Patents

Literature

100results about How to "Increase the degree of filtration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

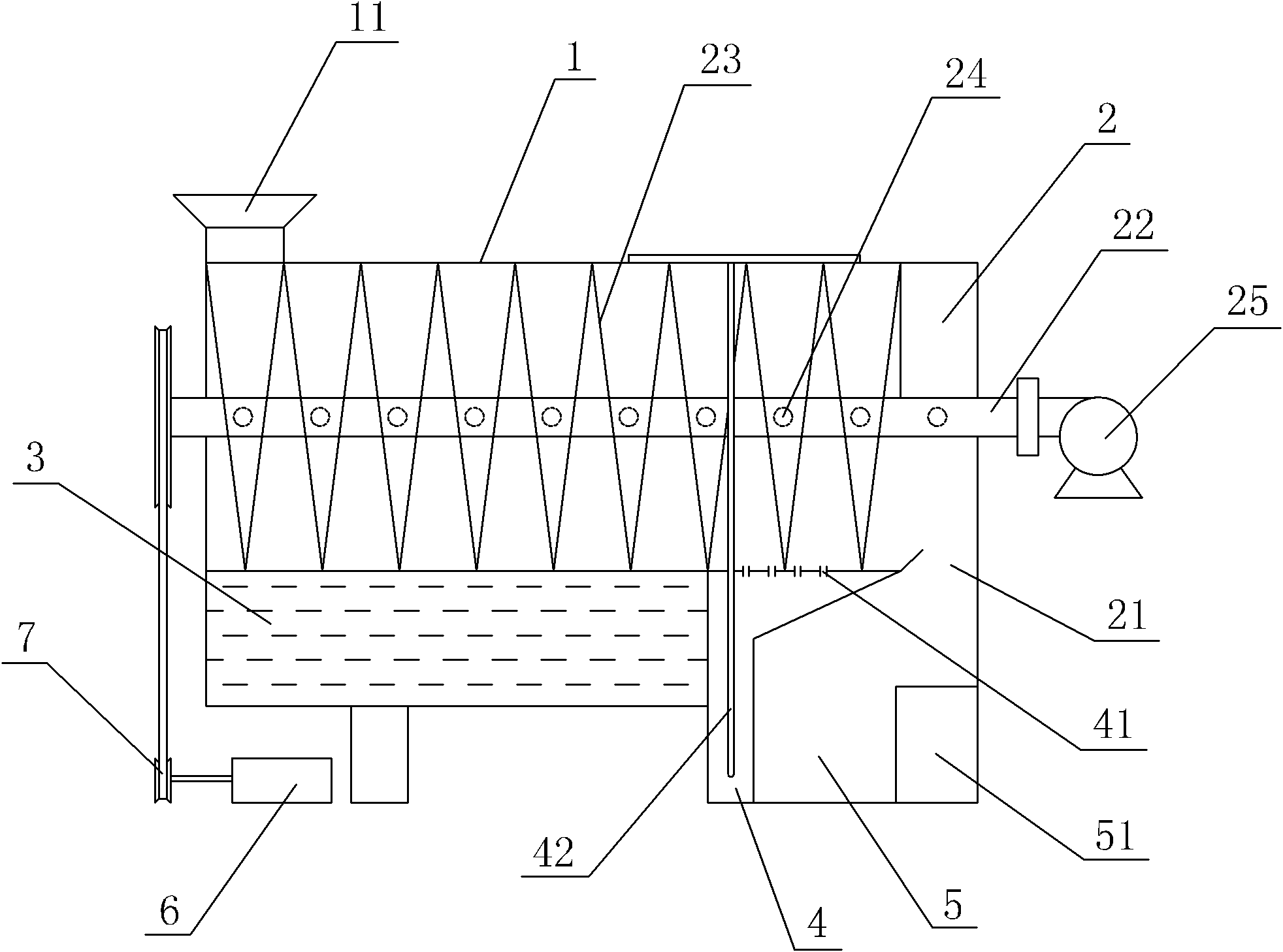

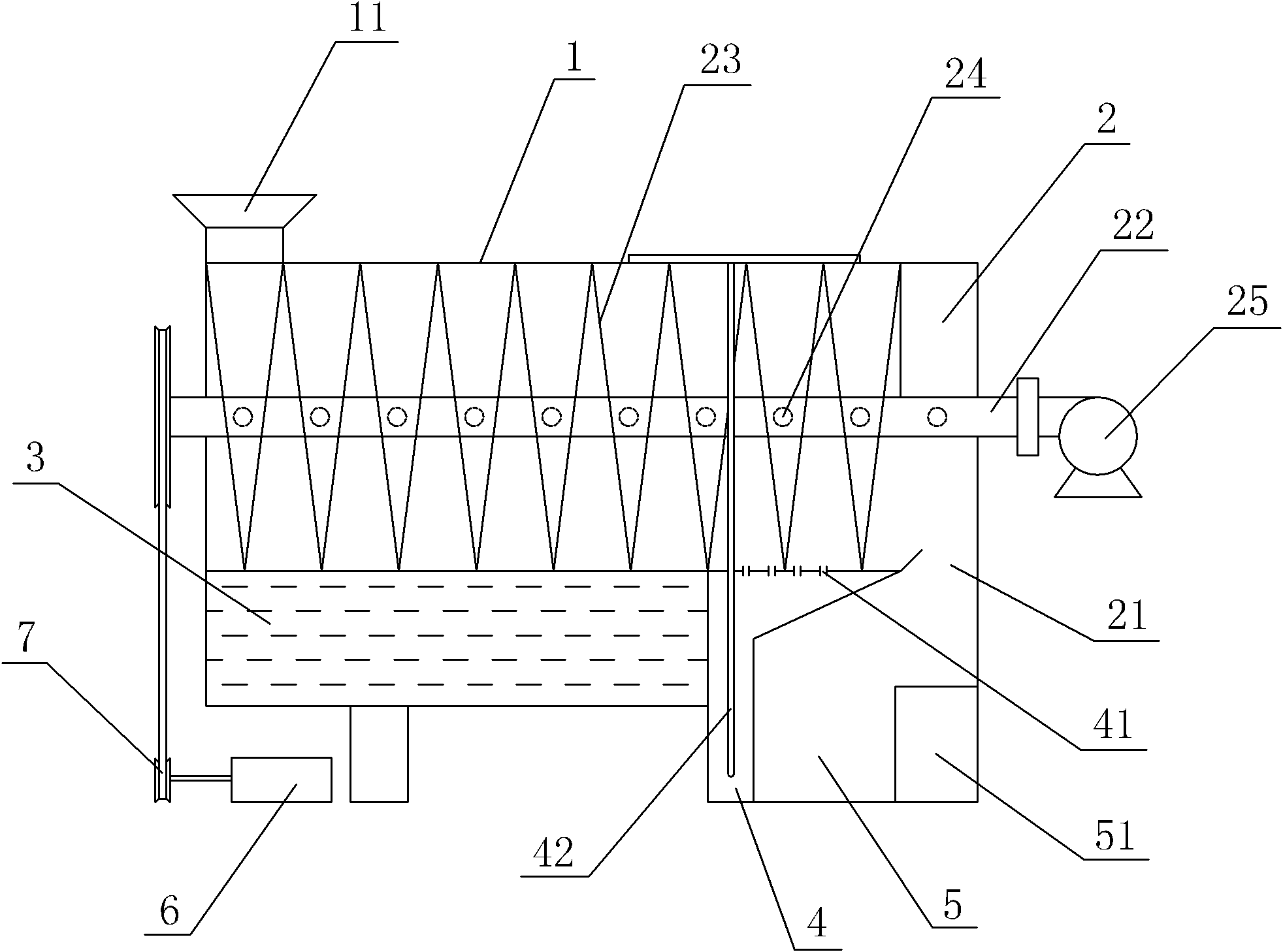

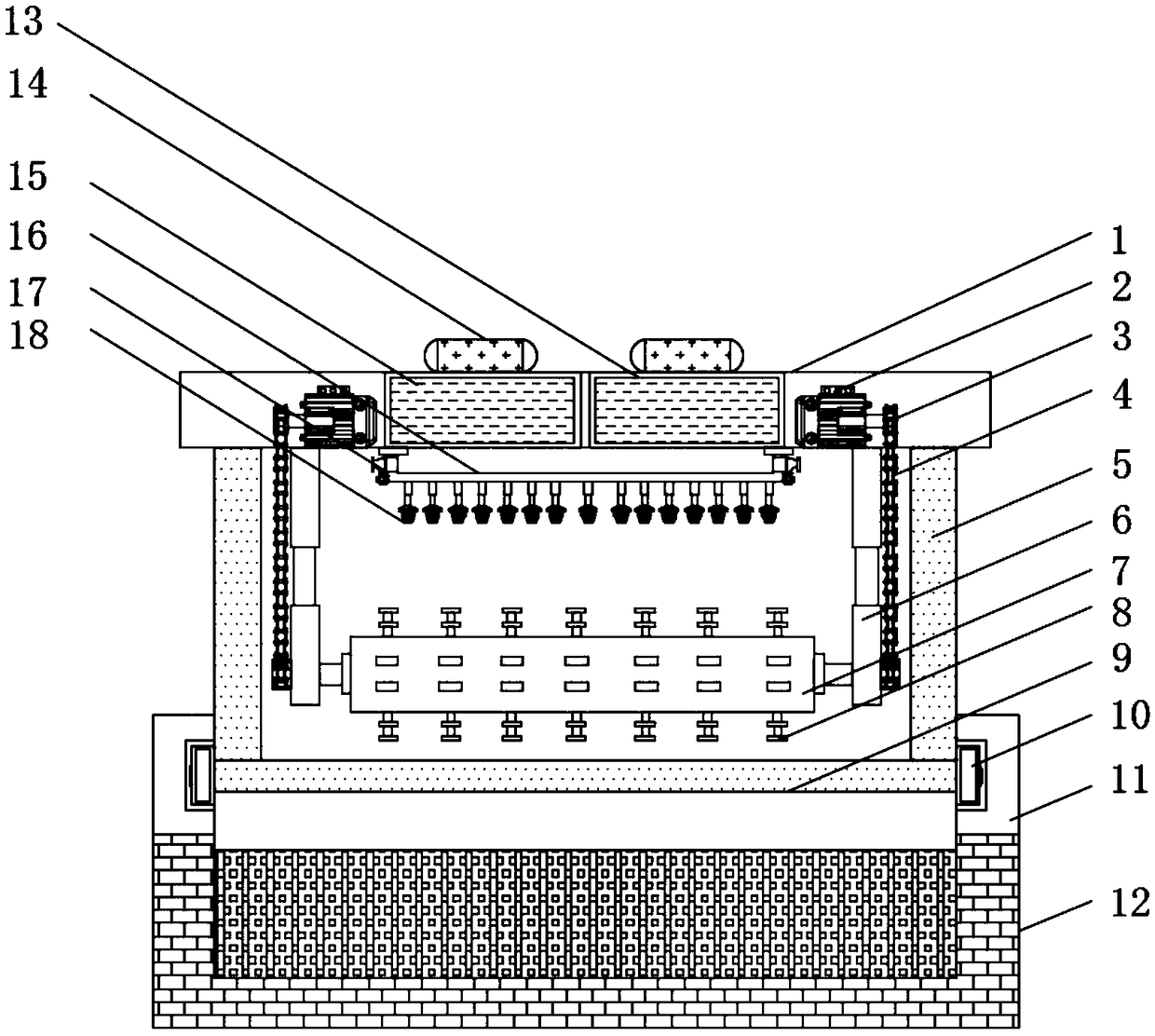

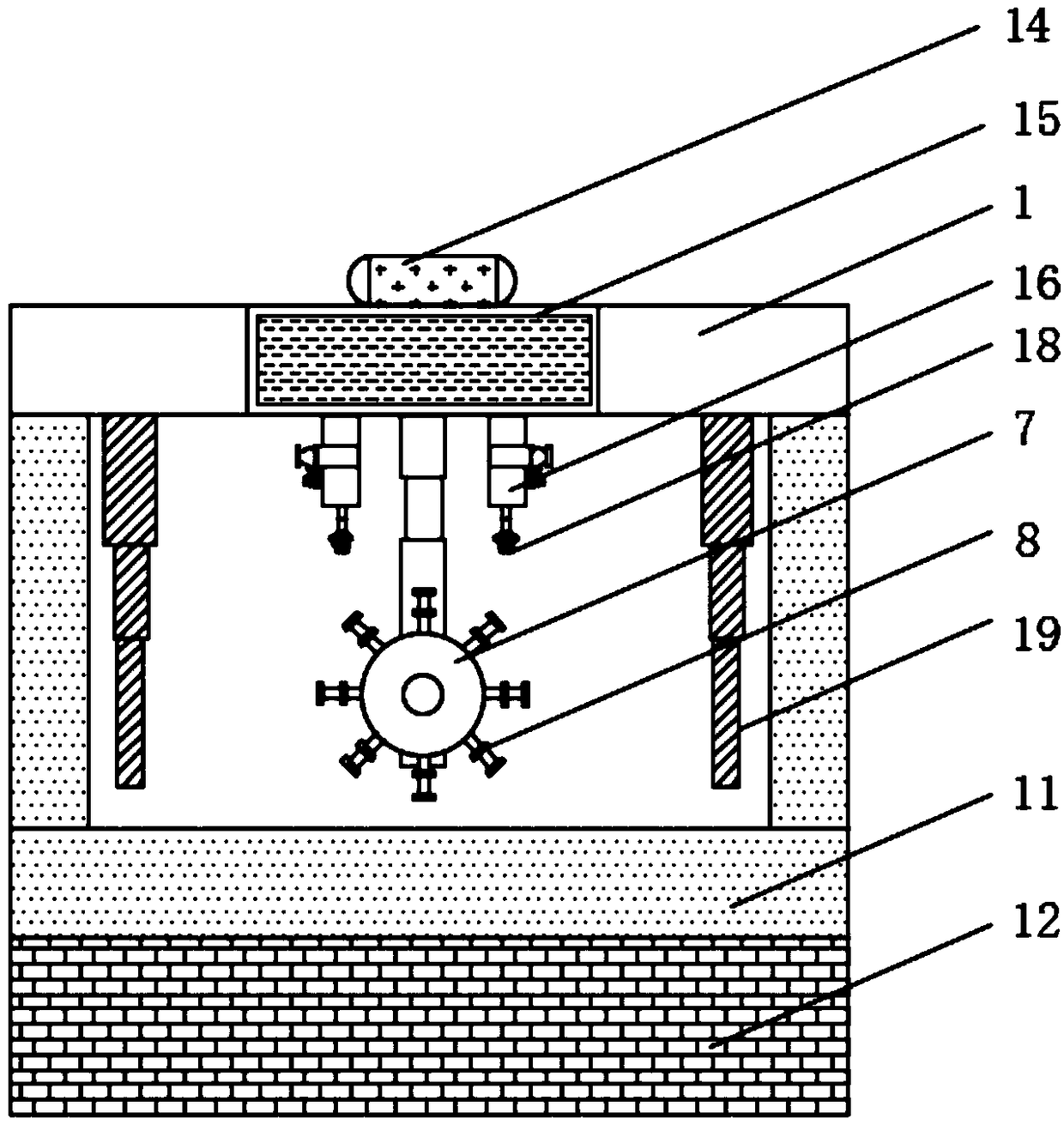

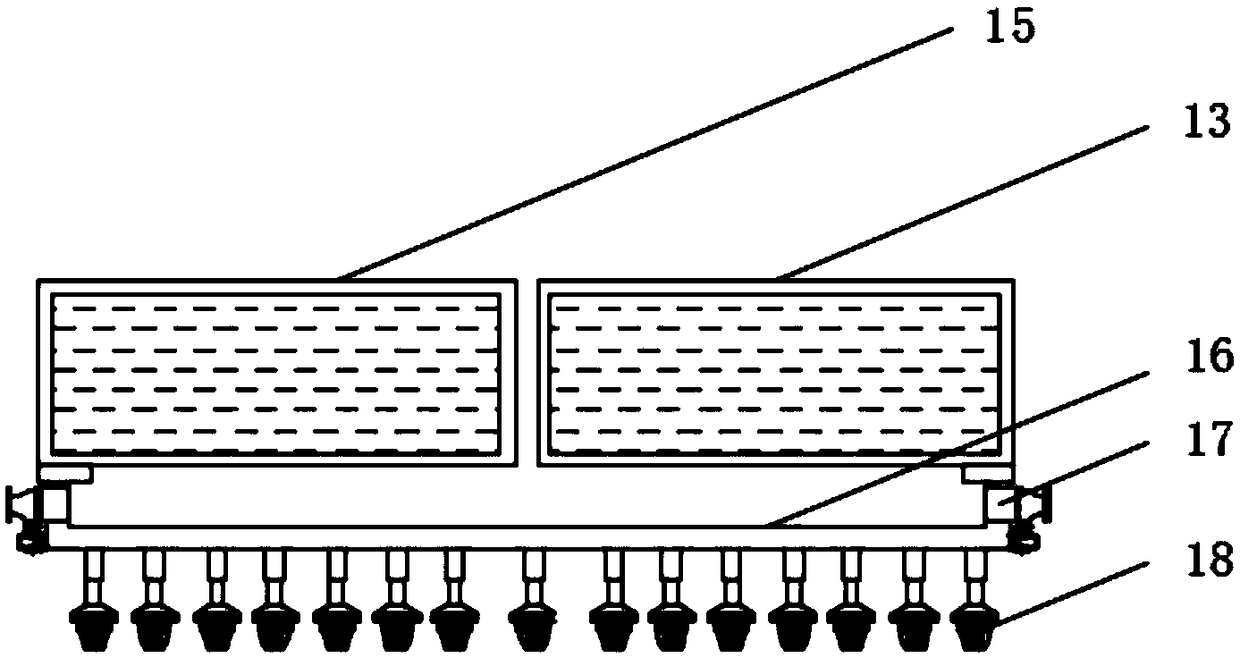

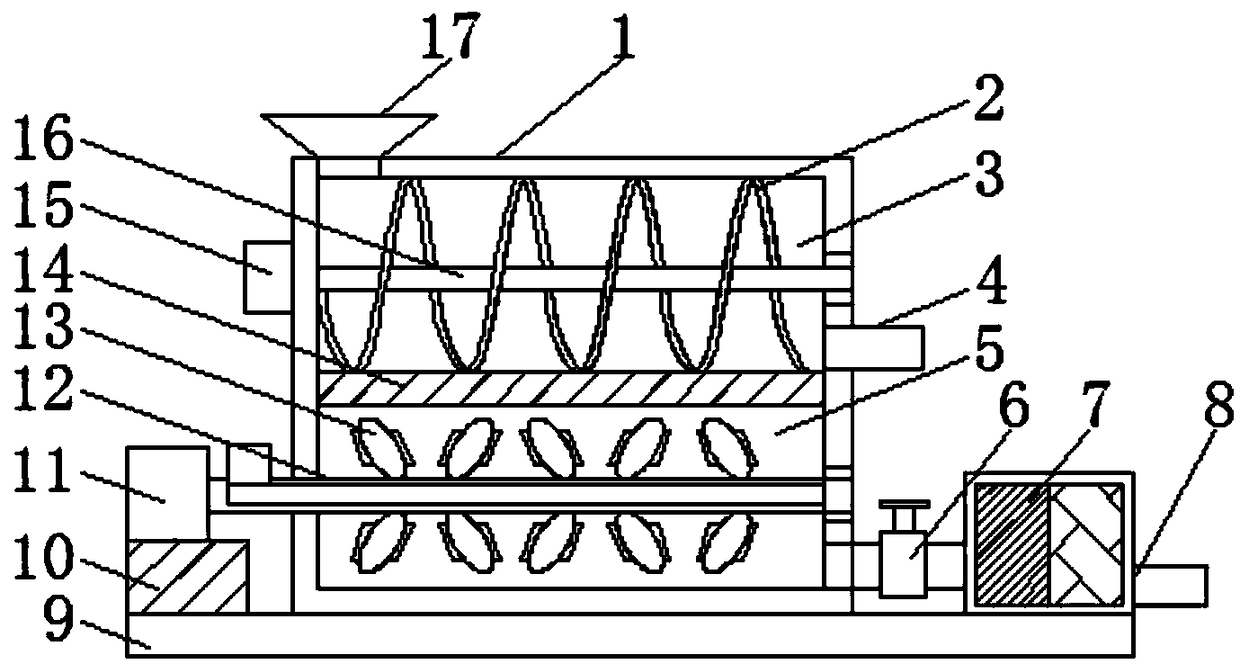

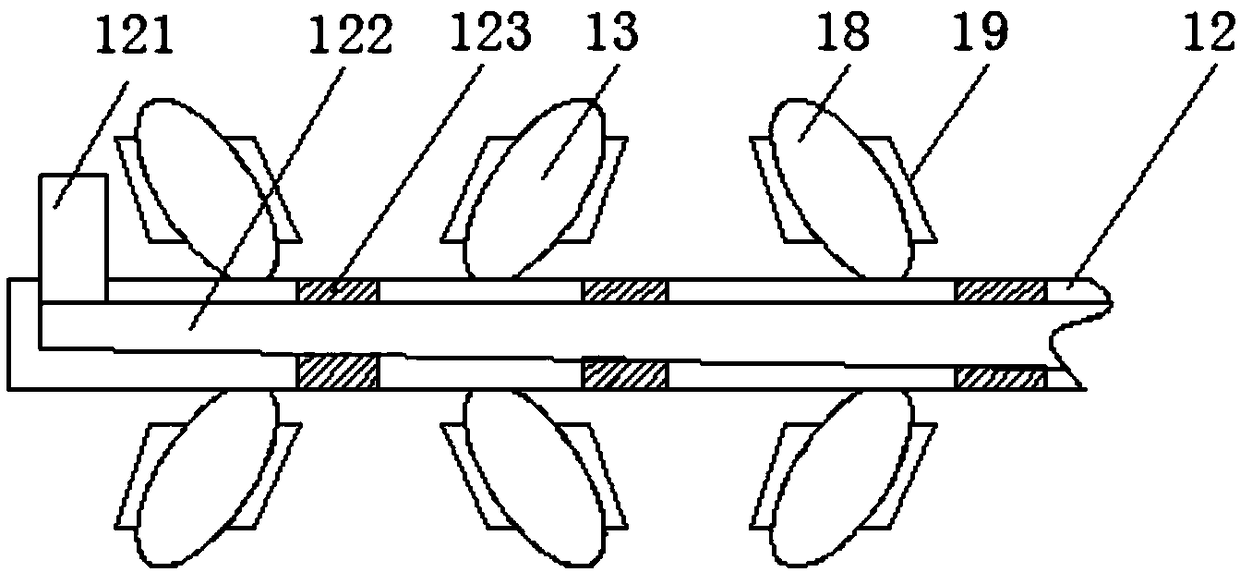

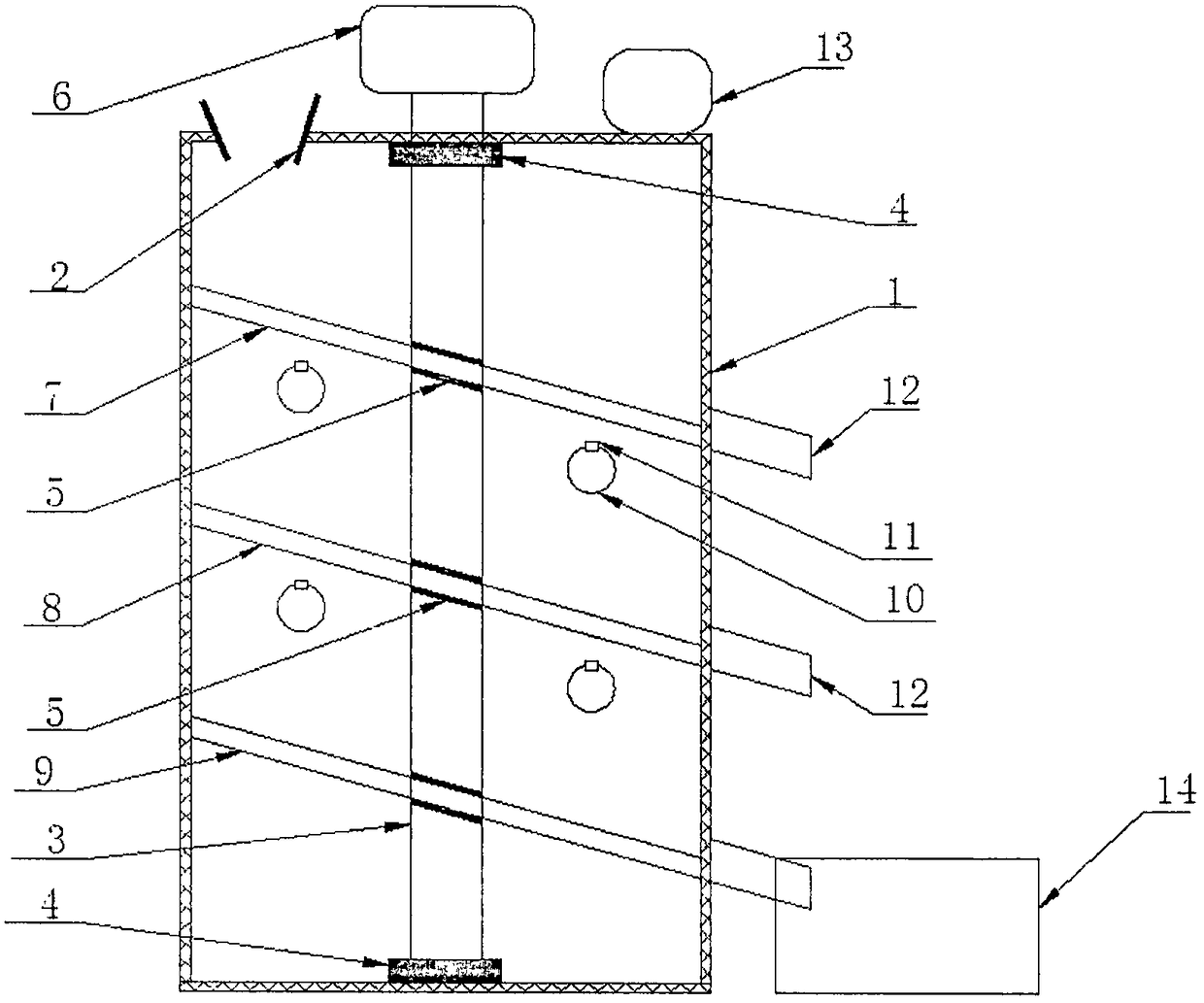

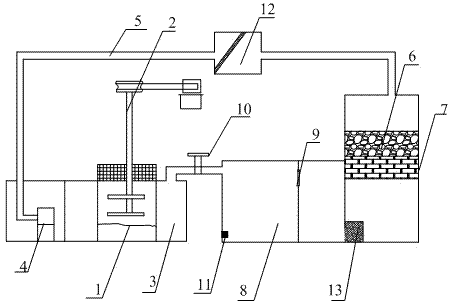

Composting device for domestic waste

InactiveCN101983951ALarge amount of processingSmall footprintClimate change adaptationOrganic fertilisersWater bathsLitter

The invention discloses a composting device for domestic waste, which comprises a sealed casing and a feeding inlet provided with the casing. A composting chamber communicating with the feeding inlet is provided inside the casing, and a discharging opening is provided with the composting chamber. A ventilated spiral agitation propeller is provided inside the composting chamber while a water bath below the composting chamber. A heating device is connected with the water bath. The composting device can provide heat for the fermentation of organic domestic waste such as kitchen garbage in the composting chamber to build out the environment benefit for microbe activities, thereby increasing the fermentation speed of organic domestic waste and the utilization rate of heat energy. Meanwhile, solar heating reduces the consumption of conventional energy and is environmental protection. A secondary composting chamber is arranged below the composting chamber, which greatly shortens the longitudinal length of the whole composting apparatus and further saves the occupation area for composting operations, thereby further increasing the composting fermentation degree and reducing workload.

