Air filter for multi-level efficient engine

An air filter and engine technology, which is applied to fuel air filters, engine components, machines/engines, etc., can solve the problems of waste of raw materials, difficult cleaning of filter impurities, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

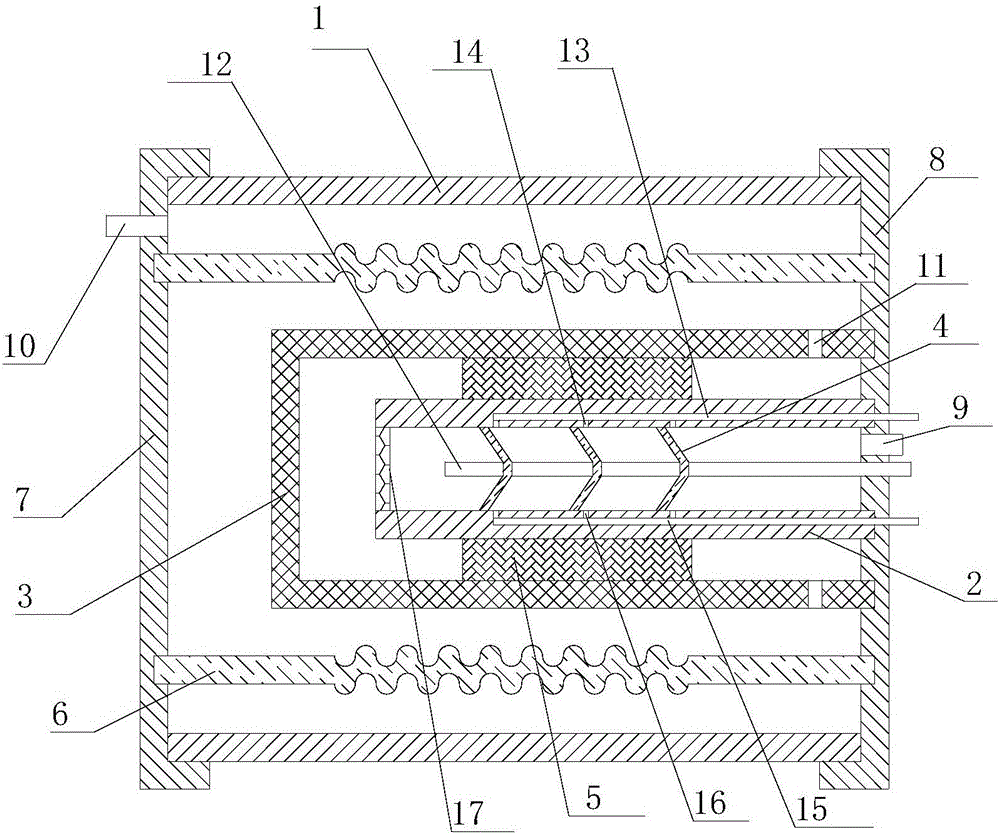

[0019] refer to figure 1 , the present invention proposes a multi-stage high-efficiency engine air filter, comprising a first filter body 1, a second filter body 2, a third filter body 3, a plurality of first filter elements 4, a second filter element 5, and a third filter element 6, of which:

[0020] The first filter body 1 is a cylinder structure with both ends open, and the first end cover 7 and the second end cover 8 are threadedly connected to the open openings at both ends of the first filter body 1 respectively, and the first end cover 7 is provided with an air inlet port 9, and the second end cover 8 is provided with an air outlet 10. The inner side of the second end cover 8 is provided with a concentric arrangement of a first annular groove, a second annular groove, and a third annular groove, and the diameters of the first annular groove, the second annular groove, and the third annular groove gradually increase. Large, the inner side of the first end cover 7 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com