Device for removing textile dust on textile fabric

A technology for textile fabrics and textile dust, which is applied to the field of textile dust removal devices on textile fabrics, can solve the problems of unclean dust cleaning, affecting the quality of textiles, and long cleaning time, so as to expand the scope of vacuuming, improve the vacuuming efficiency, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

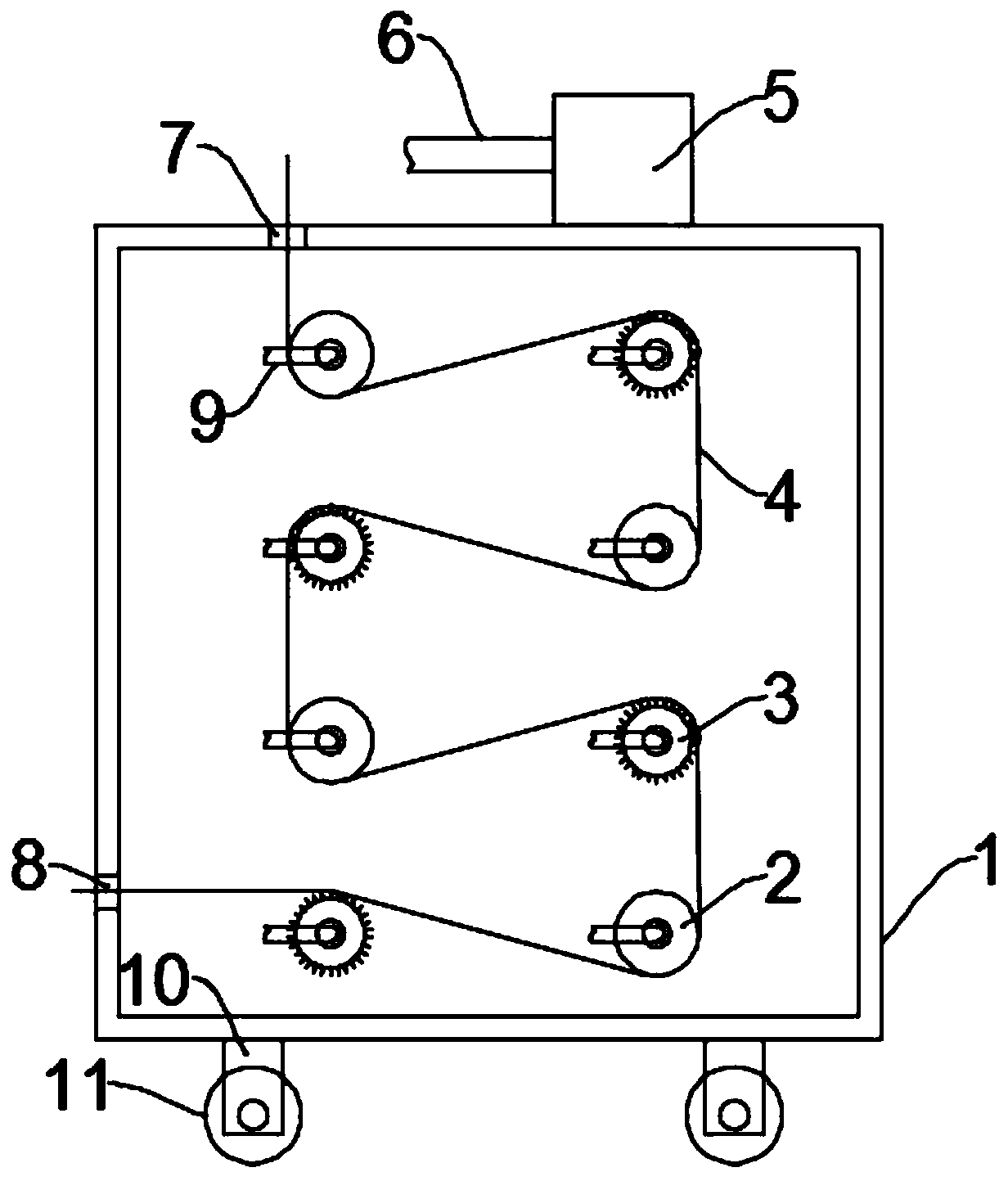

[0027] see figure 1 , in an embodiment of the present invention, a device for removing textile dust on textile fabrics, comprising a box body 1 and a dust removal assembly, the dust removal assembly is installed on the box body 1, and support legs 10 are evenly and symmetrically installed on the bottom of the box body 1, A roller 11 is installed at the bottom of the supporting leg 10, and the roller 11 is a self-locking roller to facilitate the movement of the device. The top left side of the box body 1 is provided with a feed port 7, and the lower part of the left side wall of the box body 1 is provided with an outlet. A material opening 8, a box door is installed on the right side wall of the box body 1. In this embodiment, the box door is preferably connected to the box body 1 through a hinge and a hasp. The dust removal assembly includes a guide roller 2 and a brush roller 3 And vacuum cleaner 5, a plurality of said guide rollers 2 and a plurality of said brush rollers 3 a...