Owner:NINGBO UNIV

Method for comprehensively utilizing sludge in recycling mode

InactiveCN102249508AEnvironmentally friendlyIncrease the degree of fermentationBiological sludge treatmentFertilizerMunicipal sewage

The invention discloses a method for comprehensively utilizing sludge in a recycling mode. The method comprises the following steps: dewatering sludge of a municipal wastewater treatment plant; respectively analyzing and detecting dewatered sludge, food residues, domestic garbage and human and animal excreta, and deodorizing simultaneously; sorting the deodorized sludge, food residues and domestic garbage; mixing the sludge, the food residues, the domestic garbage, the human and animal excreta, crop straws with reused fluffy sludge in a certain ration at 5-6MPa; meanwhile, controlling stirring temperature to 40-45DEG C until the moisture content of the mixture is 55-65wt%; carrying out aerobic fermentation on the mixture in a fermentation tank for 6-7 days to obtain the fluffy sludge; andcarrying out aftertreatment on the fluffy sludge to obtain fertilizer or fuel. The method has the effects of high fermentation degree, high fermentation speed and the like and is environmentally friendly, and the fertilizer or fuel obtained by aftertreatment can be used for improving soil or saving energy.

Owner:GUANGZHOU KECHENG ENVIRONMENTAL PROTECTION TECH

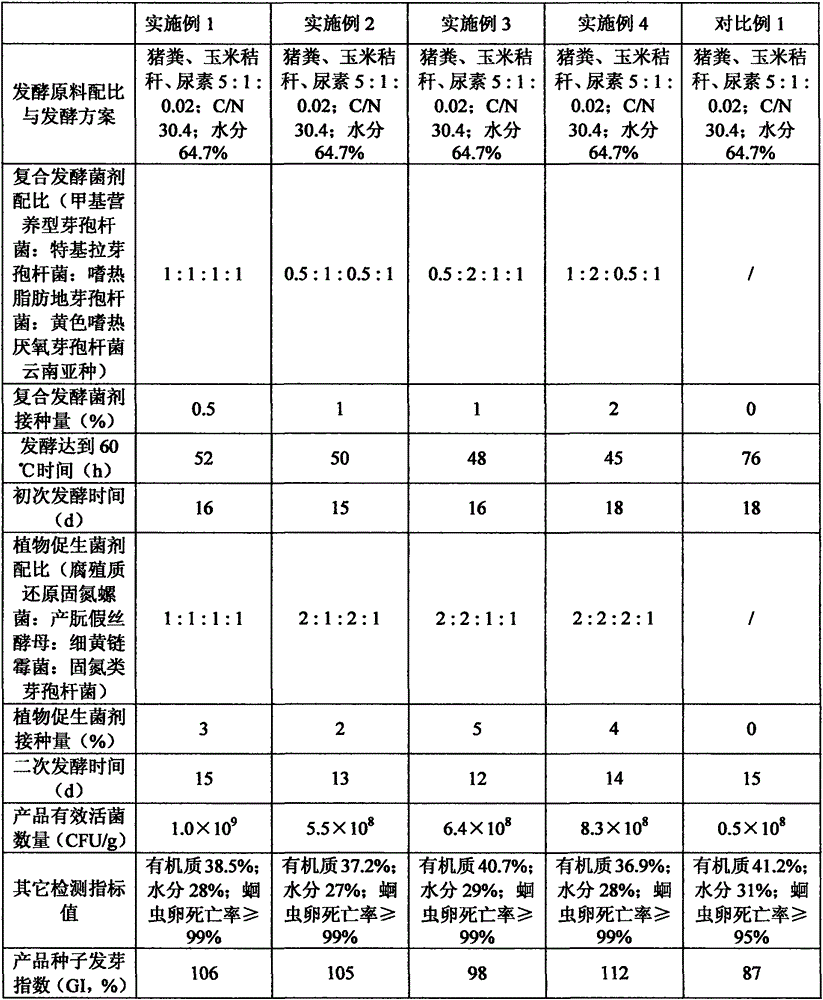

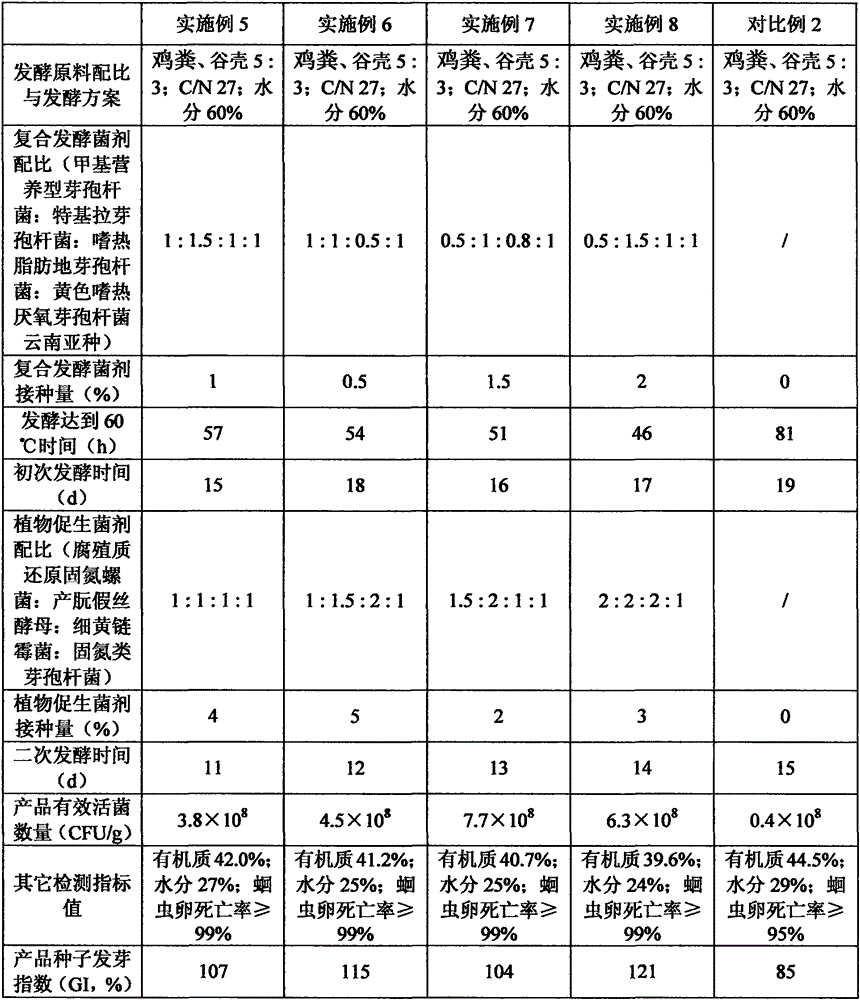

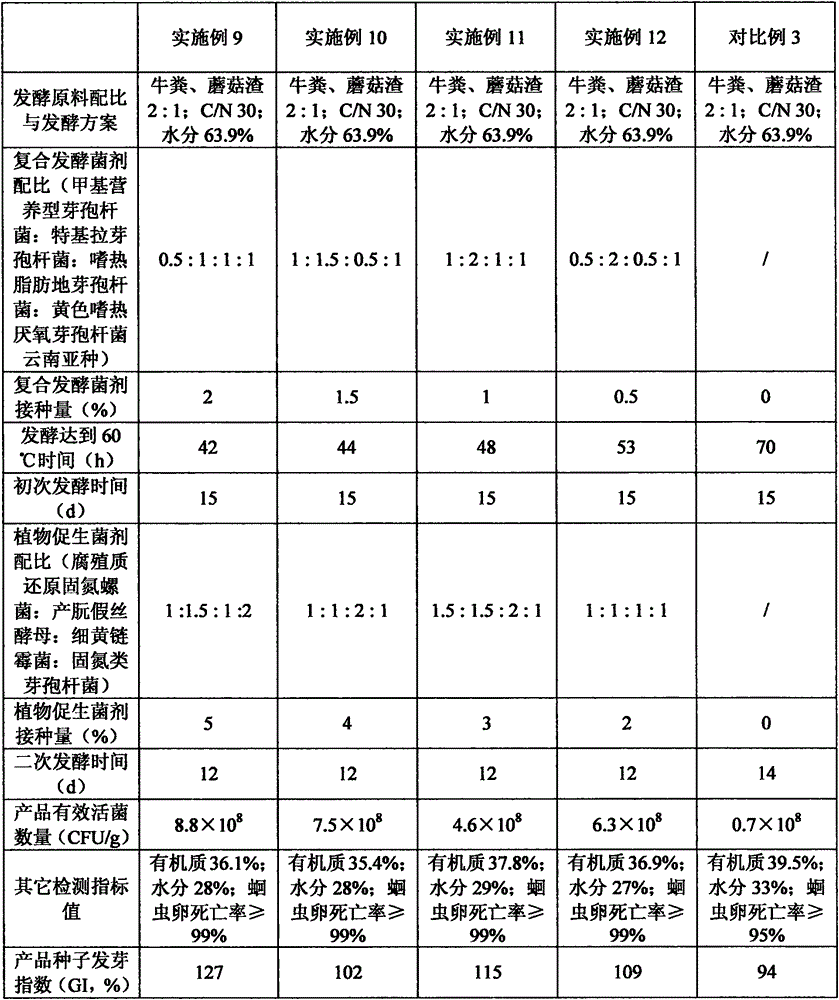

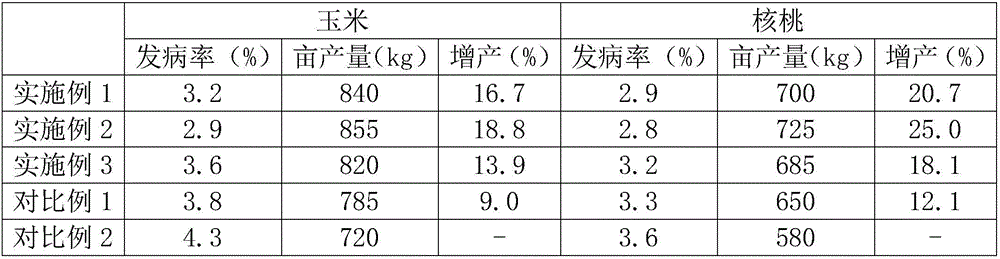

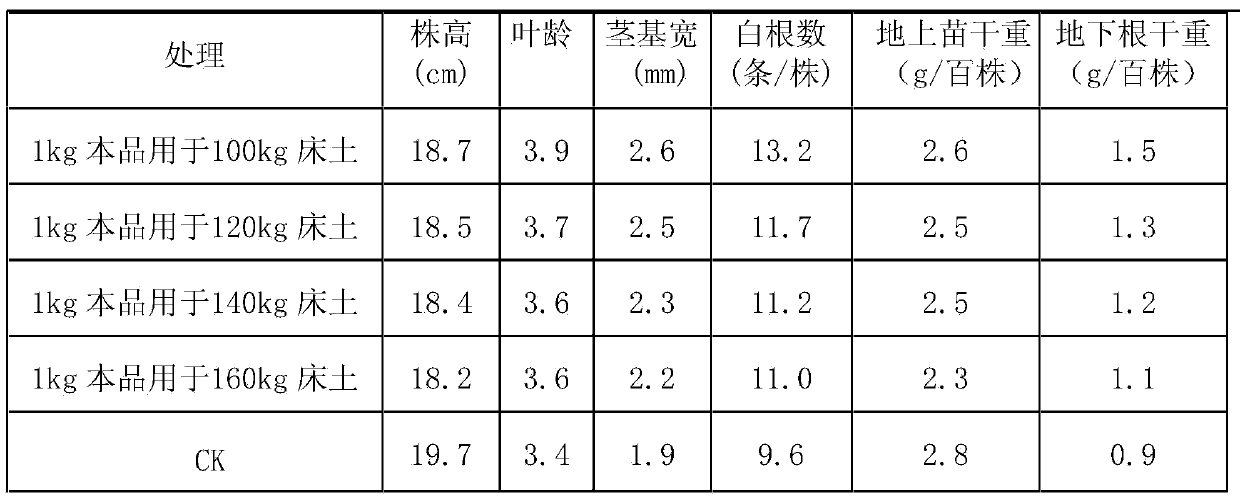

Plant-growth-promoting bio-organic fertilizer and preparation method

InactiveCN106631551AImprove filtration efficiencyIncrease the degree of filtrationBio-organic fraction processingExcrement fertilisersPlant hormoneMicrobial agent

