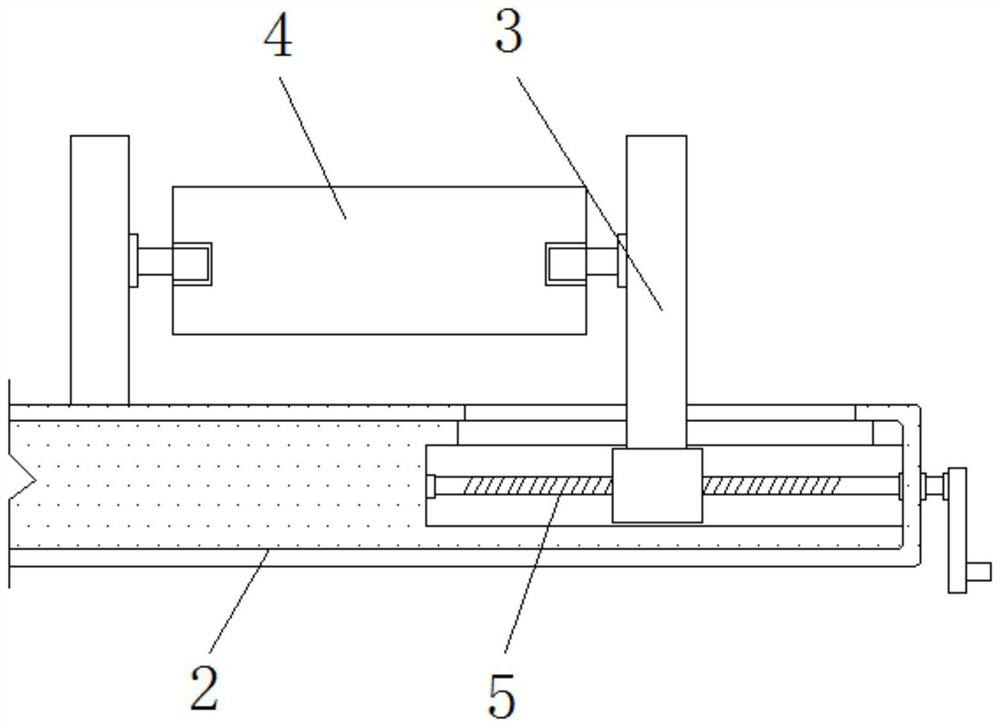

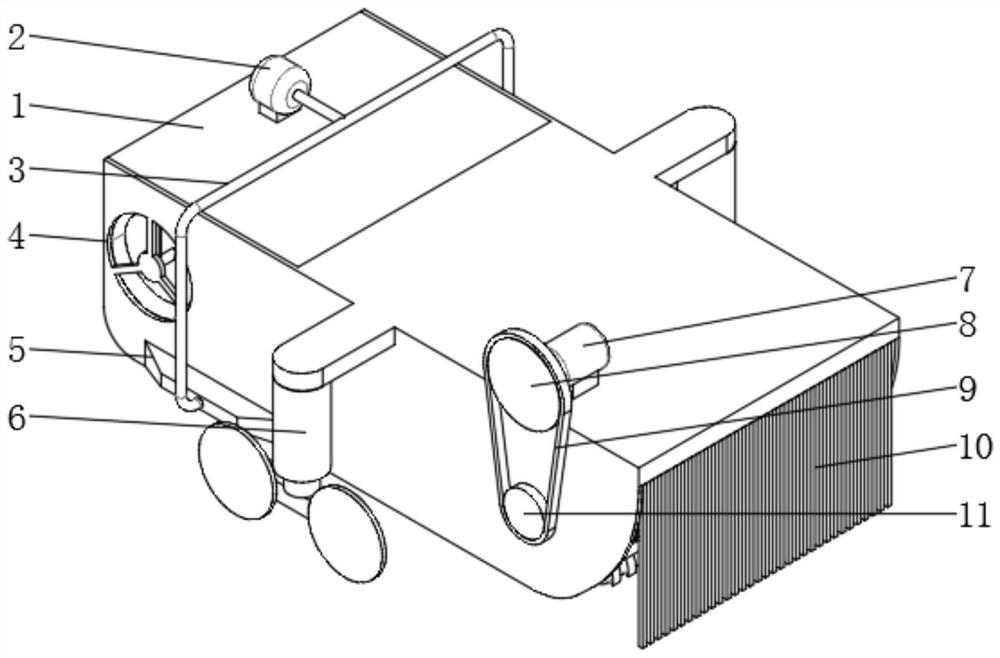

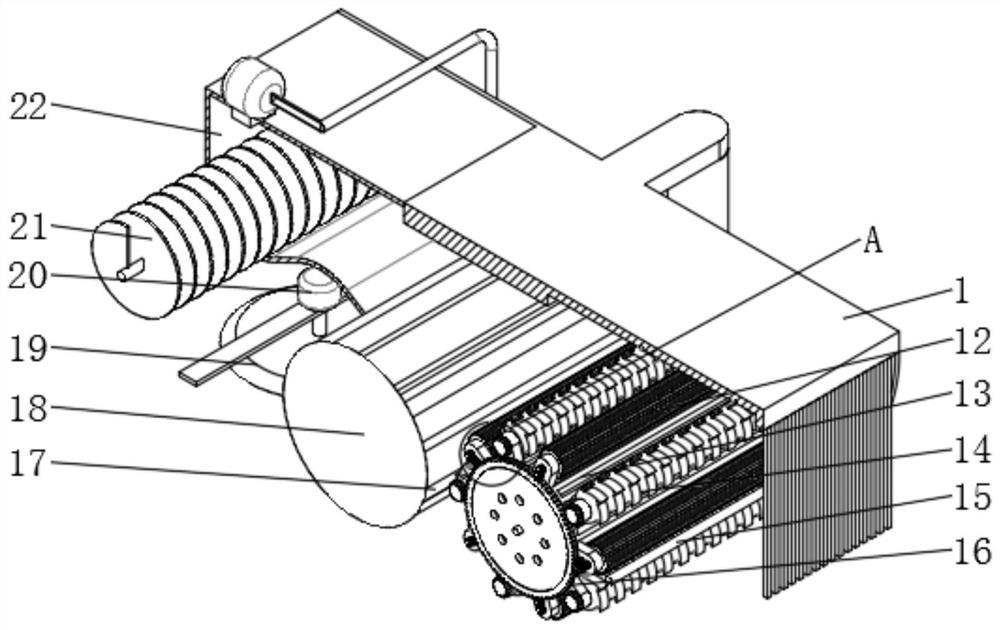

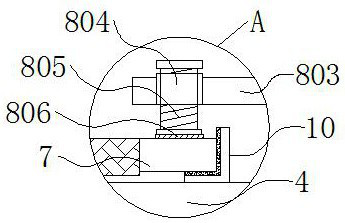

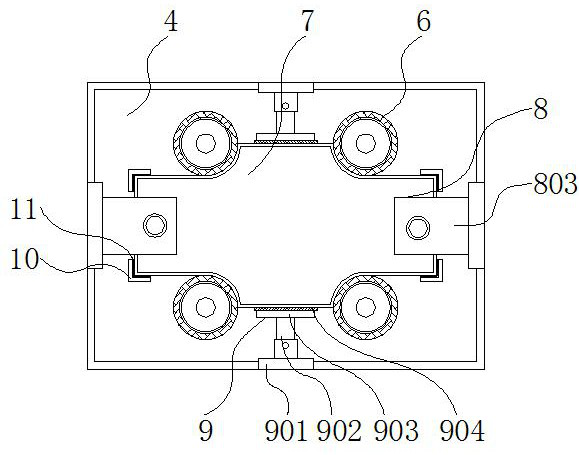

Rapid-dedusting sweeper

InactiveCN106618395AAdjustable positionExpand the vacuum rangeFloor sweeping machinesEngineeringGround level

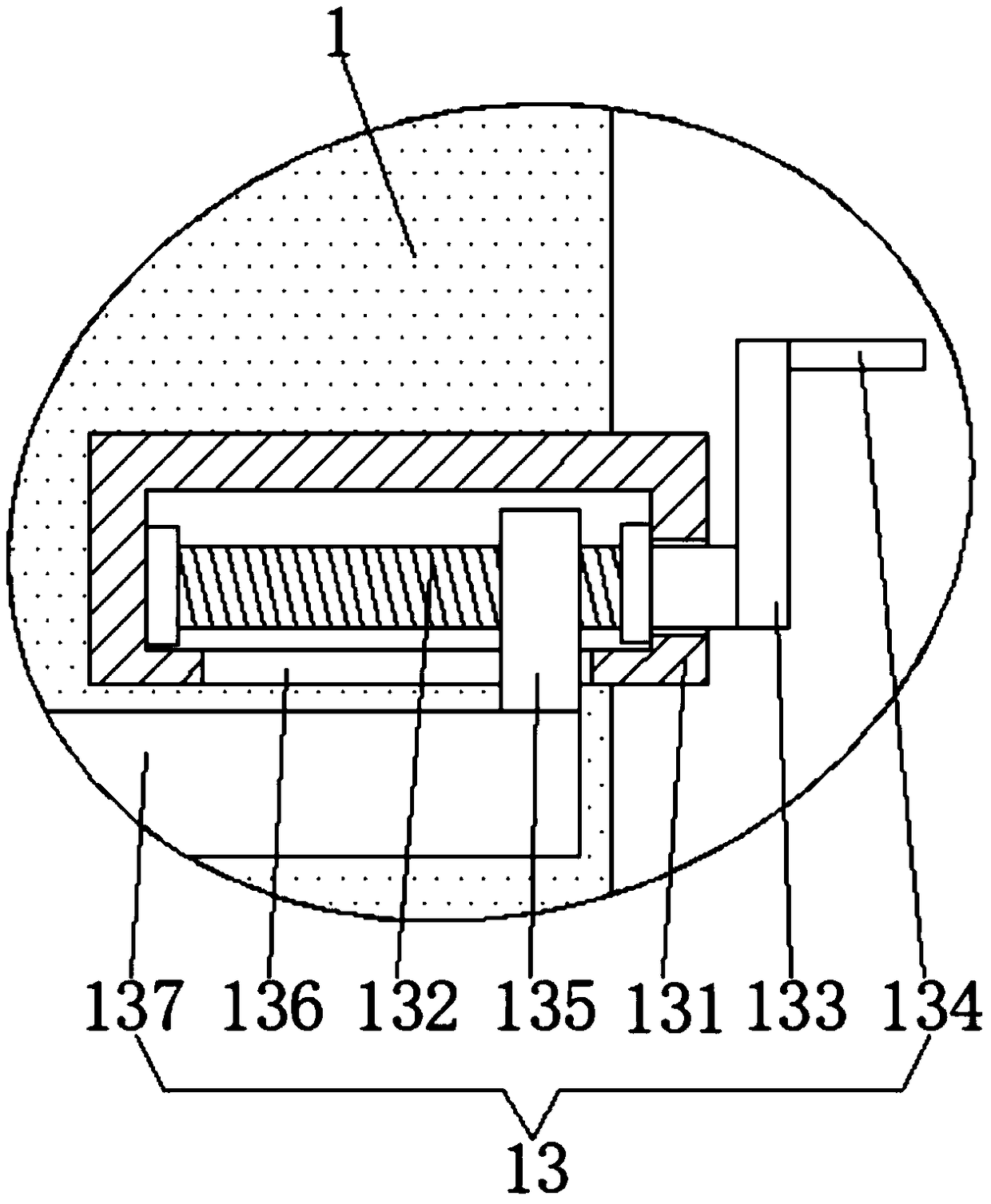

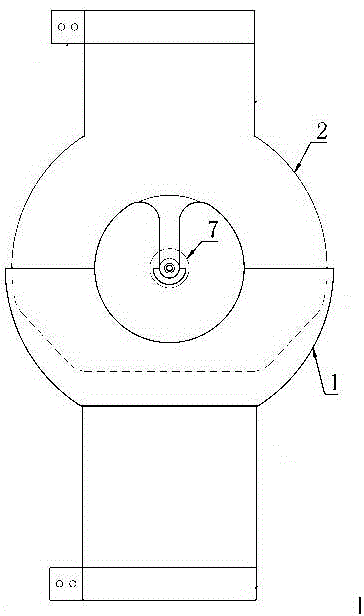

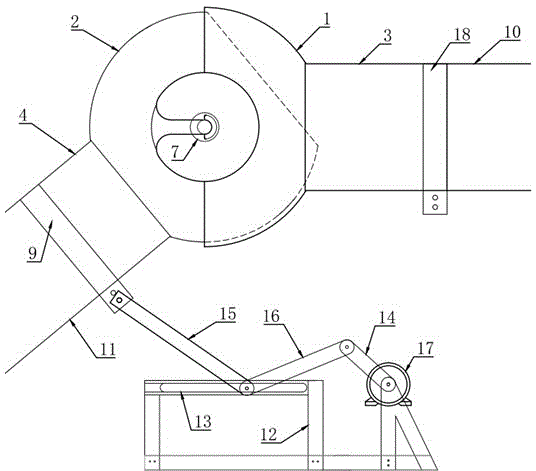

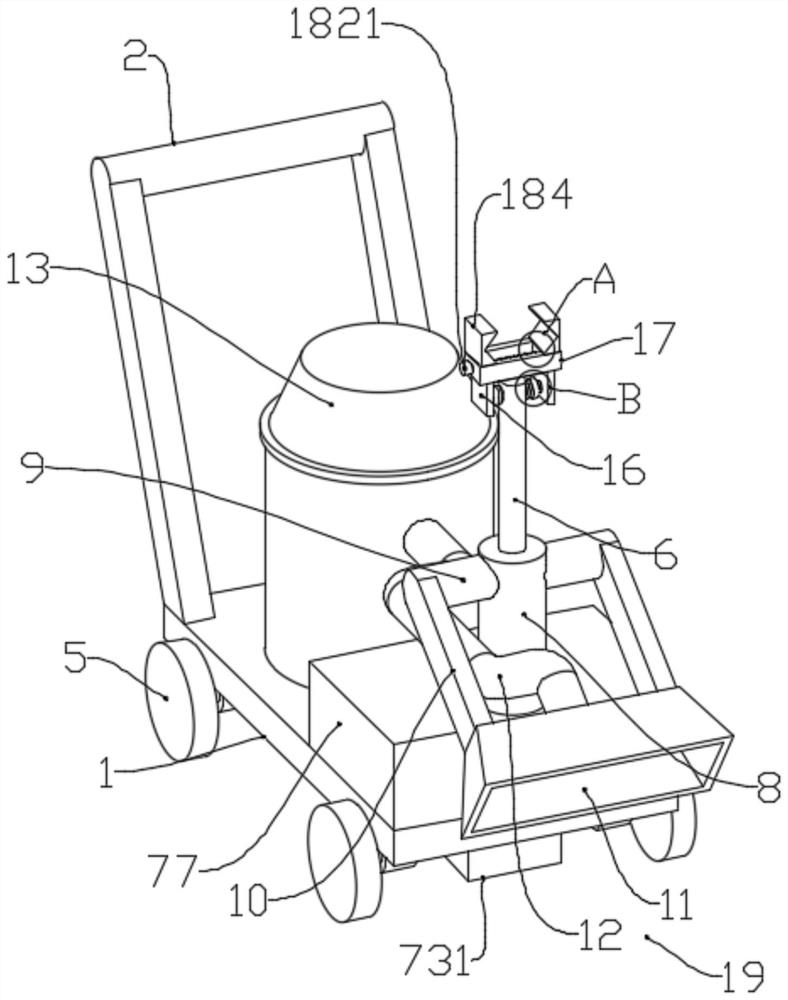

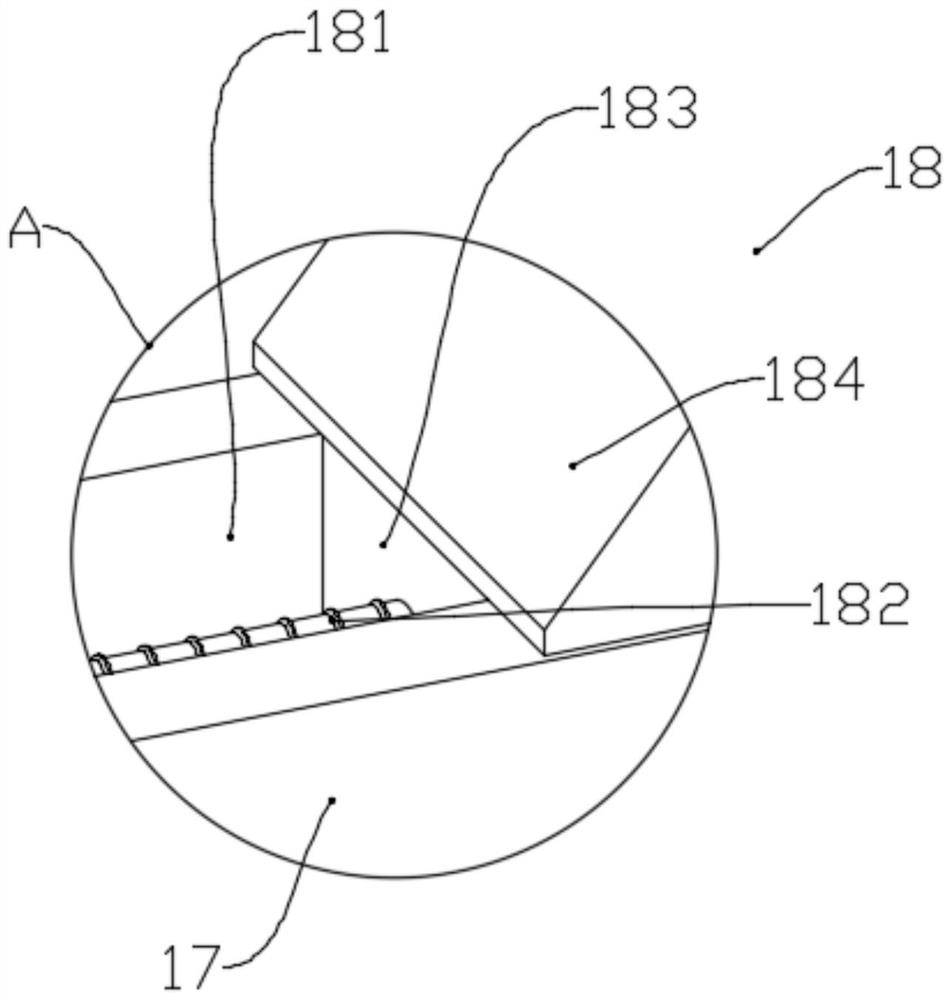

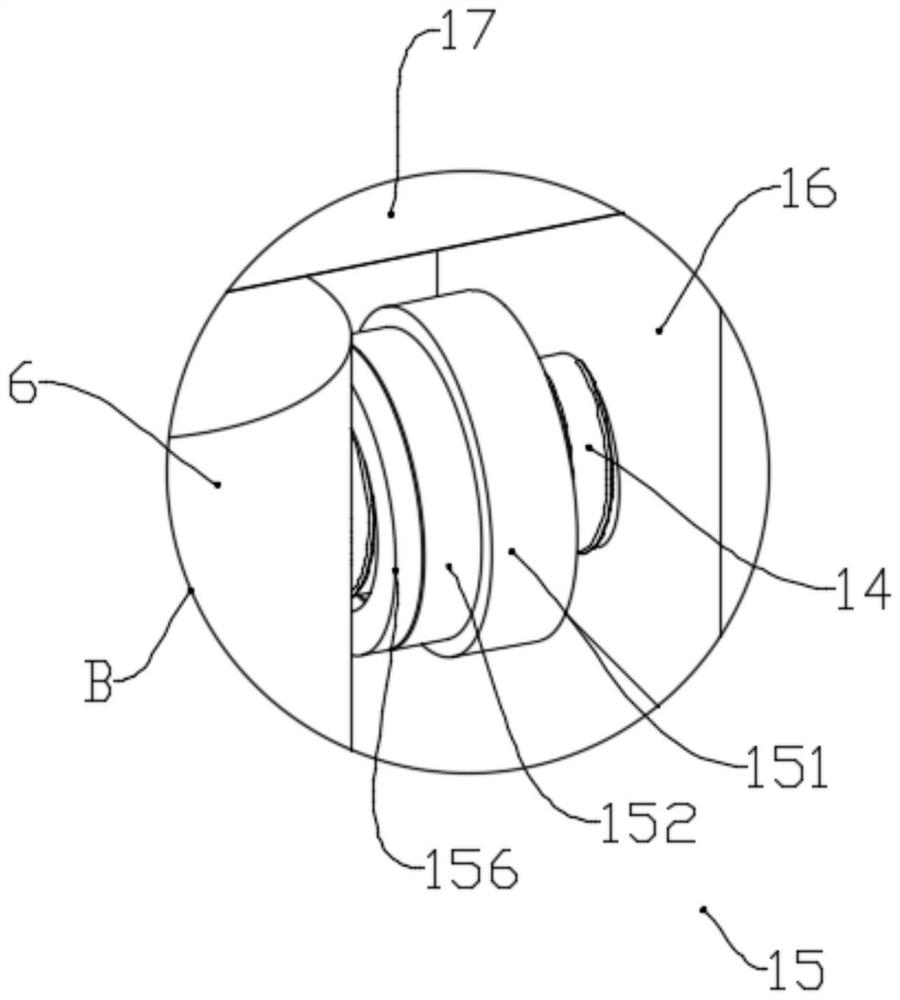

The invention provides a sweeper, and in particular relates to a rapid-dedusting sweeper. In order to solve the technical problems, the invention provides a rapid-dedusting sweeper which comprises a broom, a guide rail, a guide block, a bottom plate, a first cylinder, a side plate, a first bracket and the like, wherein the bottom of the bottom plate is provided with a roller wheel, and the left end of the top of the bottom pate is provided with the side plate; the side plate is provided with the first cylinder; the bottom plate is provided with the guide rail; the guide rail is provided with the guide block; the right end of the first cylinder is connected with the left end of the guide block; the top of the guide block is connected with the first bracket; the upper end of the right side of the first bracket is provided with a lifting device; and the lower side of the lifting device is connected with a second bracket. The rapid-dedusting sweeper is capable of conveniently regulating the broom height, conveniently replacing the broom and better fixing the broom, is wide in sweeping and dedusting range; and while a worker pushes the device to move, the device can clear and dedust a floor.

