Method and system for increasing calorific value of garbage by virtue of waste heat of garbage incineration plant

A garbage incineration and garbage technology, which is applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problems of poor fermentation and draining effect, low temperature of garbage entering the factory, and low temperature of the pile in the garbage pool, so as to improve the power on the grid, The effect of improving the degree of fermentation and simple process of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

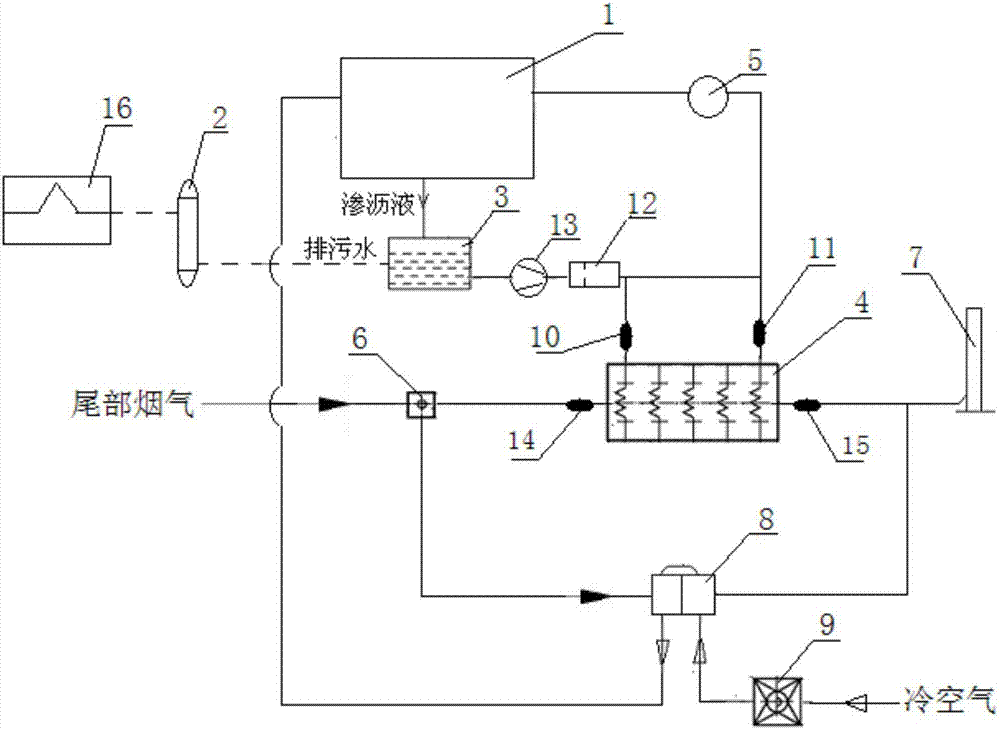

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

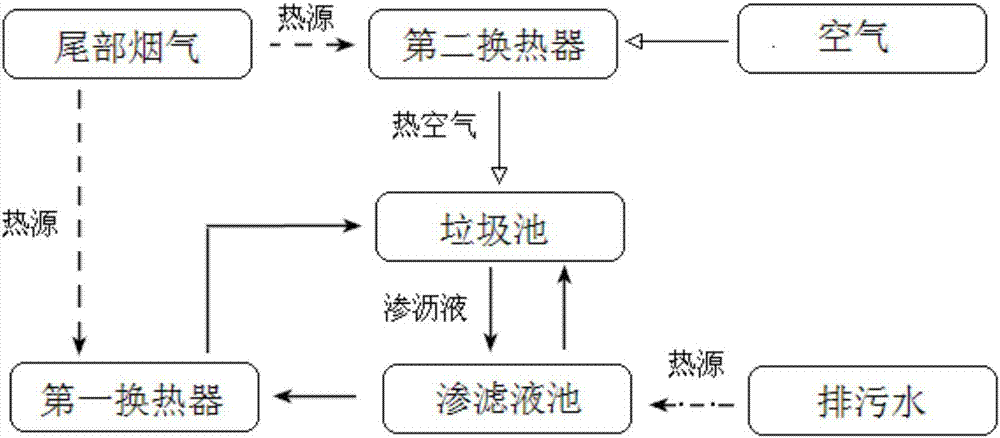

[0021] A method for increasing the calorific value of waste by utilizing waste heat of a waste incineration plant in this embodiment specifically includes: using the waste heat of tail flue gas after flue gas purification in the waste incineration system and / or the waste heat of sewage to exchange heat for leachate ; Then spray the leachate after heat exchange to the garbage pool.

[0022] In this method, the waste heat of the flue gas at the tail is also used to exchange heat with the cold air introduced from the outside; the hot air after heat exchange is introduced into the garbage pool.

[0023] The above method can effectively increase the temperature of the garbag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com