Plant-growth-promoting bio-organic fertilizer is prepared by inoculating 0.5-2% (w / w) of composite fermentation microbial agent to livestock-poultry manure and auxiliary material, fermenting, inoculating 2-5% (w / w) of plant-growth-promoting microbial agent and fermenting. A preparation method includes steps: (1), preparing a fermenting material; (2), performing high-temperature aerobic fermentation; (3), preparing the plant-growth-promoting microbial agent; (4), after-composting organic fertilizer. The plant-growth-promoting bio-organic fertilizer and the preparation method have the advantages that rapid proliferation of plant-growth-promoting functional microorganisms is realized in the process of fermenting of two times, and effective biological viable bacteria count of the organic fertilizer reaches 5x108CFU / g; composting degree is high, the organic fertilizer can generate various plant hormones including 3-indoleacetic acid, cytokinin, gibberellins and ethylene after being applied in soil, can promote plant growth and can increase yield of crops and incoming of farmers; the bio-organic fertilizer prepared by the method is low in cost, environment-friendly and high in efficiency.

Owner:山西宁邦生物科技有限公司

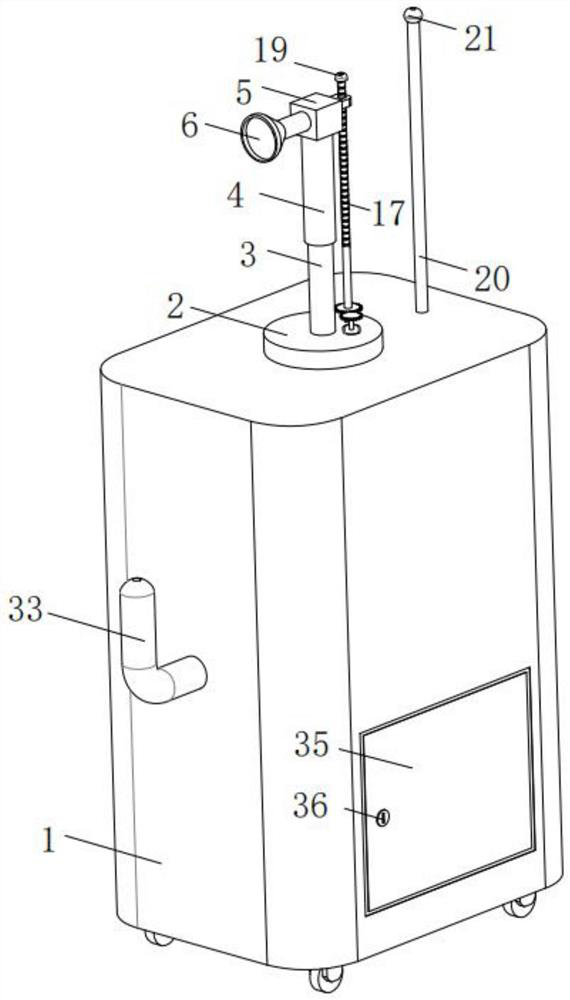

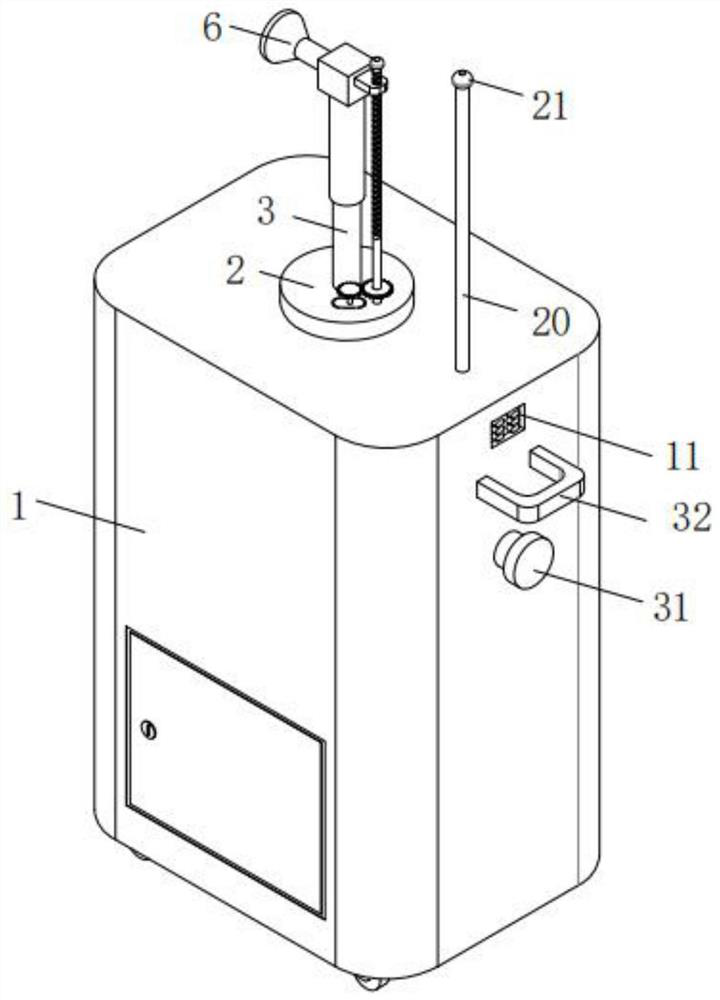

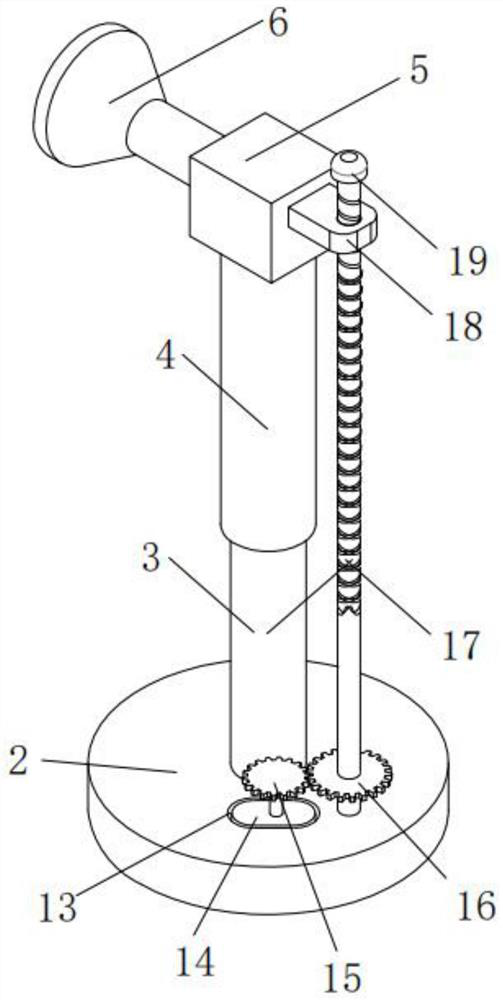

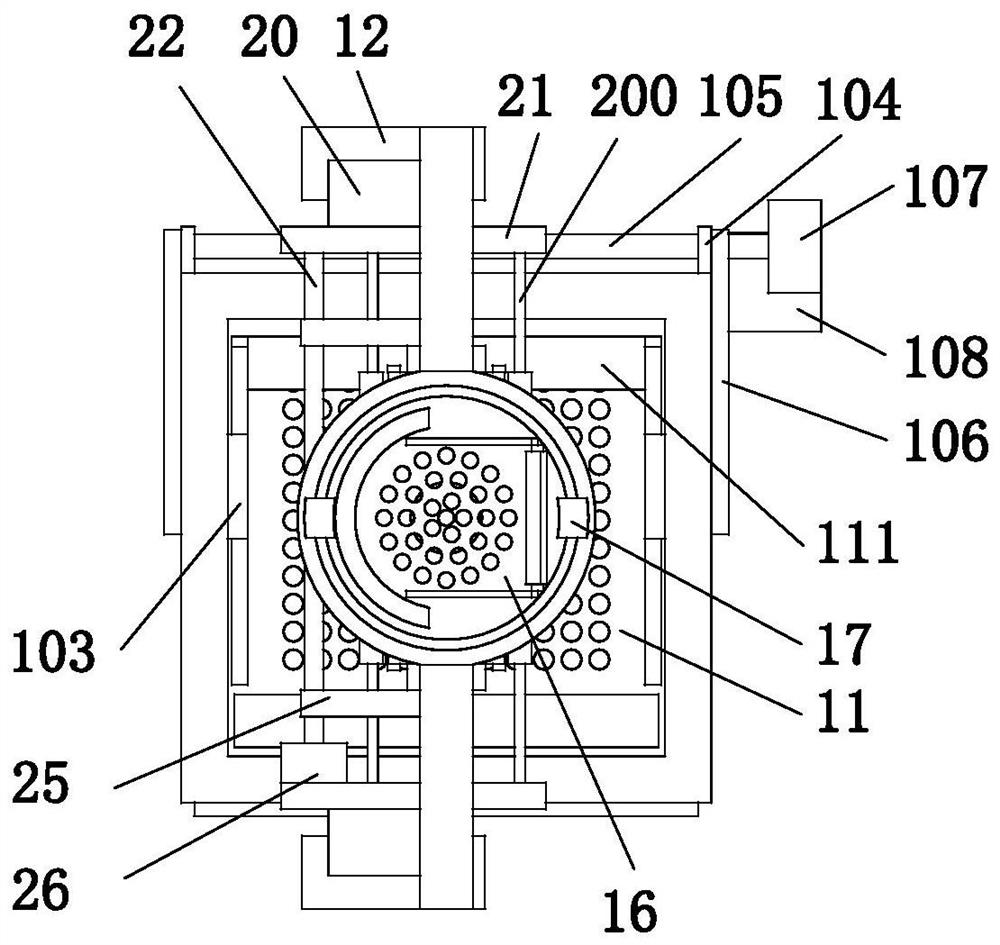

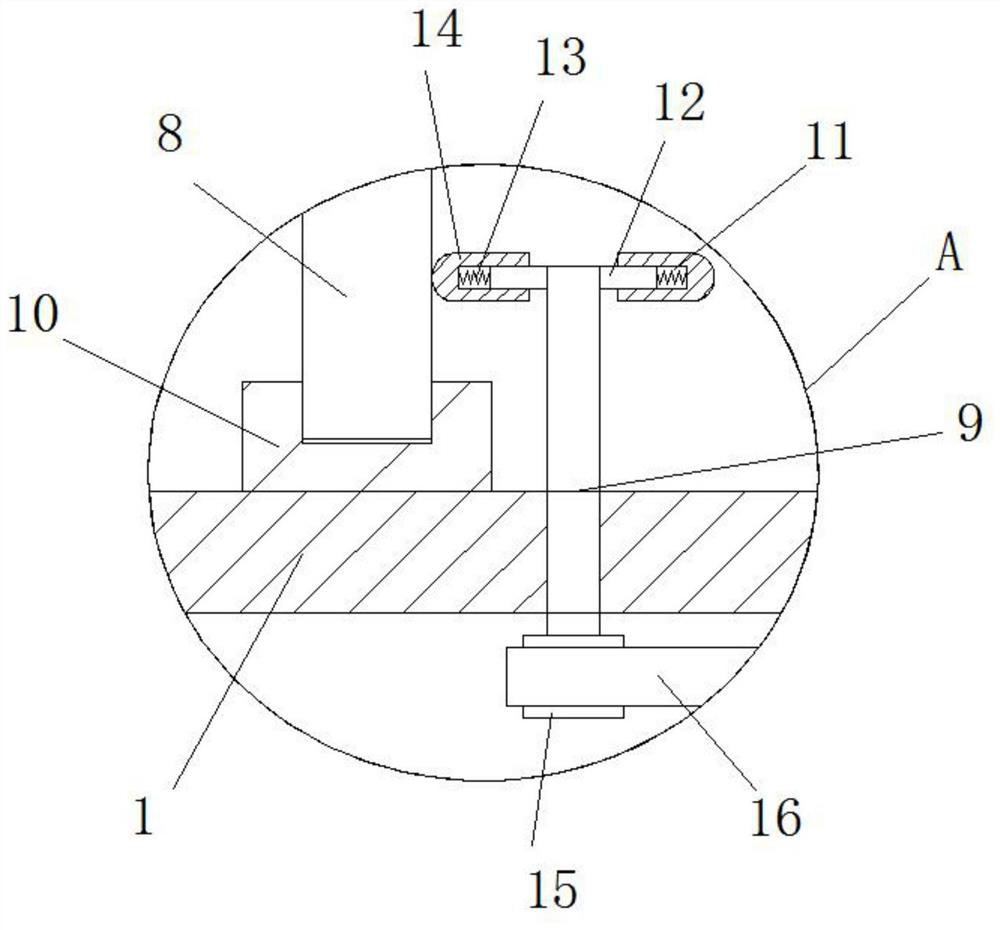

Turning device for producing organic fertilizer

InactiveCN109111264AWork fasterImprove work efficiencyOrganic fertiliser apparatusEngineeringOrganic fertilizer

The invention discloses a turning device for producing organic fertilizer. The turning device comprises a device body and a retractable rod, wherein servo motors are arranged in the device body; a rotary gear is arranged at one end of each servo motor in a transmission manner; a hinge is rotatably arranged at one end of the rotary gear in an engaging manner; one side of the hinge penetrates through the retractable rod to be rotatably provided with a turning roller. The device disclosed by the invention is internally provided with the turning roller; the retractable rod is used for adjusting the turning roller to a suitable depth according to turning requirements; the rotary gear is rotated through the servo motors and the rotary gear and the hinge are engaged to rotate and drive the turning roller; a turning cutter arranged on the surface of the turning roller is used for uniformly turning the organic fertilizer needing to be turned; the turning depth can be freely adjusted through theretractable rod; meanwhile, two groups of the servo motors can frontward and backward drive the device to rotate and work, so that the working speed and efficiency of turning the fertilizer are greatly improved.

Owner:天津富瑞丰生物科技有限公司

Method for preparing organic fertilizer for planting tomatoes

InactiveCN107337569AIncrease contact areaImprove degradation rateCalcareous fertilisersBio-organic fraction processingDisease ratesFermentation

The invention discloses a method for preparing an organic fertilizer for planting tomatoes. The method comprises the following steps: (1) powdering, namely drying organic raw materials till the water content is 10-14%, performing powdering treatment for 2-3 times repeatedly by using a powder machine, and performing high-temperature sterilization treatment; (2) performing ammoniation treatment, namely performing ammoniation treatment under a pressure condition of 0.3-0.4MPa; (3) performing magnetic fermentation, namely putting a mineral solution into a fermentation tank, and performing magnetic fermentation under conditions of vacuum degrees of 80%, 85% and 100% respectively; (4) performing enzymolysis, namely putting water into organic fermentation materials, adding mixed enzymes, and performing enzymolysis; (5) performing secondary fermentation, namely putting the mineral solution into the enzymolysis organic materials, adding fertilizer fermentation agents, and performing composting fermentation. Compared with a control group, the organic fertilizer prepared by using the method is capable of increasing the content of vitamin A in tomatoes by 32.6ug / 100g, increasing the ash content by 1.53%, and reducing the insect and disease rate by 1.79%.

Owner:界首市金牛家庭农场

Method for producing biological organic fertilizer by utilizing pericarpium zanthoxyli seed meal

InactiveCN106588500AUtilization of waste resourcesTake advantage ofSuperphosphatesBio-organic fraction processingCaladiumBiotechnology

The invention discloses a method for producing a biological organic fertilizer by utilizing pericarpium zanthoxyli seed meal, and belongs to the technical field of machining of an organic fertilizer. The organic fertilizer is prepared from the following raw materials in parts by weight: 80 to 120 parts of pericarpium zanthoxyli seed meal, 50 to 80 parts of leaves of pericarpium zanthoxyli, 30 to 50 parts of radix sophorae subprostratae, 20 to 35 parts of astragalus smicus, 10 to 15 parts of sake kasu, 20 to 36 parts of peanut shell, 6 to 10 parts of fructus cnidii, 8 to 12 parts of herba commelinae, 10 to 16 parts of lightyellow sophora root, 15 to 20 parts of calcium superphosphate, 15 to 18 parts of potassium bicarbonate, 24 to 30 parts of kieselguhr and 1 to 3 parts of microorganism bacterium agent. The pericarpium zanthoxyli seed meal biological organic fertilizer produced by the method disclosed by the invention sufficiently utilizes waste resources, and has the effects of improving soil, reinforcing soil fertility, preventing and treating diseases and insect pests and increasing both production and incomes.

Owner:QINGYANG DUNBO TECH DEV CO LTD

Air filter for multi-level efficient engine

InactiveCN106014711AImprove filtration efficiencyIncrease the degree of filtrationMachines/enginesAir cleaners for fuelFiltrationAir filter

The present invention provides a multi-stage high-efficiency engine air filter, comprising a first filter body, a second filter body, a third filter body, a plurality of first filter elements, a second filter element, a third filter element, and a first filter body. The openings at both ends are respectively screwed with a first end cover and a second end cover. The second filter body is a cylinder structure with both ends open; the third filter body is a cylinder structure with one end open and one end closed. The body is arranged in the first filter body and the cover is arranged outside the second filter body; a plurality of first filter elements are arranged in parallel in the first filter body, and the second filter body is provided with a rotating shaft arranged coaxially with it, and the plurality of first filter elements pass through The rotating shaft is installed in the second filter body and can rotate with the rotation of the rotating shaft; the second filter element is arranged in the third filter body and is sleeved on the outside of the second filter body; the third filter element is arranged in the first filter body and sleeved in the third filter body outside of the filter. The present invention can completely filter out impurities in the air by performing multi-channel filtration on the air, thereby improving the filtration efficiency of the air and the cleanliness of the filtration.