Owner:李沁浓

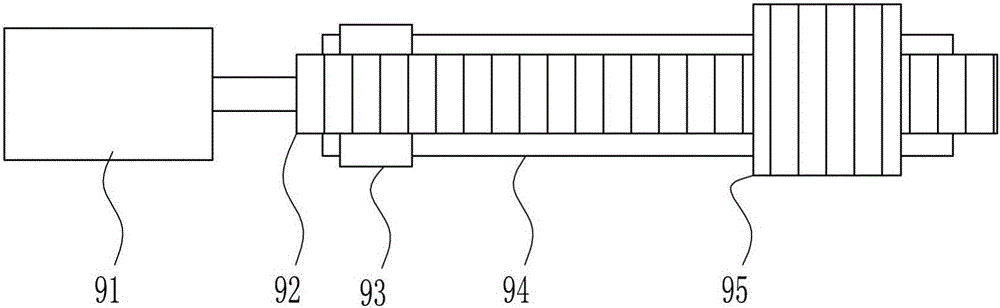

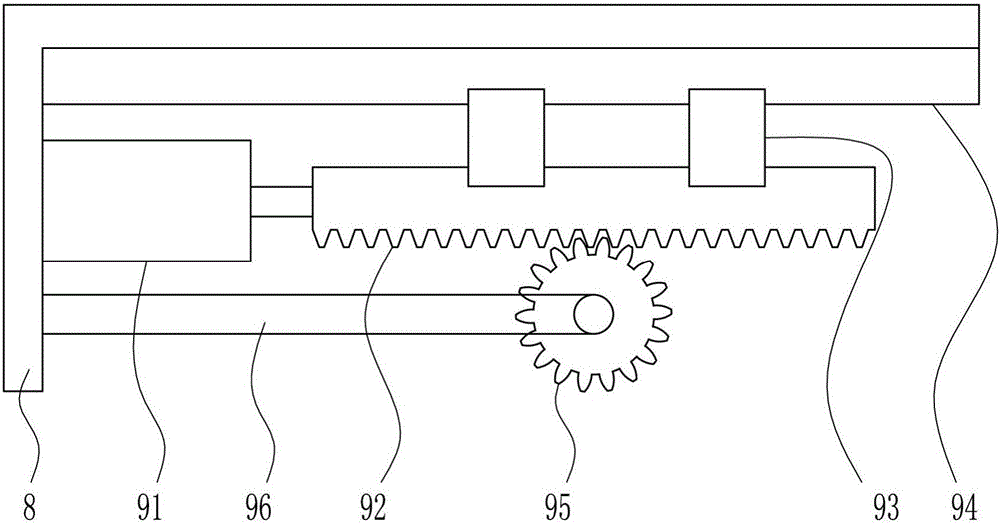

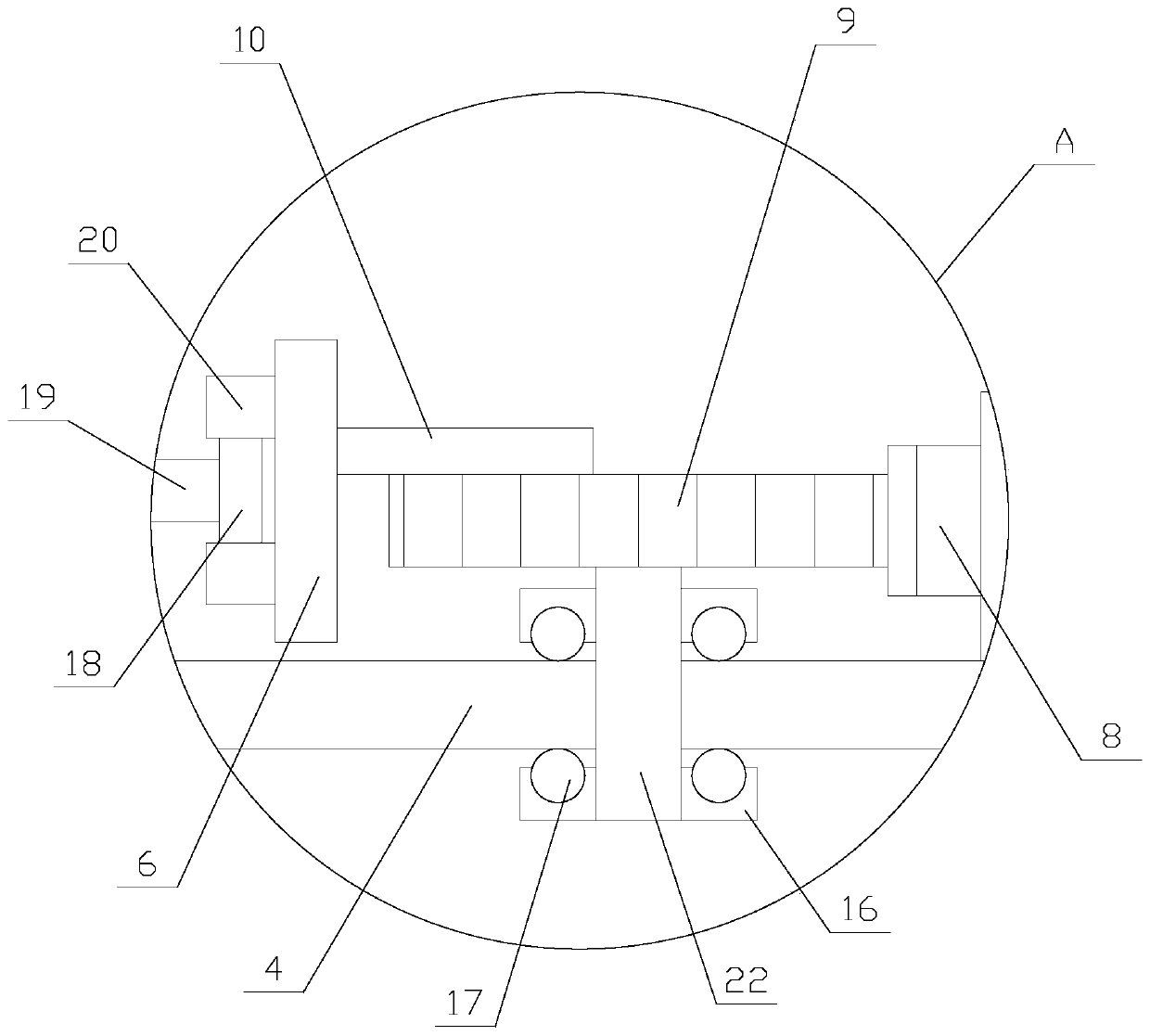

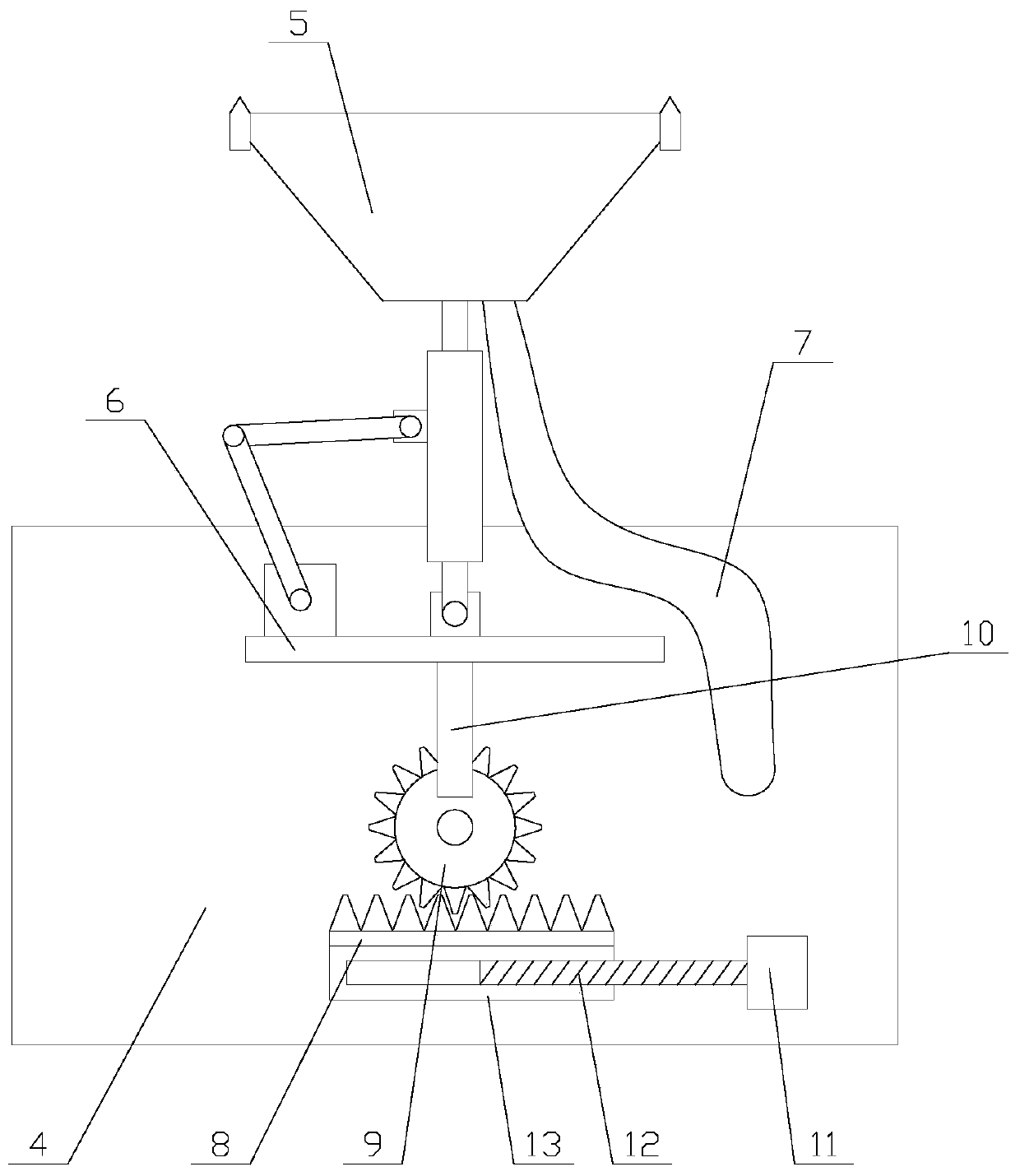

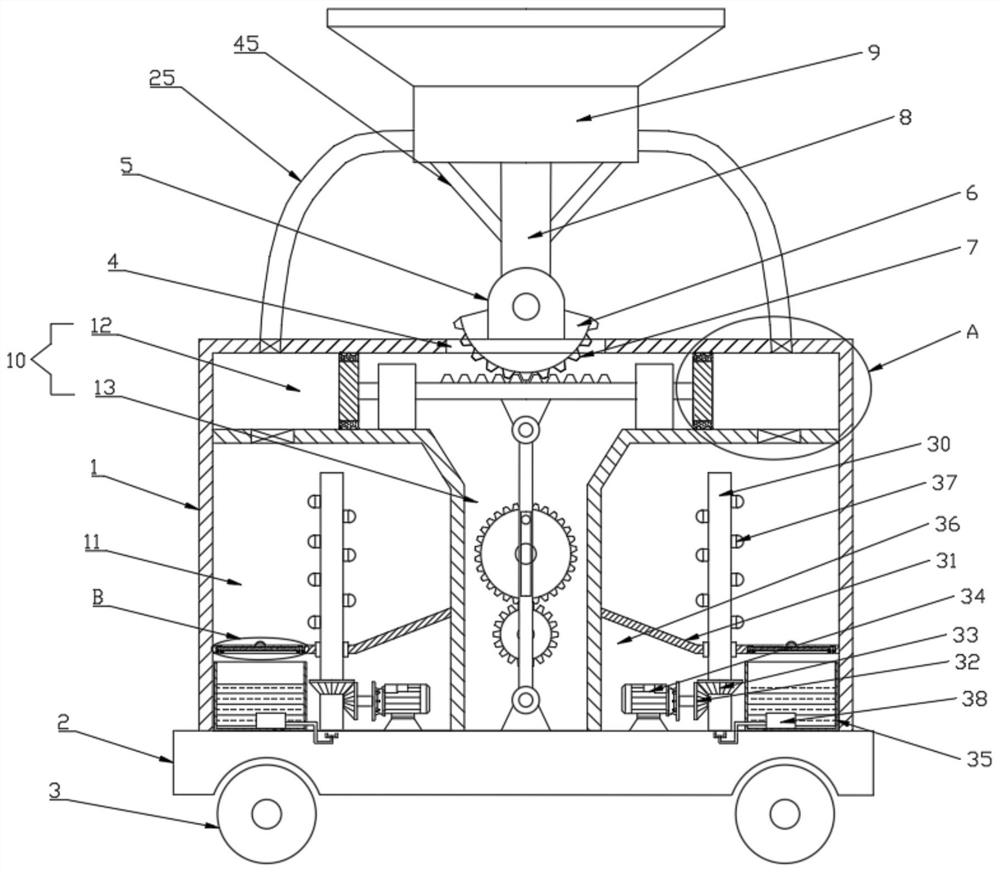

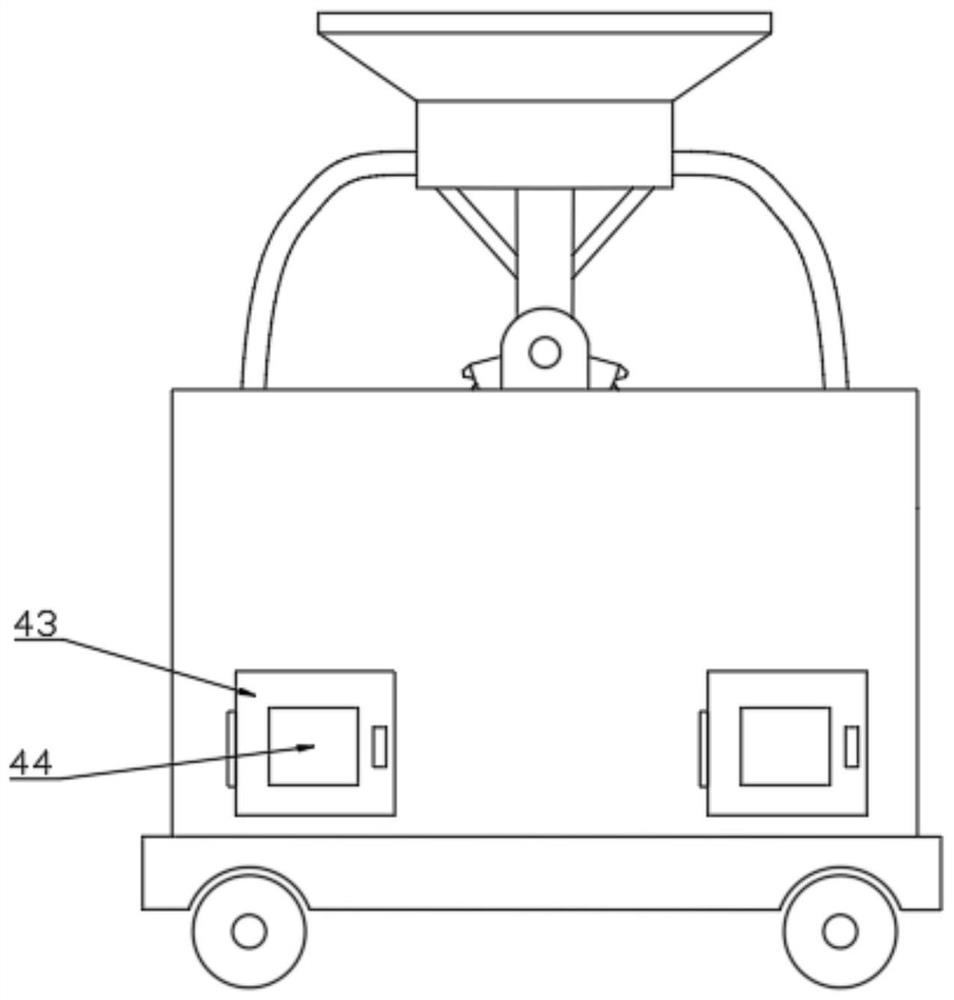

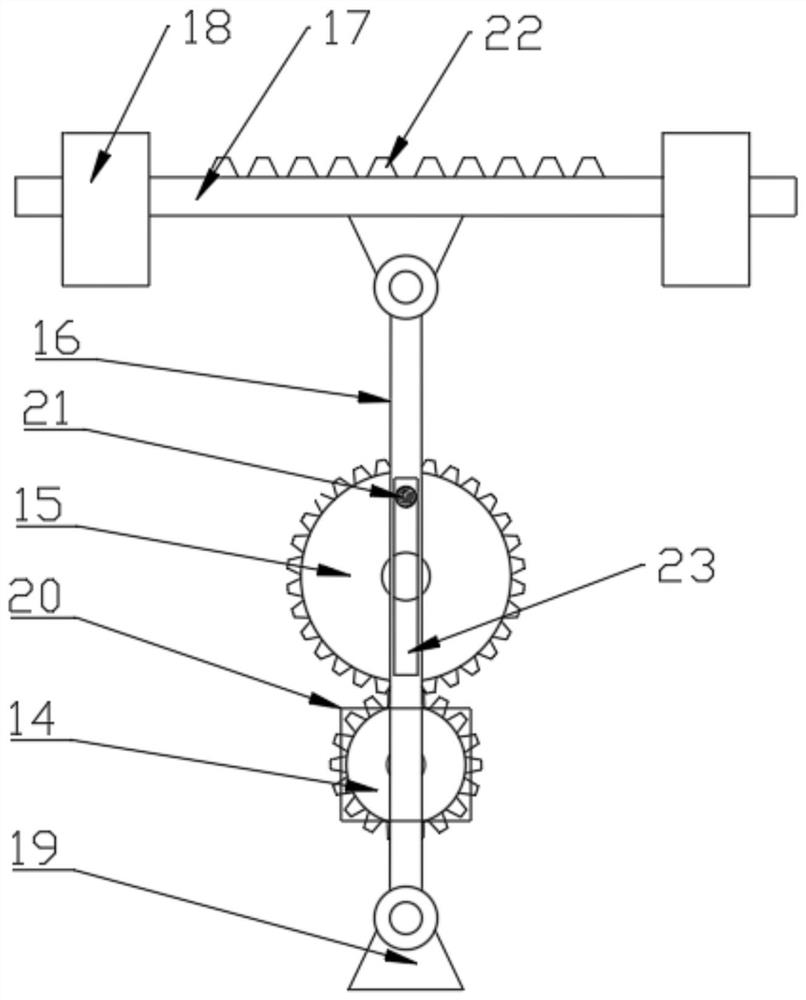

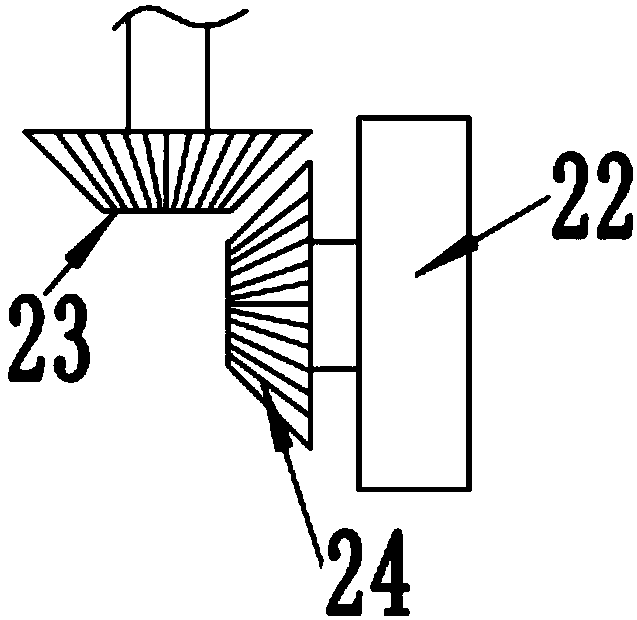

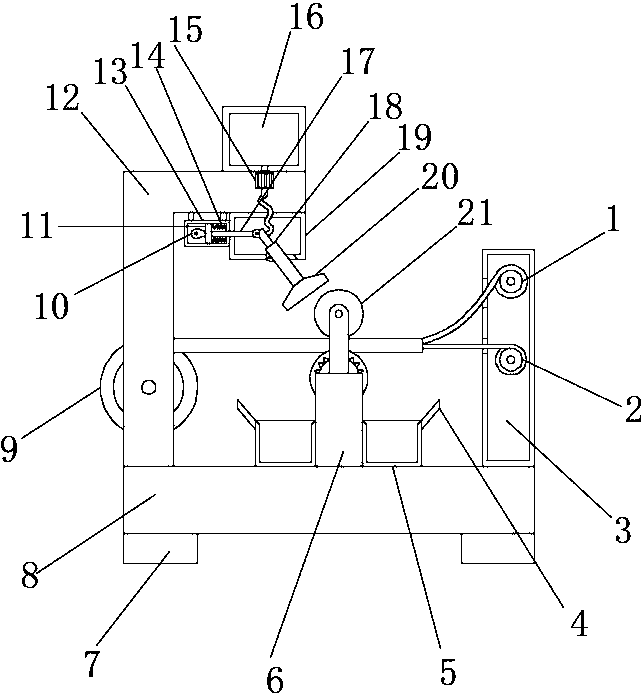

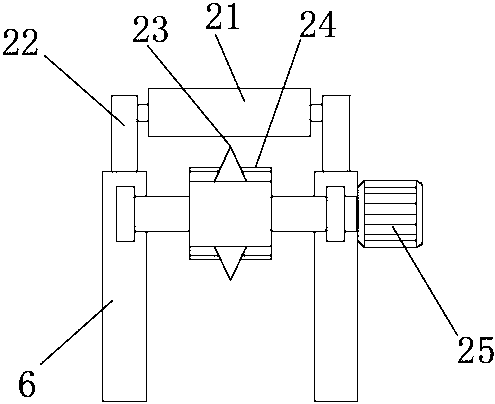

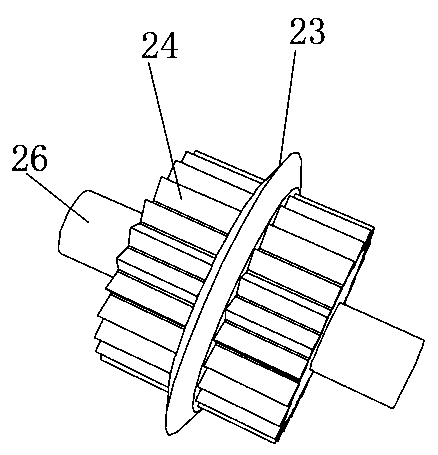

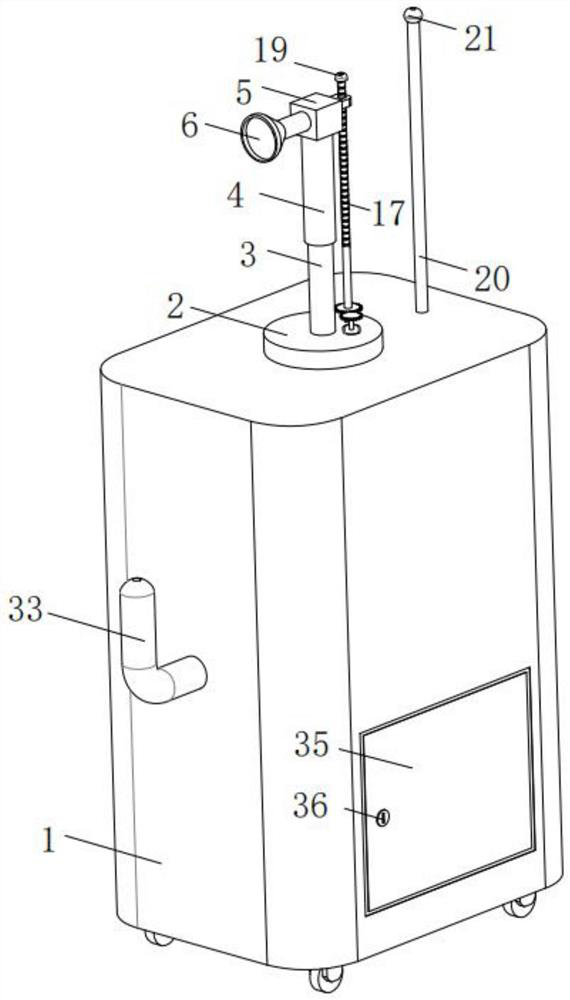

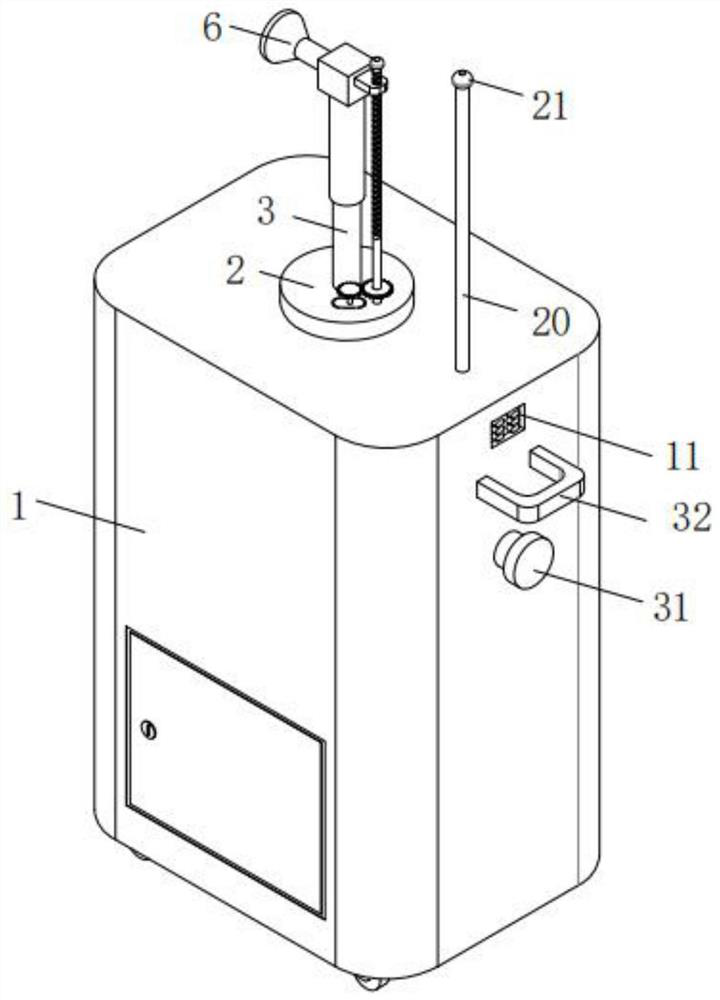

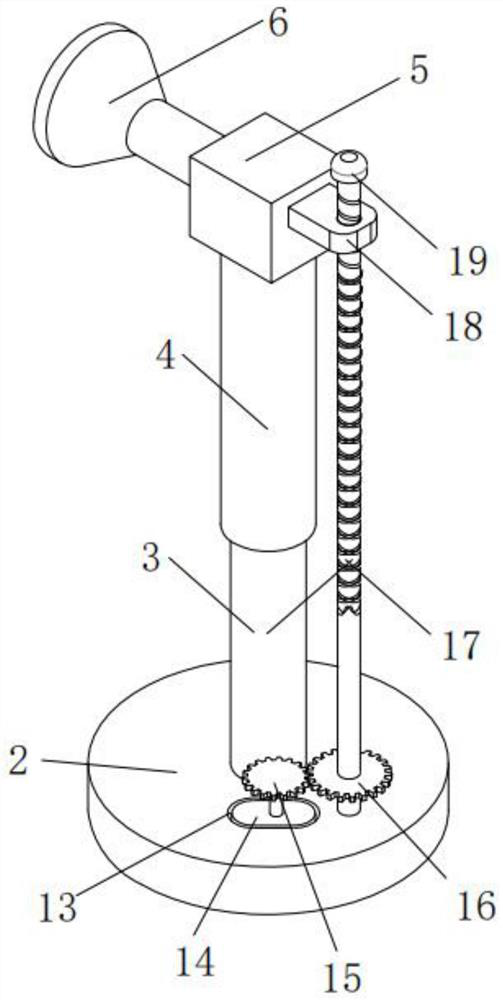

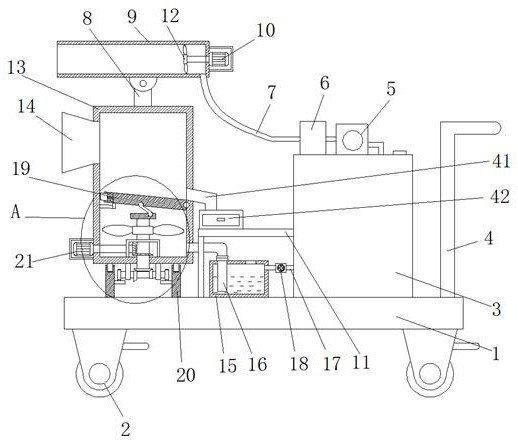

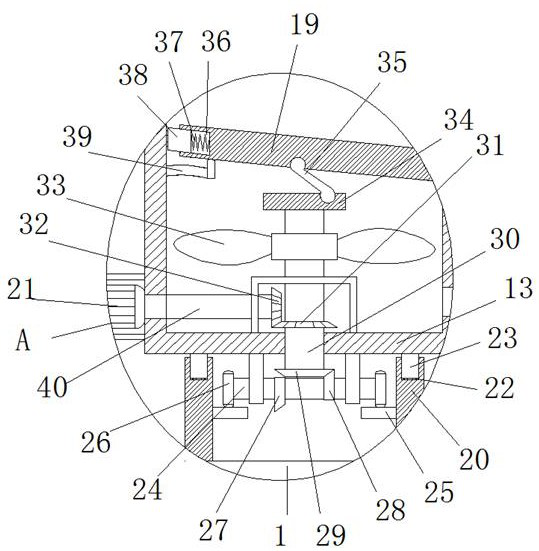

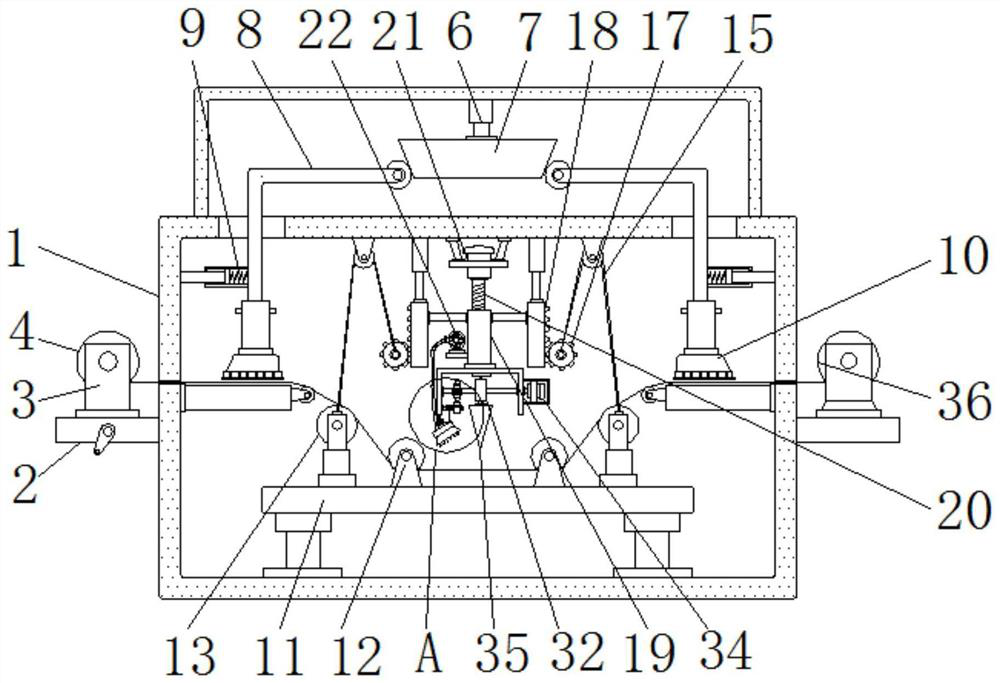

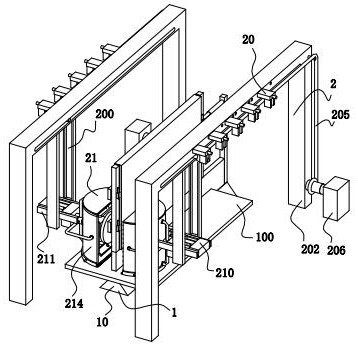

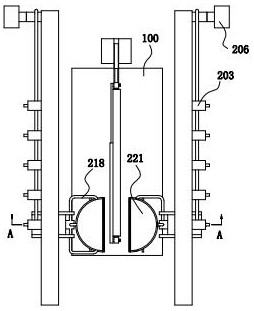

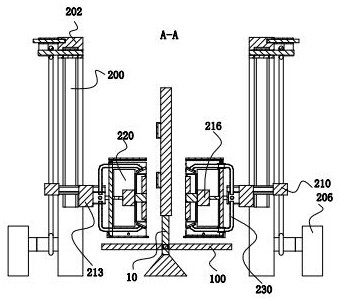

Industrial ventilation and dust removal equipment with adjusting function

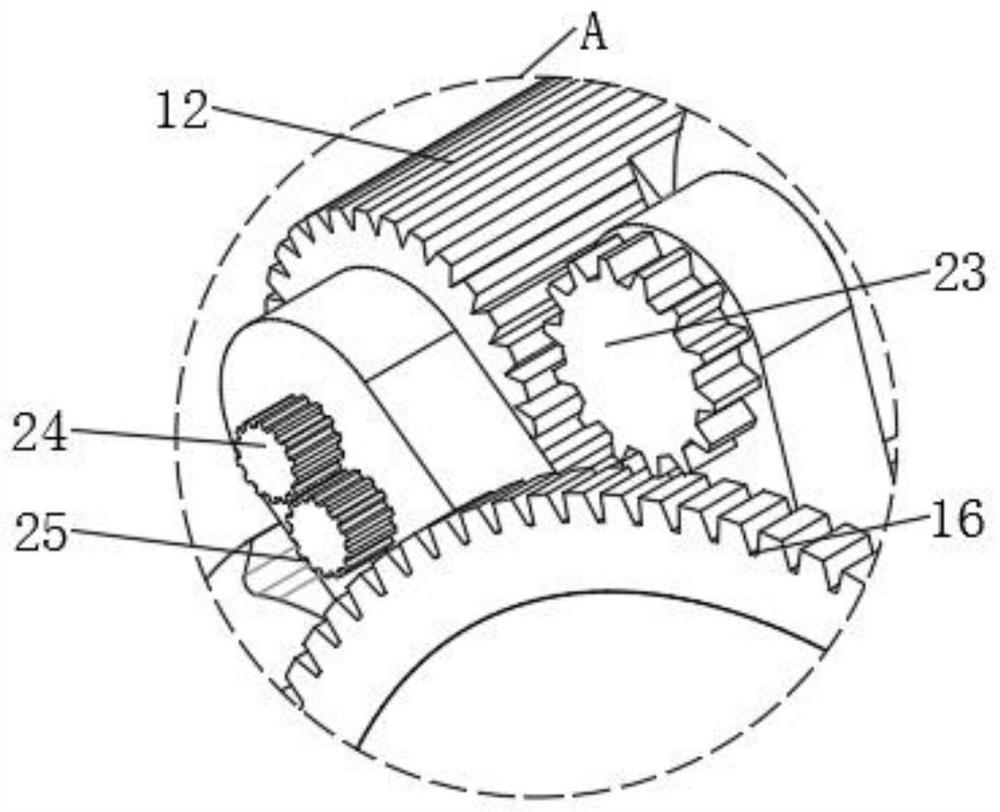

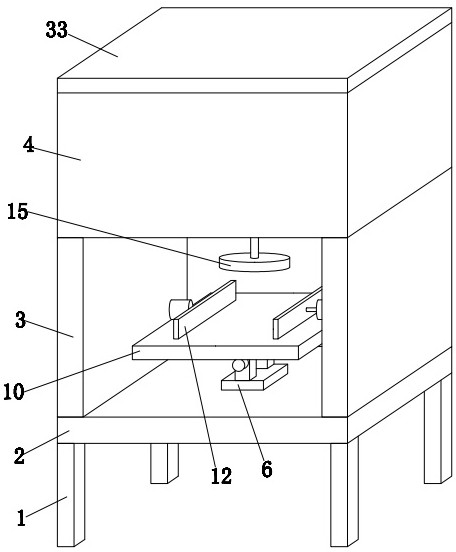

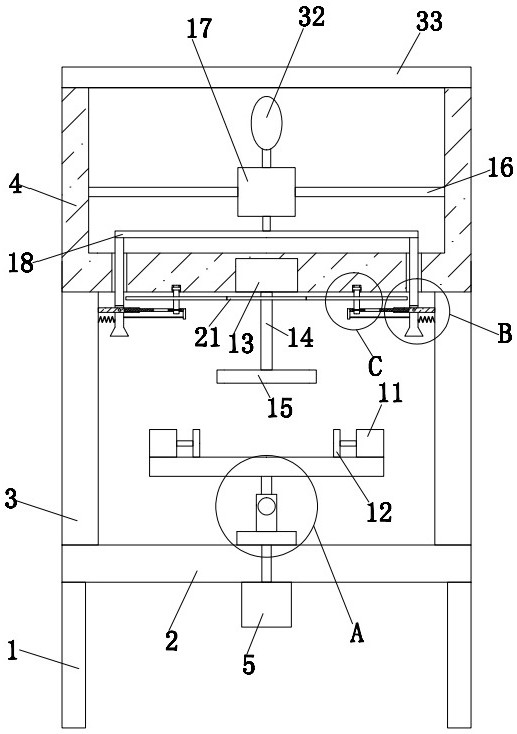

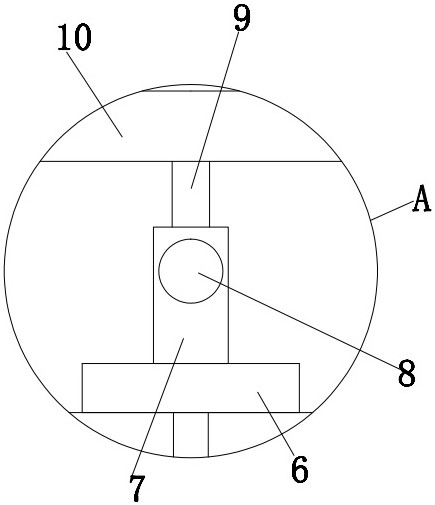

ActiveCN110899286AExpand the vacuum rangeImprove vacuuming effectDirt cleaningGear wheelDust control

The invention relates to industrial ventilation and dust removal equipment with an adjusting function. The equipment comprises a base, a host, a controller, a lifting mechanism, a platform, a dust hood, a swing mechanism, a swing plate, a connecting pipe and an adjusting mechanism. The swing mechanism comprises a translation component, a rack, a gear, a supporting component and a connecting rod. The translation component comprises a first motor, a screw rod and a translation block. The adjusting mechanism comprises a hinge component, a direction adjusting component and an air cylinder. By using the industrial ventilation and dust removal equipment with the adjusting function, the swing plate is driven by the swing mechanism to swing so that the dust hood swings at a dust source and a dustsuction range is expanded; and in addition, the adjusting mechanism is used for driving the dust hood to rotate and move so that the dust hood and the dust source keep a specific distance and angle, adust suction effect is improved, and practicability of the equipment is improved.

