Aerated grit chamber for sewage treatment

An aeration grit and sewage treatment technology, which is applied in the field of aeration grit chambers, can solve the problems of poor treatment effect, inability to crush and filter impurities, and poor aeration effect, so as to achieve improved filtration effect, convenient operation, and improved Effects of Processing Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

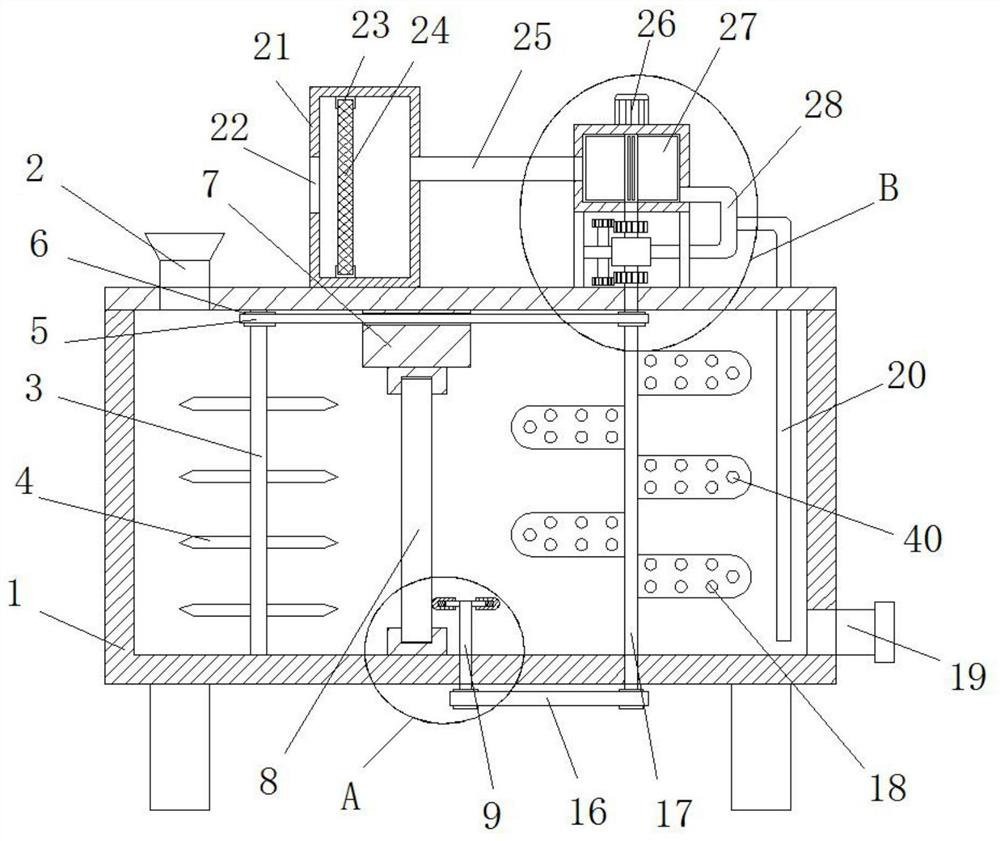

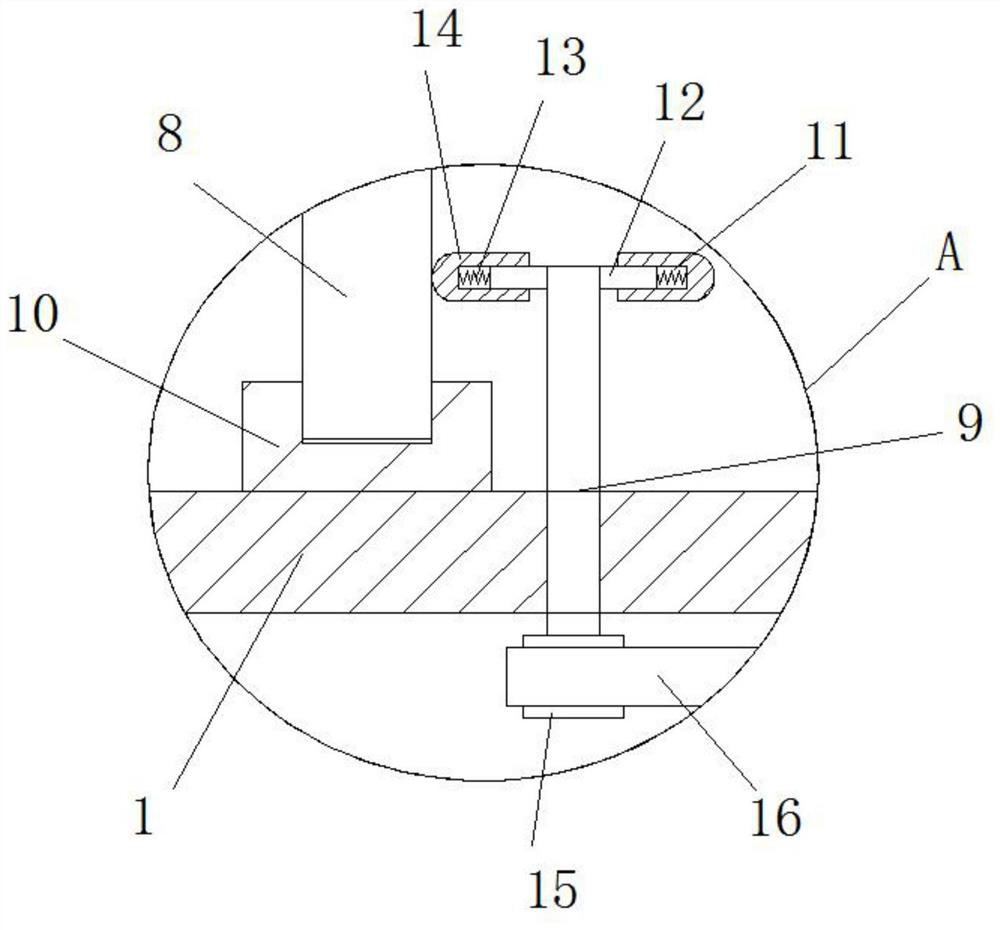

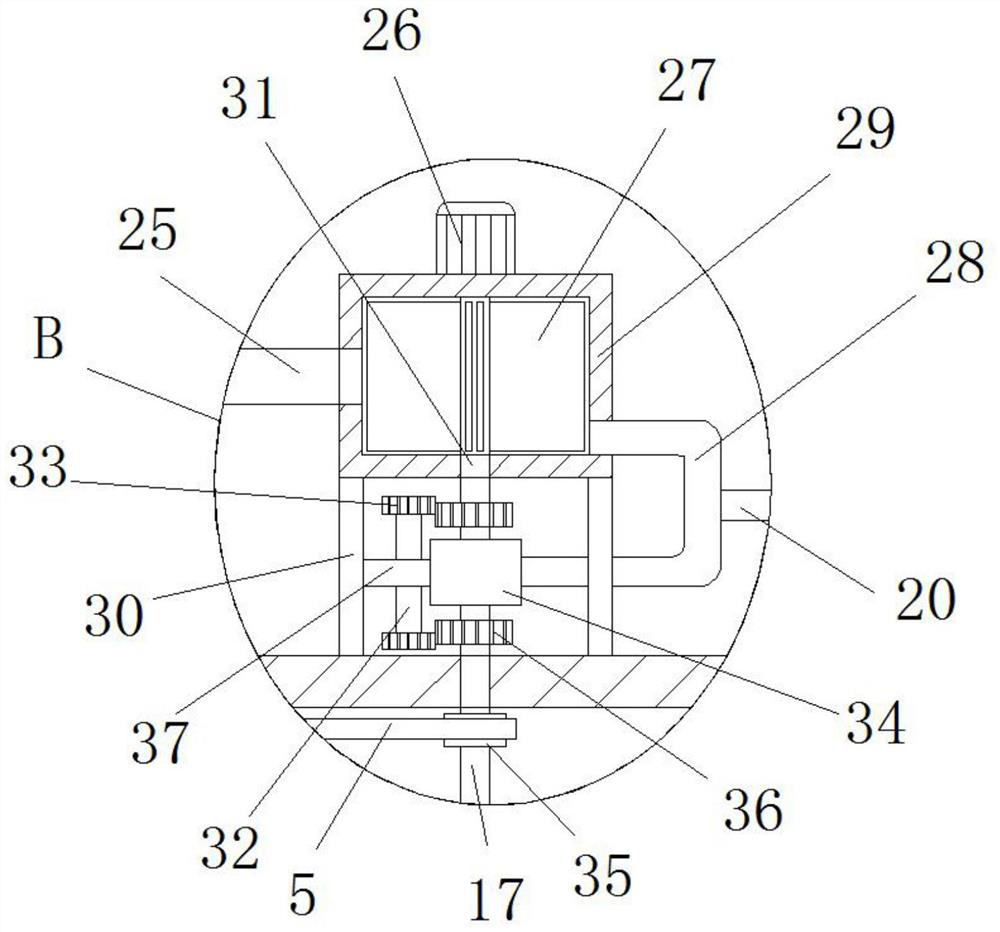

[0028] Please refer to Figure 1-Figure 5 , an aerated grit chamber for sewage treatment, comprising a treatment tank 1, the top of the treatment tank 1 is provided with a feeding port 2, one side of the treatment tank 1 is provided with a discharge pipe 19, and the vertical rotation in the treatment tank 1 is connected with Pulverizing shaft 3, a plurality of pulverizing knives 4 are fixedly installed on the outside of pulverizing shaft 3, fixed block 7 is fixedly installed on the top inner wall of treatment tank 1, all fixedly installed between the bottom of fixed block 7 and the bottom inner wall of treatment tank 1 Support bar 10, and support bar 10 is U-shaped structure, and the same filter screen 8 is movably connected between two support bars 10, and filter screen 8 can be disassembled, and the top of processing pool 1 is fixedly connected with rectangular box 21, and the rectangular box 21 The nutrient-rich film 24 is movably connected, and the top of the treatment poo...

Embodiment 2

[0039] Please refer to Figure 1-Figure 5 , an aerated grit chamber for sewage treatment, comprising a treatment tank 1, the top of the treatment tank 1 is provided with a feeding port 2, one side of the treatment tank 1 is provided with a discharge pipe 19, and the vertical rotation in the treatment tank 1 is connected with Pulverizing shaft 3, the outer side of pulverizing shaft 3 is fixedly installed with a plurality of pulverizing knives 4 by welding, on the top inner wall of processing tank 1, fixed block 7 is fixedly installed by welding, between the bottom of fixing block 7 and the bottom inner wall of processing tank 1 Both support bars 10 are fixedly installed by welding, and the support bars 10 are U-shaped structures. The same filter screen 8 is movably connected between the two support bars 10, and the filter screen 8 can be disassembled. The top of the treatment pool 1 is fixedly connected with a Rectangular box 21, nutrient-rich film 24 is movably connected in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com