Owner:WUHU AOBENMA AUTOMOBILE PARTS

Industrial sewage treatment device

InactiveCN108569830APrevent condensation from cloggingFilter thoroughlySpecific water treatment objectivesWater contaminantsDraining tubeDistillation

The invention discloses an industrial sewage treatment device and relates to the technical field of industrial environmental protection. The industrial sewage treatment device comprises a bottom plate; a filtering box is arranged at the tops of two groups of supporting rods; a separation plate is arranged in an inner cavity of the filtering box; the separation plate is used for separating the inner cavity of the filtering box into a solid box and a liquid box; a stirring box is arranged at the left side of the top of the filtering box; a water outlet pipe is arranged at the bottom of an outerwall at the right side of the stirring box; a supporting block is arranged at the right side of the top of the bottom plate; an electrolysis box is arranged at the left side of the top of the supporting block; a distillation box is arranged at the right side of the top of the supporting block; a water discharging pipe is arranged at the top of the right side of the distillation box. The device issimple in structure; a stirring device adopts a design including a sliding groove, a sliding block and a scraping sheet, so that a condition that a sedimentation substance is condensed on an inner wall of a stirring box to cause blocking so that the sedimentation efficiency is reduced is avoided; large-particle objects precipitated in sewage are separated through a solid-liquid separation net, thesolid box and the liquid box and enter an impurity groove, so that the device is prevented from being blocked and secondary pollution to water is prevented.

Owner:周圣兰

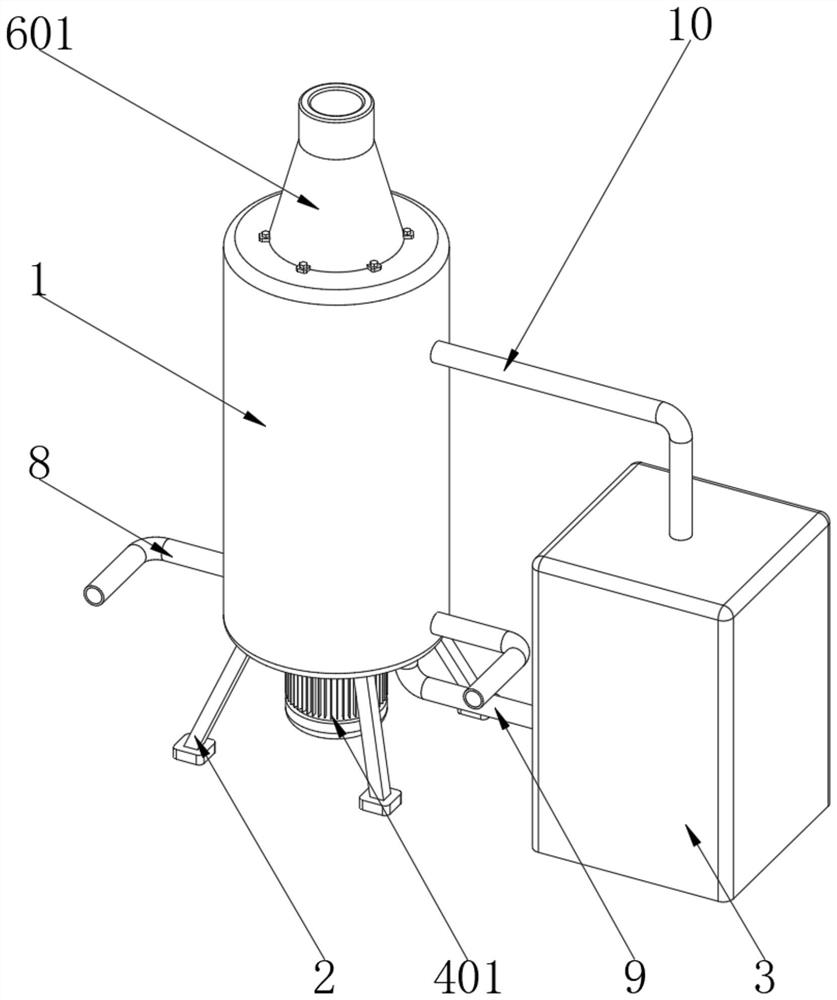

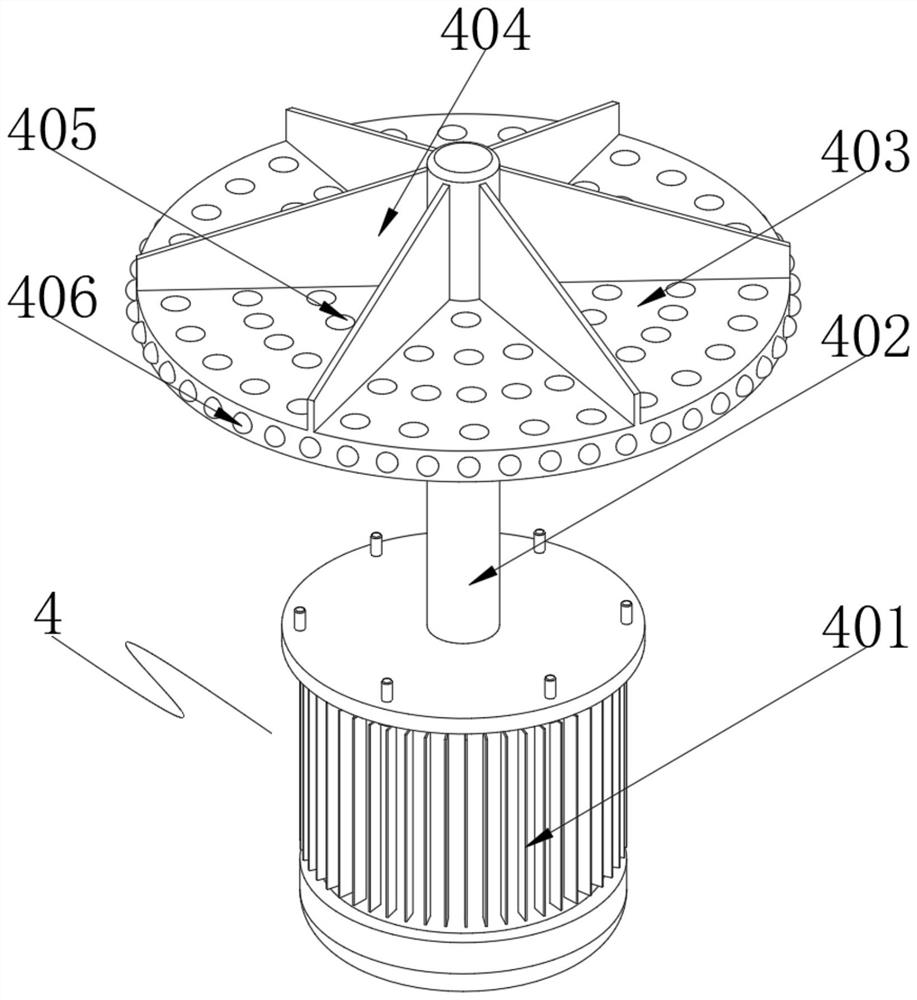

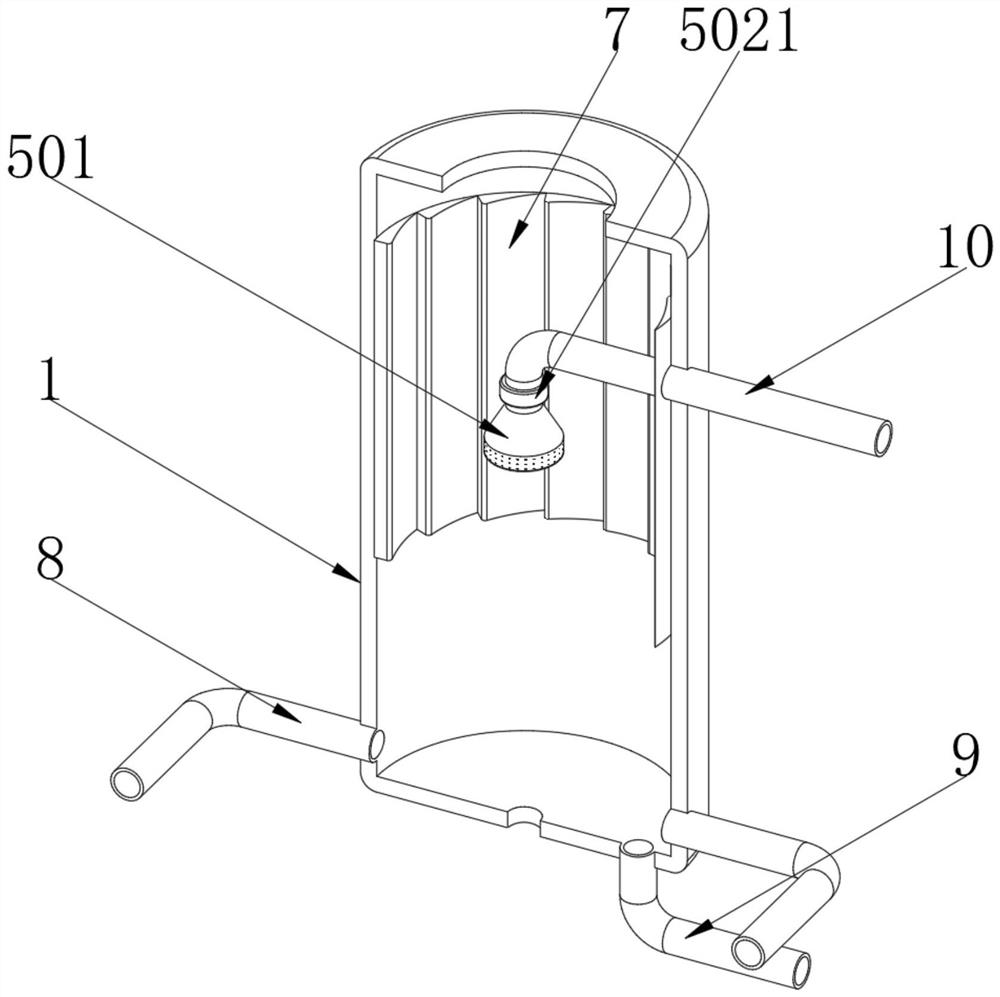

Novel environment-friendly dust removal equipment

InactiveCN112121571AImprove dust removal efficiencyIncrease the degree of filtrationCombination devicesDirt cleaningReciprocating motionDust control

The invention provides novel environment-friendly dust removal equipment, and belongs to the technical field of dust removal. The equipment comprises a dust removal box, and the upper end of the dustremoval box is rotatably connected with a turntable. The upper end of the turntable is fixedly connected with a first connecting pipe. The surface of the first connecting pipe is movably sleeved witha second connecting pipe. The upper end of the second connecting pipe is fixedly connected with a mounting pipe sleeve. The left end of the mounting pipe sleeve is fixedly connected with an air suction hopper. An up-down reciprocating motion mechanism is arranged on the upper side of the turntable. An atomizing nozzle is arranged on the right portion of the upper end of the dust removal box. A mounting cavity and a dust collection cavity are formed in the dust removal box. The first connecting pipe movably penetrates through the lower end of the turntable and extends into the mounting cavity.A rotating mechanism is arranged on the circumferential surface of the first connecting pipe located in the mounting cavity, and the lower end of the first connecting pipe is rotationally connected with a third connecting pipe. Dust in air can be comprehensively absorbed, the dust absorption efficiency is improved, and moving is convenient.

Owner:NANJING HANERSI BIOLOGY TECHNOLOGY CO LTD

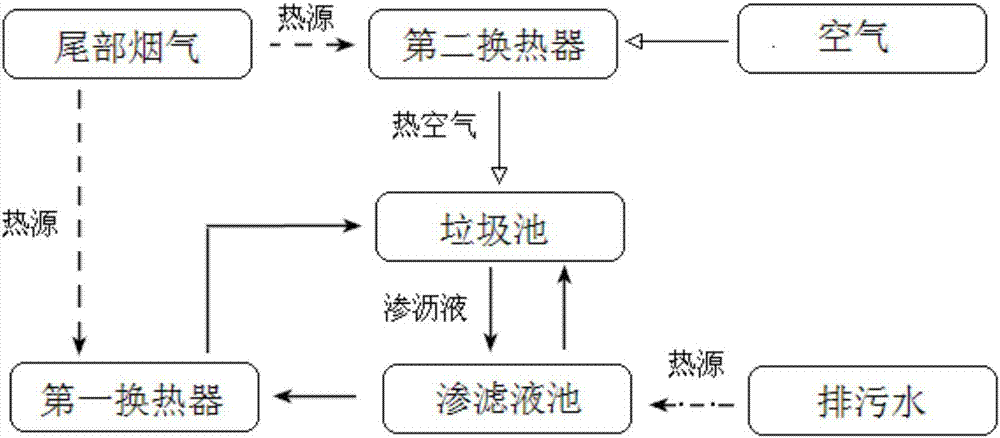

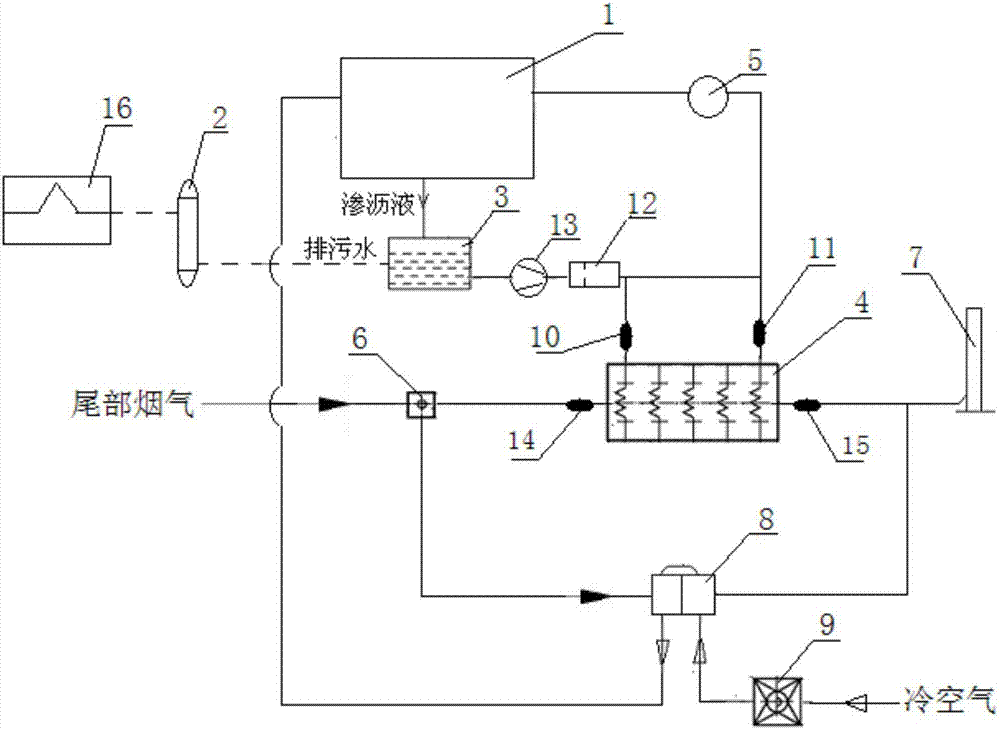

Method and system for increasing calorific value of garbage by virtue of waste heat of garbage incineration plant

ActiveCN106907719AIncrease the degree of filtrationIncrease the ambient temperatureIncinerator apparatusPower stationSewage

The invention discloses a method and system for increasing the calorific value of garbage by virtue of waste heat of a garbage incineration plant and belongs to the field of power generation by garbage incineration. The method comprises the steps: carrying out heat exchange on a leachate by virtue of tail smoke waste heat treated by smoke purification and / or sewage water waste heat in a garbage incineration system; and then, spraying the leachate subjected to heat exchange back to a garbage pool. By carrying out heat exchange on the leachate by virtue of the tail smoke waste heat treated by smoke purification and / or the sewage water waste heat in the garbage incineration system, and then, spraying the leachate back to a garbage pile of the garbage pool, the temperature of the garbage pile in the garbage pool of a low-calorific-value garbage incineration power plant can be effectively increased, and the fermentation and leaching of the garbage pile in the garbage pool can be favorably realized, so that the calorific value of the garbage incinerated in the furnace can be increased, furthermore, the on-grid energy is increased, and finally, the stable and continuous operation of a garbage power plant is favorably realized.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP

Solid-liquid spiral separation press machine

InactiveCN108793667AEasy to addIncrease mutual contactSludge treatment by de-watering/drying/thickeningPressesWater flowSewage

The invention discloses a solid-liquid spiral separation press machine in the technical field of press machines. The solid-liquid spiral separation press machine comprises a shell, wherein a baffle plate is arranged in an inner cavity of the shell; the baffle plate is used for dividing the inner cavity of the shell into a solid-liquid separation tank and a stirring tank from top to bottom in sequence; a separation motor is arranged on the outer wall of the left side of the solid-liquid separation tank; a conveying and extruding shaft is arranged in an inner cavity of the solid-liquid separation tank; the bottom part of the right side of the solid-liquid separation tank is provided with a solid outlet; a stirring motor is arranged at the top part of a supporting block; a stirring shaft is arranged in an inner cavity of the stirring tank; the bottom part of the right side of a filter tank is provided with a water flow outlet. The solid-liquid spiral separation press machine disclosed bythe invention is simple in structure, solid-liquid separation is carried out on sewage and slurry through the solid-liquid separation tank, and liquid can be filtered into the stirring tank for carrying out stirring and precipitating and can be finally discharged after being deeply filtered in the filter tank, so that pollution emission is reduced; a scraper and a hairbrush are arranged at the outer side of a spiral pushing piece, meanwhile, filter holes in the baffle plate are also prevented from being blocked, and the working efficiency is improved.

Owner:江苏三辉环保科技有限公司

Special production purification equipment for paint production

ActiveCN113332821AImprove purification efficiencyBig impactCombination devicesHazardous substanceExhaust fumes

The invention discloses special production purification equipment for paint production, and belongs to the technical field of waste gas treatment. The production purification equipment comprises a purification tank body, wherein a spiral assembly is installed at the bottom end in the purification tank body, a spraying assembly is installed at the middle end in the purification tank body, a diffusion plate is installed on the side wall in the purification tank body, a filtering assembly is mounted at the top end of the purification tank body, and gas inlet pipelines are mounted on the two sides of the bottom end of the purification tank body. The production purification equipment is scientific, reasonable and safe and convenient to use, waste gas entering the purification tank body spirally rises through the spiral assembly, purified water is sprayed in a mist state in a spiral mode through the spraying assembly, the spiral directions of the waste gas and the purified water are opposite, and the impact force of mutual collision between the waste gas and the spraying water is increased, so that harmful substances in the waste gas can be more thoroughly adsorbed and purified by the spraying water, and the purification efficiency of the waste gas is higher.