Owner:福建兴万祥建设集团有限公司

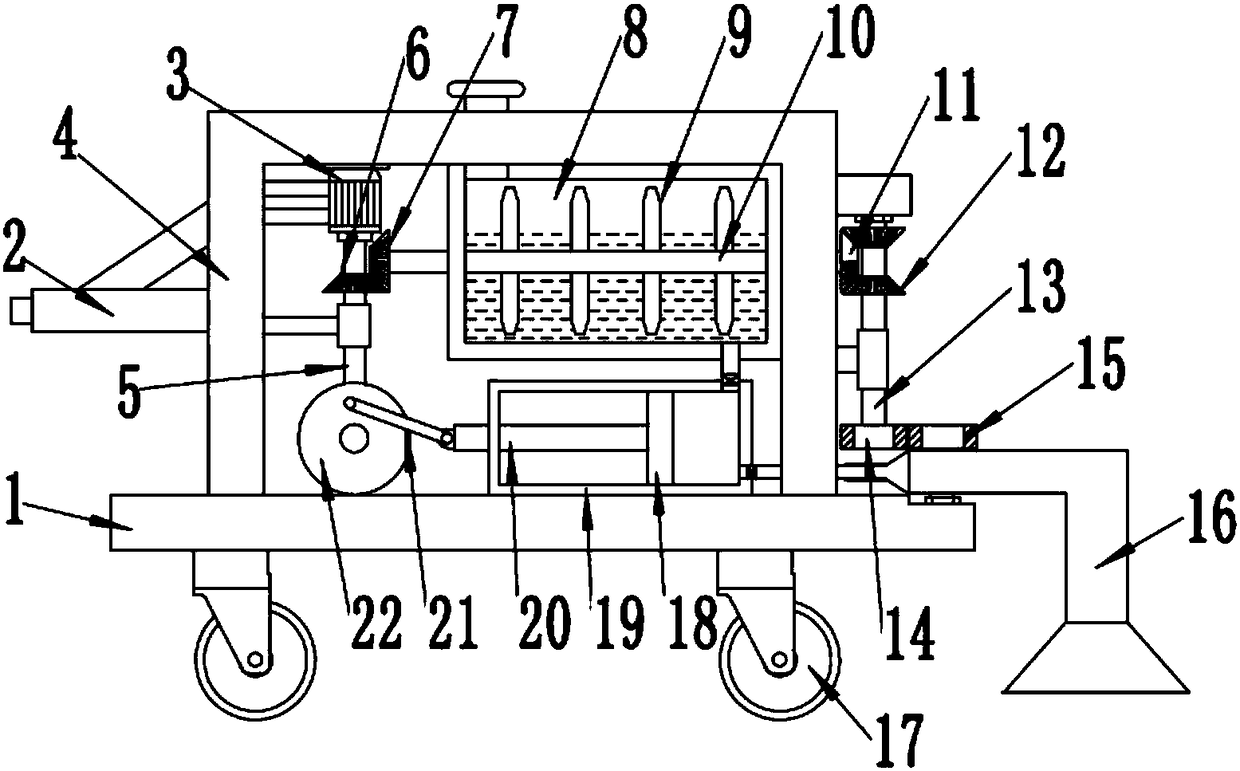

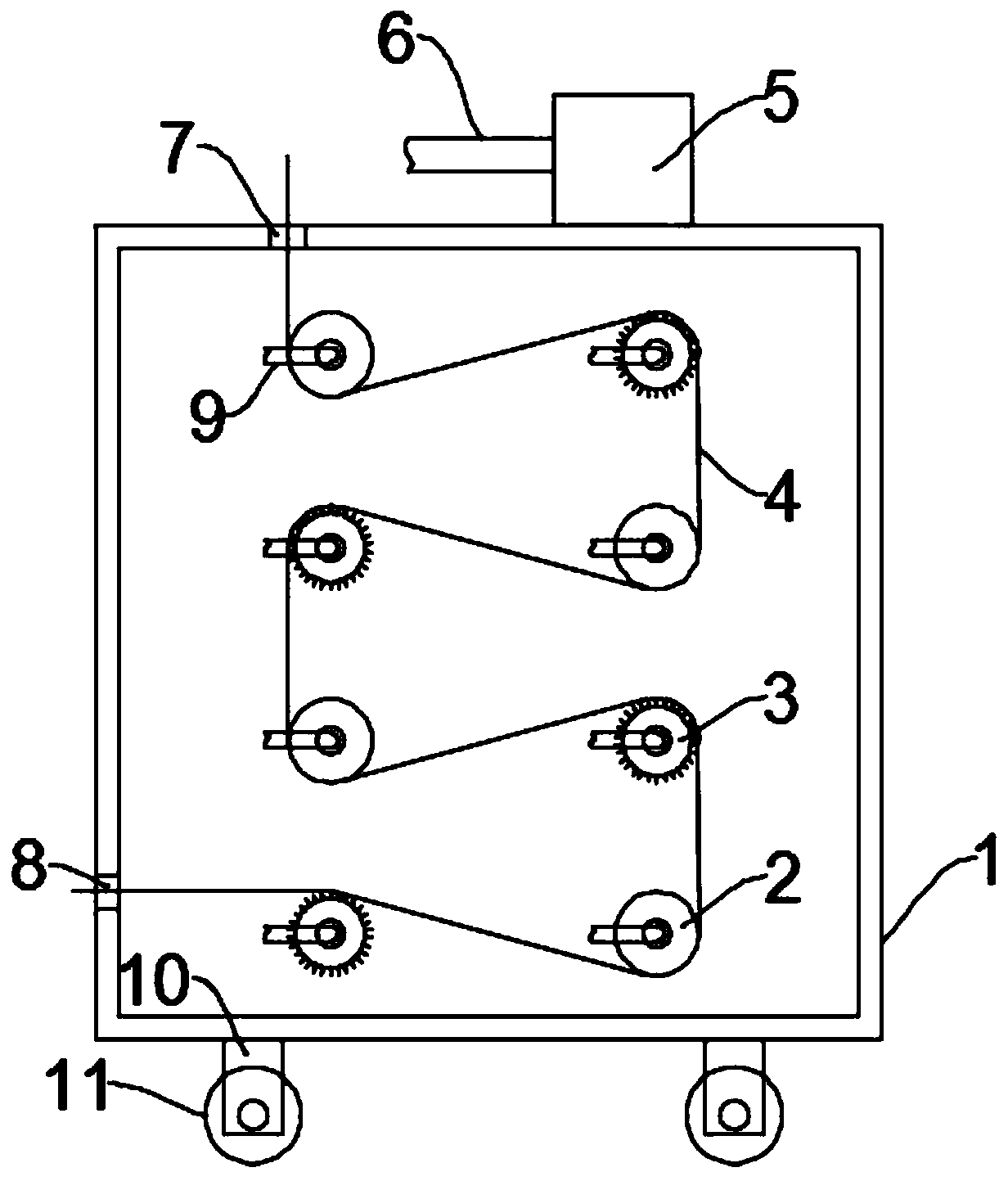

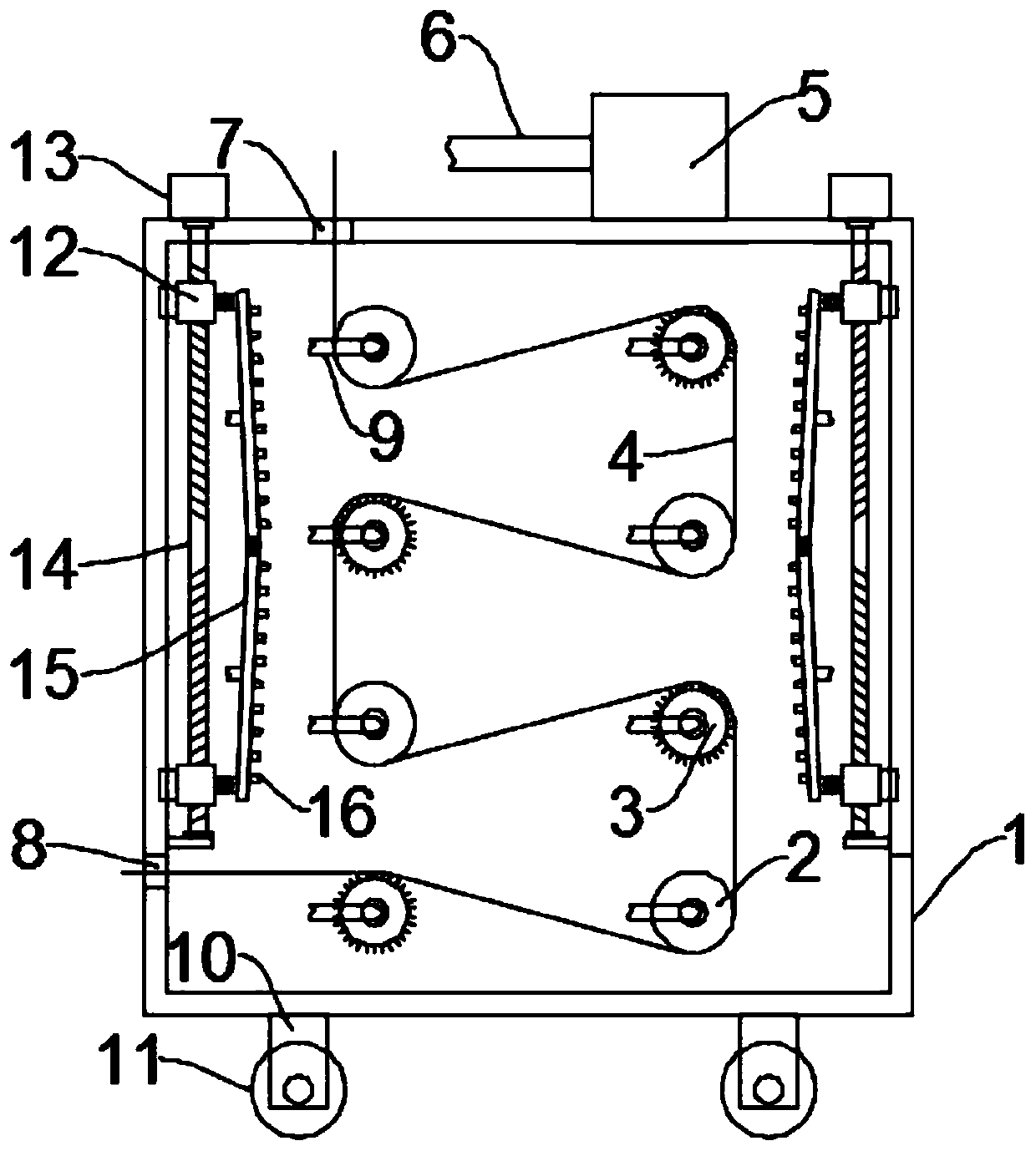

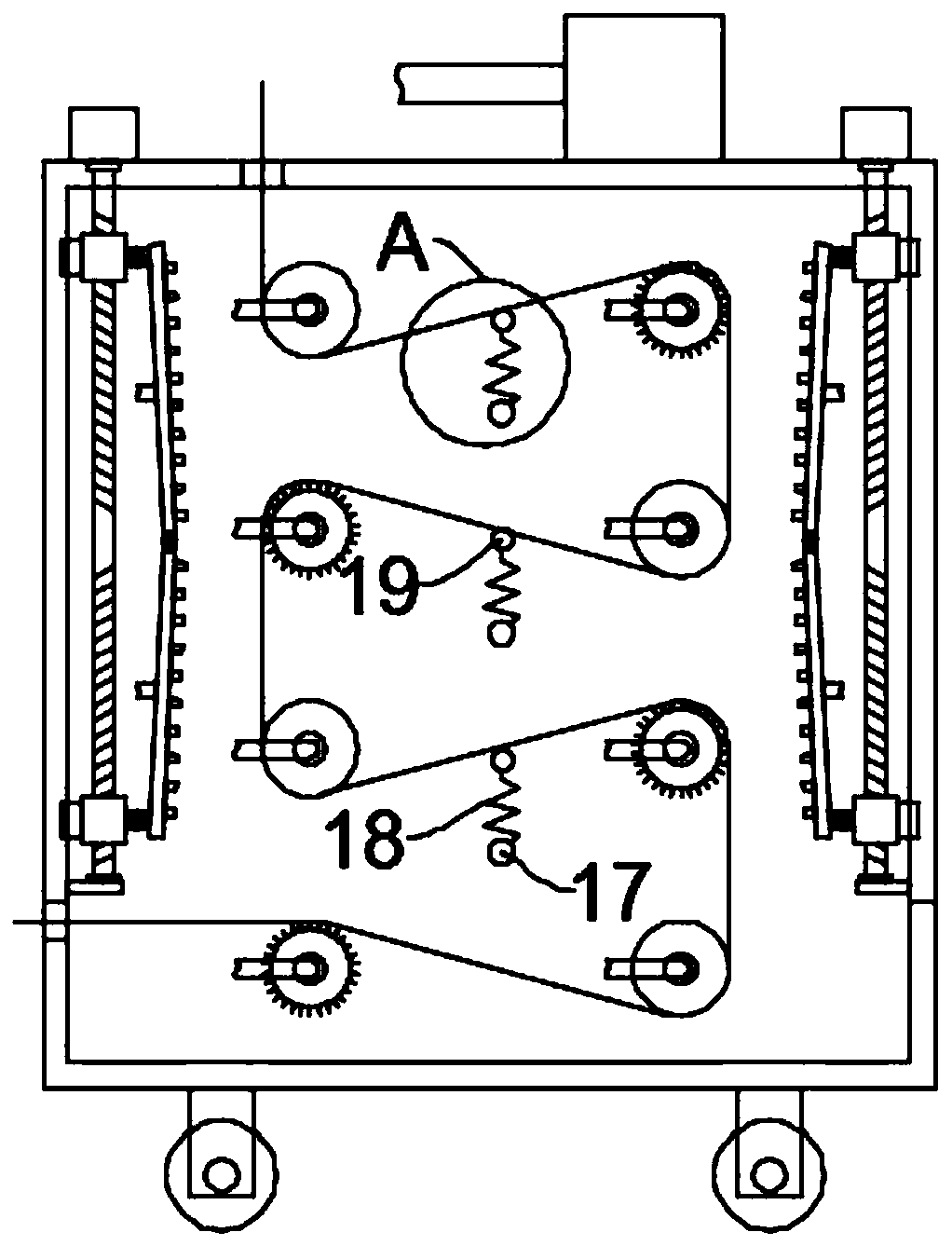

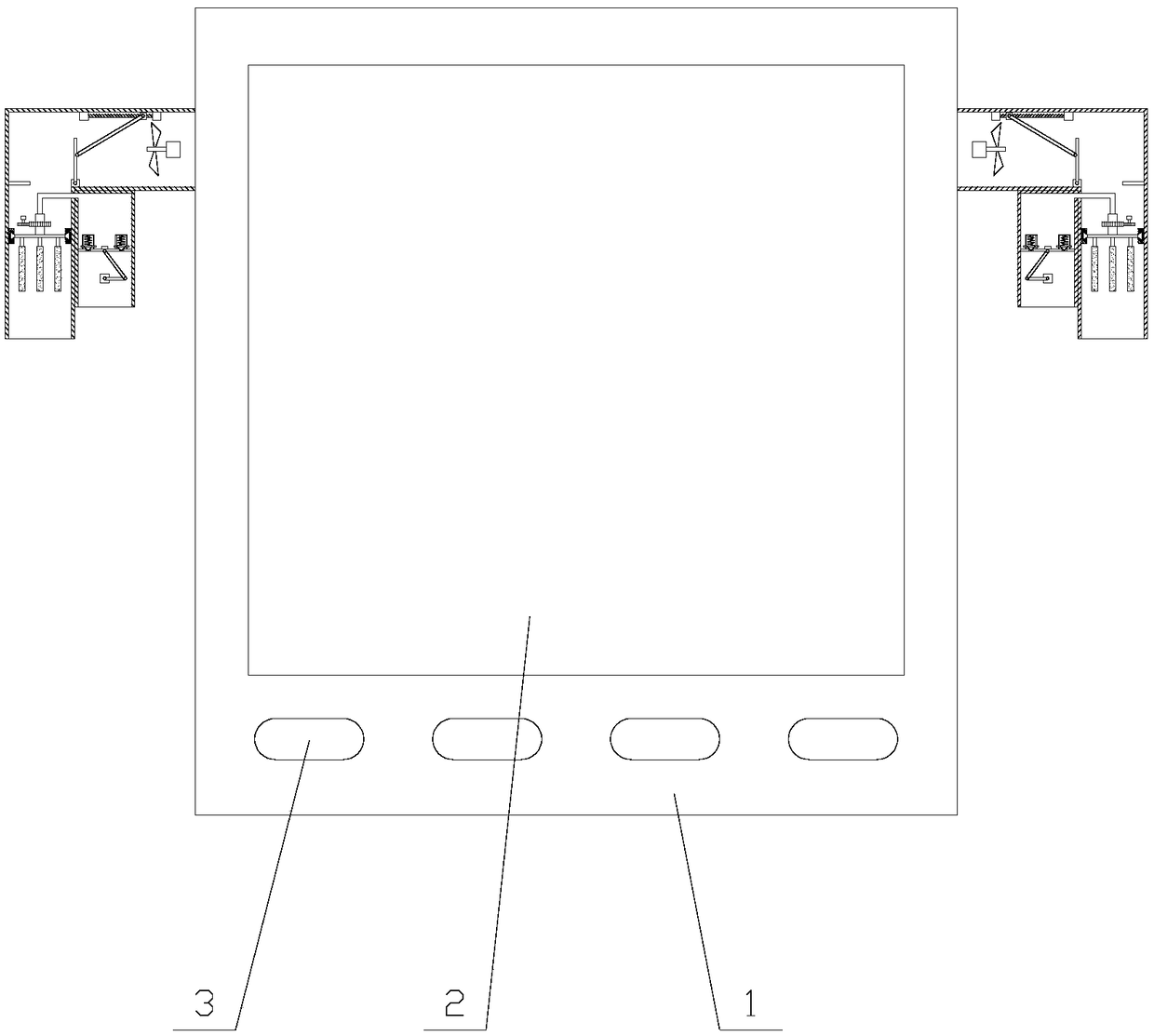

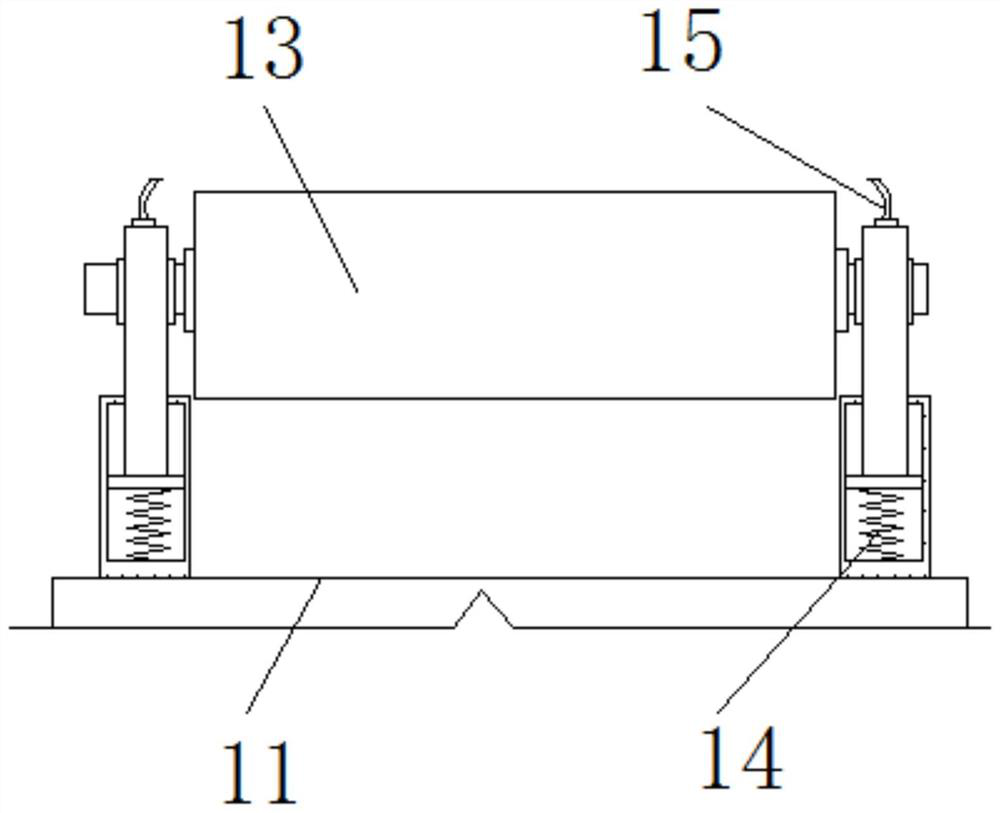

Textile dust collecting device for textile workshop

InactiveCN112176475AAchieve angle adjustmentExpand the vacuum rangeUsing liquid separation agentSeparation devicesFiberReciprocating motion

The invention discloses a textile dust collecting device for a textile workshop. The textile dust collecting device comprises a box body, a driving bin and a dust removing bin are arranged in the boxbody, an angle adjusting mechanism and a negative pressure mechanism are arranged in the driving bin, and a dust falling mechanism is arranged in the dust removing bin. By arranging the angle adjusting mechanism, angle adjustment of a dust collecting cover is achieved, and the dust collecting range is enlarged; by arranging the negative pressure mechanism, a sliding rod drives a piston plate to reciprocate while reciprocating left and right, negative pressure is generated at a cover opening of the dust collecting cover through movement of the piston plate, dust collection is conducted on the surrounding environment through an air guide pipe, an induced draft fan does not need to be additionally arranged, and the production cost is reduced; textile dust sucked into the dust removing bin issubjected to efficient dust falling by arranging the dust falling mechanism; and impurities such as the dust and cotton fibers are filtered by arranging a filter screen, filtered clear water flows into a water tank again, cyclic utilization of water is achieved, and water resources are saved.

