Smoke dust suction device applied to laser surface decontamination

An inhalation device and a technology for fume and dust, which are applied to the cleaning method using tools, the cleaning method using gas flow, the cleaning method and utensils, etc., which can solve the problems of affecting the dust suction effect, reducing the inhalation ability, and unable to effectively remove the dust of the adsorption tube. , to achieve the effect of expanding the vacuuming range, increasing the flow rate, and improving the vacuuming effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand the technical content of the present invention, specific embodiments are provided below, and the present invention is further described in conjunction with the accompanying drawings.

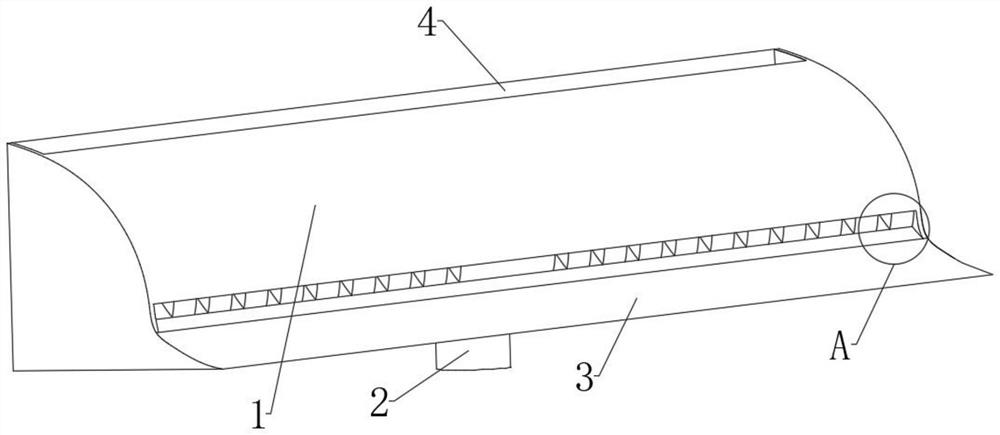

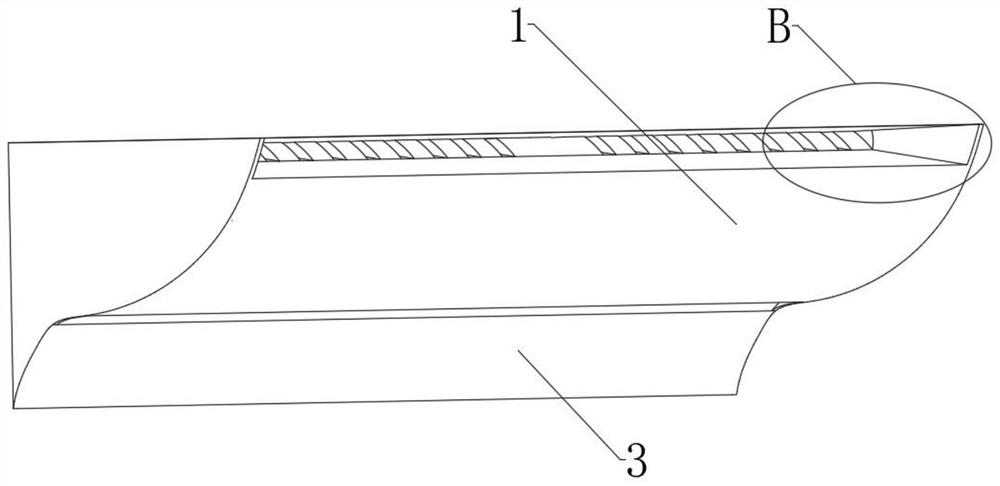

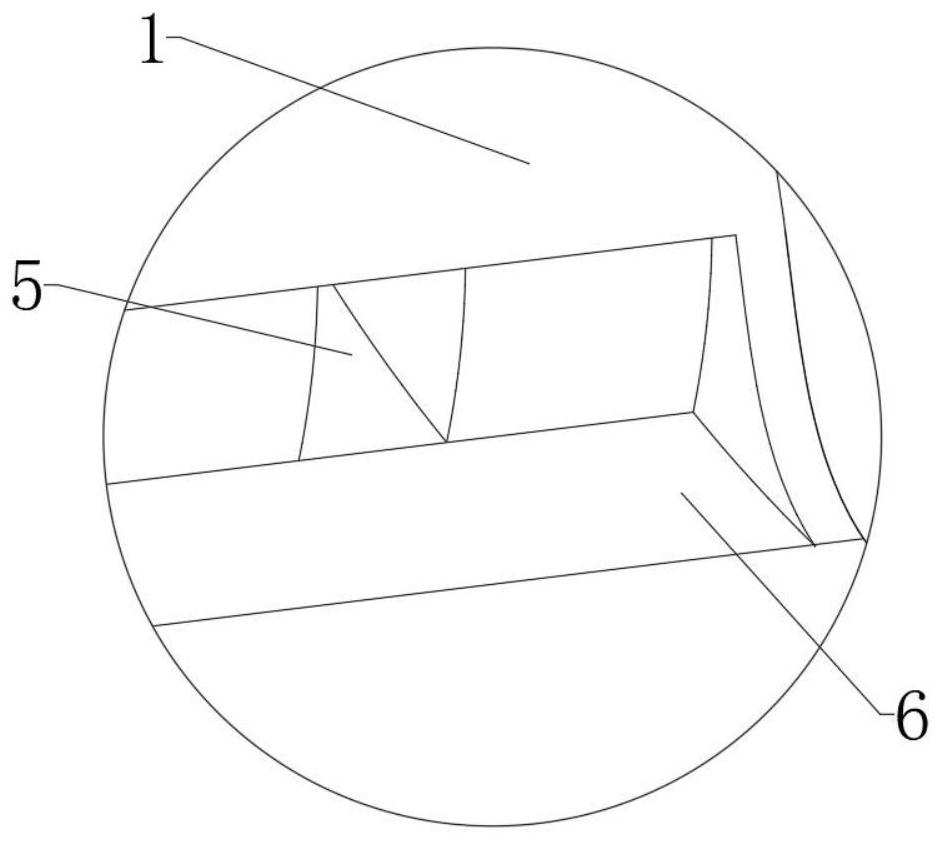

[0030] see Figures 1 to 7 , the present invention provides a smoke suction device applied to laser surface decontamination, comprising a housing 1 and a rotating shaft 8, a circular cavity 12 is arranged transversely in the housing 1, and the cavity 12 is arranged along the length direction of the housing 1, The top, the front side and the middle of the bottom of the housing 1 are respectively provided with a first guide groove 4, a second guide groove 6 and an air outlet 10, specifically, the first guide groove 4 is arranged on the top of the housing 1 the rear side of the housing, the second guide groove 6 is arranged at the bottom of the front side of the housing 1, the first guide groove 4 and the second guide groove 6 are arranged along the length direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com