Owner:苏州维斯勒姆智能科技有限公司

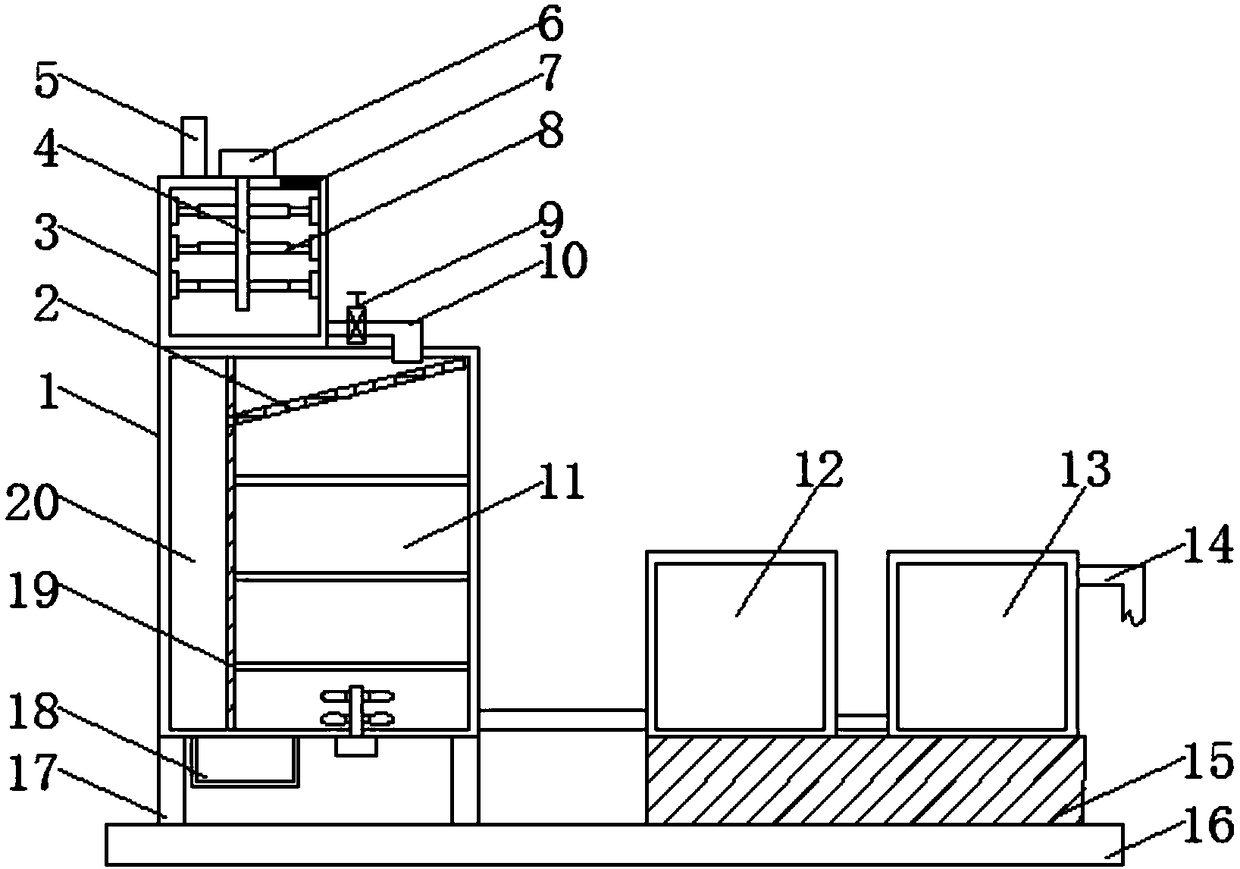

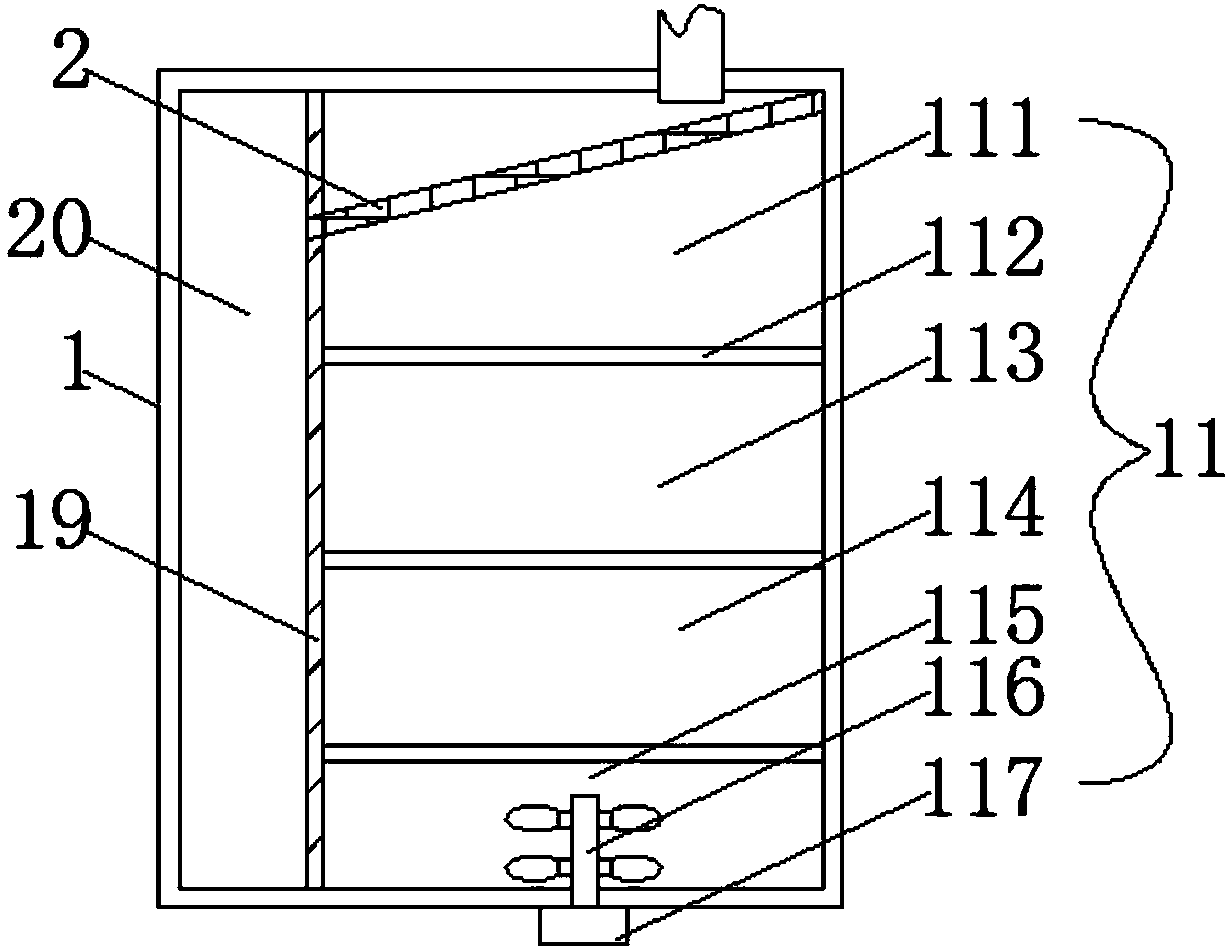

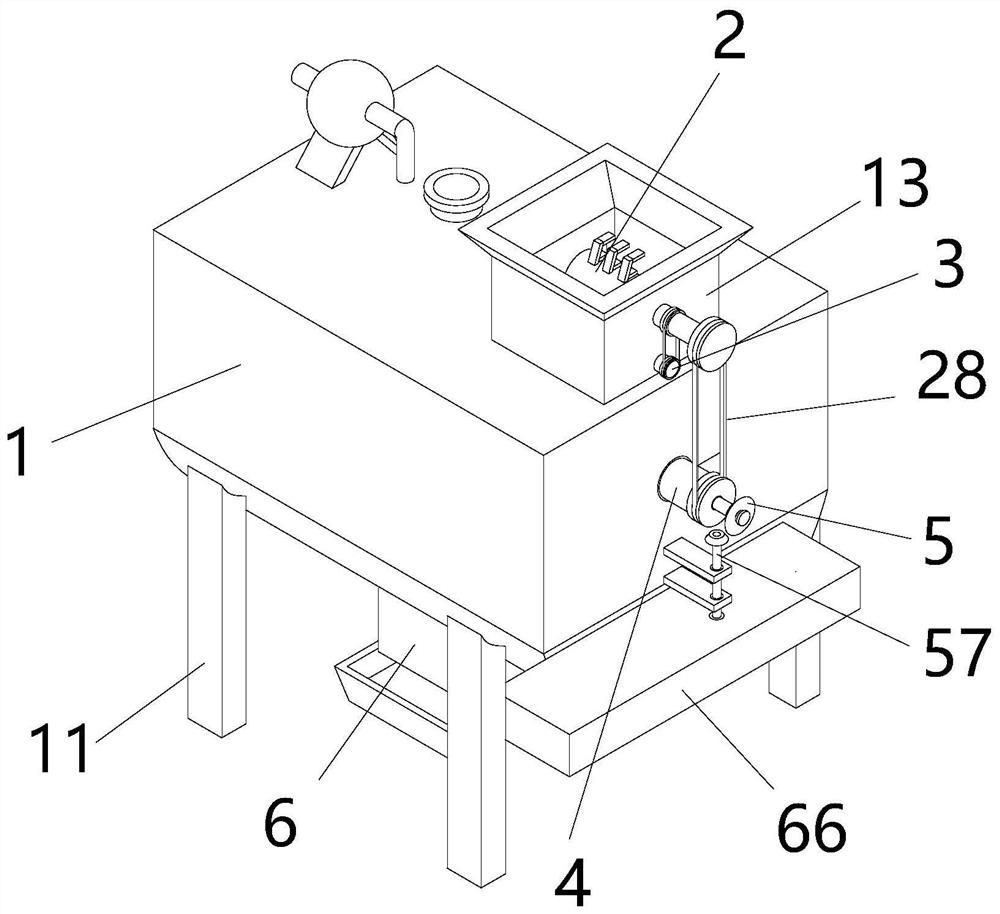

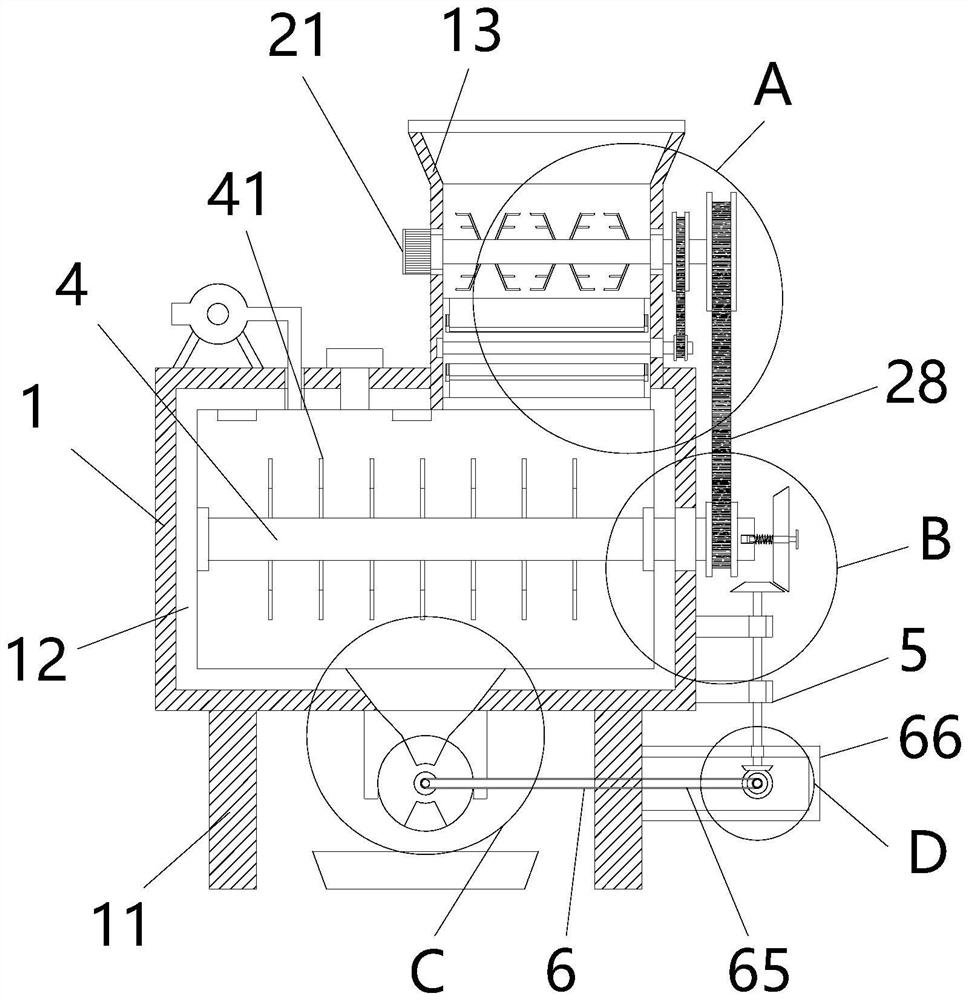

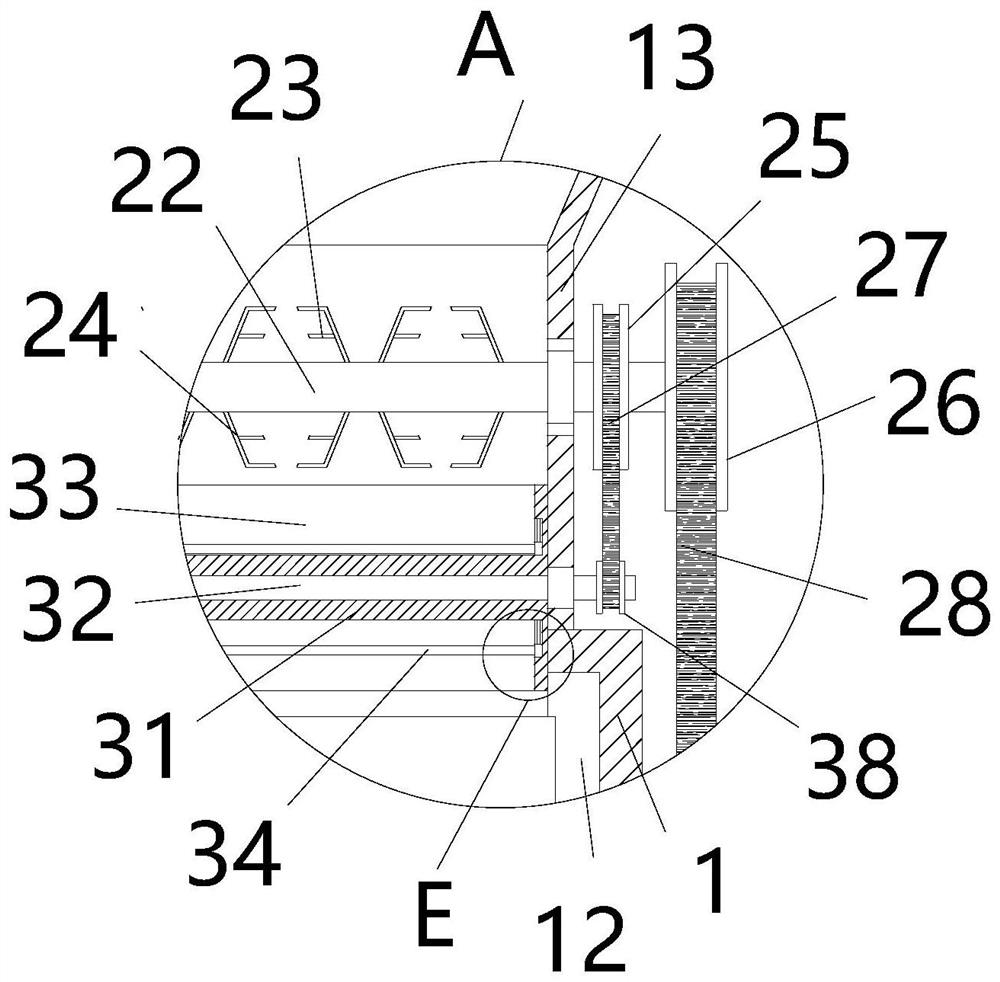

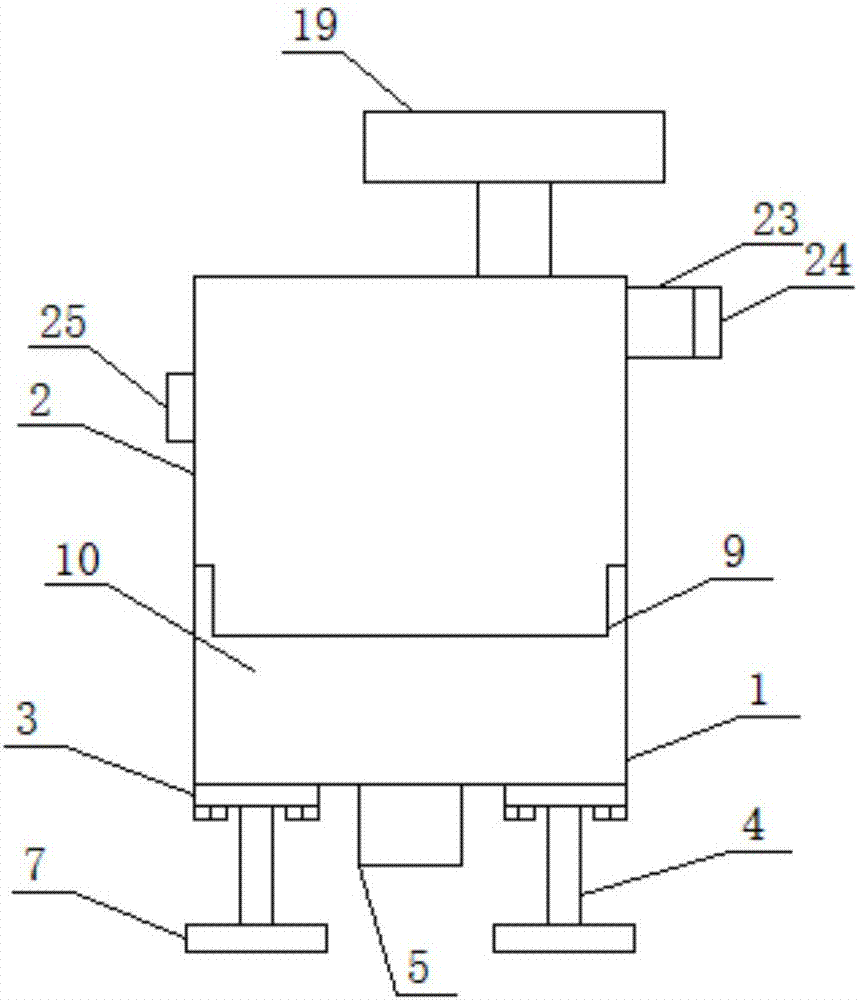

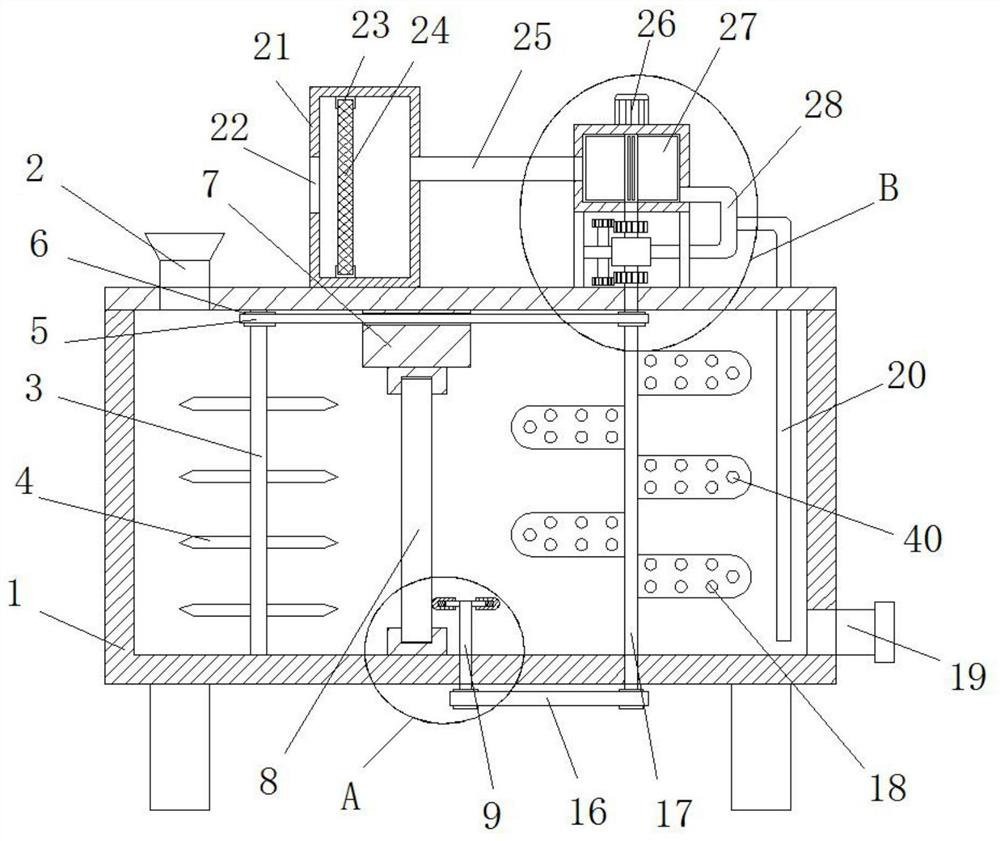

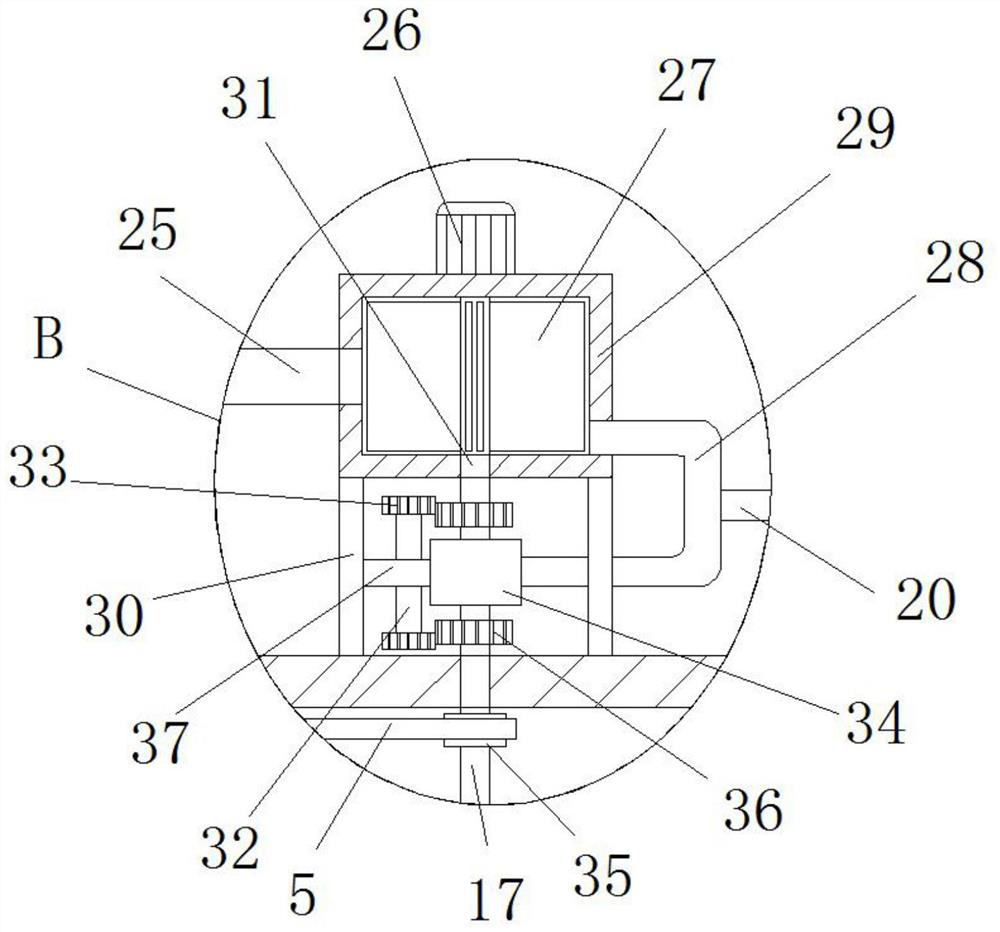

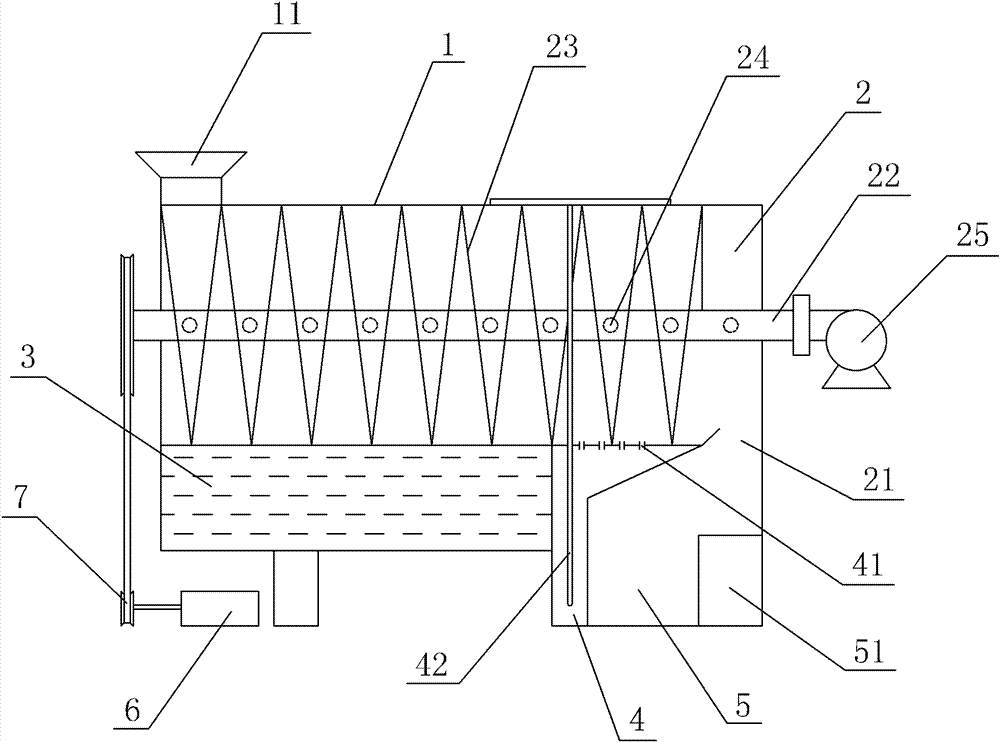

Fermentation equipment for producing organic fertilizer by utilizing wastes and working method thereof

ActiveCN112250492AImprove filtration efficiencyReduce fermentation costsBio-organic fraction processingMicroorganism based treatmentAgricultural engineeringOrganic fertilizer

The invention relates to the technical field of organic fertilizer fermentation, and discloses fermentation equipment for producing an organic fertilizer by utilizing wastes and a working method thereof. The fermentation equipment comprises a box body, a feeding box is fixedly installed on the right side of the top of the box body, a crushing mechanism and a feeding device are arranged on the feeding box, and the feeding device comprises a feeding cylinder and a feeding rotating rod; a linkage transmission device is arranged on the rightmost side wall surface of the stirring rod. According tothe fermentation equipment for producing the organic fertilizer by utilizing the wastes and the working method of the fermentation equipment, the power output unit servo motor moves, the materials arecut by the crushing rod, the cut materials are quantitatively injected by the feeding rotating rod, the fermented materials are mixed and stirred by the stirring rod, the fermented materials are regularly and quantitatively discharged by the discharging cylinder, multiple groups of structures are connected with one another, and the fermentation efficiency of the materials is synchronously promoted; meanwhile, the fermentation cost of organic materials is reduced, and the method is more environmentally friendly, meets the modern green development requirement and has high practicability and creativity.

Owner:黑龙江三兄弟钾肥有限公司

Dust purifier

InactiveCN107213741AIncrease the degree of filtrationPlay a spraying roleCombination devicesAir filtrationLiquid water

The invention discloses a dust purifier, which comprises a bottom shell and a top shell with a 51 single chip microcomputer fixed on the outer part. The bottom shell and an outer shell are connected through a thread structure; a connecting plate is fixed to the edge of the bottom part of the bottom shell through a bolt; a support rod integrated with the connecting plate is arranged on the bottom part of the connecting plate; a base plate is arranged on the bottom part of the support rod; an air filtration space is arranged in the center of the inner part of the upper surface of the bottom shell; an outer air inlet pipeline integrated with the bottom shell is arranged in the center of the bottom part of the bottom shell; a first air inlet through hole for communicating the outside world and the air filtration space is formed in the outer air inlet pipeline. According to the dust purifier provided by the invention, a preliminary sponge filtration function can be firstly carried out dust, and then a filtration function of liquid water is carried out, so that a filtration degree is high; in addition, when the device is used for collecting dust and filtering, a large-scale spraying function can be realized at the same time, so that the filtration efficiency is improved.

Owner:吴逸倩

Intercropping method for heshouwu and maize

ActiveCN106034690AReduce labor costsDoes not affect the harvestPlant cultivationCultivating equipmentsGrowth timeAgroforestry

The invention relates to the technical field of crop growing and specifically relates to an intercropping method for heshouwu and maize. The method includes steps of a, soil preparation and seed preparation which comprising selecting a piece of appropriate land and performing soil preparation and seed preparation; b, planting comprising performing heshouwu transplanting in the first ten-day period of March and planting maize 20 to 30 days later after the heshouwu is planted; c, rack constructing comprising putting up a rack between two heshouwu seedlings and winding the seedlings onto rods manually; d, field management comprising performing field management according to the growth condition of heshouwu and maize; e, harvesting. According to the invention, growth time and space rules of heshouwu and maize are utilized fully for achieving harmonious development. A problem of insufficient use of land during the heshouwu planting process is solved effectively. Besides, labor cost for weeding during the heshouwu planting process is also reduced and an aim of improving heshouwu yield and quality is achieved.

Owner:GUANGXI NANYIZAI SCI & TECH CO LTD

Oolong tea two-fermentation process

InactiveCN106332991AIncrease the degree of filtrationGood fermentation consistencyPre-extraction tea treatmentOOLONG TEA LEAFChemistry