Owner:蒋秀兰

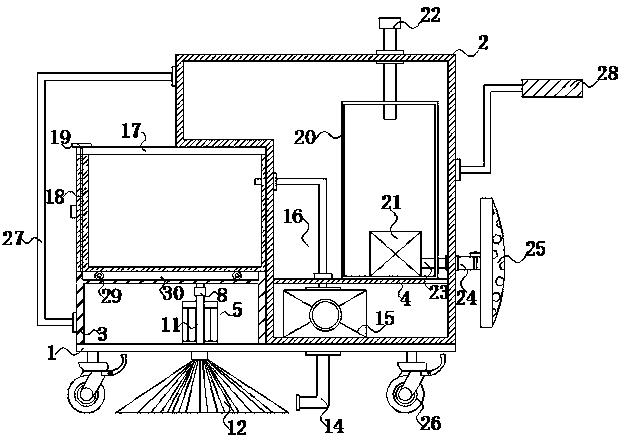

Garden road dust clearing device

ActiveCN108166425AWell mixedImprove adsorption efficiencyUsing liquid separation agentRoad cleaningGear driveArchitectural engineering

The invention discloses a garden road dust clearing device. The garden road dust clearing device comprises a bottom plate, a bracket, a dust falling cavity and a cylinder body; the bracket is fixedlymounted at the upper end of the bottom plate, a motor is mounted on the inner side of the bracket, the output end of the motor is fixedly connected with a rotating shaft, and a bevel gear A is fixedlymounted on the rotating shaft and engaged with a bevel gear B fixedly mounted at the left end of a stirring shaft; and the stirring shaft penetrates through a dust falling box and simultaneously penetrates through the vertical end of the right side of the bracket and is fixedly connected with an incomplete bevel gear, and stirring bars are symmetrically on the stirring shaft of the inner side ofthe dust falling box. The garden road dust clearing device is novel in design, water in the dust falling box is stirred through rotating of the arranged stirring bars, mixing of dust airflow and clearwater is facilitated, the efficiency and effect of dust being adsorbed by the clear water are improved, and the dust is prevented from escaping again with the airflow; and an arranged driving gear drives a dust sucking hood to swing back and forth through a driven gear, the dust sucking range of the dust sucking hood is enlarged accordingly, and the dust sucking efficiency is improved.

Owner:刘华英

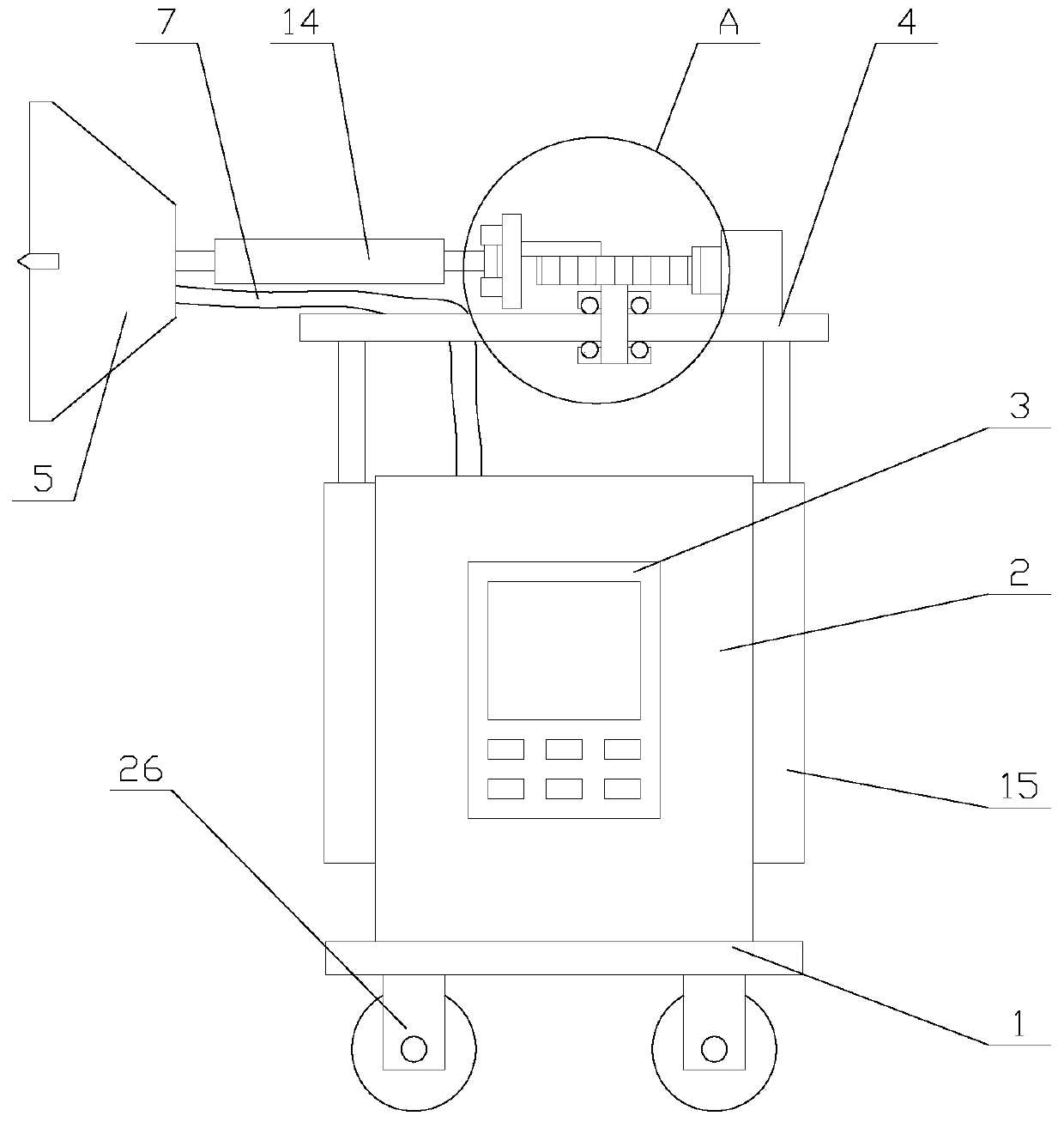

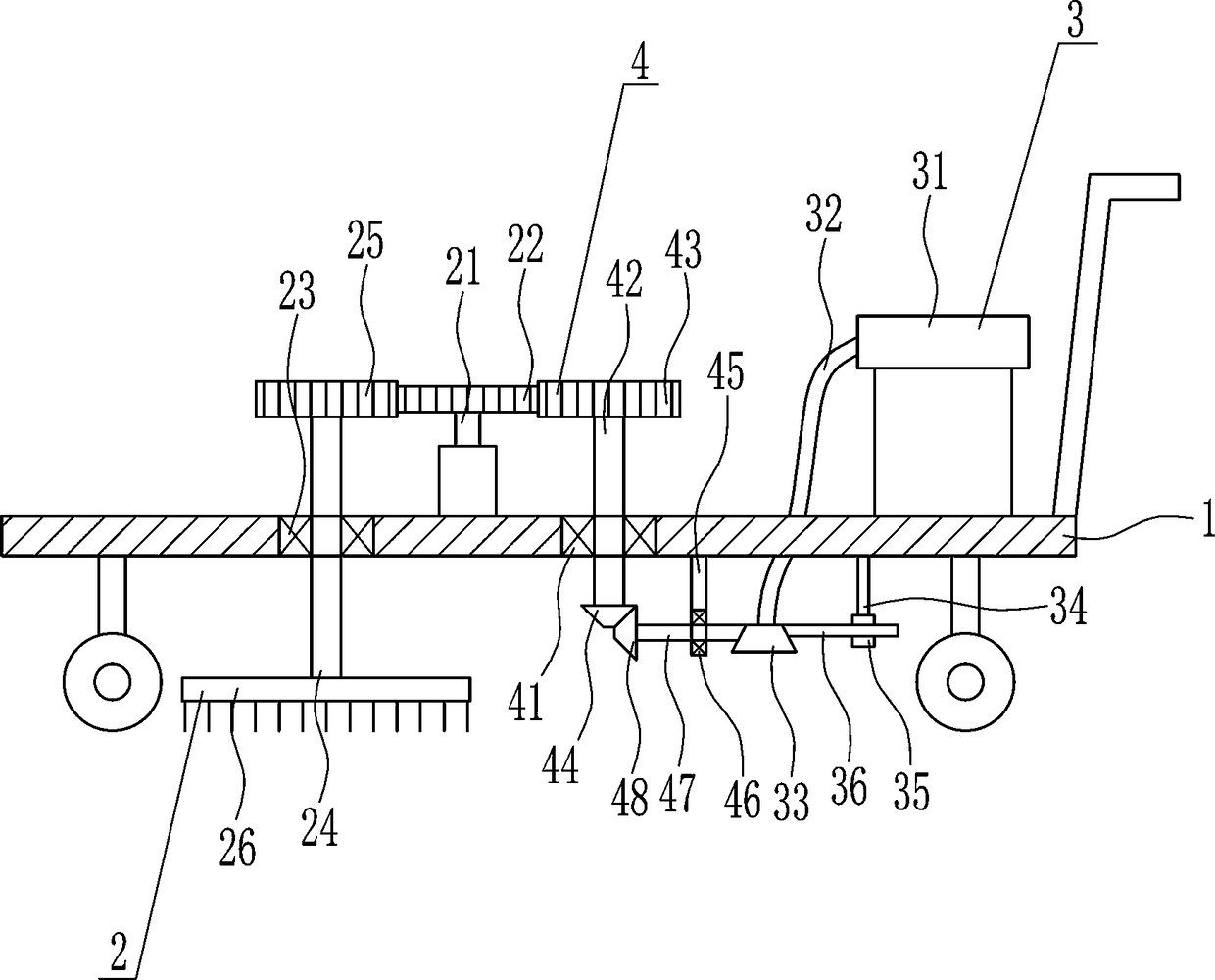

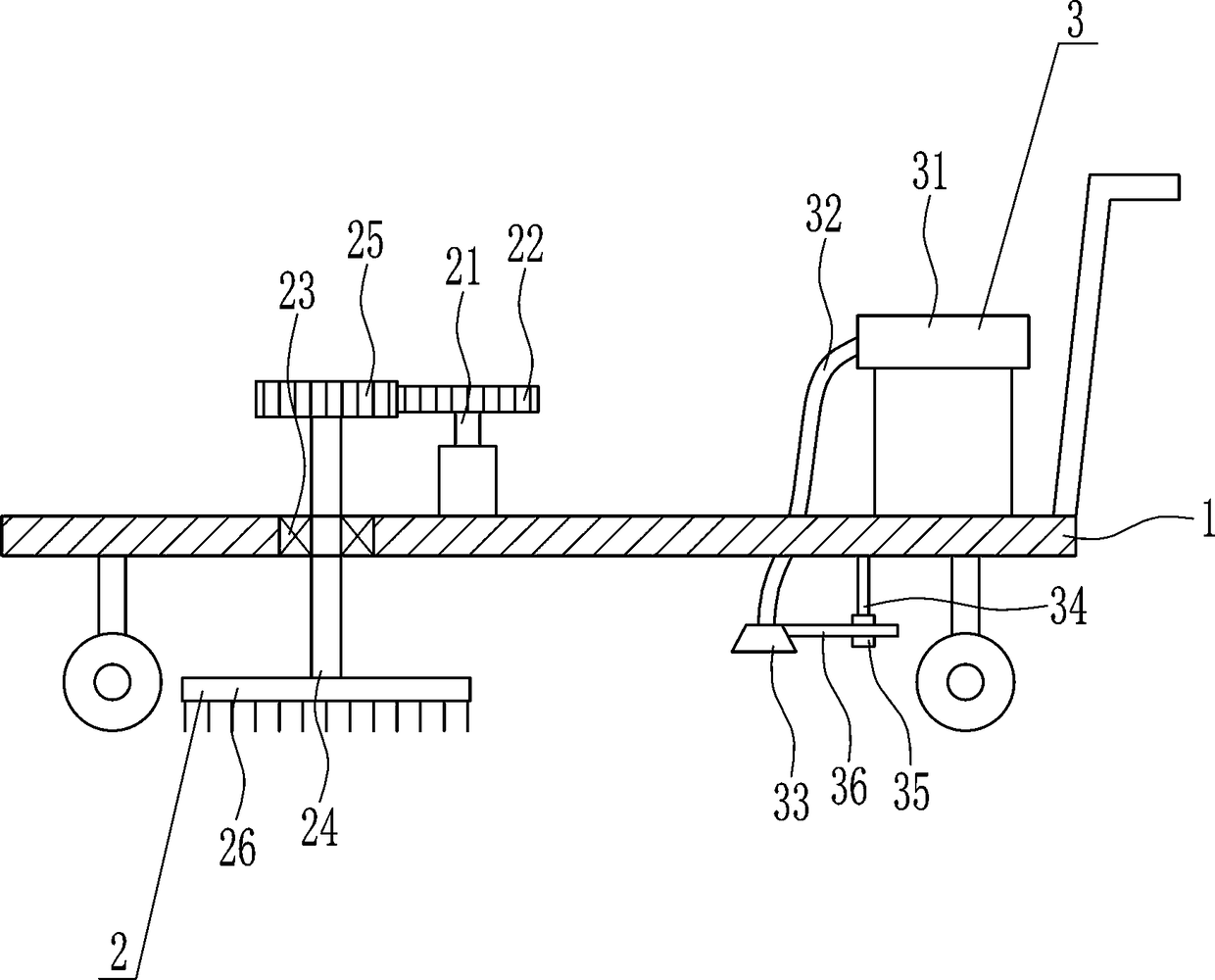

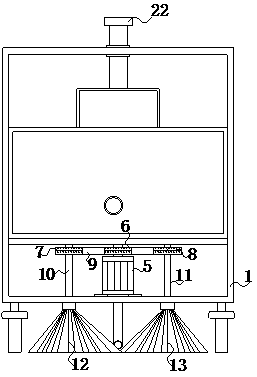

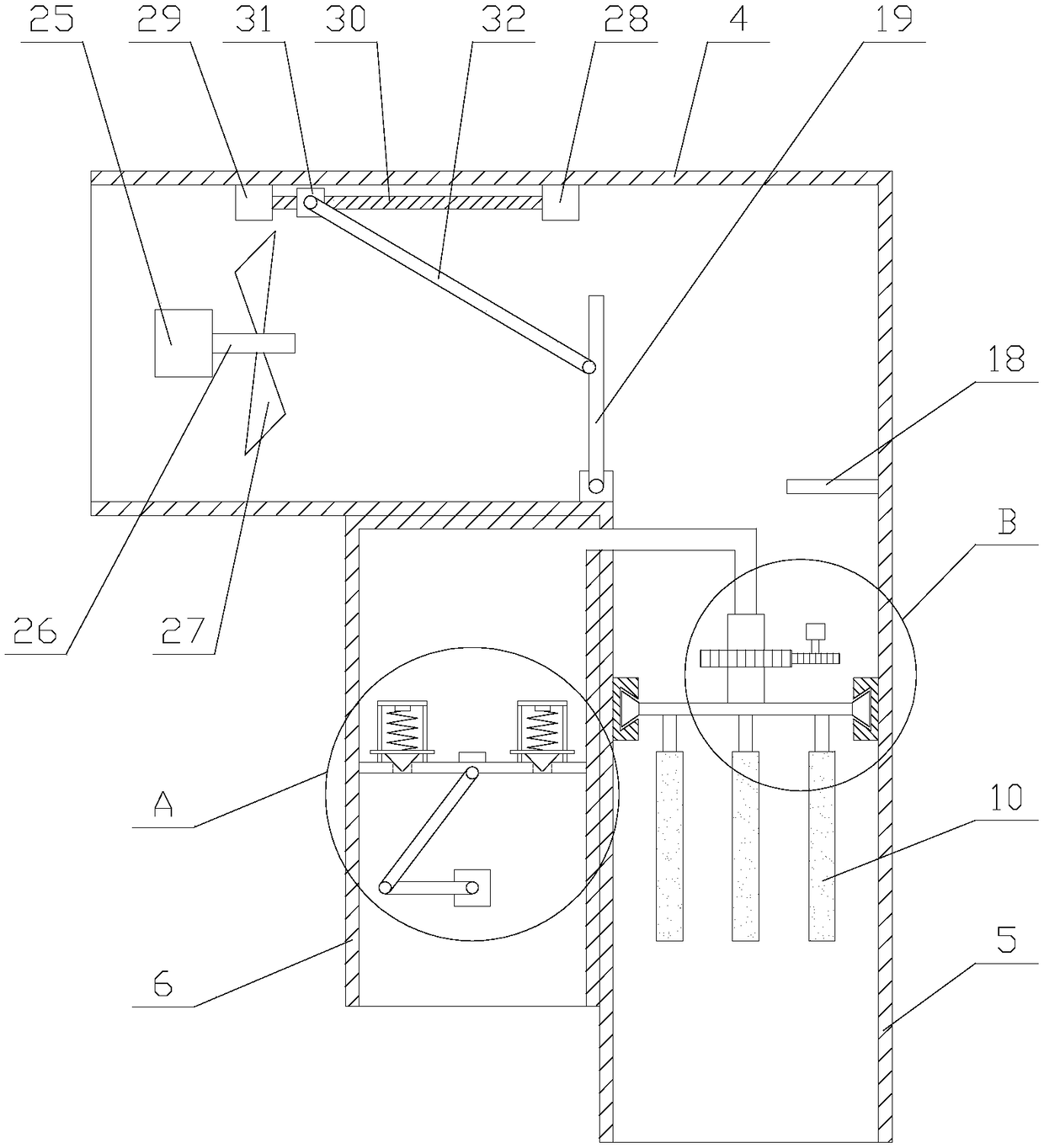

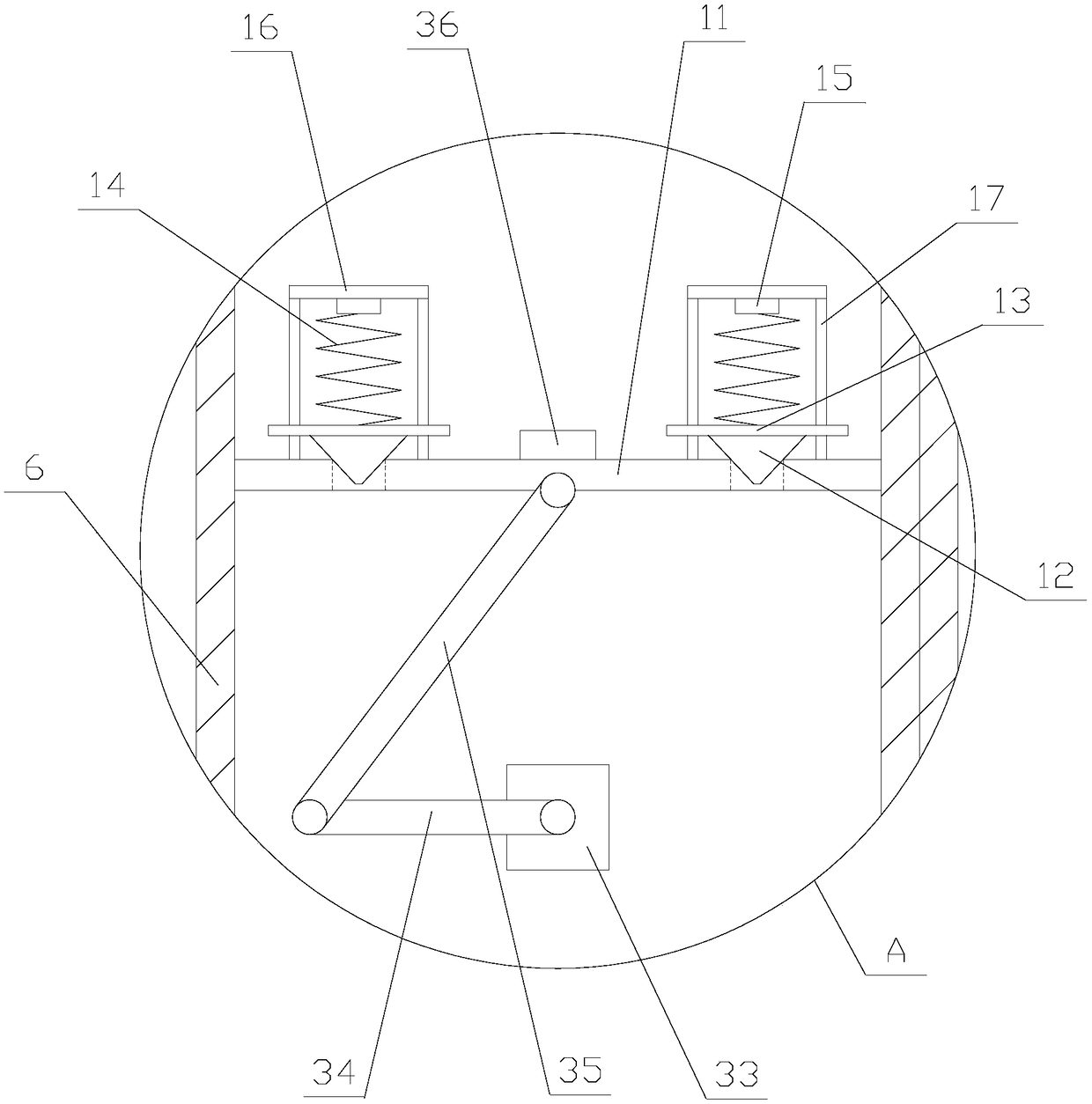

Alley cleaning device used for garden

The invention relates to a cleaning device, in particular to an alley cleaning device used for a garden. The alley cleaning device used for the garden is high in work efficiency and clean in sweep. The alley cleaning device used for garden comprises a trolley and the like. A cleaning device is installed on the left side of the top portion of the trolley, and a dust exhaust device is installed on the right side of the top portion of the trolley. The alley cleaning device used for garden cleans an alley through the cleaning device, and exhausts the rubbishes which are cleaned out through the exhaust dust device; a swing device can be driven by the cleaning device to work; the exhaust dust device can be driven by the swing device to work; and the dust collection scope is increased ,so that the cleaning effect is improved.