Embodiment 2

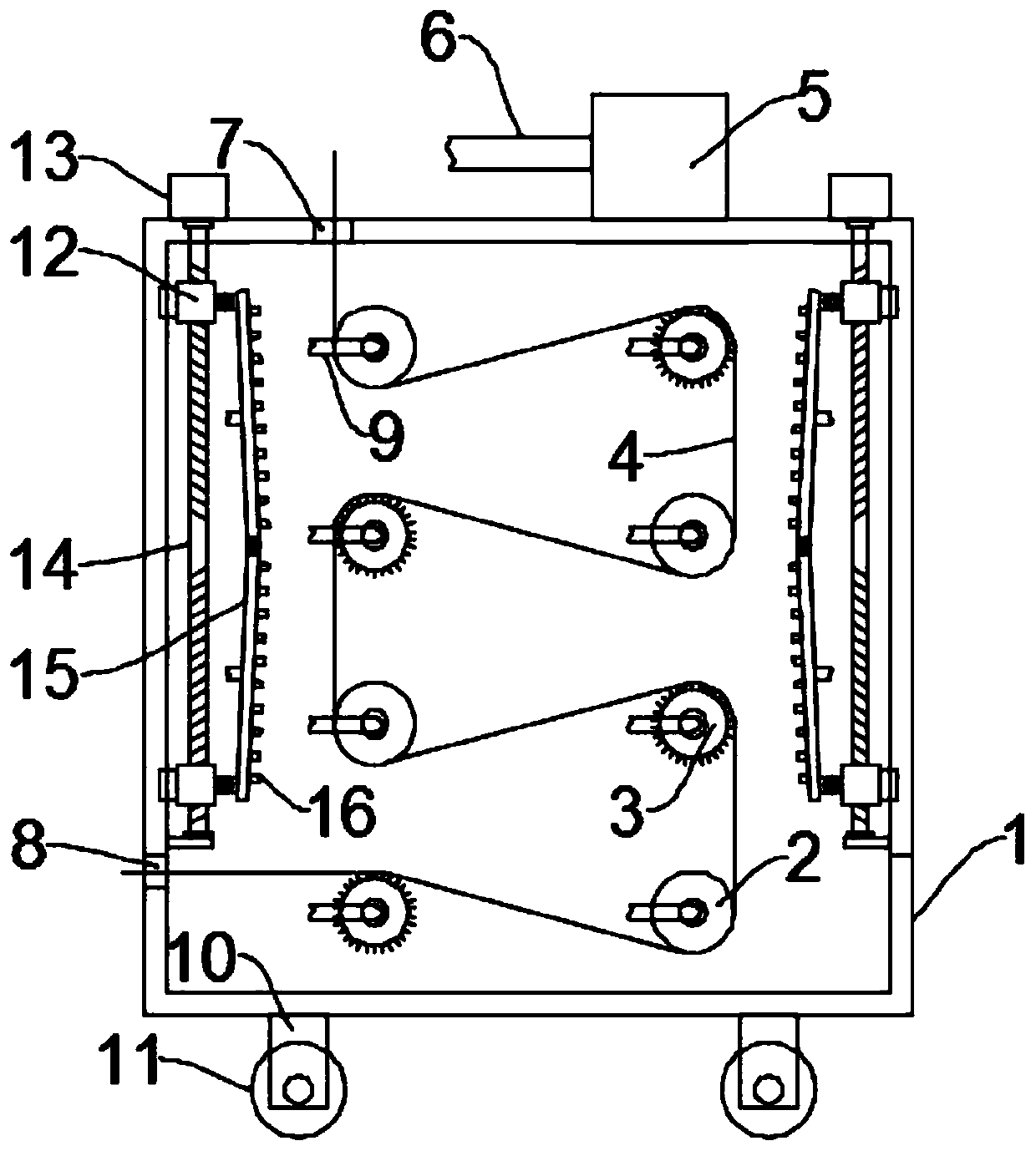

[0029] see figure 2 , in an embodiment of the present invention, a device for removing textile dust on textile fabrics, comprising a box body 1 and a dust removal assembly, the dust removal assembly is installed on the box body 1, and support legs 10 are evenly and symmetrically installed on the bottom of the box body 1, A roller 11 is installed at the bottom of the supporting leg 10, and the roller 11 is a self-locking roller to facilitate the movement of the device. The top left side of the box body 1 is provided with a feed port 7, and the lower part of the left side wall of the box body 1 is provided with an outlet. A material opening 8, a box door is installed on the right side wall of the box body 1. In this embodiment, the box door is preferably connected to the box body 1 through a hinge and a hasp. The dust removal assembly includes a guide roller 2 and a brush roller 3 And vacuum cleaner 5, a plurality of said guide rollers 2 and a plurality of said brush rollers 3 ...