The invention provides an oolong tea two-fermentation process, which comprises: (1) picking and sunshine withering; (2) first fermentation, wherein fermentation is performed for 6-8 h at a temperature of 16-22 DEG C under a humidity of 75-85% under a CO2 concentration of 600-650 ppm; (3) rolling; (4) charcoal baking; (5) second fermentation, wherein fermentation is firstly performed for 20-30 min at a temperature of 30 DEG C under a humidity of 95%, then is performed for 40-50 min at a temperature of 28 DEG C under a humidity of 90%, and finally is performed for 70-80 min at a temperature of 26 DEG C under a humidity of 95%; (6) first machine baking; (7) cooling; (8) second machine baking; and (9) packaging. According to the present invention, with the method of the present invention to ferment the oolong tea, the fermentation degree of the oolong tea is high, the fermentation uniformity is good, and the taste is good.

Owner:柳城县国营伏虎华侨农场茶厂

Acidity-adjusting nutritional agent for dry rice seedling raising bed soil

ActiveCN104211544AIncrease the degree of filtrationGood physical and chemical propertiesFertilizer mixturesAmmonium sulfateFertility

The invention discloses an acidity-adjusting nutritional agent for dry rice seedling raising bed soil and relates to the rice seedling raising technique. The acidity-adjusting nutritional agent is prepared from the following raw materials in parts by weight: 60-70 parts of fermented rice husk, 4-6 parts of 60% dilute sulfuric acid, 12-17 parts of ammonium sulfate, 12-17 parts of calcium superphosphate, 1-2 parts of potassium chloride and 0.5-0.8 part of zinc sulfate; a preparation method of the acidity-adjusting nutritional agent comprises the steps of (1) preparing materials, (2) performing acid treatment and (3) mixing. The acidity-adjusting nutritional agent is capable of either adjusting the acidity or enhancing the fertility, and also capable of improving the physicochemical properties of the bed soil; besides, the preparation method of the acidity-adjusting nutritional agent has the characteristics of wide raw material source, simple process, low cost, suitability for production in south of China; the acidity-adjusting nutritional agent is applicable to dry-raising machine transplanted seedlings and hand transplanted seedlings of early season rice, middle-season rice and late-season rice all over the country.

Owner:湖南省湘晖农业技术开发有限公司

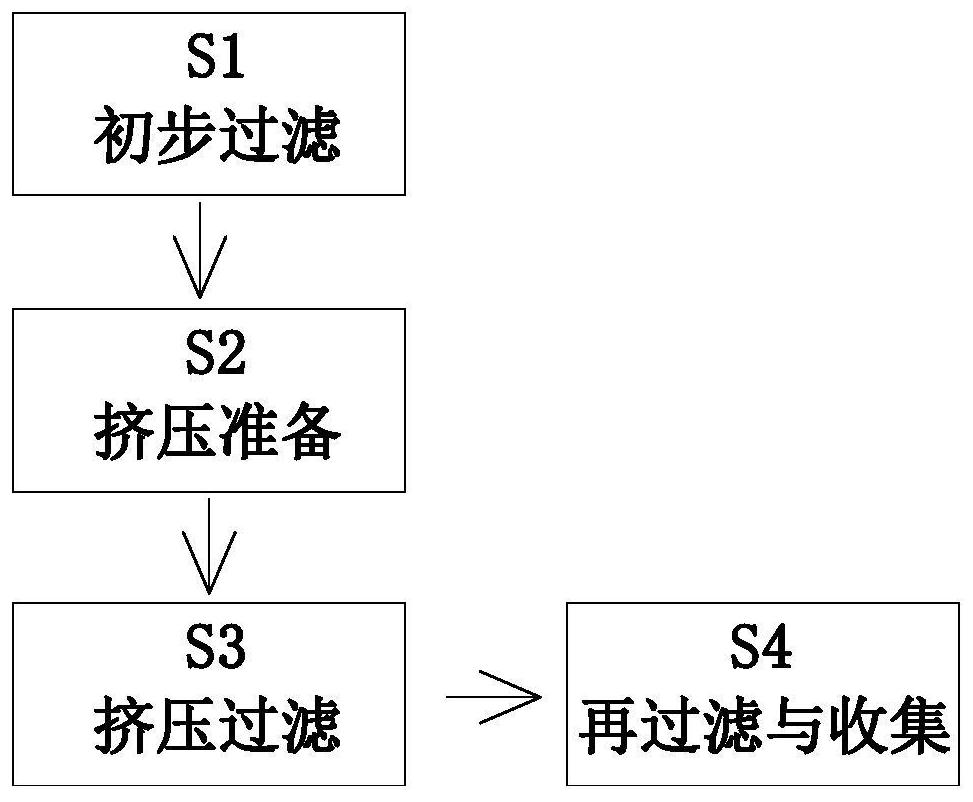

Collected rubber raw material preprocessing method

ActiveCN111823442AIncrease the degree of filtrationImprove the fineness of filtrationProcess engineeringIndustrial engineering

The invention relates to a collected rubber raw material preprocessing method. A collected rubber raw material preprocessing device is used by the collected rubber raw material preprocessing method. The collected rubber raw material preprocessing device comprises a collecting and filtering mechanism and an extrusion mechanism. The lower end of the collecting and filtering mechanism is installed onthe existing working ground in a sliding fit mode, and the extrusion mechanism is arranged at the upper end of the collecting and filtering mechanism. According to the collected rubber raw material preprocessing method, the design concept of the combination of multiple filtering structures is adopted to preprocess collected rubber raw materials, the filtering degrees of the arranged multiple filtering structures are improved in sequence, and then the whole filtering degree of the rubber raw materials is greatly improved. Meanwhile, the extrusion mechanism can fulfill the function that the airand the rubber raw materials are extruded to generate the pressure so as to conduct secondary filtering operation on the rubber raw materials, and the filtering refinement degree of the rubber raw materials can be greatly improved by the function.

Owner:日照宏达橡胶股份有限公司

Processing method for pericarpium citri reticulatae Liupao tea

InactiveCN109380545AEnhance colorImprove qualityPre-extraction tea treatmentPericarpium citri reticulataeSteaming

The invention provides a processing method for pericarpium citri reticulatae Liupao tea, and belongs to the technical field of tea processing. The processing method includes the steps of preparation of raw Liupao tea and preparation of the pericarpium citri reticulatae Liupao tea; the preparation of the raw Liupao tea includes the steps of fresh leaf de-enzyming, initial kneading, retorting, re-kneading and drying; the preparation of the pericarpium citri reticulatae Liupao tea includes the steps of selection of pericarpium citri reticulatae, initial steaming, cold fermentation, re-steaming and aging. The processing method has the advantages of simple process, easy operation and high production practicability, and the method ensures high quality and high efficiency of processing of the pericarpium citri reticulatae Liupao tea, especially improves the quality of the color, aroma, taste, shape and leaf bottom of the pericarpium citri reticulatae Liupao tea, increases the output of tea making and improves the quality of the pericarpium citri reticulatae Liupao tea.