Owner:台州市路桥高精模具厂

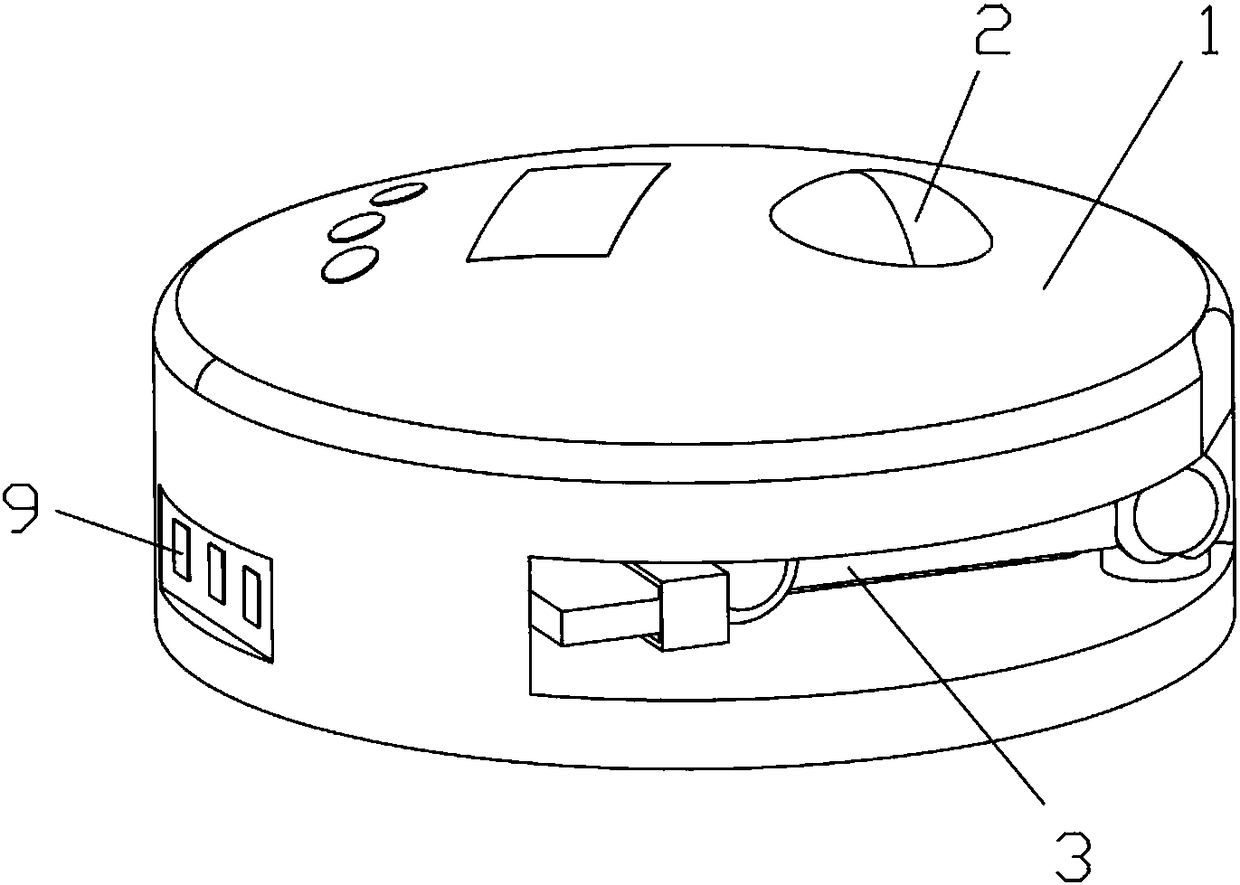

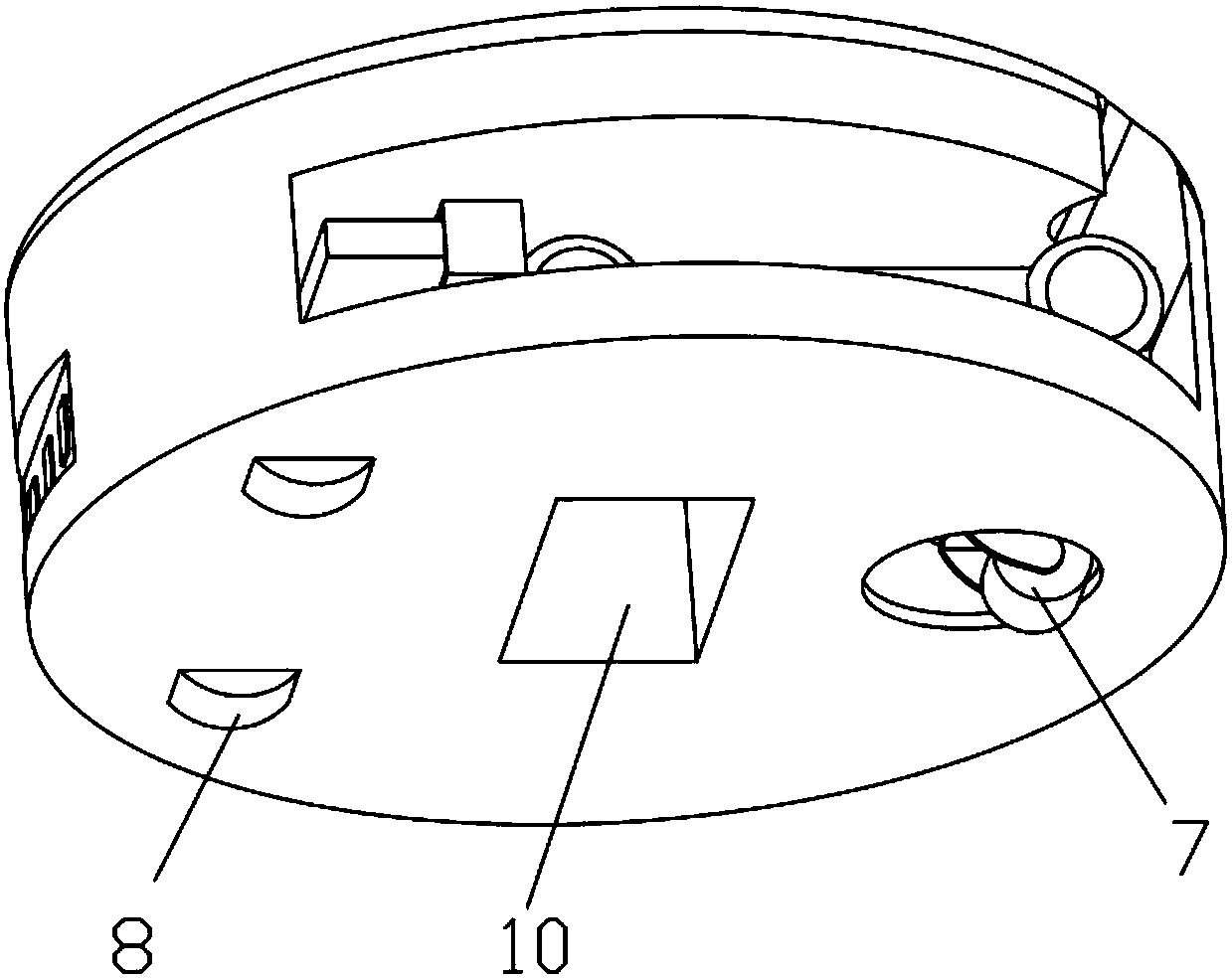

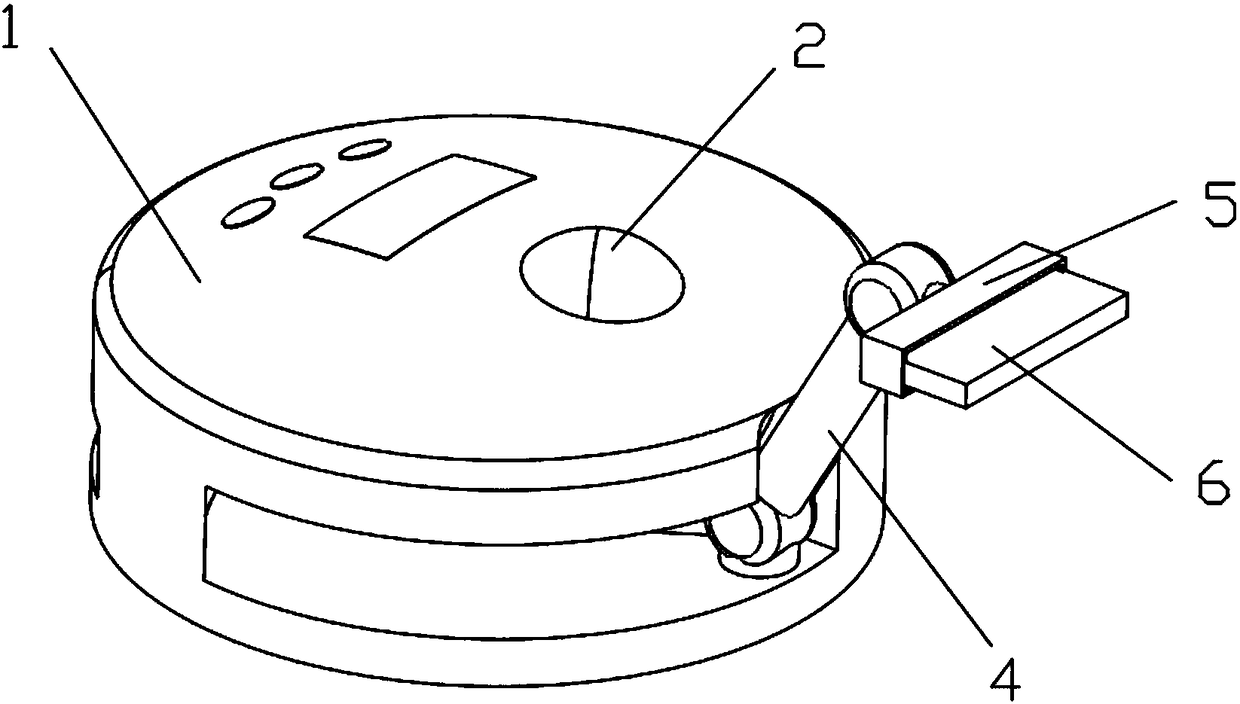

Sweeping robot

InactiveCN108403013ASmart cleaningHigh degree of intelligenceAutomatic obstacle detectionTravelling automatic controlEngineeringVacuum cleaner

The embodiment of the invention relates to the field of household appliances, and discloses a sweeping robot. The sweeping robot comprises a dust collector body, a scanning device, an auxiliary cleaning device and a control device. The dust collector body is used for cleaning the ground. The scanning device is arranged on the vacuum cleaner body for scanning the surrounding environment. The auxiliary cleaning device is arranged on the cleaner body for assisting the cleaner body to perform cleaning. The control device is electrically and respectivelyconnected to the scanning device, the auxiliary cleaning device and the vacuum cleaner body, which is used to identify the content scanned by the scanning device, and plan the cleaning route and control the movement of the vacuum cleaner body according to the scanned content. The control device is also used to control the auxiliary cleaning device to clean the dead angle position when the cleaner body moves to the cleaning dead angle position. The sweeping robot in the invention can be cleaned to a blind angle with a larger dust collecting range and more intelligent cleaning.

Owner:SHANGHAI YUDE COMM TECH

Quick stripping device for power cable recycling

ActiveCN111243800AImprove recycling efficiencyIncrease frictionBasic electric elementsElectronic waste recyclingPower cableCopper wire

The invention belongs to the technical field of electric power tools, and in particular relates to a quick stripping device for power cable recycling. According to an existing peeling mode, a blade ismanually held for peeling; the safety performance during peeling is low; and the recovery efficiency of a cable is influenced. According to the invention, the quick stripping device comprises a base;two first supporting plates are fixed on the outer wall of the top of the base through screws; the outer walls of the opposite sides of the two first supporting plates are connected with the same rotating rod through bearings; the outer wall of the rotating rod is sleeved with a peeling knife; the outer walls, located on the two sides of the peeling knife, of the rotating rod are sleeved with anti-skid wheels; and second supporting plates are fixed on the outer walls of the tops of the two first supporting plates through screws. According to the invention, the peeled cable sheath and the internal copper wire can be respectively wound on a sheath winding roller and a wire winding roller; the automation degree is high; manpower and material resources are saved; the safety in the peeling process is improved; and the recycling efficiency of the cable is improved.

Owner:CRANE GRP OF HUNAN CABLE TECH

Dust collection device for building construction and working method of dust collection device

InactiveCN110552307AEasy to collectExpand the scope of cleaningRoad cleaningFixed frameArchitectural engineering

The invention discloses a dust collection device for building construction and a working method of the dust collection device, and relates to the field of buildings. The dust collection device for thebuilding construction comprises a base, a U-shaped dust collecting box and a sucking rod, wherein a box body, a fixing frame and a driving motor are fixed on the outer surface of the top of the base;walking wheels are rotationally arranged on the outer surface of the bottom of the base; a first gear is fixedly arranged on an output shaft of the driving motor; two groups of sliding rails are arranged at the top of the fixing frame; a first rotating rod and a second rotating rod are rotationally arranged at the top of the inner side of the fixing frame; one end of the first rotating rod extends below the base and is fixedly provided with a first rotating cleaning brush; one end of the second rotating rod extends below the base and is fixedly provided with a second rotating cleaning brush;and a second gear is fixedly arranged on the outer wall of the first rotating rod. According to the device and the method, the cleaning range and the dust collection range are expanded, so that the dust removal effect is improved.

Owner:陕西闹闹馨馨知识产权服务有限公司

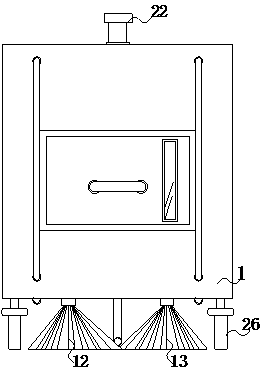

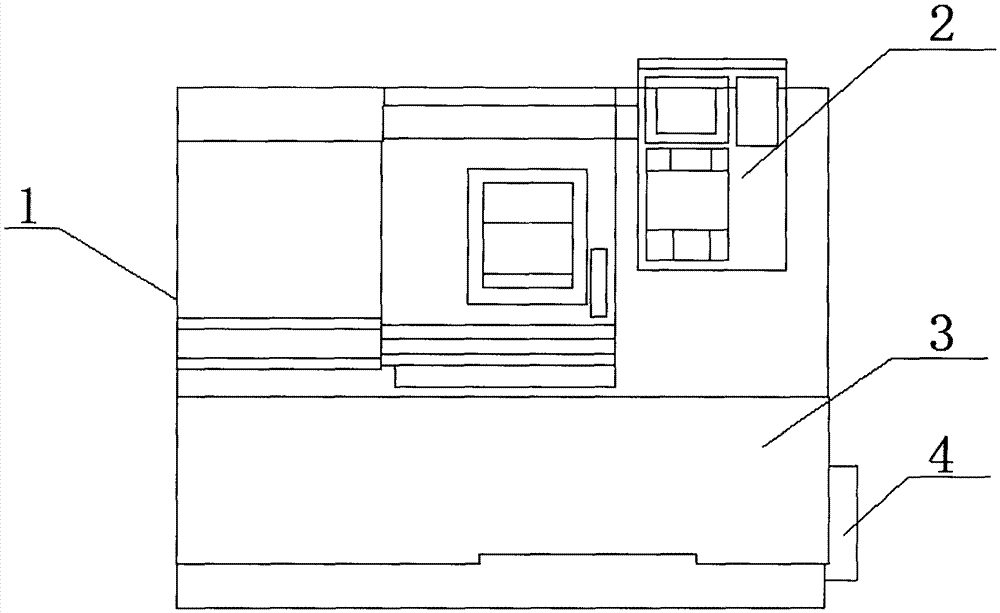

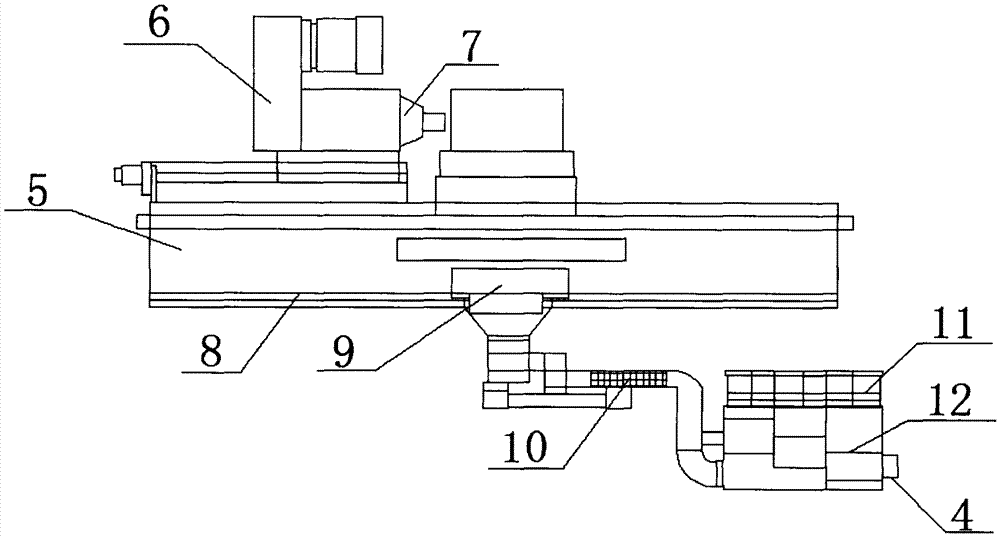

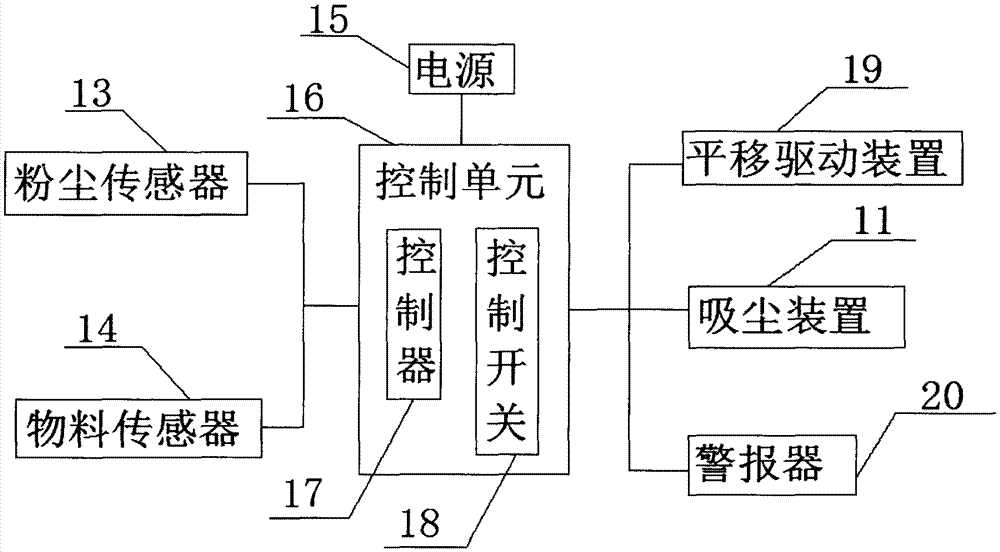

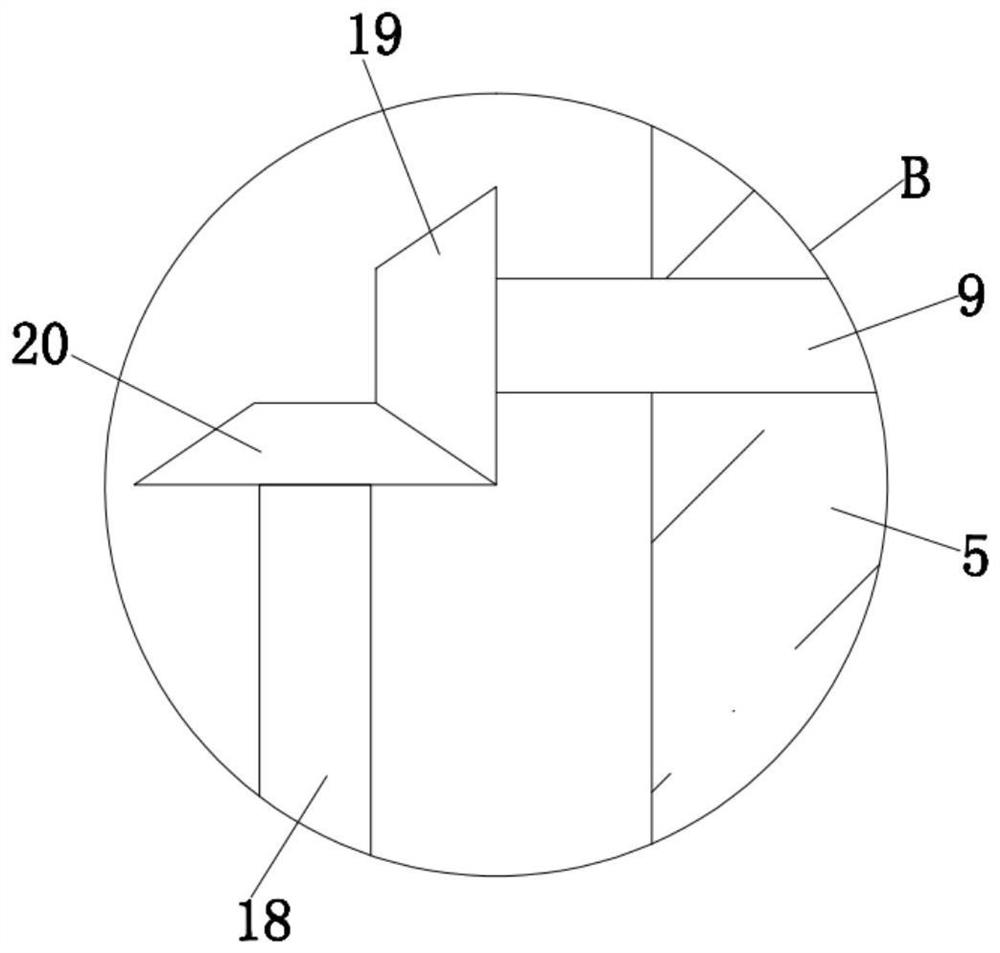

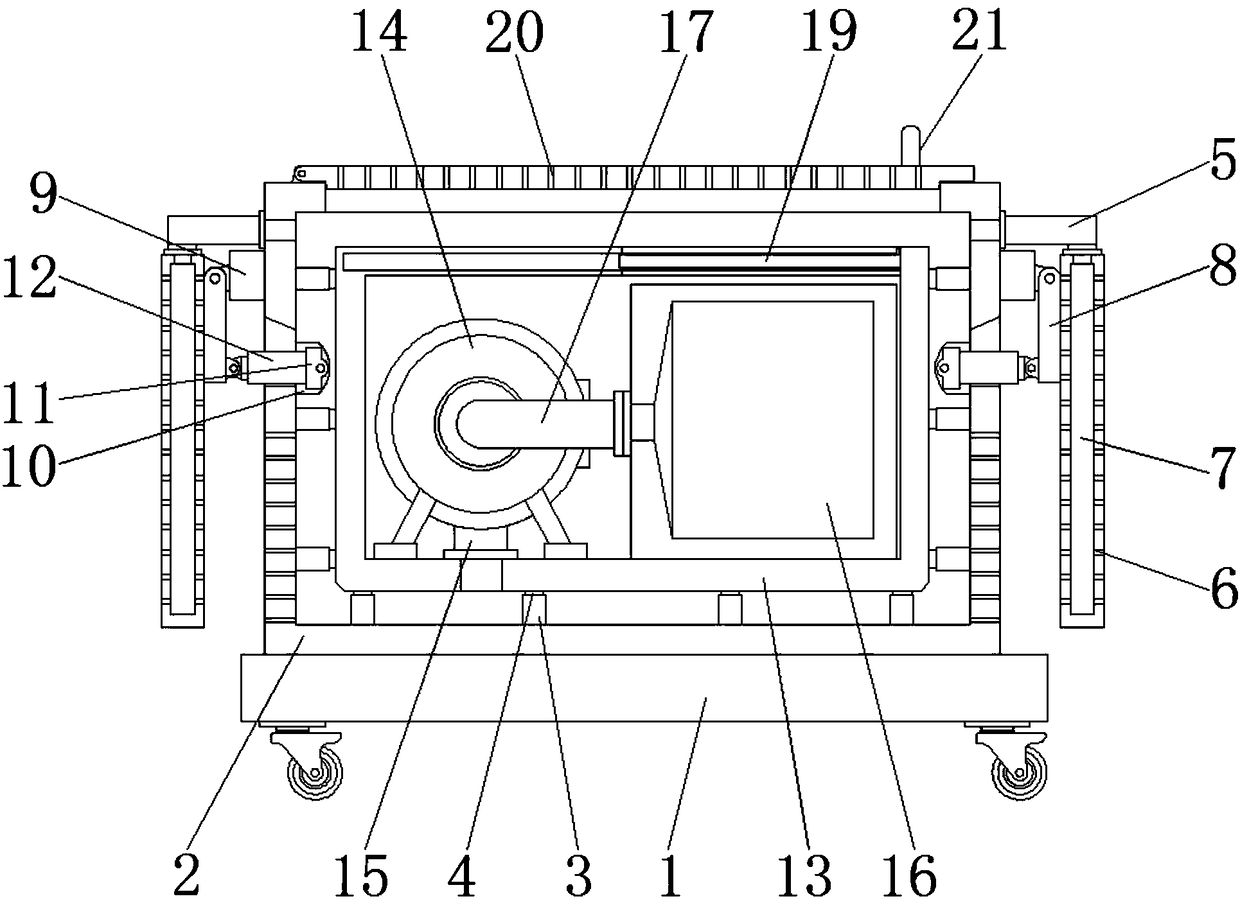

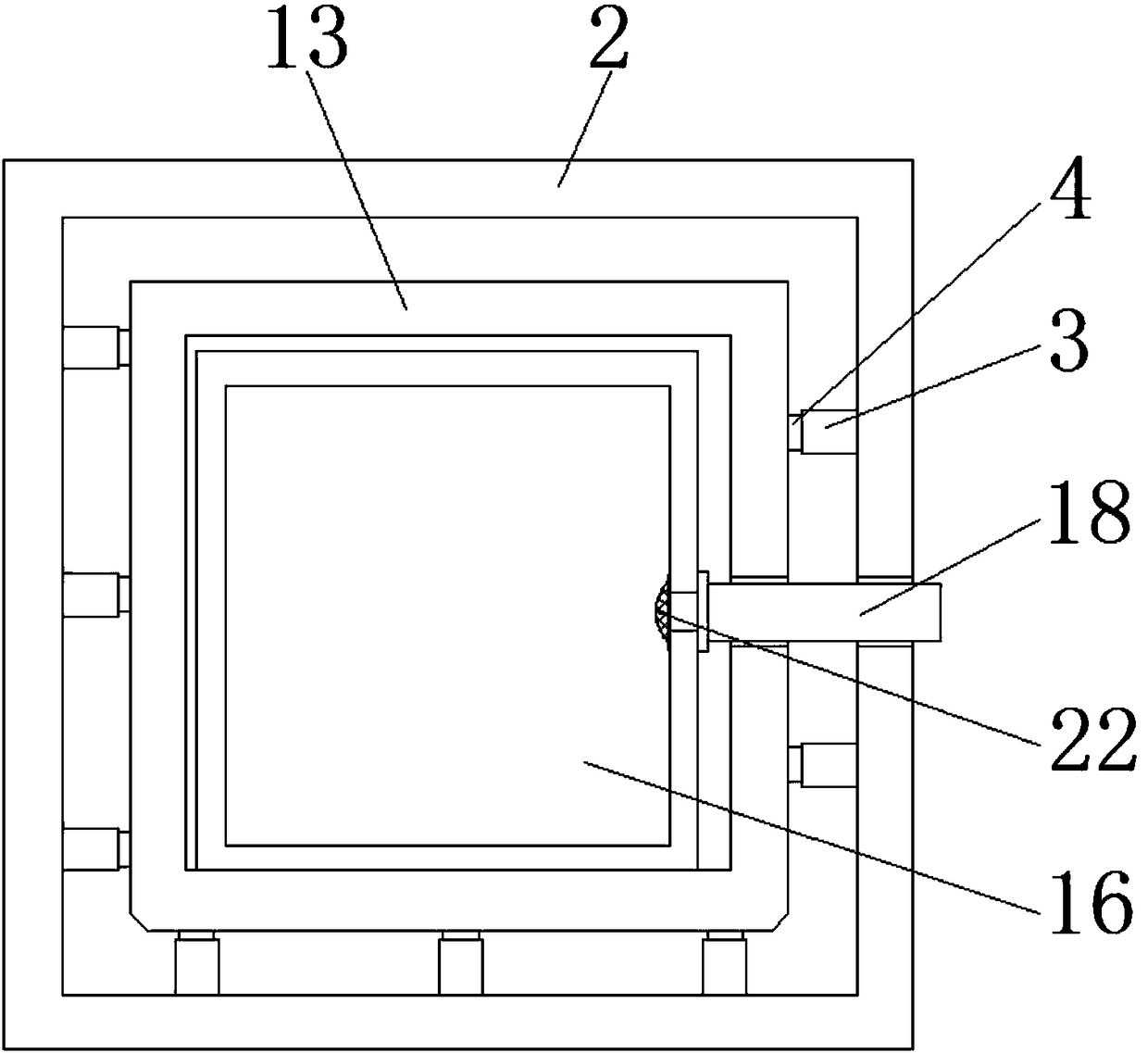

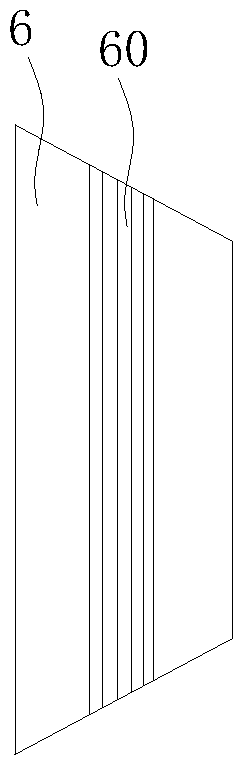

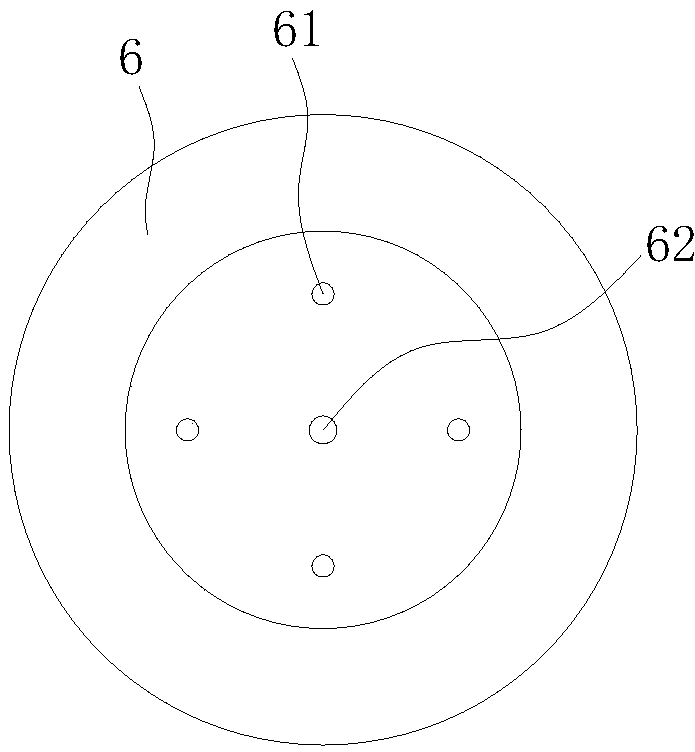

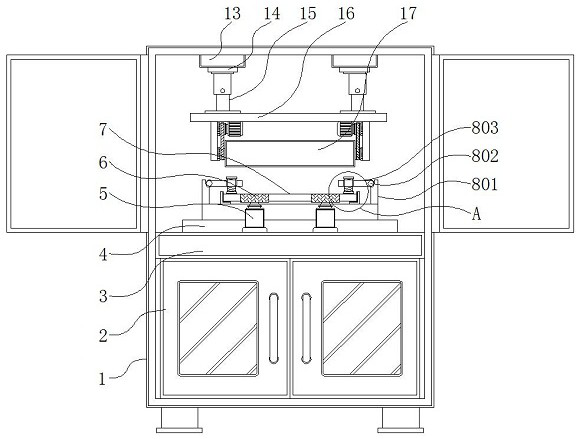

High-airtightness numerically-controlled machine tool with material suction device

InactiveCN105436985AImprove sealingExpand the vacuum rangeMaintainance and safety accessoriesNumerical controlPush pull

The invention relates to a high-airtightness numerically-controlled machine tool with a material suction device. The high-airtightness numerically-controlled machine tool with the material suction device comprises a numerically-controlled machine tool body which is provided with an operation platform. A base is arranged at the bottom of the numerically-controlled machine tool body. A machine frame and a dust suction device are arranged in the numerically-controlled machine tool body. A cutting device and a fixture are arranged on the machine frame. The fixture is mounted on the cutting device. A rail is arranged at the bottom of the machine frame. The dust suction device comprises a dust suction cover, a retractable hose, a dust suction unit and a containing device. The dust suction cover is connected with the dust suction unit through the retractable hose. A cavity is formed in the dust suction unit. The containing device is arranged in the cavity. A push-pull handrail is arranged on one side of the containing device. A dust sensor is arranged in the numerically-controlled machine tool body. A material sensor is arranged in the containing device. The high-airtightness numerically-controlled machine tool with the material suction device is reasonable in design, flexible in use and wide in working range.

