Power tool

A technology of power tools and drive shafts, which is applied in the direction of grinding workpiece supports, etc., can solve the problems of large sudden torque, impact, laborious operation, etc., and achieve reliable and firm clamping, easy operation, and strong hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

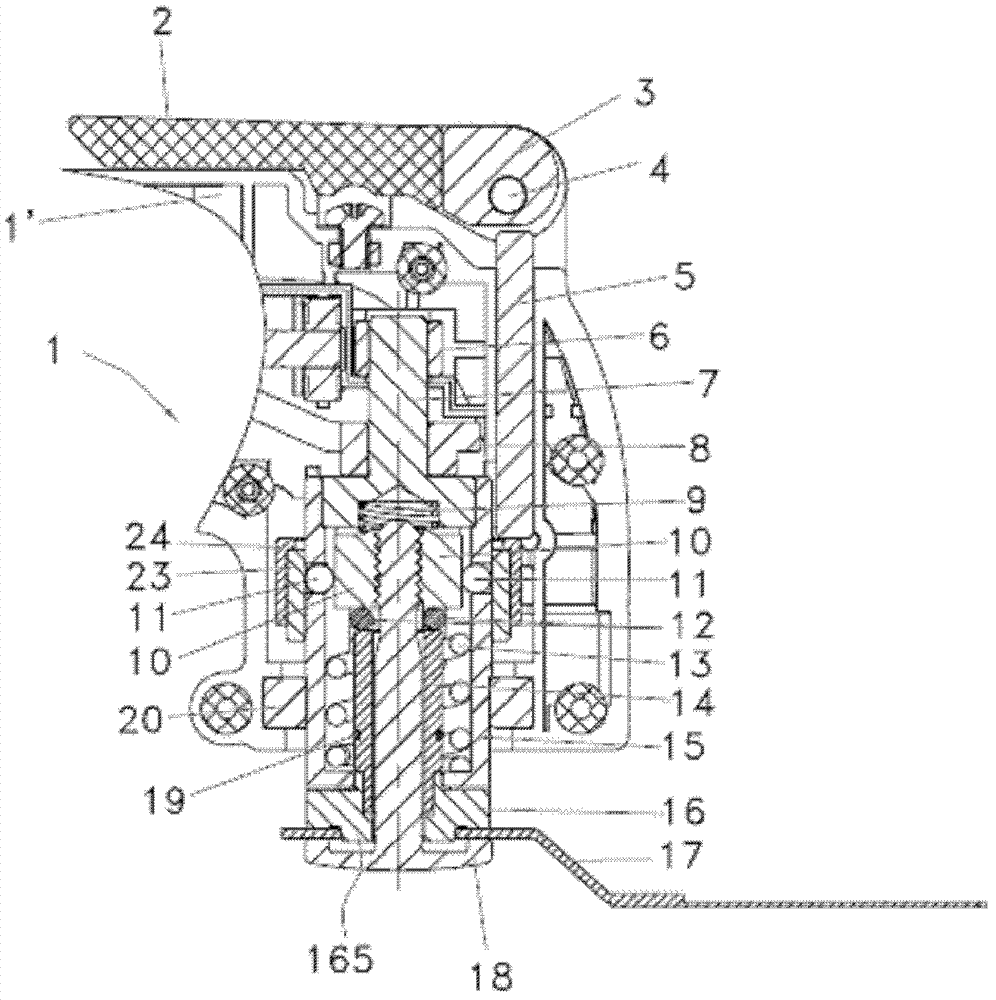

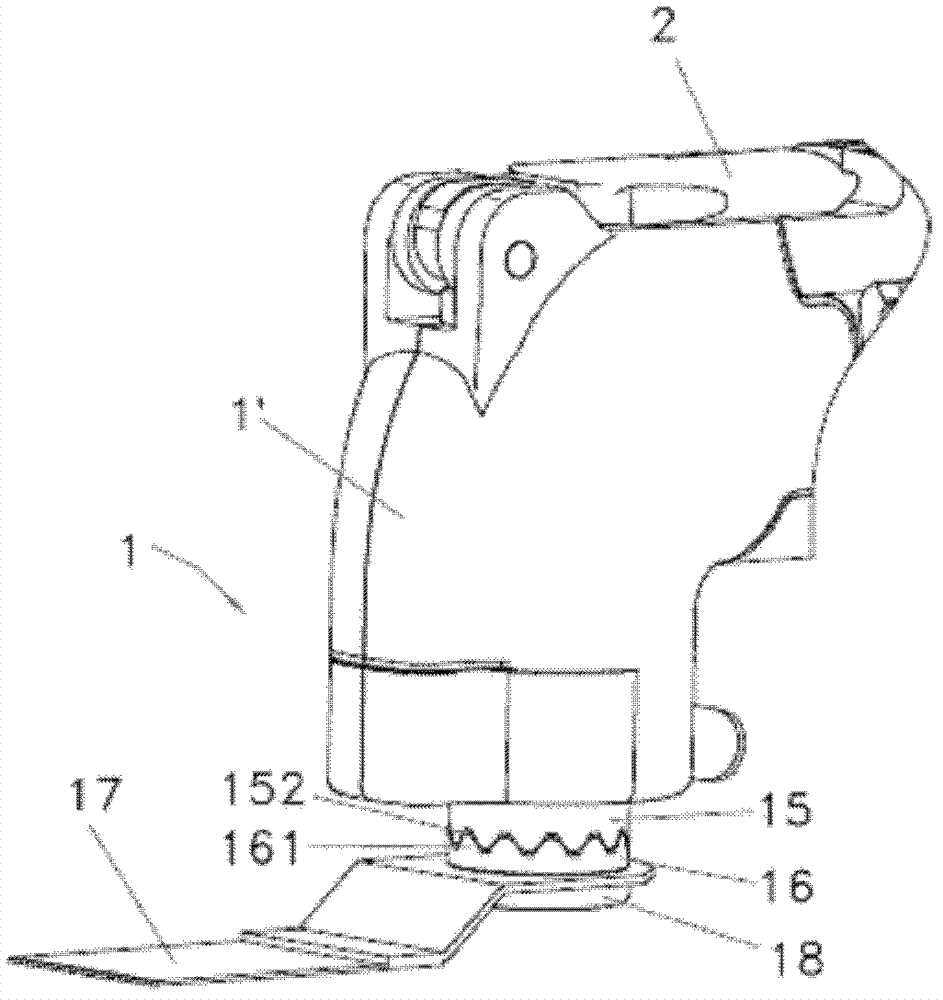

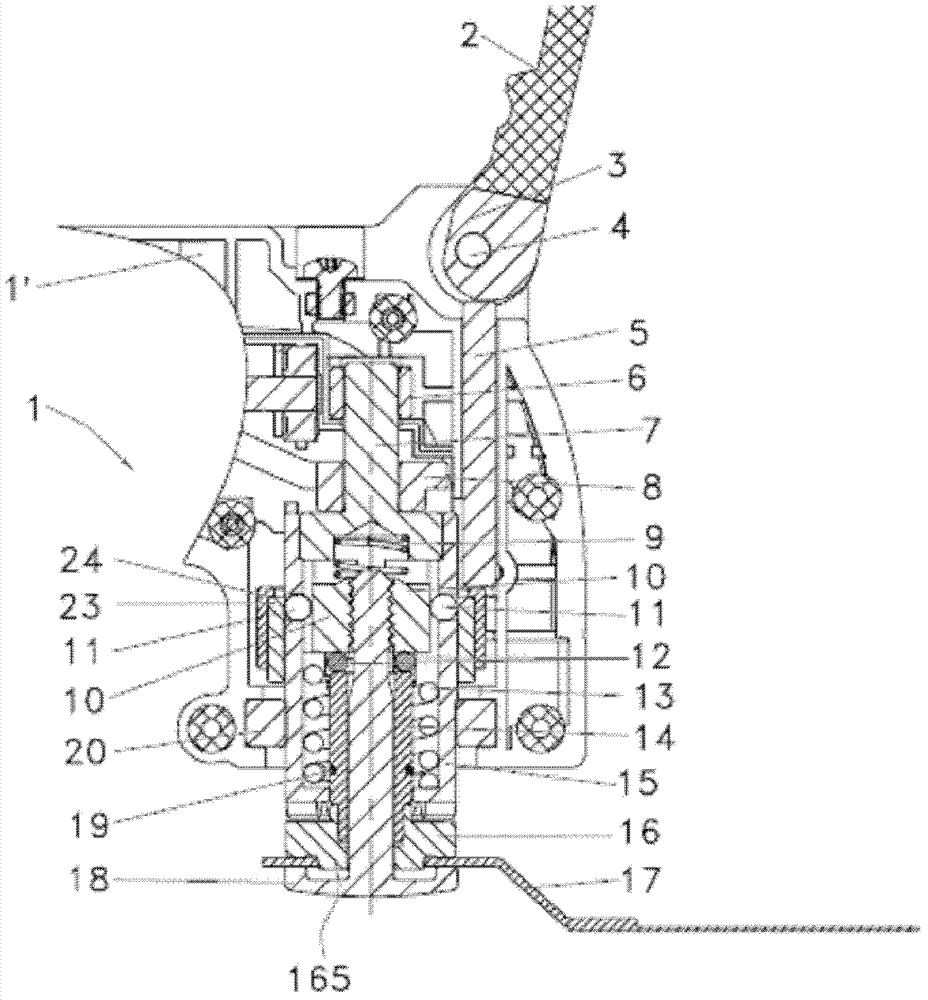

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0033] Such as Figure 1a to Figure 4c and Figure 7 As shown, the present invention is preferably described as a power tool 1 that drives the working element 17 in an oscillating manner. The power drive shaft of the power tool 1 is supported by bearings 6, 20 and rotates around its axis Y under the action of the vibrating bracket 8 in a small The reciprocating swing of the yaw angle is high-frequency, the drive shaft is configured to support the journal 7 and the hollow shaft 15, the vibration support 8 is interference-pressed on the support journal 7, and the support journal 7 and the hollow shaft 15 pass through Surplus pressure installed.

[0034] The working element 17 can be quickly clamped to the power tool 1 through the clamping mechanism, and the clamping mechanism includes a fastening element 18 and a locking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com