Textile dust collecting device for textile workshop

A collection device and textile dust technology, which is applied in the field of textile dust collection devices for textile workshops, can solve the problems of limited dust removal range and reduce the overall dust removal effect of textile workshops, and achieve the effects of reducing production costs, increasing the range, and saving water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

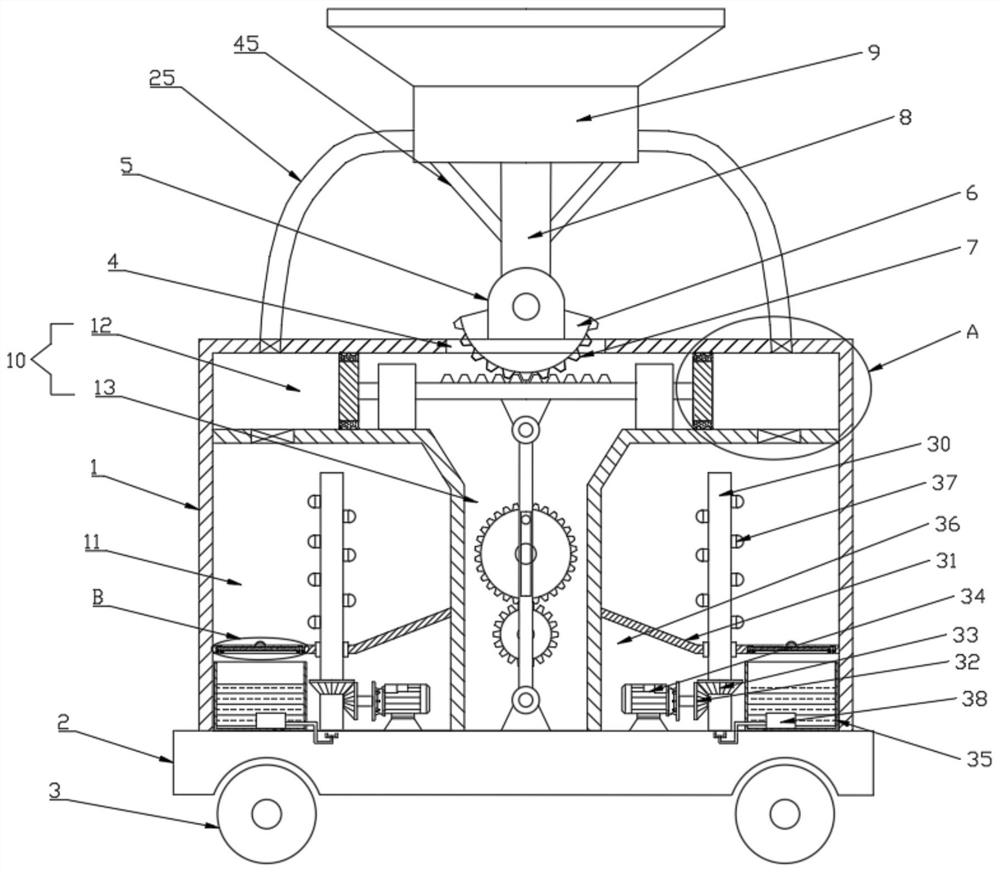

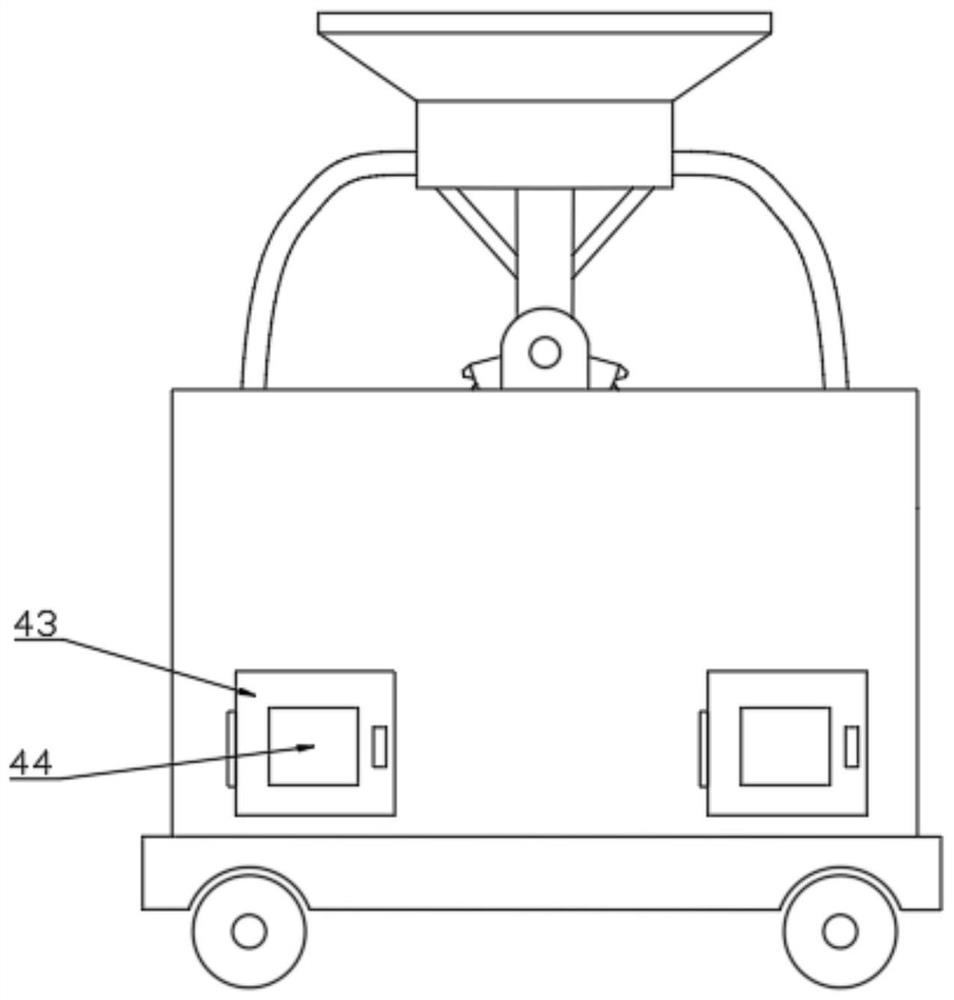

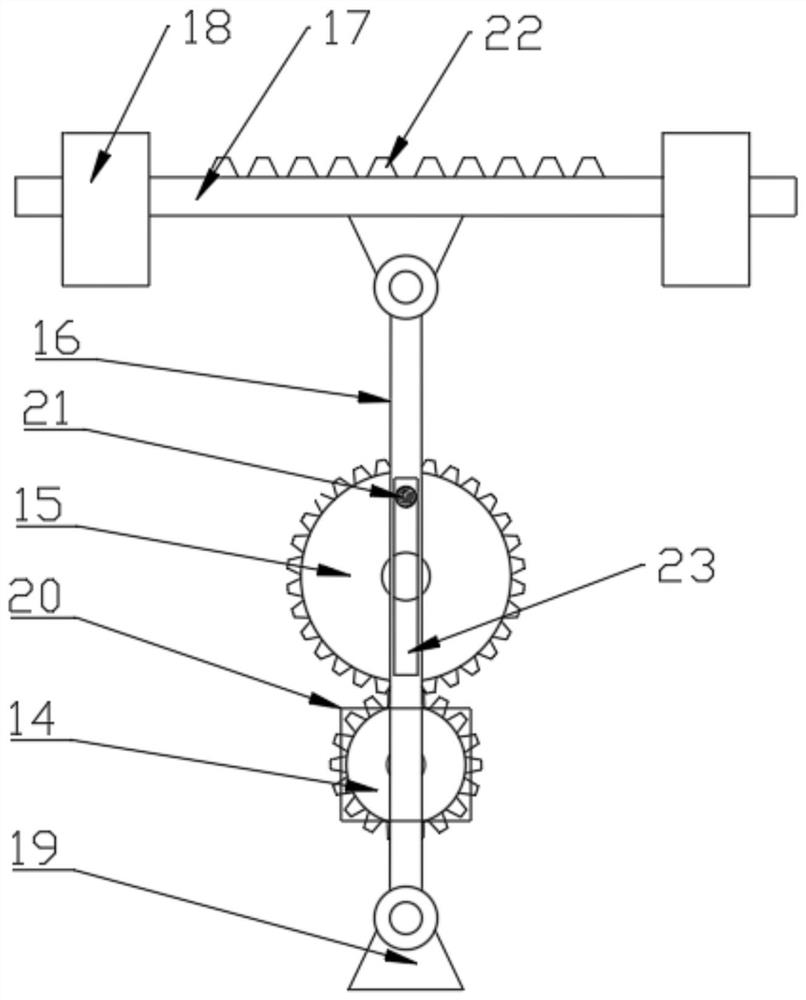

[0026] see Figure 1-6 , a textile dust collection device for a textile workshop, comprising a box body 1, the bottom surface of the box body 1 is provided with a base 2 and moving wheels 3 located at the four corners of the bottom surface of the base 2, and the top surface of the box body 1 is provided with a Hole 4, fixed block 5 is arranged symmetrically on both sides of described through hole 4, and described fixed block 5 is provided with rotating block 6 by pin shaft rotation, and the bottom surface of described rotating block 6 is arranged in through hole 4, and rotating block 6 The bottom surface is provided with gear teeth 7, and the top surface of the rotating block 6 is provided with a dust collection cover 9 through a connecting rod 8. The box body 1 is provided with a driving bin 10 and a dust collection bin 11, and the dust collection bin 11 is symmetrically arranged on On both sides of the drive chamber 10, the drive chamber 10 includes a horizontal chamber 12 a...

Embodiment 2

[0030] This embodiment has been improved on the basis of Embodiment 1, specifically:

[0031]Described dust collecting bin 11 is provided with dust-reducing mechanism, and described dust-reducing mechanism comprises rotating shaft 30, deflector 31, first helical gear 32, second helical gear 33, second motor 34 and water tank 35, and described dust-collecting bin 11. A sealed chamber 36 is provided through the deflector 31. A water tank 35 and a second motor 34 are respectively arranged on the left and right sides of the sealed chamber 36. The output end of the second motor 34 is connected with a first helical gear 32, so The bottom surface of the rotating shaft 30 is rotatably connected with the bottom surface of the dust collection bin 11 through bearings, and the second helical gear 33 meshing with the first helical gear 32 is sleeved on the rod body of the rotating shaft 30 located in the sealed bin 36, and the rotating shaft 30 is a hollow shaft , and the rotating shaft 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com