Owner:CHANGSHU HUIYI MECHANICAL&ELECTRICAL CO LTD

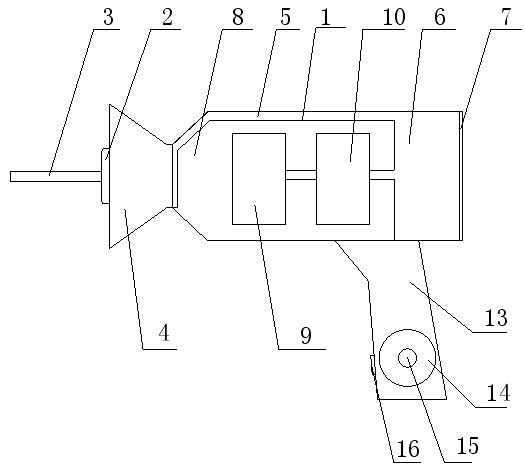

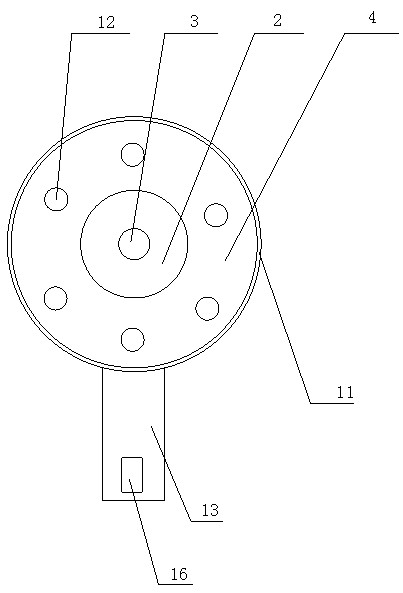

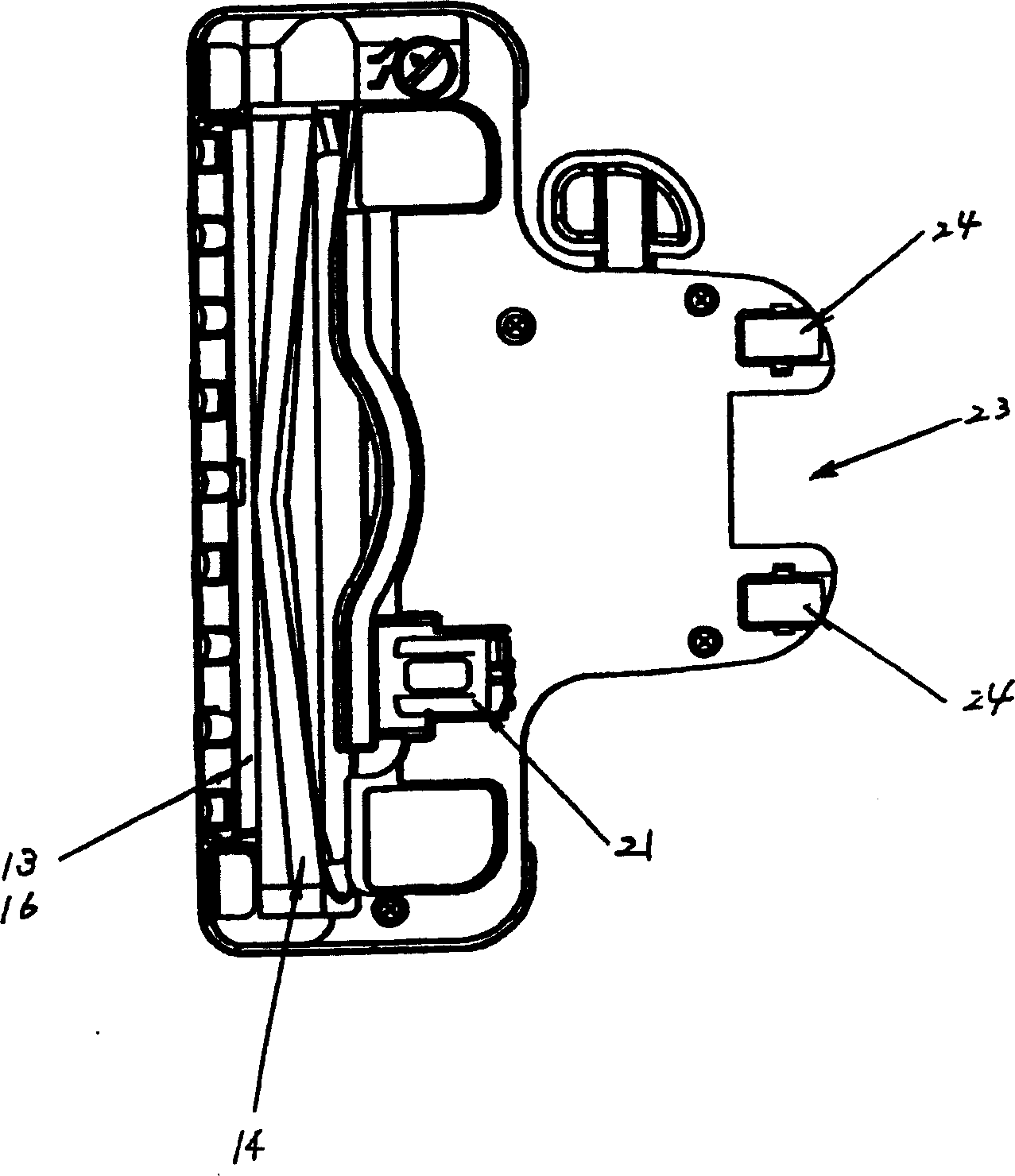

Dust collecting electric drill with illumination function

InactiveCN102658384AIncrease the suction areaVacuum thoroughlyPortable power-driven toolsPortable drilling machinesElectricityEngineering

The invention discloses a dust collecting electric drill with illumination function, which comprises an electric drill main body, an electric drill bit holder, and an electric drill bit. The electric drill main body head part is provided with the electric drill bit holder, and the electric drill bit holder is provided with the electric drill bit, wherein a dust collecting mask is arranged between the electric drill bit holder and the electric drill main body and connected with a hose, the hose is connected with a dust / drill cuttings storage chamber, the dust / drill cuttings storage chamber has one side provided with an opening and the other side connected with a driving chamber, a driving motor is arranged in the driving chamber and connected with a suctioning fan, the suctioning fan communicates with the dust / drill cuttings storage chamber, an interlayer is arranged in the dust collecting mask, and a plurality of illuminating lamps are arranged in the interlayer. The invention has the advantages that the dust collecting part of an improved electric drill is increased, that the dust collecting range covered by the dust collecting mask is larger, that dust collection is thorough, that the illuminating lamps arranged on the dust collecting mask can bring convenience to work at night, and that a wire storage device at an electric drill handle can hold electric drill wires to convenience long-distance work.

Owner:黄正兴

Novel environment-friendly dust removal equipment

InactiveCN112121571AImprove dust removal efficiencyIncrease the degree of filtrationCombination devicesDirt cleaningReciprocating motionDust control

The invention provides novel environment-friendly dust removal equipment, and belongs to the technical field of dust removal. The equipment comprises a dust removal box, and the upper end of the dustremoval box is rotatably connected with a turntable. The upper end of the turntable is fixedly connected with a first connecting pipe. The surface of the first connecting pipe is movably sleeved witha second connecting pipe. The upper end of the second connecting pipe is fixedly connected with a mounting pipe sleeve. The left end of the mounting pipe sleeve is fixedly connected with an air suction hopper. An up-down reciprocating motion mechanism is arranged on the upper side of the turntable. An atomizing nozzle is arranged on the right portion of the upper end of the dust removal box. A mounting cavity and a dust collection cavity are formed in the dust removal box. The first connecting pipe movably penetrates through the lower end of the turntable and extends into the mounting cavity.A rotating mechanism is arranged on the circumferential surface of the first connecting pipe located in the mounting cavity, and the lower end of the first connecting pipe is rotationally connected with a third connecting pipe. Dust in air can be comprehensively absorbed, the dust absorption efficiency is improved, and moving is convenient.

Owner:NANJING HANERSI BIOLOGY TECHNOLOGY CO LTD

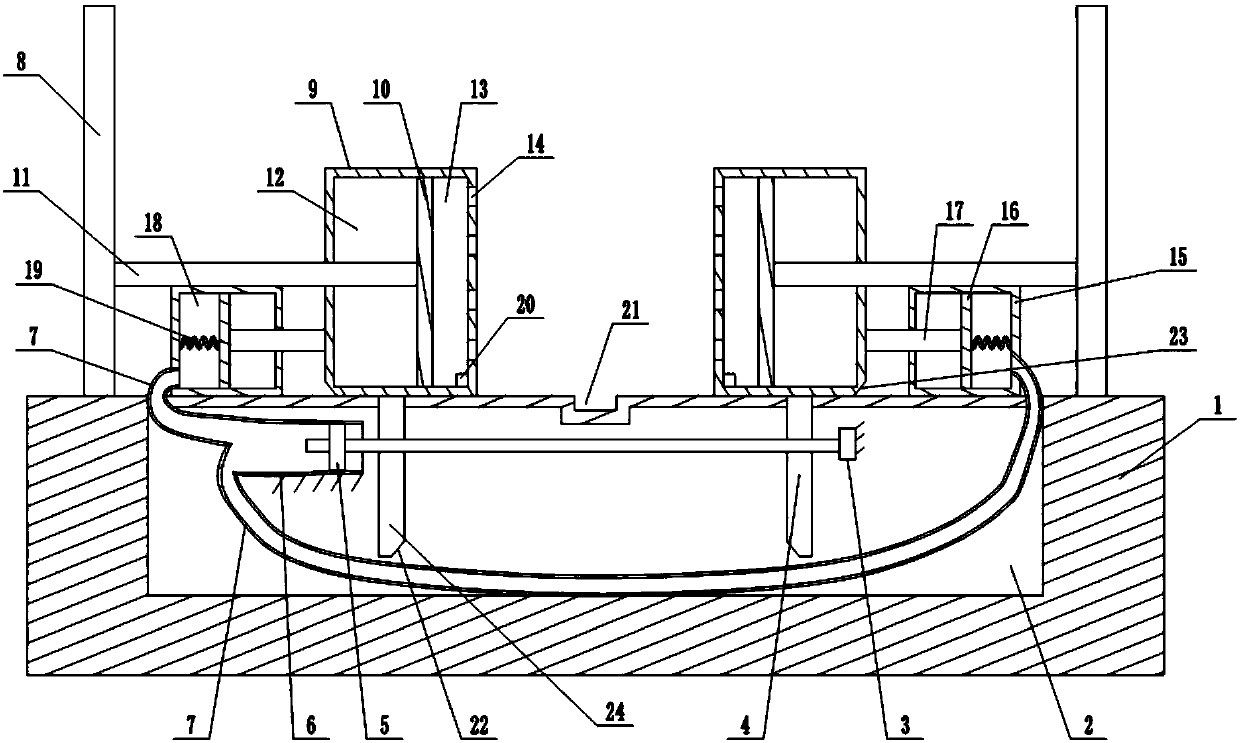

Clamping and cleaning device for automobile part machining

InactiveCN107838702AAffect fixed effectsHigh precisionPositioning apparatusGrinding work supportsEngineeringSlide plate

The invention relates to the field of automobile parts, and discloses a clamping and cleaning device for automobile part machining. The clamping and cleaning device comprises a working table, guide columns, a sunken part, a notch, first cylinders and second cylinders, wherein first sliding plates divide the first cylinders into first communicating parts and first moving parts; a plurality of air holes are formed in one end, which is close to the sunken part, of each first moving part; second sliding plates are connected into second cylinders in a sliding manner; second push rods are fixed on the second sliding plates; the second push rods extend out of the second cylinders, and are connected to the first communicating parts in a sliding manner; the second sliding plates divide the second cylinders into second communicating parts and second moving parts; a motor and a main air pipe are mounted in the notch; the main air pipe communicates with two branch pipes; and the two branch pipes are respectively connected with the different second communicating parts. The clamping and cleaning device can realize dual fixing on a workpiece and clean the workpiece twice, so that the workpiece machining precision can be improved, and fragments produced during workpiece machining also can be cleared away; and the workpiece machining quality is improved.

Owner:宁波江北清锐汽车零部件有限公司

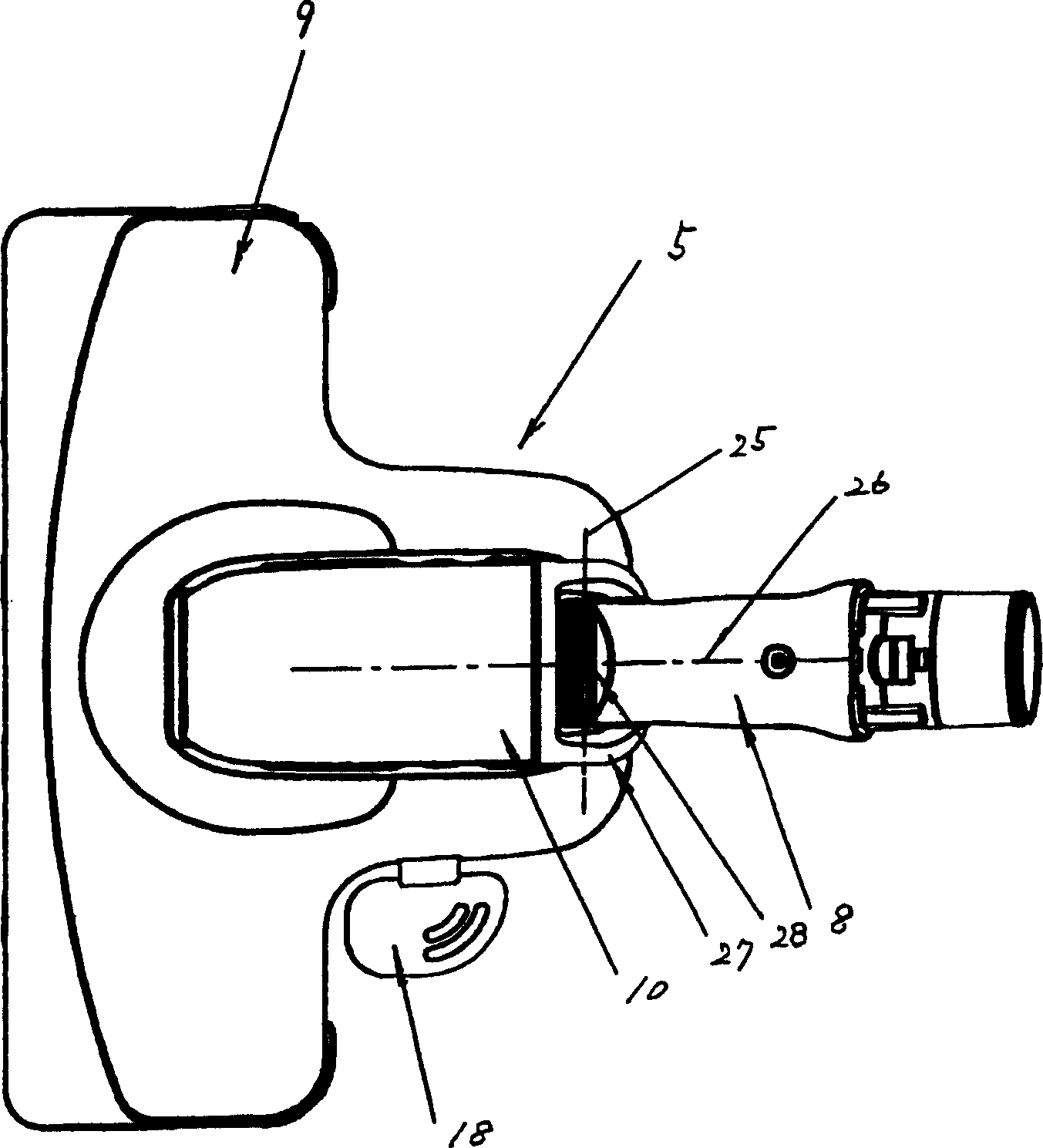

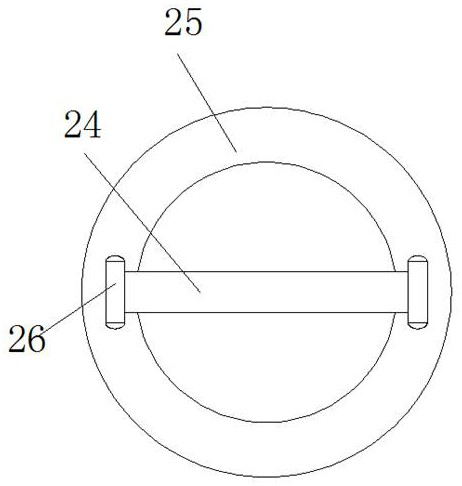

Electric cleaner sucker and the electric cleaner having the sucker

InactiveCN1827026AExpand the vacuum rangeImprove ease of useSuction nozzlesLeft directionEngineering

The invention provides a dust collector nozzle and an electric dust collector using said nozzle. The dust collector nozzle comprises a suction nozzle (10), the back part of which is connected with rotary connection pipe (8) and mounted or dismounted from suction nozzle main body (5). When the detachable suction nozzle is mounted to main body of suction nozzle and the connection pipe is rotated upward to place with angle being 90 degree relative to the horizontal surface of main body of suction nozzle, the connection pipe can rotate for 90 degree in right and left direction as well as downwards. Then, the connection pipe can rotate downwardly for about 90 degree when the main body of suction nozzle is raised; which makes it is convenient for bottom surface of said main body to contact to surface on higher place for dust cleaning.

Owner:PANASONIC CORP

Device for removing textile dust on textile fabric

InactiveCN110485140ATo achieve the purpose of dust removalImprove dust removal efficiencyMechanical cleaningPressure cleaningEngineeringDust fall

The invention discloses a device for removing textile dust on a textile fabric. The device comprises a box body and a dust removal assembly, the dust removal assembly is arranged on the box body, a feeding hole is formed in the left side of the top of the box body, and a discharging opening is formed in the lower part of the left side wall of the box body. The dust removal assembly comprises a guide roller, a brush roller and a dust collector; dust suction units are arranged on the two sides of an inner cavity of the box body; each dust collection unit comprises a forward and reverse rotationmotor, a bidirectional screw rod, an inner threaded sleeve and a dust suction plate. The device comprises a plurality of knocking and shaking devices. Each knocking and shaking device comprises a second motor, a spring and a knocking ball. The dust removal assembly is arranged, the brush roller can brush fluff, dust and the like on the dust removal assembly, then the dust is sucked by the dust collector, and the aim of dust removal is achieved. The dust removal efficiency is high, and the effect is good. The dust suction units are arranged, so that the dust collection range is expanded, and the dust collection efficiency is improved; the knocking and shaking devices are arranged, so that a textile body is continuously knocked, the dust falls down due to inertia, and the dust removal efficiency is further improved.

Owner:枣阳市博大纺织有限公司

Power instrument with good heat dissipation effect

ActiveCN108957068AEasy accessFlexible structureDispersed particle filtrationTime integral measurementElectric powerPiston

The invention relates to a power instrument with good heat dissipation effect. The power instrument comprises a main body and two heat dissipating devices. Each heat dissipating device comprises a horizontal pipe, a vertical pipe and a gas conveying pipe, wherein a gas guiding mechanism is arranged in the horizontal pipe, a gas conveying mechanism is arranged in the gas conveying pipe, a dust suction mechanism is arranged in the vertical pipe, the dust suction mechanism comprises a rotating assembly, a connecting pipe, a rotating pipe, a branch pipe and a plurality of filter bags, and the gasconveying mechanism comprises a lifting assembly, a piston and two closing assemblies, each closing assembly comprises through holes, blocking blocks, pressing plates, springs, coils, horizontal plates and two vertical rods. The power instrument with good heat dissipation effect adsorbs dust in the air by means of the dust suction mechanism when the air flows in the vertical pipe, ensures that clear air enters the main body, achieves good heat dissipation effect, and conveys the gas into the connecting pipe by means of the gas conveying mechanism so as to blow air to the interior of the filterbags and blow off the dust, thereby realizing the continuous dust suction capability of the equipment, and improving the practicality of the equipment.

Owner:中共山东省委机关服务中心

Blasting dust purification treatment equipment

InactiveCN111841226AExpand the spraying rangePlay a role in dust suppressionCombination devicesDirt cleaningArchitectural engineeringLiquid tank

The invention belongs to the technical field of dust treatment and especially relates to blasting dust purification treatment equipment. The invention aims to overcome the problem that an existing engineering blasting dust degradation treatment device is limited in effective dust absorption range and is thus low in use reliability. The blasting dust purification treatment equipment comprises a bottom plate, wherein four universal wheels are arranged at the bottom of the bottom plate; brake pads are arranged on the four universal wheels; an annular block, a liquid tank, a water tank and two push handles are fixedly connected to the top of the bottom plate; a rectangular box is rotationally installed at the top of the annular block; one side of the rectangular box communicates with a dust suction port; the dust suction port is of a horn structure; a supporting rod is fixedly installed at the top of the rectangular box; an atomizing cylinder is rotationally installed at the top of the supporting rod; the atomizing cylinder is connected with an air blowing structure; the top of the water tank communicates with a water pump; and a water outlet of the water pump communicates with an atomizer. The blasting dust purification treatment equipment is simple in structure and convenient to operate, a dust collection and dust suppression range can be expanded, and use performance is improved.

Owner:惠安县崇武镇栓锋广告设计中心

Tailoring device facilitating replacement of textile fabric winding roller and used for textile fabric processing

ActiveCN112030523AEasy to replaceAdjustable tightnessSevering textilesDirt cleaningStructural engineeringDrive motor

The invention discloses a tailoring device facilitating replacement of a textile fabric winding roller and used for textile fabric processing. The tailoring device comprises a device body, the fabricwinding roller, a driving motor, a cutting blade and a winding roller, a supporting plate is fixedly installed in the middle of the left end of the device body, and the fabric winding roller is installed at the inner side of an adjusting plate; the lower end of the adjusting plate is installed on a threaded rod, the inner end of a toothed plate is fixedly installed at the side edge of a movable column, a driving screw is installed at the upper end of the movable column, a connecting rod is installed in the middle of a circular gear and installed in the middle of a connecting block in a penetrating manner, and a tailoring blade is fixedly installed at the lower end of the connecting block; and the tailoring blade is installed in the middle of the lower end of a protective frame. According to the tailoring device facilitating replacement of the textile fabric winding roller and used for textile fabric processing, cloth can be preliminarily ironed in the tailoring process, meanwhile, thetightness degree of the cloth during fixing can be adjusted, and dust and plush generated during tailoring can be effectively treated.