Owner:广西梧州六堡茶股份有限公司

Cavitation reaction type ore screening device

InactiveCN108480182AIncrease the degree of filtrationImprove efficiencySievingScreeningCavitationEngineering

The invention discloses a cavitation reaction type ore screening device which comprises a shell, a feeding hole, a rotary shaft, a first screen, a second screen, a bottom plate, cavitation pipes and discharge holes; the shell is of a cylinder cavity structure; the feeding hole and a control cabinet are fixedly installed at the top end of the shell; the rotary shaft is installed at the middle partin the shell and is connected with the shell through a bearing; the top end of the rotary shaft is in transmission connection with the output end of a motor; outer wall of the rotary shaft in the shell is in transmission connection with the first screen, the second screen and the bottom plate through speed changing devices respectively; the cavitation pipes are arranged in the shell; the upper surfaces of the cavitation pipes are fixedly connected with cavitation nozzles respectively; and one sides of the first screen, the second screen and the bottom plate are fixedly connected with the discharge holes through the shell respectively. By adopting the cavitation reaction type ore screening device provided by the invention, through the cavitation principle and the slantingly rotating screens, the filtering degree is increased, and the efficiency is also improved.

Owner:WEIHAI OCEAN VOCATIONAL COLLEGE

Preparation method of watermelon peel feed for breeding sheep

InactiveCN107198031AIncrease the degree of filtrationImprove ripenessFood processingAnimal feeding stuffAnimal sciencePeanut meal

The invention discloses a preparation method of watermelon peel feed for breeding sheep. The method comprises the following steps: (1) slicing watermelon peel, and drying the watermelon peel slices at temperature until the water content of the sliced watermelon peel is 30-35%; (2) carrying out solid state fermentation, specifically, spraying mixed bacteria liquid into the dried and sliced watermelon peel, and carrying out fermentation for twice at the constant temperature; (3) frying, specifically, putting the fermented watermelon peel into a drum type frying machine at the temperature of 62-67 DEG C for frying, respectively adding corn flour, peanut meal, liquorice root powder, tea powder, iodine salt and the like, blending and frying; (4) drying, specifically, drying the product at the temperature of 43-47 DEG C until the water content is 13-16%; (5) preparing the feed, specifically, weighing the components such as the watermelon peel powder, the corn flour and plant straw according to the mass, evenly mixing, using a granulator to prepare the watermelon peel feed for breeding the sheep. Compared with corn concentrated feed, the watermelon peel feed for breeding the sheep can enable the sheep to reach the same weight within the same time, and reduces the feeding cost by 15.6%, thus increasing the economic benefit of sheep breeding.

Owner:合肥合丰牧业股份有限公司

Roxburgh rose red soup drink and preparation method thereof

InactiveCN102232586ARealize manual controlIncrease the fragranceFood preparationVitamin CSuperoxide dismutases

The invention discloses a roxburgh rose red soup drink and a preparation method thereof. In the invention, the high-quality red soup drink with excellent color, fragrance and taste is prepared by using the leaves, buds and young fruits of roxburghrose which is a rosaceous plant with rich vitamin C, vitamin P, superoxide dismutase (SOD) and other nutrients as raw materials and by performing fermentation treatment in modes such as pilling green, pilling red, killing red and roasting.

Owner:唐俊

Preparation method of cow manure organic fertilizer

InactiveCN107382472AIncrease the decomposition rangeInhibitionBio-organic fraction processingExcrement fertilisersHuskAmmonium hydroxide

The invention discloses a preparation method of cow manure organic fertilizer. The preparation method is characterized by comprising steps as follows: (1) cow manure pretreatment: cow manure is squeezed and aired until the moisture content ranges from 30% to 40%; (2) pulverization treatment: a pulverizer performs pulverization treatment; (3) mixing: pulverized rice husk and cow manure are mixed uniformly; (4) ammoniation treatment: 9%-11% of ammonium hydroxide is added for ammoniation treatment; (5) fermentation in a fermentation pool: a leavening agent accounting for 3%-6% of the total mass of the mixture is added, and fermentation is performed in the fermentation pool; (6) deodorized fermentation: a fertilizer leavening agent accounting for 2%-3% of the total mass of the mixture is added for layered fermentation; (7) drying and granulation: the granular cow manure organic fertilizer with the moisture ranging from 15% to18% is prepared. The obtained cow manure fertilizer contains rich nutrition, ingredients are decomposed sufficiently, operation is simple, practicability is realized, and the utilization rate of the cow manure and rice husk is increased.

Owner:当涂县海纳农业科技有限公司

Preparation process for improving taste of functional ginger beverage

InactiveCN110169519AGreat tasteOutstanding fragrancePre-extraction tea treatmentYeast food ingredientsInitial treatmentBlack tea

The invention relates to the technical field of ginger beverages, and provides a preparation process for improving the taste of a functional ginger beverage, comprising the following steps: step 1, selecting raw materials: selecting fresh and tender ginger, washing to remove mud, then peeling, beating for later use, then respectively selecting fresh red tea leaves and stevia, weighing the ginger,the red tea leaves and the stevia according to a weight ratio of 5:3:2; step 2, initial treatment: placing the red tea leaves and the stevia are at a temperature of -5 DEG C, freezing for 100-120min,and spreading and drying at 22-26 DEG C until the red tea leaves and the stevia wither. The black tea leaves, stevia leaves and the ginger are adopted to prepare the beverage together, the red tea leaves are rich in various nutrient elements; after fermentation, the scent is more prominent, and after a series of treatments, fermentation with the ginger is performed, thus breaking through a conventional preparation method, and fundamentally improving the taste of the ginger beverage.

Owner:CHONGQING UNIV OF ARTS & SCI

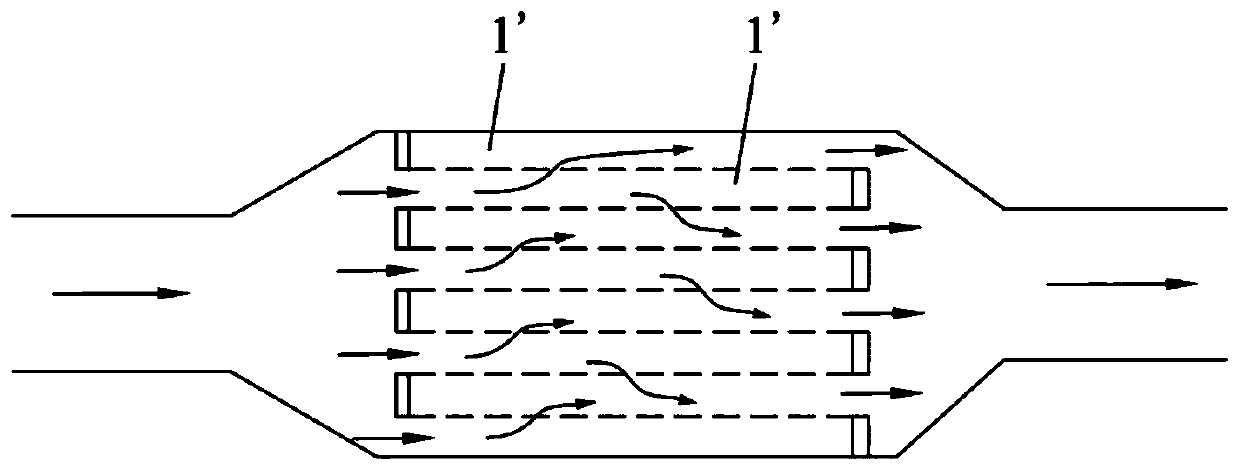

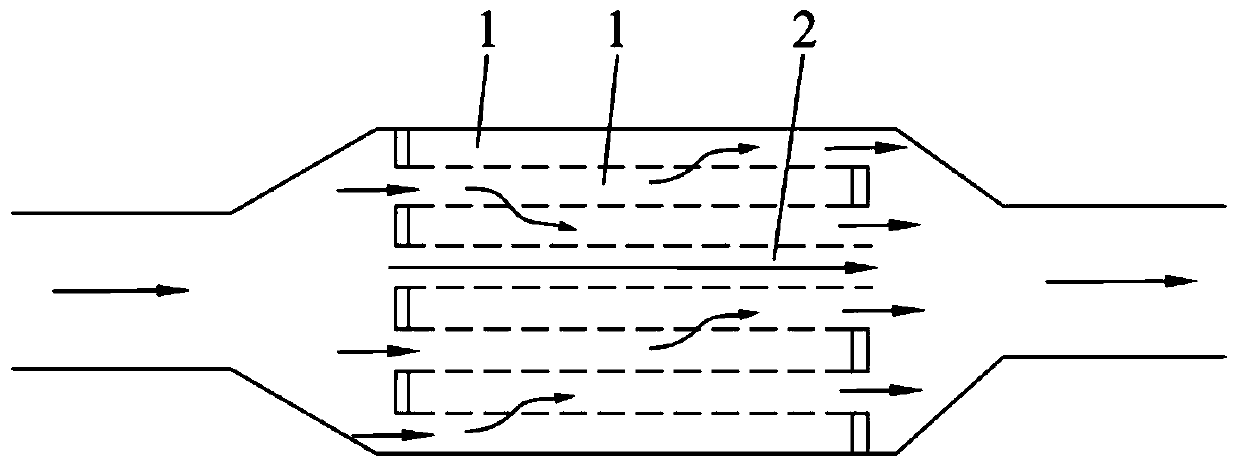

Exhaust particle catcher and vehicle

ActiveCN111577424AIncrease the degree of filtrationLow degree of filtrationExhaust apparatusSilencing apparatusParticulatesControl theory

The invention discloses an exhaust particle catcher and a vehicle, and belongs to the field of motor vehicle exhaust. The exhaust particle catcher comprises a filter passageway. The filter passagewaycomprises multiple parallel adjacent runners. The adjacent runners are isolated through porous filter walls. The runners comprise the first runners and the second runners, inlets or outlets of the first runners are opened, the inlets of the adjacent first runners are not simultaneously opened, and inlets and outlets of the second runners are opened. The vehicle comprises the exhaust particle catcher. The second runners with the conducting inlets and outlets are used as rapid flow passageways of exhaust, the filtering degree of the exhaust flowing through the second runners is small, thus, thefiltering degree of the whole exhaust is reduced, particular matter is prevented from being excessively caught and filtered, the accumulation speed of carbon particles and ash on the porous filter walls is reduced, rapid rise of back pressure of the exhaust is avoided, the regeneration frequency is reduced, and finally torque output losses of an engine are reduced.

Owner:CHINA FIRST AUTOMOBILE

Sea cucumber enzyme and preparation method thereof

PendingCN107772476AIncrease contentHigh nutritional valueSugar food ingredientsYeast food ingredientsSlurryIsomaltulose

The invention discloses a sea cucumber enzyme and a preparation method thereof, wherein the preparation method of the sea cucumber enzyme comprises the following steps: firstly, respectively preparingsea cucumber autolysis slurry, donkey-hide gelatin slurry, spirulina slurry and a gordon euryale seed saccharification liquid, then mixing and adding water for fermentation to obtain a sea cucumber fermentation liquid, finally adding isomaltulose, xylitol, malto-oligosaccharide and xanthan gum, performing high-pressure homogenization and then sterilizing to obtain the sea cucumber enzyme. The seacucumber enzyme is high in nutritional values, easy to digest and absorb, natural and coordinated in taste, and also has the efficacies of enhancing immunity, moisturizing the lung and tonifying thespleen, strengthening the brain and soothing the mind, lowering the blood lipid, and having anti-cancer and anticoagulation properties.

Owner:烟台欧顺生物科技有限公司 +1

Energy-saving polyethylene circulating washing device

InactiveCN102921667ASimple structureLow costPlastic recyclingMultistage water/sewage treatmentWater supplyRubbing

The invention discloses an energy-saving polyethylene circulating washing device, which solves problems of the plastic washing equipment in the prior art that the wastewater cannot be repeatedly utilized, water sources are wasted and the environment is affected. The energy-saving polyethylene circulating washing device comprises a mesh type plastic washing groove and a rotary rubbing washer which is arranged in the mesh type plastic washing groove, wherein left and right sides of the mesh type plastic washing groove are respectively provided with an exchanger main groove and a wastewater output device; the wastewater output device mainly comprises a wastewater output pump; the wastewater output pump is communicated with a wastewater regenerating mechanism by a wastewater output pipe; a regenerated water secondary storage tank communicated with the wastewater regenerating mechanism by a runner is arranged on the side surface of the wastewater regenerating mechanism; the wastewater regenerating mechanism is divided into a main storage chamber and a direct water supply chamber; a hand control valve is also arranged on a conduit between the exchanger main groove and the direct water supply chamber; a water level sensor is also arranged on the side wall of the direct water supply chamber; an impurity sediment box with an inclined filter screen is also arranged on the wastewater output pipe; and a subacid silicon sand layer is also arranged at the bottom of the wastewater regenerating mechanism close to the runner.

Owner:成都思诚机电设备有限公司

Aerated grit chamber for sewage treatment

InactiveCN112340863AIncrease the degree of filtrationImprove filtering effectWater aerationTreatment involving filtrationTreatment pondEnvironmental protection

The invention discloses an aerated grit chamber for sewage treatment, which mainly comprises a treatment tank, a feeding port is formed in the top of the treatment tank, a discharging pipe is arrangedon one side of the treatment tank, a smashing shaft is vertically and rotationally connected into the treatment tank, a plurality of smashing cutters are fixedly installed on the outer side of the smashing shaft, and a fixing block is fixedly installed on the inner wall of the top of the treatment tank. Support bars are fixedly mounted between the bottom of the fixing block and the inner wall ofthe bottom of the treatment tank, each support bar is of a U-shaped structure, a same filter screen is movably connected between each pair of support bars, and a rectangular box is fixedly connected to the top of the treatment tank. A plurality of crushing shafts are arranged to drive the plurality of smashing cutters to crush residues in sewage, the sewage is filtered through the filter screens,and the filtering degree of the sewage can be improved by crushing the residues in the sewage; the aerated grit chamber is convenient to operate, impurities in sewage in the treatment tank can be crushed and filtered, the aeration effect is improved, and the treatment effect is improved.

Owner:高武

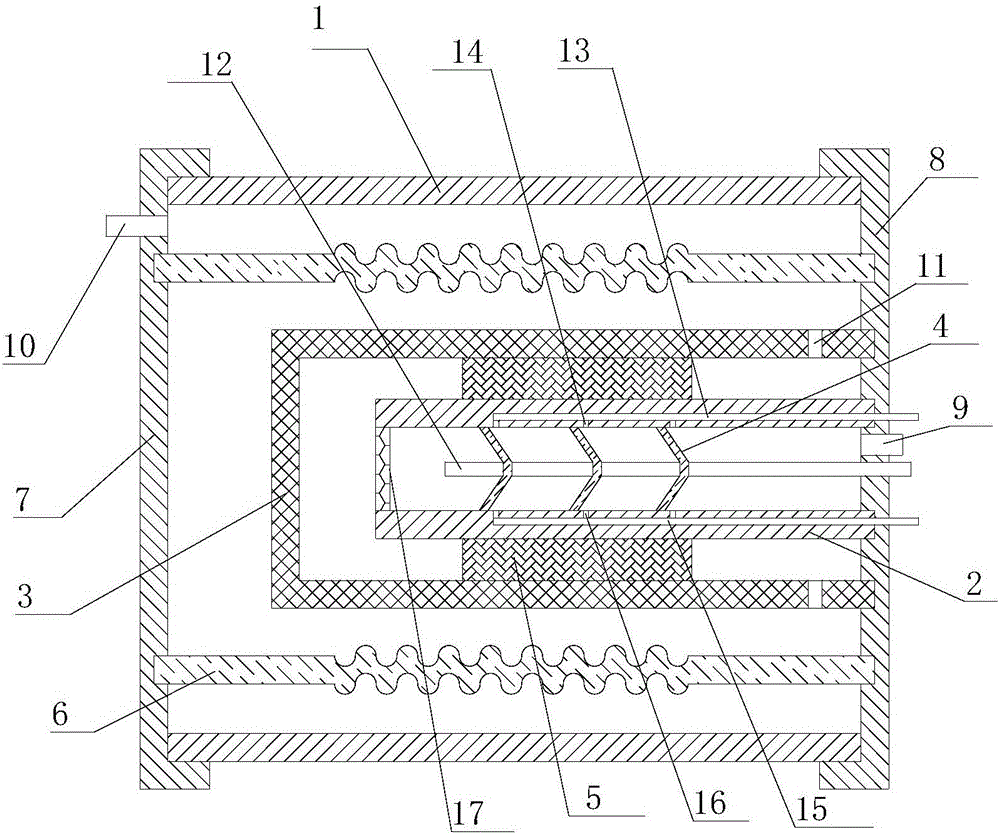

Composting device for domestic waste

InactiveCN101983951BLarge amount of processingSmall footprintClimate change adaptationOrganic fertilisersWater bathsLitter

The invention discloses a composting device for domestic waste, which comprises a sealed casing and a feeding inlet provided with the casing. A composting chamber communicating with the feeding inlet is provided inside the casing, and a discharging opening is provided with the composting chamber. A ventilated spiral agitation propeller is provided inside the composting chamber while a water bath below the composting chamber. A heating device is connected with the water bath. The composting device can provide heat for the fermentation of organic domestic waste such as kitchen garbage in the composting chamber to build out the environment benefit for microbe activities, thereby increasing the fermentation speed of organic domestic waste and the utilization rate of heat energy. Meanwhile, solar heating reduces the consumption of conventional energy and is environmental protection. A secondary composting chamber is arranged below the composting chamber, which greatly shortens the longitudinal length of the whole composting apparatus and further saves the occupation area for composting operations, thereby further increasing the composting fermentation degree and reducing workload.

