Spraying and dust falling device for road and bridge construction

A bridge construction and dust suppression device technology, applied in the direction of smoke and dust removal, road surface cleaning, separation methods, etc., can solve the problems of construction personnel's physical damage, untimely treatment, secondary pollution, etc., to reduce labor intensity, improve efficiency, and increase scope Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

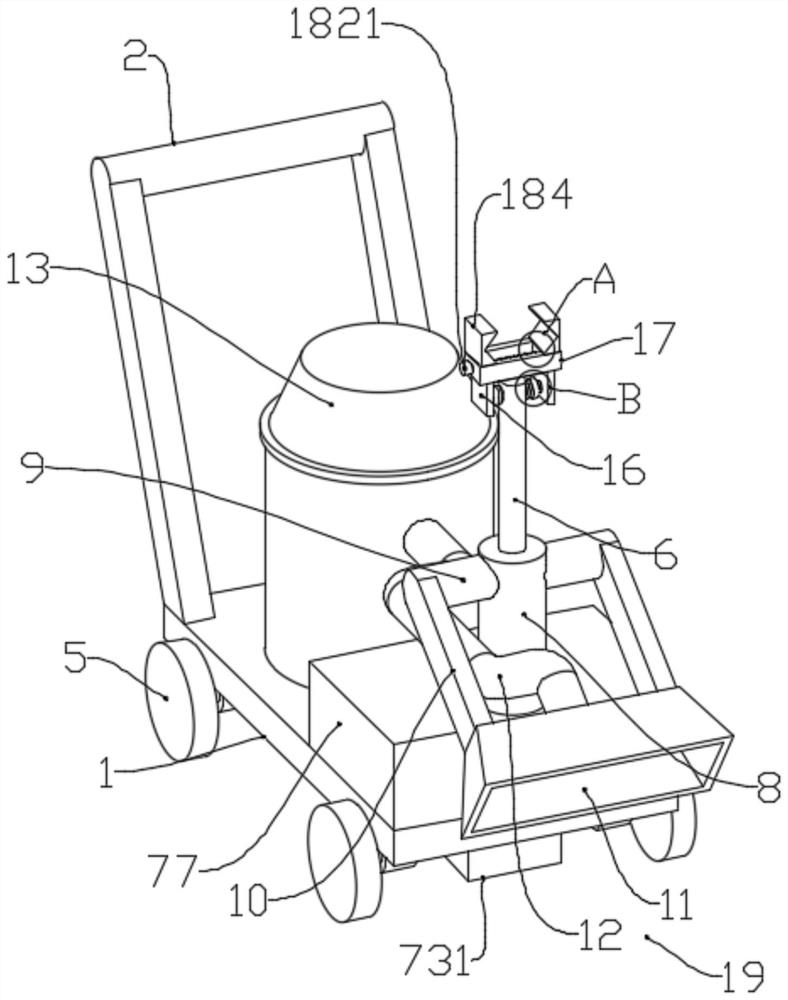

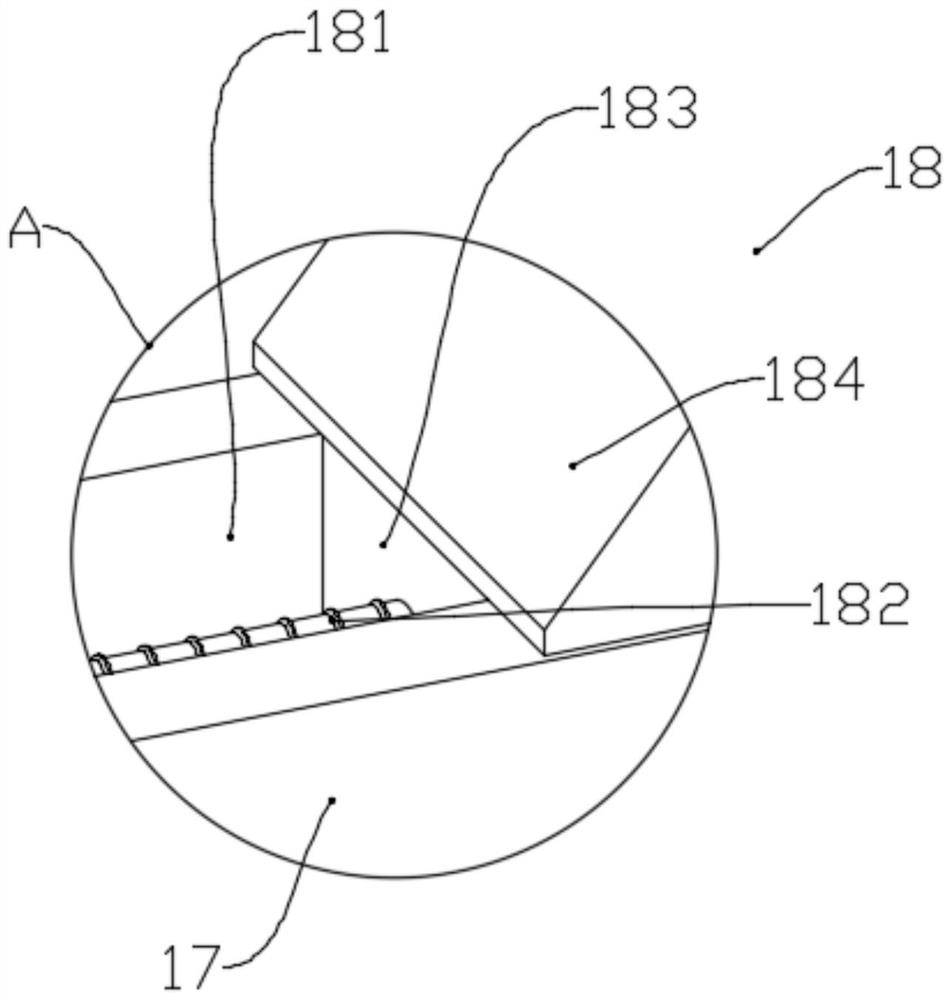

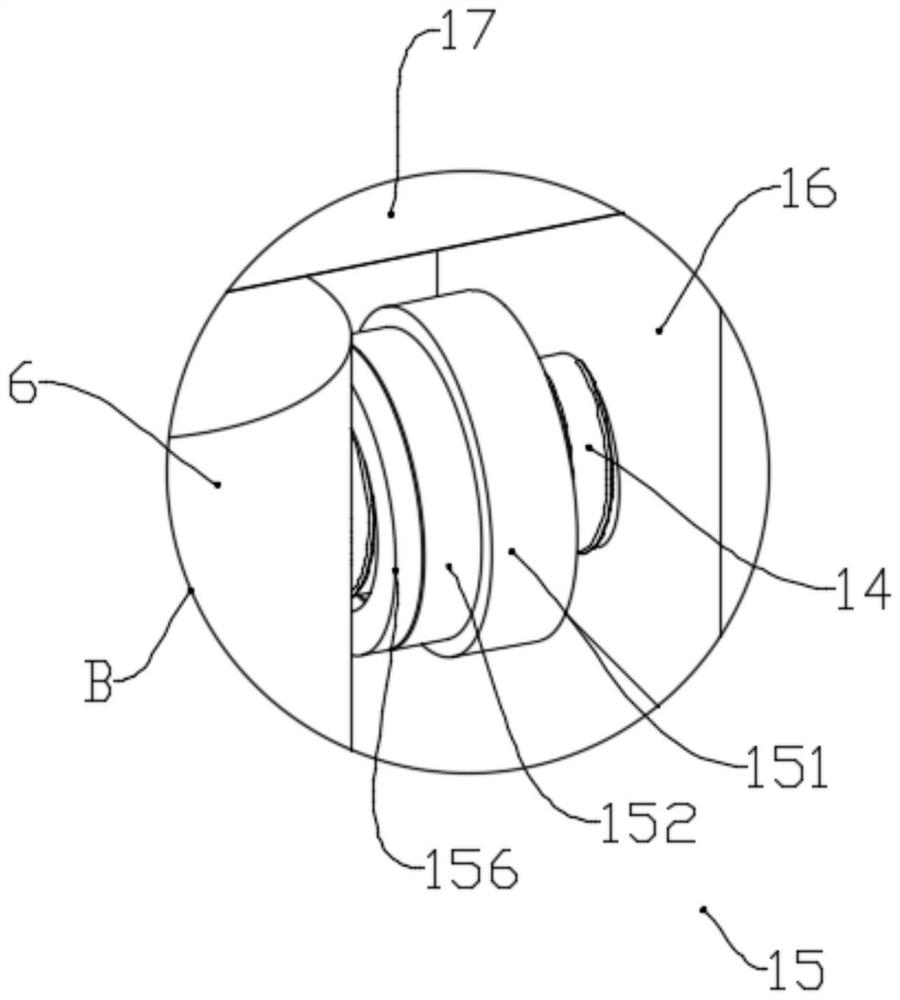

[0029] Example: such as Figure 1-8 As shown, a spraying and dust suppression device for road and bridge construction of the present invention comprises a base plate 1, one end of the base plate 1 is fixedly provided with a handrail 2, and the four corners of the bottom of the base plate 1 are fixedly provided with a fixed block 3, and the fixed block 3 is rotated and inserted with a connection The two ends of the shaft 4 and the connecting shaft 4 are symmetrically fixed with rollers 5, and the top of the bottom plate 1 away from the handrail 2 is rotated and inserted with a mounting rod 6, and a connecting mechanism 7 is fixed between the mounting rod 6 and one of the connecting shafts 4, The bottom end of mounting rod 6 is fixedly provided with dust-absorbing mechanism 19, and the top both sides of mounting rod 6 are symmetrically rotated and inserted with rotating rod 14, and rotating rod 14 is fixedly provided with limit mechanism 15, and rotating rod 14 is away from an en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com