Owner:嘉兴德基机械设计有限公司

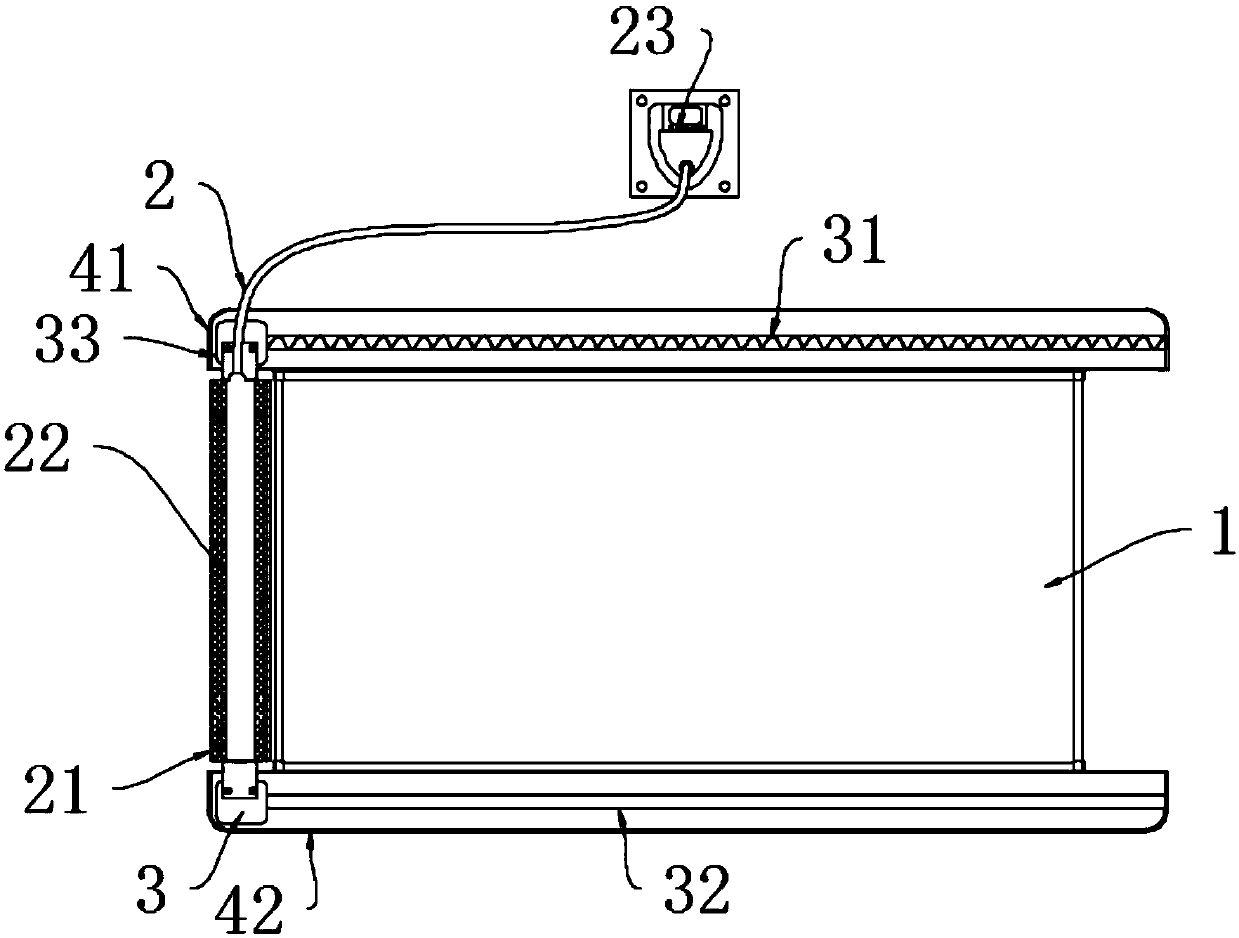

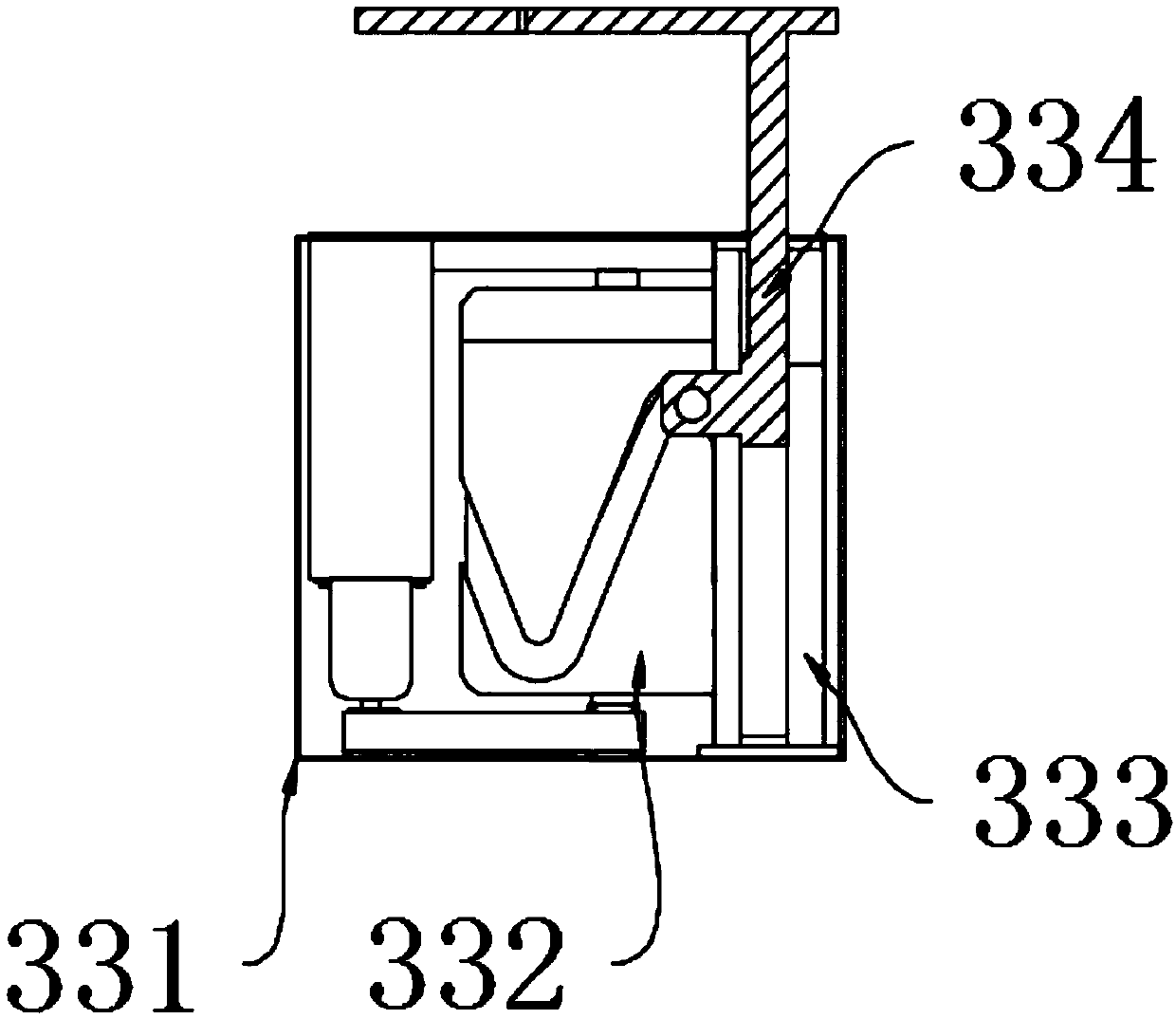

Sectional cleaning type teaching blackboard

PendingCN109515035AReduce classroom distractionsAvoid rubbing by mistakeBoard cleaning devicesWriting boardsEngineeringBiomedical engineering

Owner:大竹县周家镇中心小学

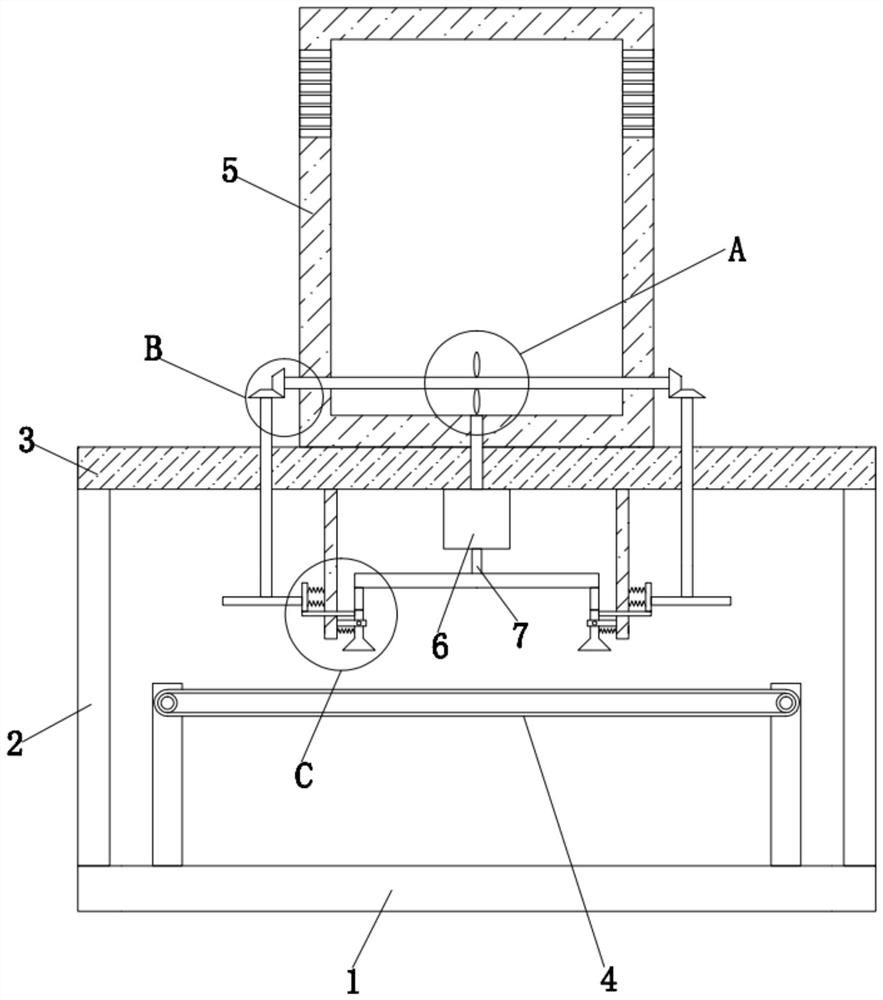

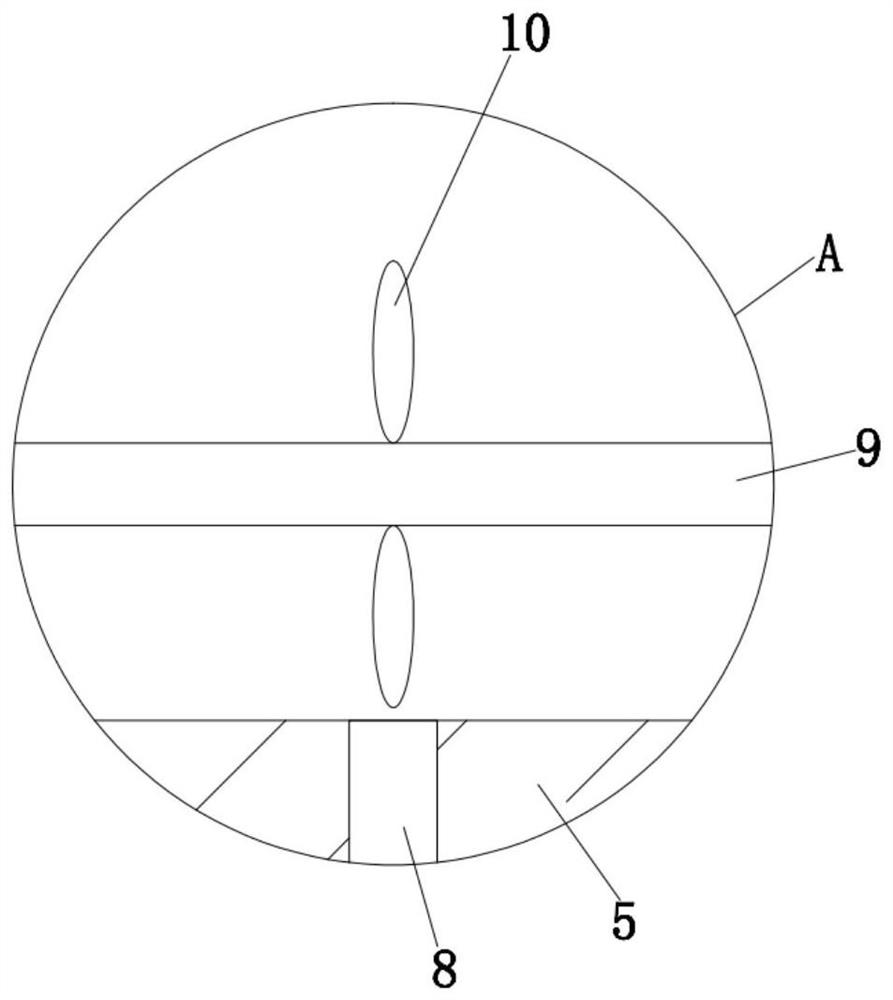

Conveying device for optical fiber sensor production

InactiveCN112517542AImprove cooling efficiencySpeed up the flowControl devices for conveyorsCleaning using gasesDust controlMechanical engineering

The invention belongs to the field of optical fiber sensors, particularly relates to a conveying device for optical fiber sensor production. The conveying device for optical fiber sensor production aims to solve the problems that an existing conveying device does not have a dust removal function in the process of conveying an optical fiber sensor, and since a controller cannot be cooled, the service life of the controller is shortened. The conveying device for optical fiber sensor production comprises a base, wherein supporting plates are fixedly connected to the two sides of the top of the base, the tops of the two supporting plates are fixedly connected with the same top plate, a conveying belt is arranged at the top of the base, a controller is fixedly connected to the top of the top plate, a dust collector is fixedly connected to the bottom of the top plate, an air inlet pipe is fixedly connected to an air inlet of the dust collector, and an air outlet pipe is fixedly connected toan air outlet of the dust collector. The conveying device for optical fiber sensor production has the dust removal function in the conveying process of the optical fiber sensor; a dust suction pipe can swing, so that the dust removal range is widened, and then the dust removal efficiency is improved; and heat dissipation of the controller is facilitated.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

Spraying and dust reduction device used for powder spraying and work process thereof

ActiveCN108056700AIncrease the collection areaImprove work efficiencySuction filtersSuction nozzlesWork in processEngineering

The invention discloses a spraying and dust reduction device used for powder spraying and relates to the technical field of dedusting equipment. The device includes a base, a dedusting box is fixedlyinstalled on the top of the base, a supporting column is fixedly installed on the inner wall of the dedusting box, and one end of the supporting column is fixedly provided with a damping pad; a dust sucking pipe is communicated with the upper portion of the side wall of the dedusting box, and the end, away from the dedusting box, of the dust sucking pipe is communicated with a dust sucking plate;a negative pressure cavity is formed in the dust sucking plate, a supporting plate is fixedly installed on one side of the dust sucking plate, a fixing base is fixedly installed on the side wall of the dedusting box, the top of the dust sucking plate is hinged to one side of the fixing base through a hinge, and a fixing disc is fixedly installed on the inner wall of the dedusting box. According tothe spraying and dust reduction device used for powder spraying and a work process thereof, electric retractable rods can be utilized to lift the supporting plate up, by rotating the dust sucking plate to a horizontal state, the dusk sucking plate can be utilized to suck dust in the air, the collection area is enlarged, the work efficiency can be greatly improved, and time and labor are saved.

Owner:泰州市天宇交通器材有限公司

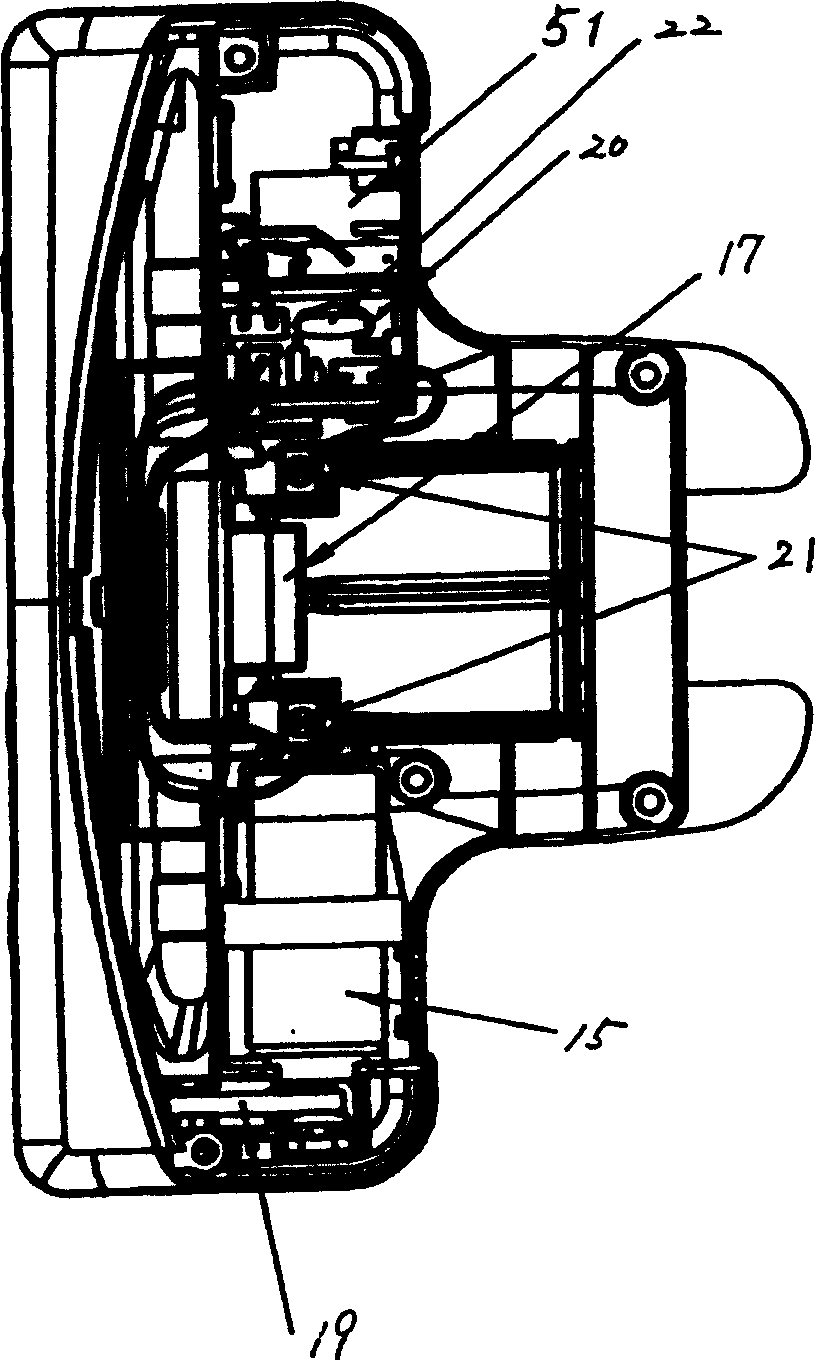

Dust-collection electrical drilling machine

InactiveCN105081400AExpand the vacuum rangeKeep healthyDirt cleaningPortable drilling machinesDrill holeDrill bit

The invention discloses a dust-collection electrical drilling machine and provides the dust-collection electrical drilling machine which is capable of effectively collecting dust and convenient to operate. The dust-collection electrical drilling machine comprises an electrical drilling machine body, an electrical drill and a handle. The electrical drill is arranged in the front of the electrical drilling machine body, and the handle is connected to the lower portion of the electrical drilling machine body. The dust-collection electrical drilling machine further comprises a dust collection mechanism which comprises a dust collection cover, a plurality of positioning rods and a plurality of sleeve tubes. The dust collection cover is of a hollow structure, the section of the dust collection cover is in an isosceles trapezoid shape, an elastic layer is arranged in the middle of the dust collection cover, and the small end of the dust collection cover faces the electrical drill. A drilling hole is formed in the center of the small end of the dust collection cover, a cover hole is formed in the center of the large end of the dust collection cover, and the electrical drill is arranged in the drill hole and the cover hole respectively. According to the dust-collection electrical drilling machine, the operation is reliable, and dust pollution is greatly reduced; the incidence of 'pneumoconiosis' is reduced, and the worker body health is guaranteed.

Owner:YANGZHOU LANHAI CONSTR MACHINERY

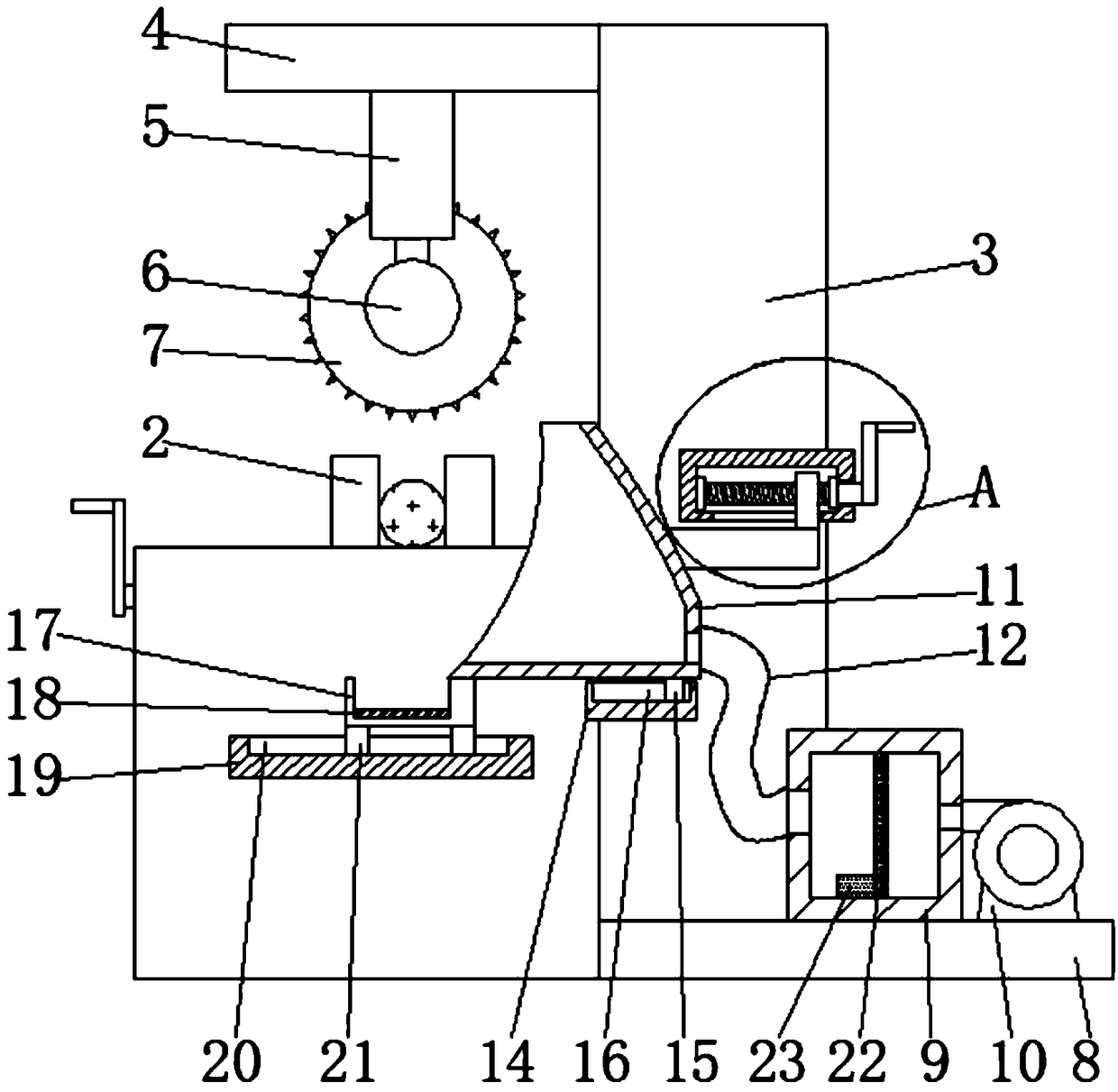

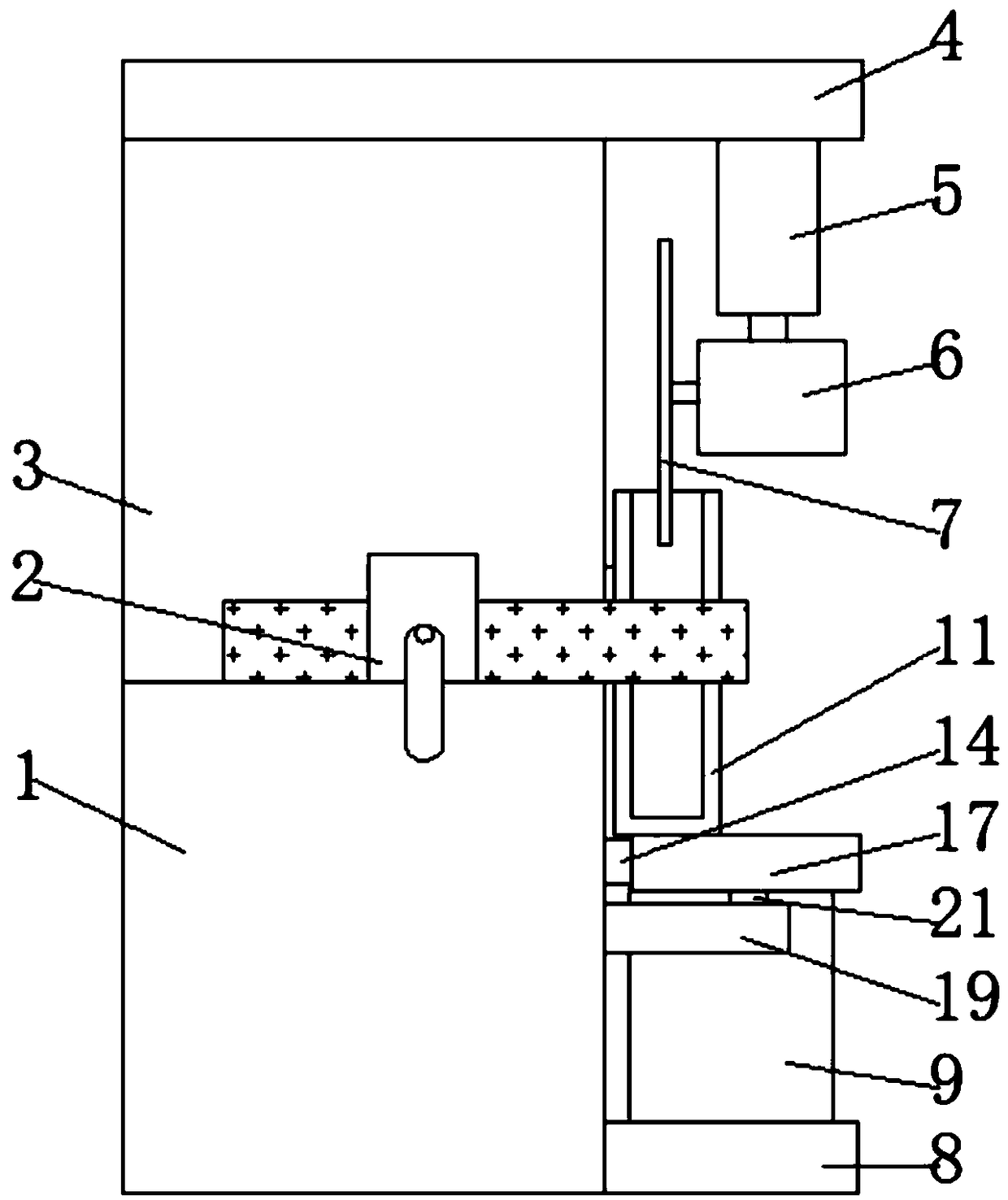

Environment-friendly cutting device for machining mechanical parts

InactiveCN108907348APracticalWith suctionPositioning apparatusMaintainance and safety accessoriesElectric machineryWorking environment

The invention discloses an environment-friendly cutting device for machining mechanical parts. The cutting device comprises a worktable, the top of the worktable is provided with a clamping mechanism,and raw materials are clamped in the clamping mechanism; a first supporting plate is fixedly connected to the right side of the worktable, a second supporting plate is fixedly connected to the top ofthe right side of the first supporting plate, an air cylinder is fixedly connected to the front side of the bottom of the second supporting plate, and a motor is fixedly connected to the output end of the air cylinder. According to the cutting device, a cutting disc is driven by the motor to cut the raw materials, and a fan can suck powdered scraps generated during cutting into a placement box through a corrugated pipe and a dust collection sleeve; thus, the cutting device has the advantages that the generated powdered scraps can be sucked for removal, and the quality of the working environment is improved; the problem that existing cutting devices cannot suck the generated powdered scraps for removal, and the working environment is polluted is solved; the environment-friendly cutting device for machining the mechanical parts is high in practicality and convenient to use by people.