Embodiment 3

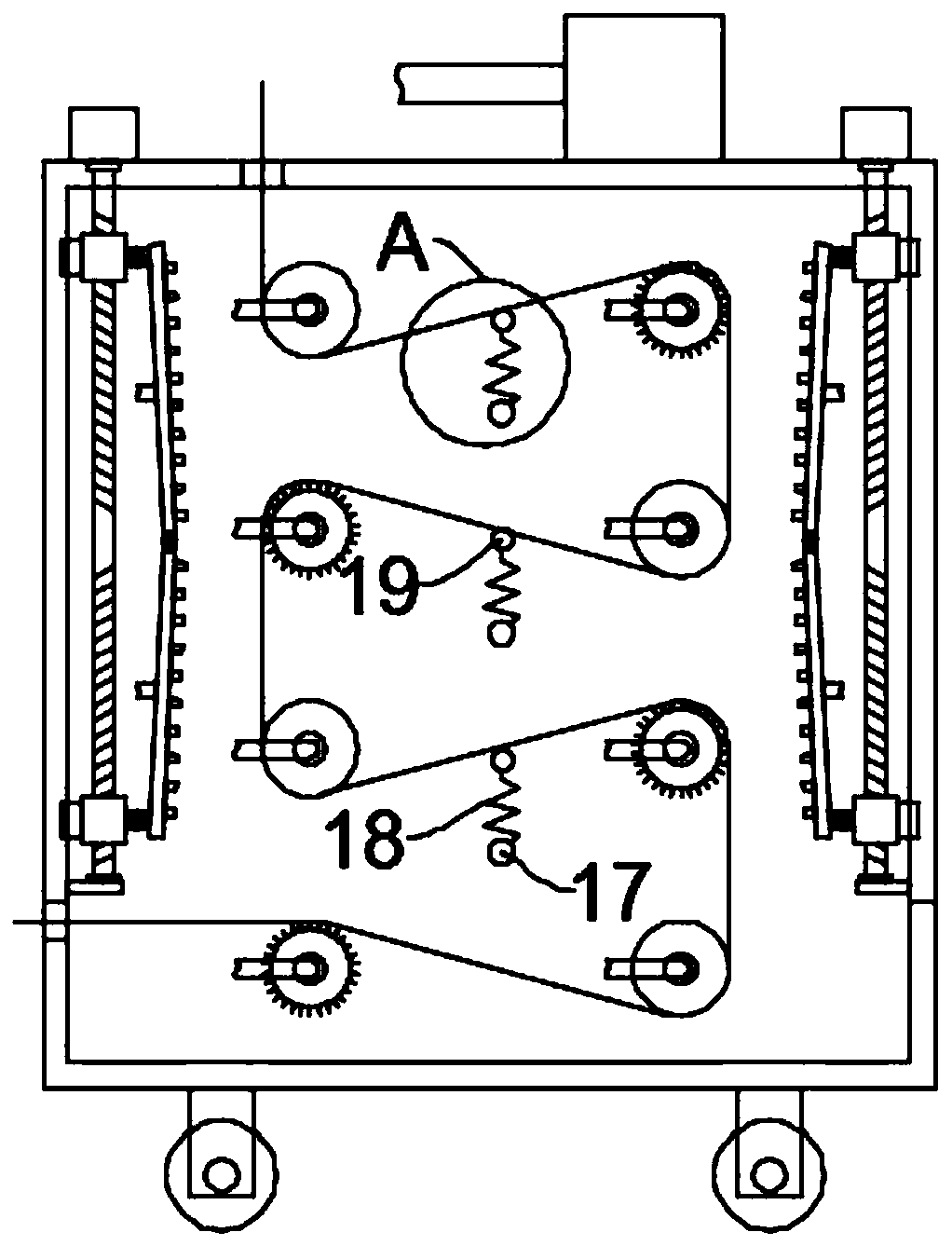

[0032] see Figure 3-4 , in an embodiment of the present invention, a device for removing textile dust on textile fabrics, comprising a box body 1 and a dust removal assembly, the dust removal assembly is installed on the box body 1, and support legs 10 are evenly and symmetrically installed on the bottom of the box body 1, A roller 11 is installed at the bottom of the supporting leg 10, and the roller 11 is a self-locking roller to facilitate the movement of the device. The top left side of the box body 1 is provided with a feed port 7, and the lower part of the left side wall of the box body 1 is provided with an outlet. A material opening 8, a box door is installed on the right side wall of the box body 1. In this embodiment, the box door is preferably connected to the box body 1 through a hinge and a hasp. The dust removal assembly includes a guide roller 2 and a brush roller 3 And vacuum cleaner 5, a plurality of said guide rollers 2 and a plurality of said brush rollers 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com