Pollutant separation device of rainwater and sewage pipeline

A technology for separating devices and pollutants, which is applied in the fields of grease/oily substance/float removal device, water/sewage treatment, water/sludge/sewage treatment, etc., which can solve problems such as affecting operation and easy clogging of filters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

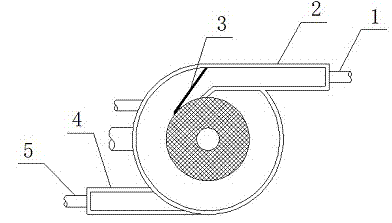

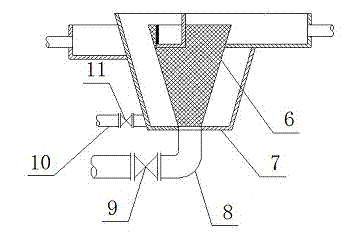

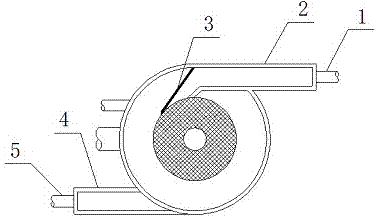

[0009] Attached below figure 1 and attached figure 2 The present invention is further described:

[0010] As shown in the accompanying drawings, the invention is mainly composed of an inlet channel 2, an overflow weir 3, an outlet channel 4, an inner conical screen 6, an outer conical cylinder 7, a slag discharge pipe 8 and a sewage pipe 10, and the overflow weir is composed of 3. Connect the water inlet channel 2 and the inner conical screen 6, and have the same height and tangent to the inner conical screen 6. The outlet channel 4 is tangent to the outer conical cylinder 7, and the channel bottom of the outlet channel 4 is slightly lower than the channel bottom of the inlet channel 2. A slag discharge valve 9 and a sewage valve 11 are installed in the horizontal section of the slag discharge pipe 8 and the sewage pipe 10. The slag discharge valve 9 is opened regularly according to the actual situation, and the sewage valve 11 is normally open and closed when necessary. O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com