Owner:湖州吴兴恒鑫机械有限公司

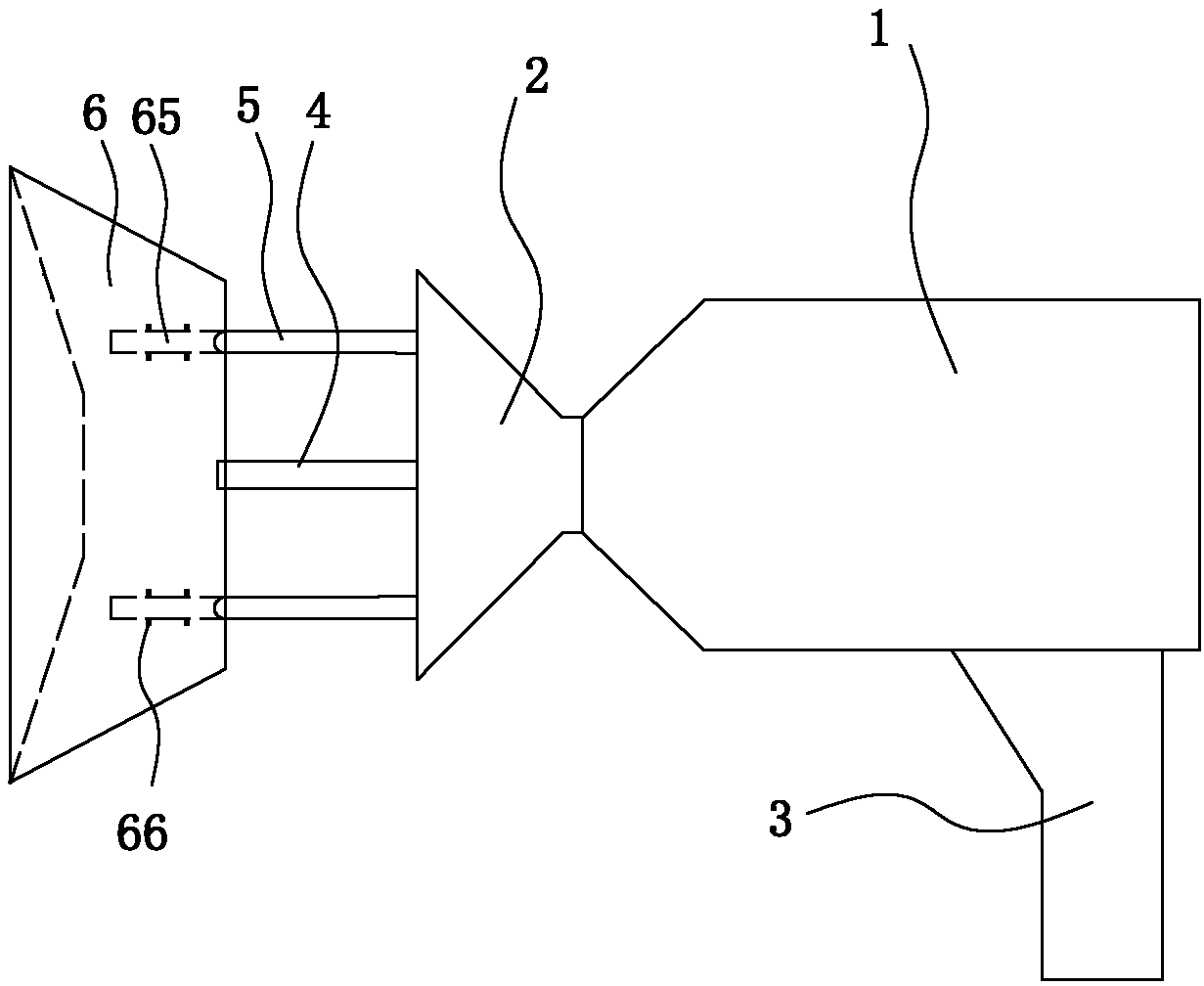

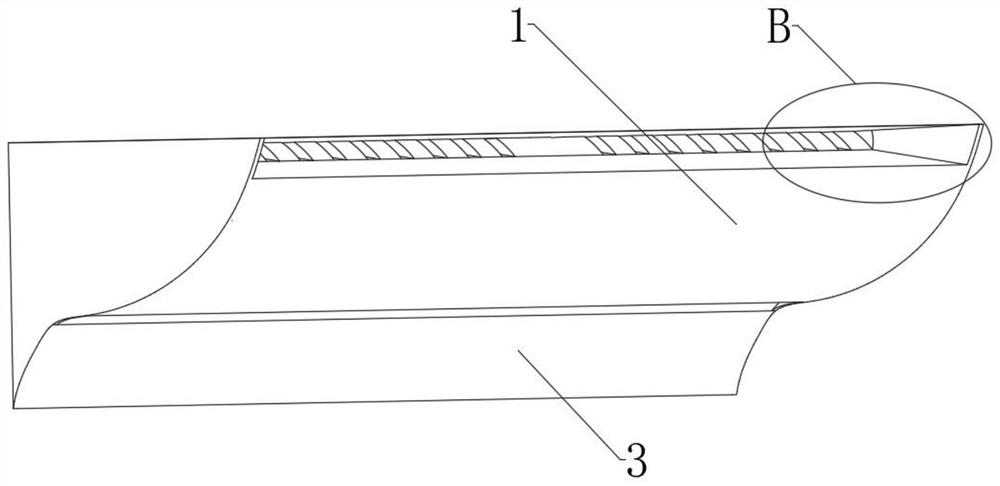

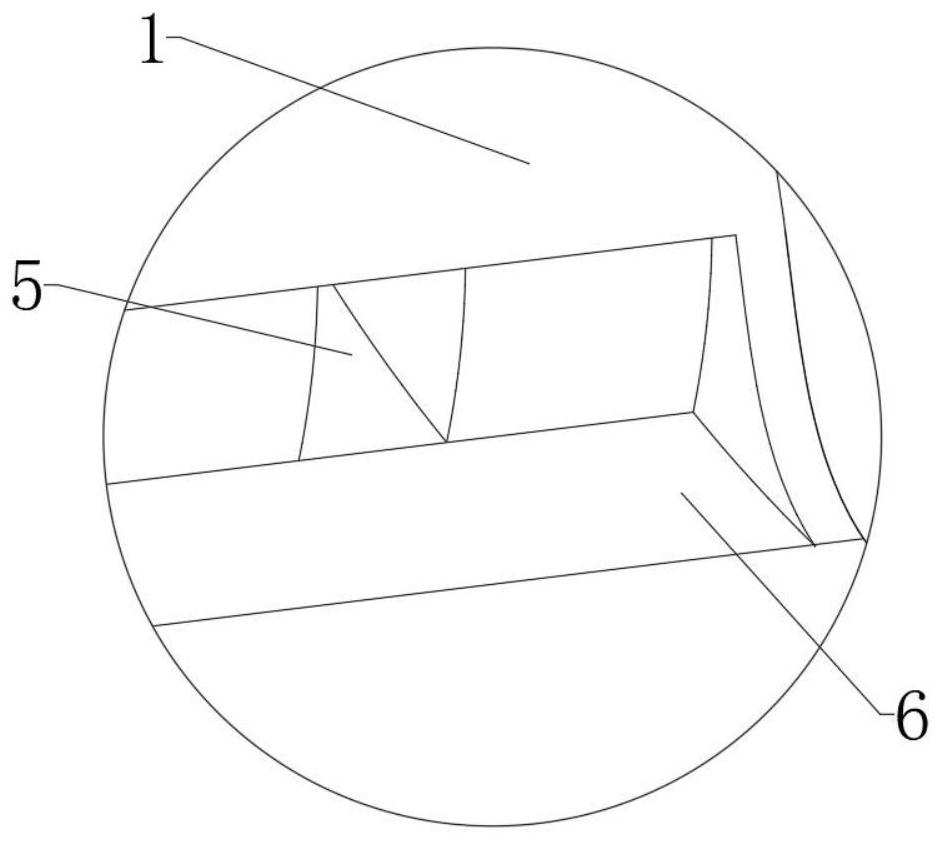

Variable-angle connector and manufacturing method and application thereof

ActiveCN104676160AFlexible trackingExpand the vacuum rangeAdjustable jointsDirt cleaningEnvironmental qualityEngineering

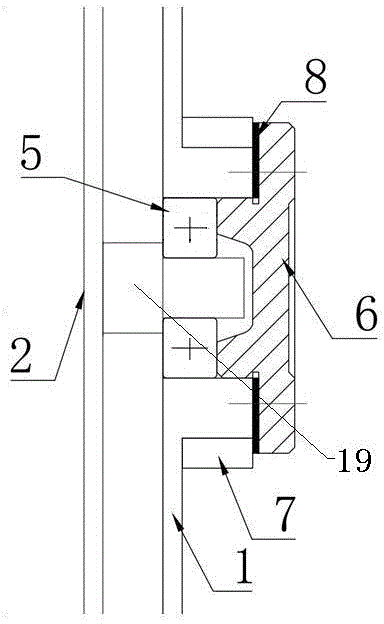

The invention relates to a variable-angle connector. The variable-angle connector is mainly applied to connection between a dust hood and a dust removal pipe in an industrial dust removal system. The connector comprises a large-diameter hemispheric connector (1), a small-diameter hemispheric connector (2), a bearing (5), a bearing end cover (6), a radial fastening ring (7), a clamping groove (8) and a stepped shaft (19), wherein the small-diameter hemispheric connector (2) is connected onto the large-diameter hemispheric connector (1) through the stepped shaft (19), then the radial fastening ring (7) is sleeved, the bearing (5) and the bearing end cover (6) are assembled and screws are tightened. The connector can realize angle change from 0 degree to 45 degrees, the space limitation is broken through, the dust hood is not like the traditional dust hood which is fixed at a position in a space but is enabled to flexibly track smoke dust according to the produced amount and scattering direction of the dust smoke, the dust suction range is expanded, the maximum-efficiency absorption is achieved and the environmental quality is improved.

Owner:UNIV OF SCI & TECH BEIJING

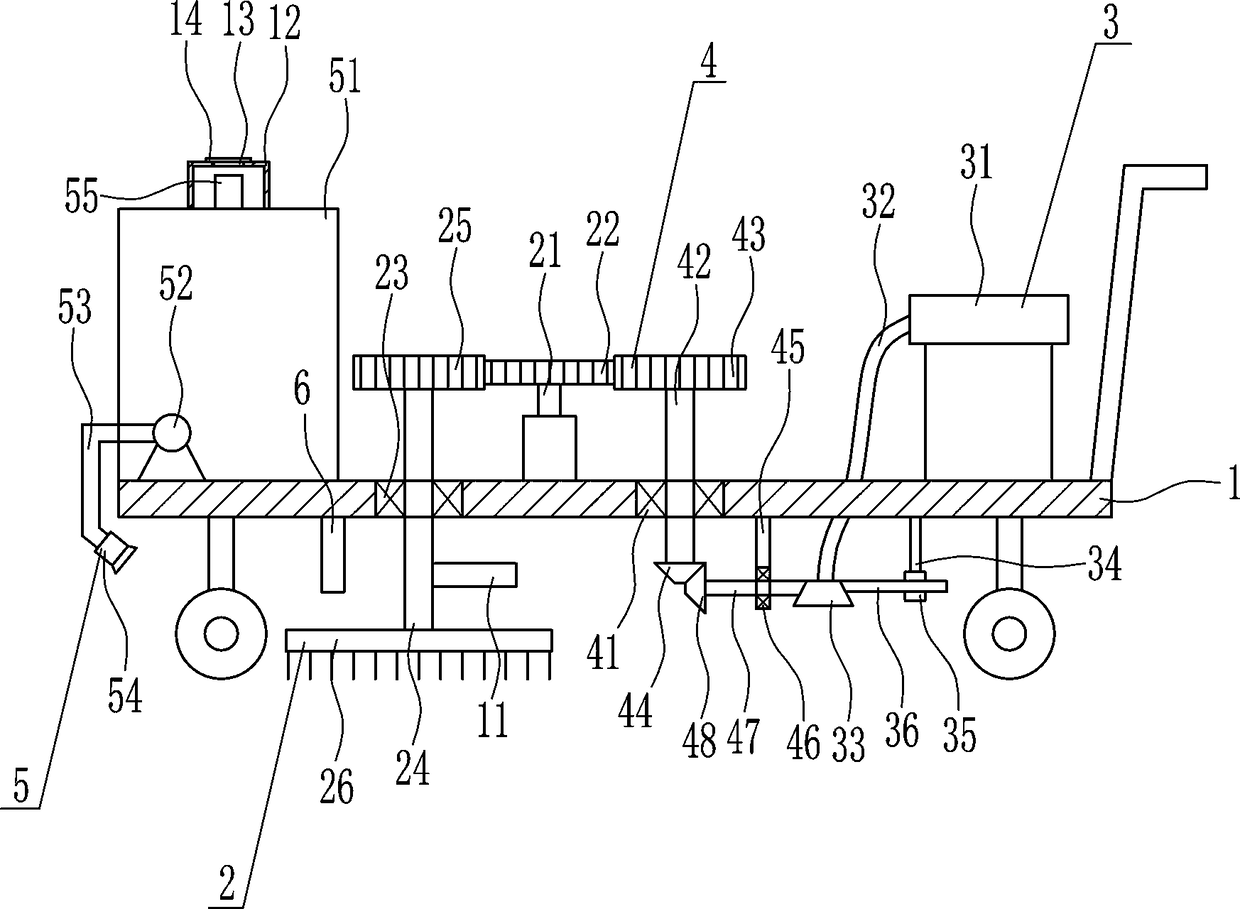

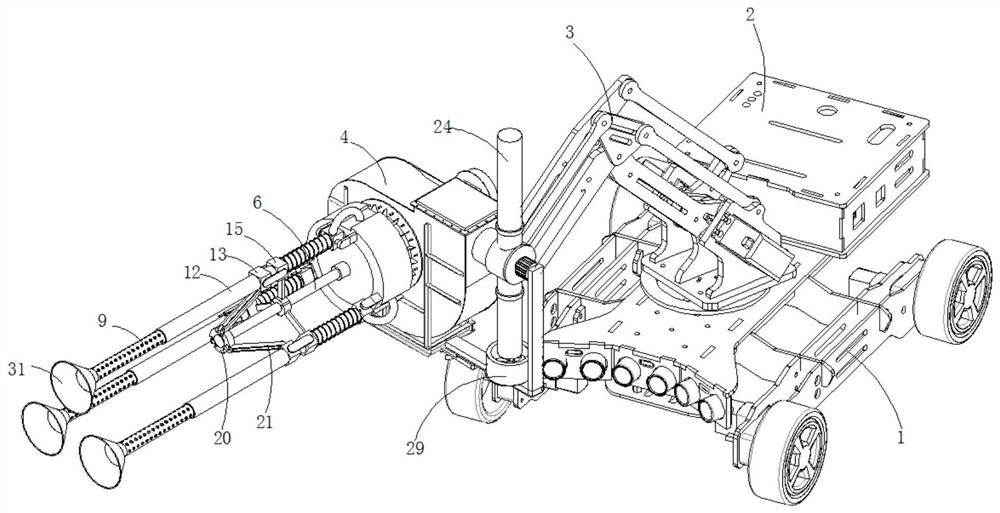

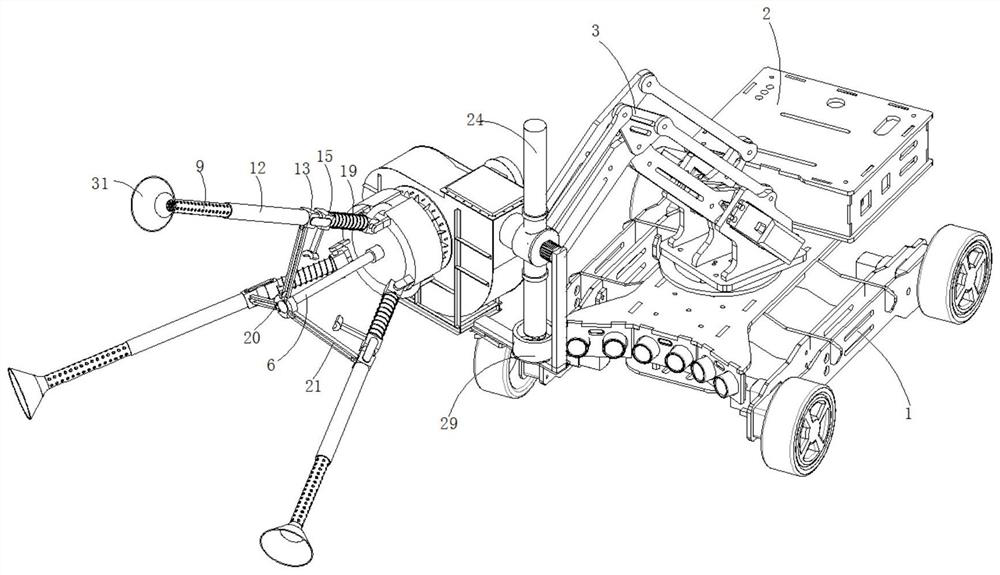

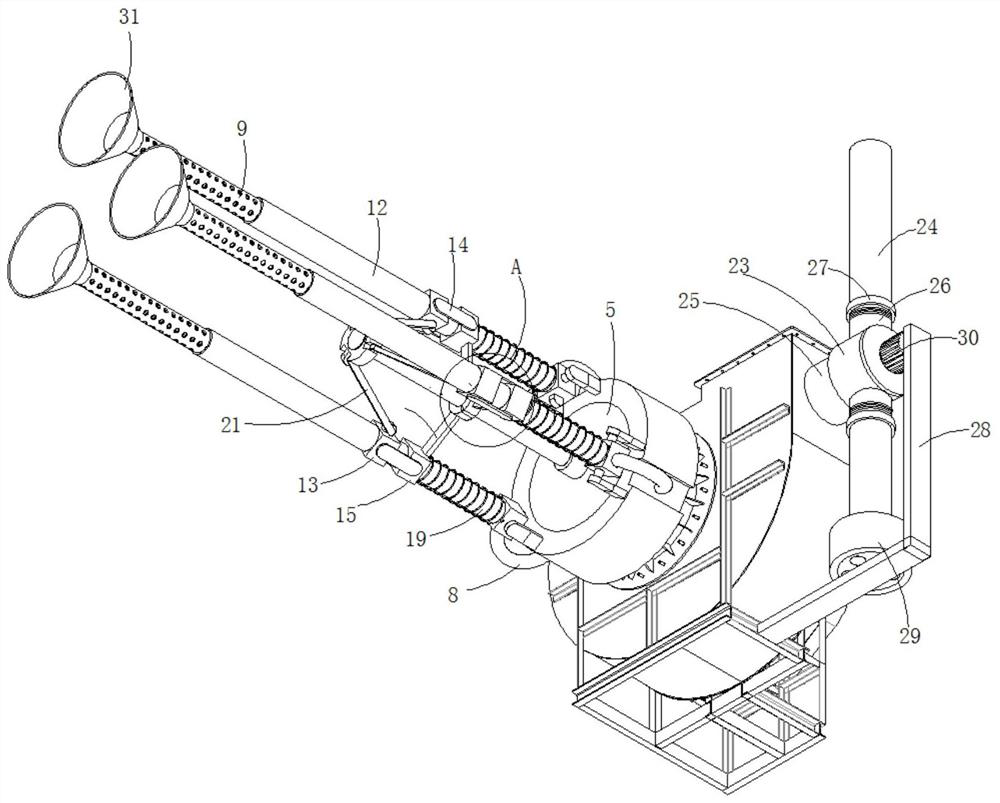

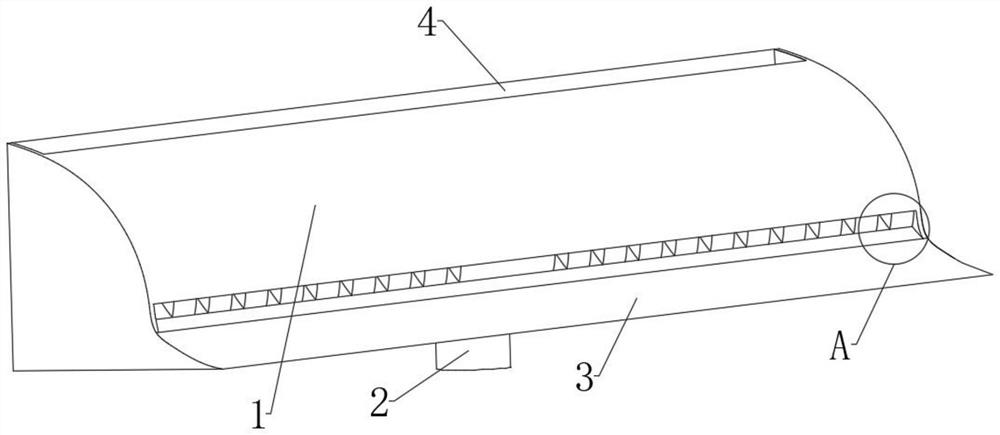

Dust removing equipment for mine and use method thereof

ActiveCN111648815AAdapt to dust removal functionExpand the vacuum rangePump componentsDust removalDust controlStructural engineering

The invention discloses dust removing equipment for a mine and a use method thereof, and belongs to the technical field of mine dust removal. The dust removing equipment for the mine comprises a vehicle body, a PLC electronic control box and a mechanical arm. The PLC electronic control box and the mechanical arm are both mounted on the vehicle body, and the movable end of the mechanical arm is fixedly connected with a centrifugal fan through a support. An air inlet of the centrifugal fan is fixedly connected with a sealing plate, and a telescopic air cylinder is mounted in the middle of the sealing plate. The edge of the sealing plate is movably connected with evenly distributed air ducts, and snakeskin hoses communicate between the air ducts and the air inlet. The ends, away from the snakeskin hoses, of the air ducts are fixedly connected with air collecting pipes, and evenly distributed air collecting holes are formed in the air collecting pipes. The inner walls of the air collectingpipes are fixedly connected with spirally arranged air guide sheets, and the air guide sheets extend into the air ducts. The outer walls of the air collecting pipes are sleeved with sealing barrels,and the sealing barrels are in sliding connection with the air ducts. The dust removing equipment can carry out dust removal aiming at dust generating points within different ranges, and is high in applicability, convenient to adjust and good in dust removing continuity.

Owner:惠东嘉华材料有限公司

Smoke dust suction device applied to laser surface decontamination

PendingCN112974409AAvoid cloggingEfficient removalCleaning using toolsCleaning using gasesEngineeringCircular cavity

The invention relates to a smoke dust suction device applied to laser surface decontamination. The smoke dust suction device comprises a shell and a rotating shaft, wherein a circular cavity is formed in the shell, and a first flow guide groove, a second flow guide groove and an air outlet are formed in the middle of the top, the middle of the front side and the middle of the bottom of the shell correspondingly; a plurality of first tangential air inlets and second tangential air inlets are formed in the air outlet ends of the first flow guide groove and the second flow guide groove at intervals correspondingly, the first tangential air inlets and the second tangential air inlets deviate from the axis part of the cavity, the rotating shaft is arranged in the cavity, and the two ends of the rotating shaft are rotationally connected with the shell correspondingly; and a first spiral brush and a second spiral brush are arranged at the two sides of the rotating shaft respectively, and the rotating directions of the first spiral brush and the second spiral brush are opposite. According to the smoke dust suction device, through the cooperative design of the shell and the rotating shaft, the problems that because dust in an existing adsorption pipe cannot be effectively removed, the suction capacity is reduced and the dust collection effect is affected are effectively solved.

Owner:HAINAN NUCLEAR POWER

Municipal old road milling device

ActiveCN113622274ACan't touchIncrease speedPlastic recyclingDirt cleaningPavement maintenanceAgricultural engineering

The invention discloses a municipal old road milling device, and relates to the field of pavement maintenance, the old municipal road milling device comprises a treatment box, the top of the treatment box is provided with a driving assembly, the inner walls of the two sides of the treatment box are rotatably provided with rotary drums, and the two sides of the outer side walls of the rotary drums are fixedly provided with a plurality of support connecting plates which are distributed at equal intervals. Through the arrangement of the driving assembly, the transmission assembly, the rotary drum, the crushing rollers and the milling wheels, the driving assembly provides power to enable the rotary drum to rotate, the rotary drum rotates rapidly, and the milling wheels and the crushing rollers which are distributed on a supporting connecting plate and a supporting mounting plate at equal intervals are made to rotate through the transmission assembly; the transmission assembly enables the rotating speed of the crushing roller to be higher than that of the milling wheel and the rotating directions of the crushing roller and the milling wheel to be opposite, the milling wheel mills a road surface, particles are generated and thrown between the crushing roller and the rotary drum to be crushed, the rotating speed of the crushing roller is higher than that of the milling wheel, so that the situation of material blockage is avoided, and cement crushed into particles is thrown to the rear part by the whole rotary drum.

Owner:CIVIL ENG OF CHINA CONSTR SECOND ENG BURESU

Machining grinding device with angle convenient to adjust

PendingCN114523386AEasy to grindExpand the vacuum rangeGrinding drivesGrinding machinesElectric machineryEngineering

The invention belongs to the field of machining, and particularly relates to a machining polishing device convenient for angle adjustment, which comprises four support plates I, an angle adjustment structure and a dust collection structure, the tops of the four support plates I are fixedly connected with a table plate, and the top of the table plate is fixedly connected with two support plates II; a box body is fixedly connected to the tops of the two second supporting plates, a mounting groove is formed in the bottom of the box body, a servo motor is fixedly connected into the mounting groove, a rotating shaft is fixedly connected to an output shaft of the servo motor, a grinding disc is fixedly connected to the bottom end of the rotating shaft, and the angle adjusting structure is arranged on the platen. The dust collection structure is arranged on the second supporting plate and the box body, and the angle adjusting structure comprises a working plate, two push rod motors and two pressing plates. According to the device, a workpiece can be conveniently pressed and fixed, the grinding angle of the workpiece can be conveniently adjusted, meanwhile, generated dust can be conveniently removed in the grinding process, and the air quality is improved.

Owner:CHUZHOU VOCATIONAL & TECHN COLLEGE

Spraying and dust falling device for road and bridge construction

PendingCN114405193AReduce labor intensityImprove dust removal effectUsing liquid separation agentDirt cleaningDust fallHandrail

The invention discloses a road and bridge construction spraying dust fall device which comprises a bottom plate, a handrail is fixedly arranged at one end of the bottom plate, fixing blocks are fixedly arranged at the four corners of the bottom of the bottom plate, connecting shafts are rotatably inserted into the fixing blocks, rolling wheels are symmetrically and fixedly arranged at the two ends of the connecting shafts, and a mounting rod is rotatably inserted into the top of the end, away from the handrail, of the bottom plate. A connecting mechanism is fixedly arranged between the mounting rod and one of the connecting shafts, a dust collection mechanism is fixedly arranged at the bottom end of the mounting rod, rotating rods are symmetrically and rotationally inserted into the two sides of the top end of the mounting rod, limiting mechanisms are fixedly arranged on the rotating rods, and a supporting plate is fixedly arranged at the ends, away from the mounting rod, of the rotating rods; a fixing base is fixedly arranged at the end, away from the rotating rod, of the supporting plate, and a fixing mechanism is fixedly arranged at the top of the fixing base. According to the spraying and dust falling device for road and bridge construction, dust on the ground and water drops adsorbing the dust can be cleaned while spraying and dust falling are carried out, rotating spraying and dust suction are carried out in the moving process through the connecting mechanism, and the efficiency is improved.

Owner:CHONGQING VOCATIONAL COLLEGE OF TRANSPORTATION

Rust removing and chamfering equipment provided with multi-edge processing structure and used for machining electronic parts

PendingCN112077694ARealize multi-sided chamfering operationsImprove processing efficiencyEdge grinding machinesGrinding carriagesElectric machineEngineering

The invention discloses rust removing and chamfering equipment provided with a multi-edge processing structure and used for machining electronic parts, and relates to the technical field of machiningof the electronic parts. The equipment comprises a machine body, a dust suction mechanism and a polishing and rust removal mechanism; a storage cabinet is arranged on the lower side inside the machinebody; a supporting seat is fixed to the upper side of the storage cabinet; a machining platform is fixed to the middle of the upper side of the supporting seat; rotating motors are embedded in the two sides inside the machining platform; chamfering discs are mounted above the rotating motors; a main electronic part body is arranged between the chamfering discs and is located above the middle of the machining platform; first positioning mechanisms are arranged on the left side and the right side of the upper side of the machining platform; and second positioning mechanisms are arranged on thefront side and the back side of the upper side of the machining platform. The equipment has the beneficial effects that the chamfering discs are conveniently driven to rotate through the rotating motors, so that the chamfering discs can be used for polishing and deburring chamfers of the main electronic part body.

Owner:深圳市华博自动化设计有限公司

Concrete precast slab surface layer polishing device

ActiveCN114310532AAvoid stackingSuction in timeGrinding drivesGrinding work supportsPolishingWorking environment

The invention relates to the field of concrete precast slab surface machining, in particular to a concrete precast slab surface layer polishing device which comprises a fixing mechanism and a polishing mechanism, and on the basis that the function of changing the position of a polishing part is achieved, an execution part mainly plays a role in limiting the single-time moving distance of the polishing part, and the polishing part can be used for polishing the surface layer of the concrete precast slab. The situation that the nth grinding part and the (n + 1) th grinding part of the surface of the concrete prefabricated slab are overlapped, and consequently the surface of the concrete prefabricated slab is in a non-uniform grinding state is avoided, and the dust collection plates are arranged in multiple directions, so that the dust collection range is enlarged, dust collection dead corners are reduced, and the dust collection efficiency is improved. The dust generated by polishing is timely sucked by the dust suction machine to the greatest extent, the probability that the dust is scattered into the working environment is reduced, a closed space can be formed when the cover shell is in contact with the concrete precast slab, the effect of covering the dust is achieved, and then the dust suction machine can timely suck the dust and reduce the probability that the dust is scattered all around.

Owner:徐州奥星新型建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com