Owner:NINGBO UNIV

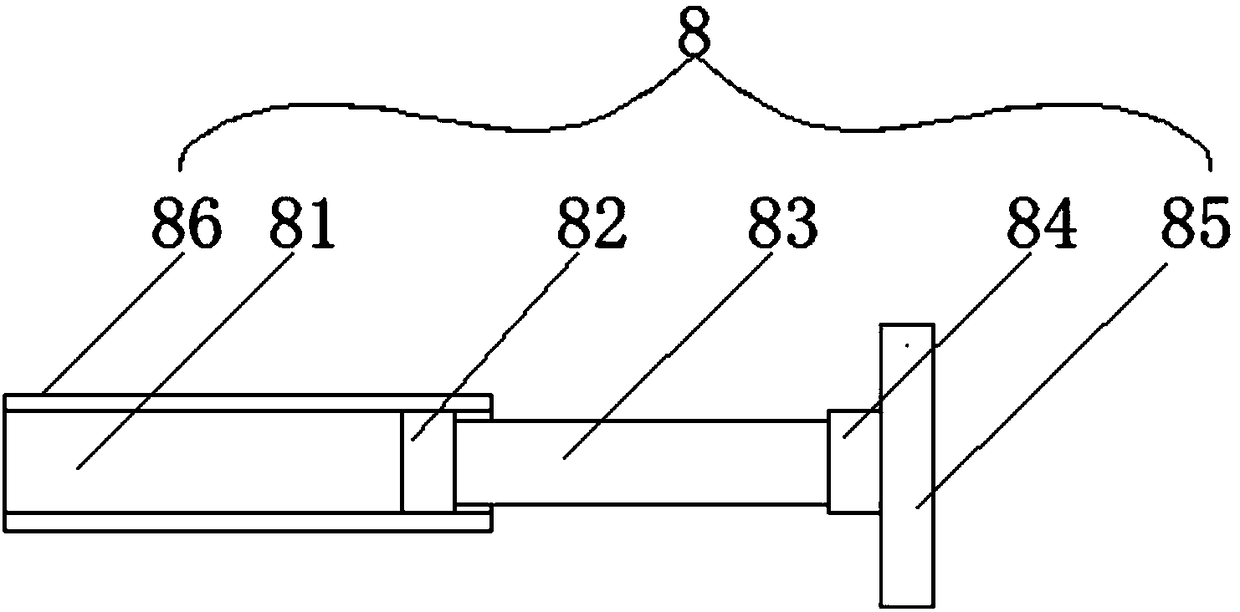

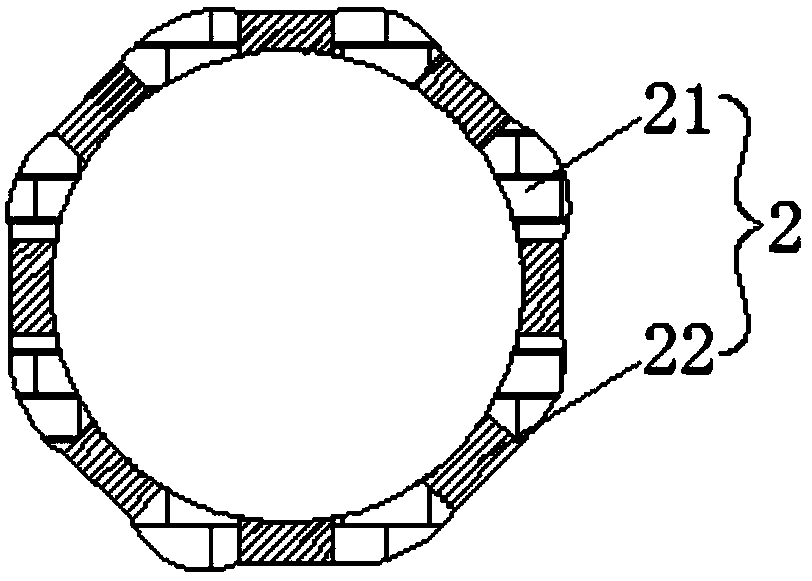

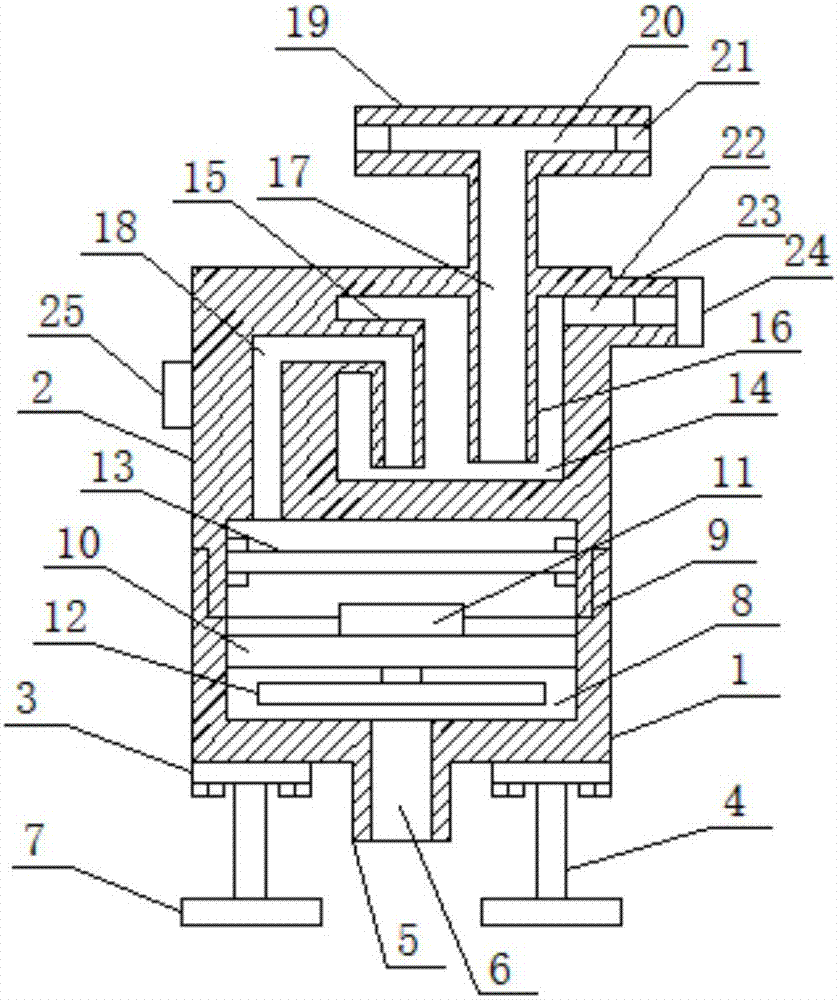

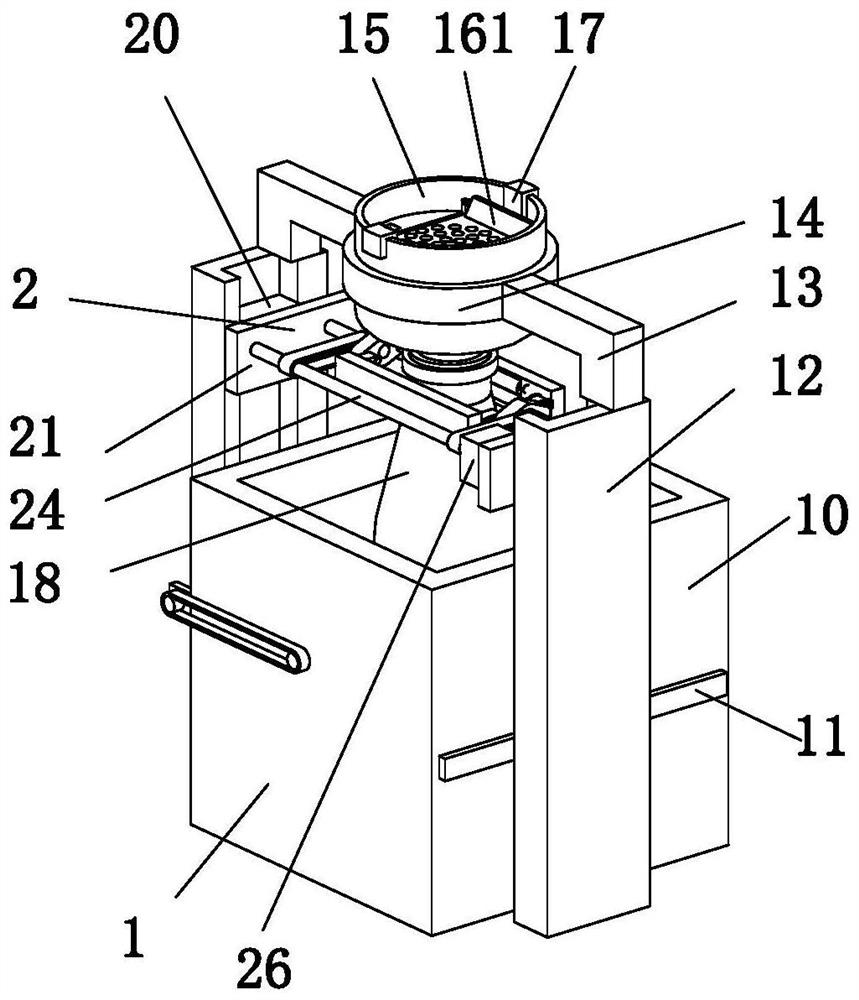

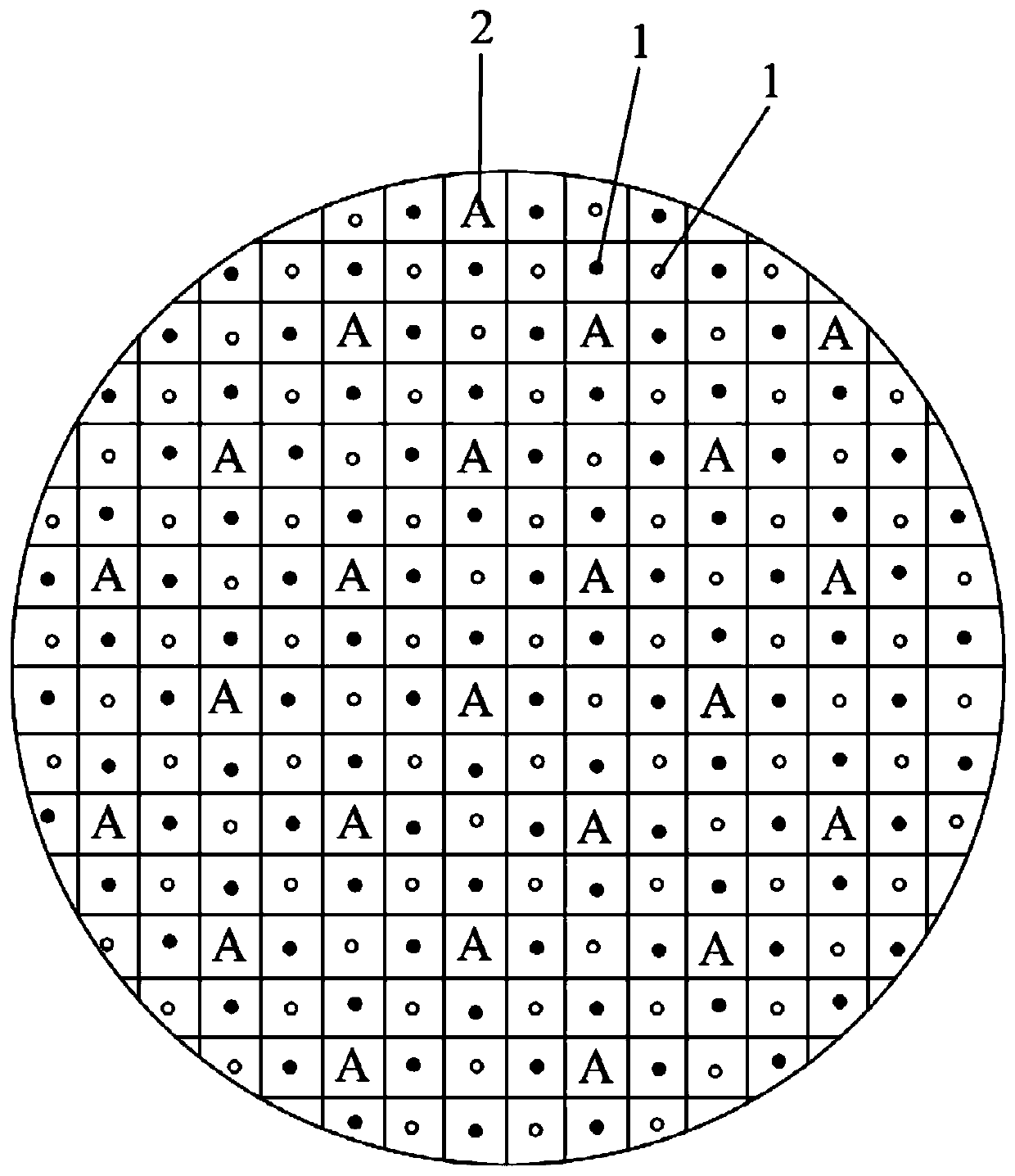

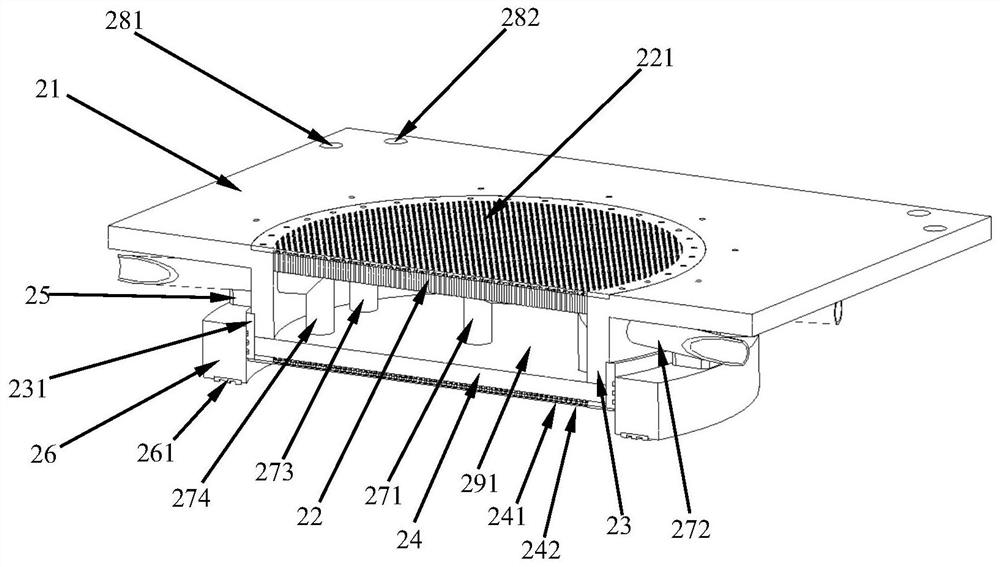

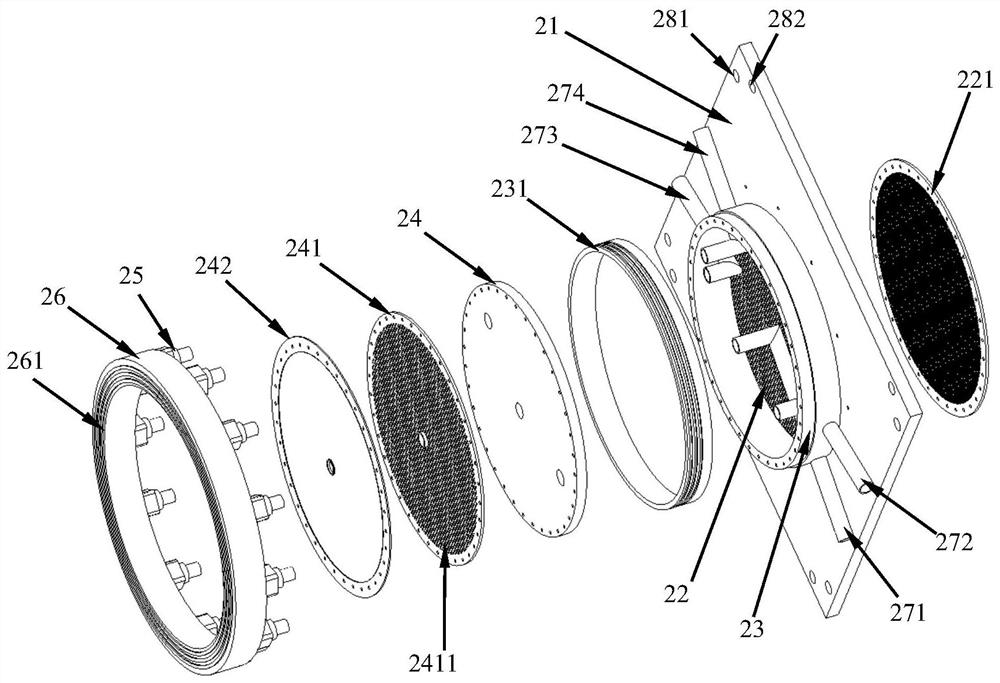

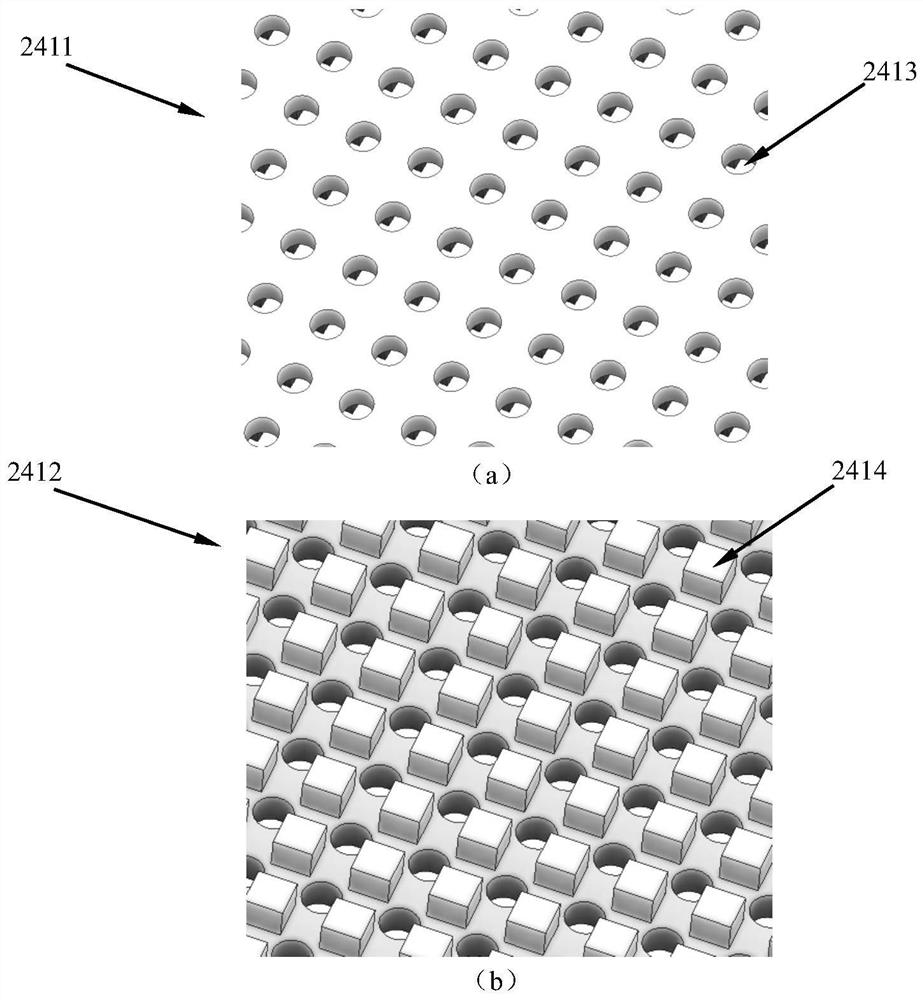

Filter pressing assembly, filter press and filter pressing method

The invention relates to a filter pressing assembly, which comprises a base plate, a through hole area in the middle of the base plate, a piston wall which surrounds the through hole area and extends downwards is arranged on the bottom face of the base plate, and a piston top plate, a channel plate and first filter cloth are sequentially arranged at the bottom end of the piston wall from top to bottom; the piston top plate is provided with a second pipe used for guiding fluid into a groove and a fourth pipe used for discharging the fluid in the groove, the outer surface surrounding the piston wall is sleeved with a piston sleeve, and the lower surface of the first filter cloth and the inner surface of the piston sleeve define a filter pressing cavity, and a first pipe for leading in slurry to be filtered is arranged in the filter pressing cavity. The invention also relates to a filter press comprising the filter pressing assembly and a filter pressing method. The product has the advantages of high operation pressure, high filter pressing speed, low liquid content of a filter cake, reliable structure, convenience in automatic operation and the like, and is particularly suitable for filter pressing of systems difficult to filter, such as activated sludge and pectin.

Owner:金锣水务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com