Differential rotary type cleaning device and belt cleaner as well as method thereof

A technology of differential rotation and cleaning devices, which is applied in the direction of cleaning devices, conveyors, conveyor objects, etc., can solve problems such as sticking of large viscous mineral materials and difficult cleaning of conveyor belts, and achieve strong cleaning capabilities, high efficiency, and The effect of small speed difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

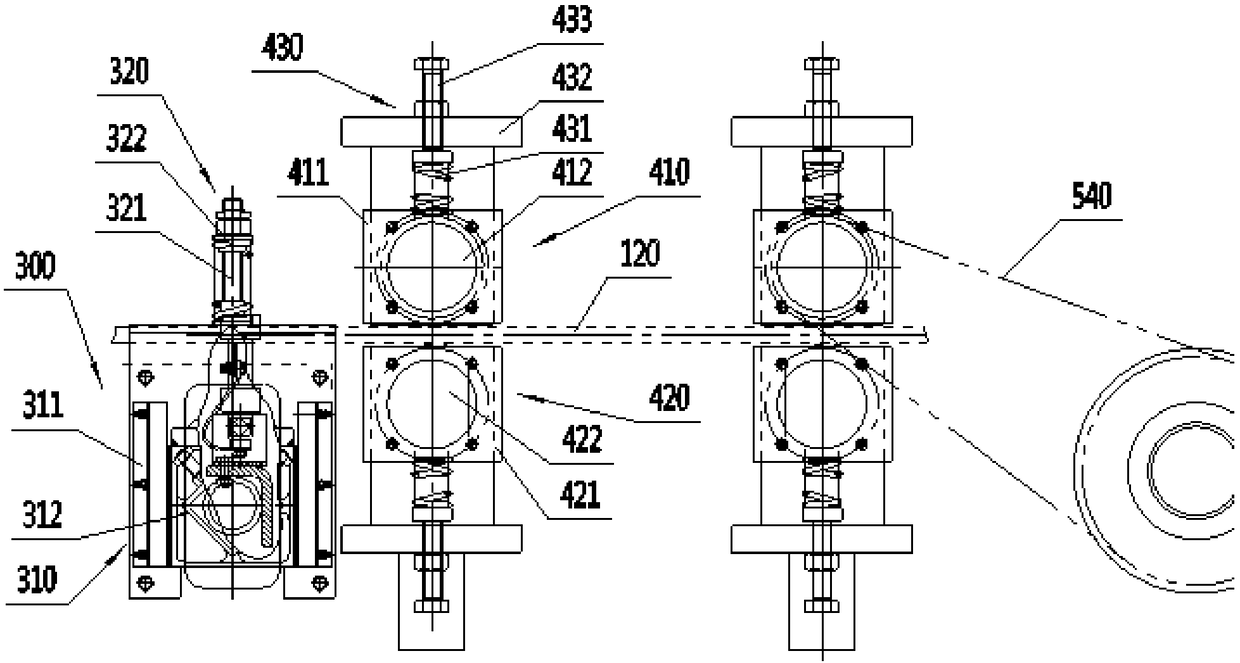

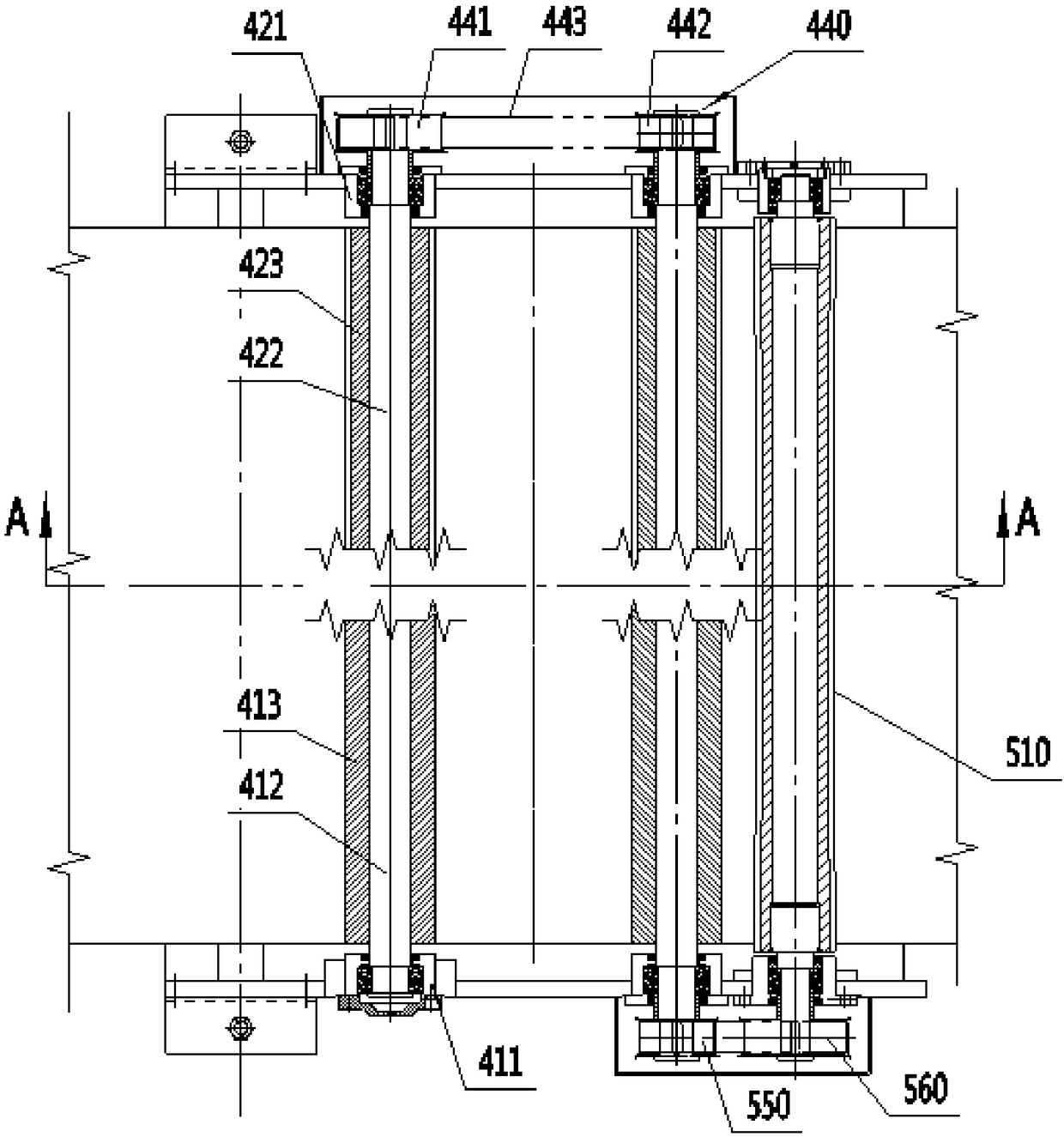

[0048] This embodiment provides a differential rotary cleaning device, which is mainly used for cleaning the bonded mineral materials on the surface of the conveyor belt when the belt conveyor transports mineral materials, especially the highly cohesive mineral materials. figure 2 , image 3 and Figure 4 Its structure and working principle are described in detail.

[0049] Such as figure 2 As mentioned above, the differential rotary cleaning device mainly includes two pairs of roller mechanisms, a plurality of pressing mechanisms 430 and a synchronous wheel assembly 440, wherein the two pairs of roller mechanisms are used to bond ore to the working surface of the conveyor belt 120 of the belt conveyor 100. The material is cleaned; the pressing mechanism 430 is used to adjust the pressing degree of the roller mechanism and the surface of the conveyor belt 120, so that the roller mechanism can realize the cleaning action; and the synchronous wheel assembly 440 is used to co...

Embodiment 2

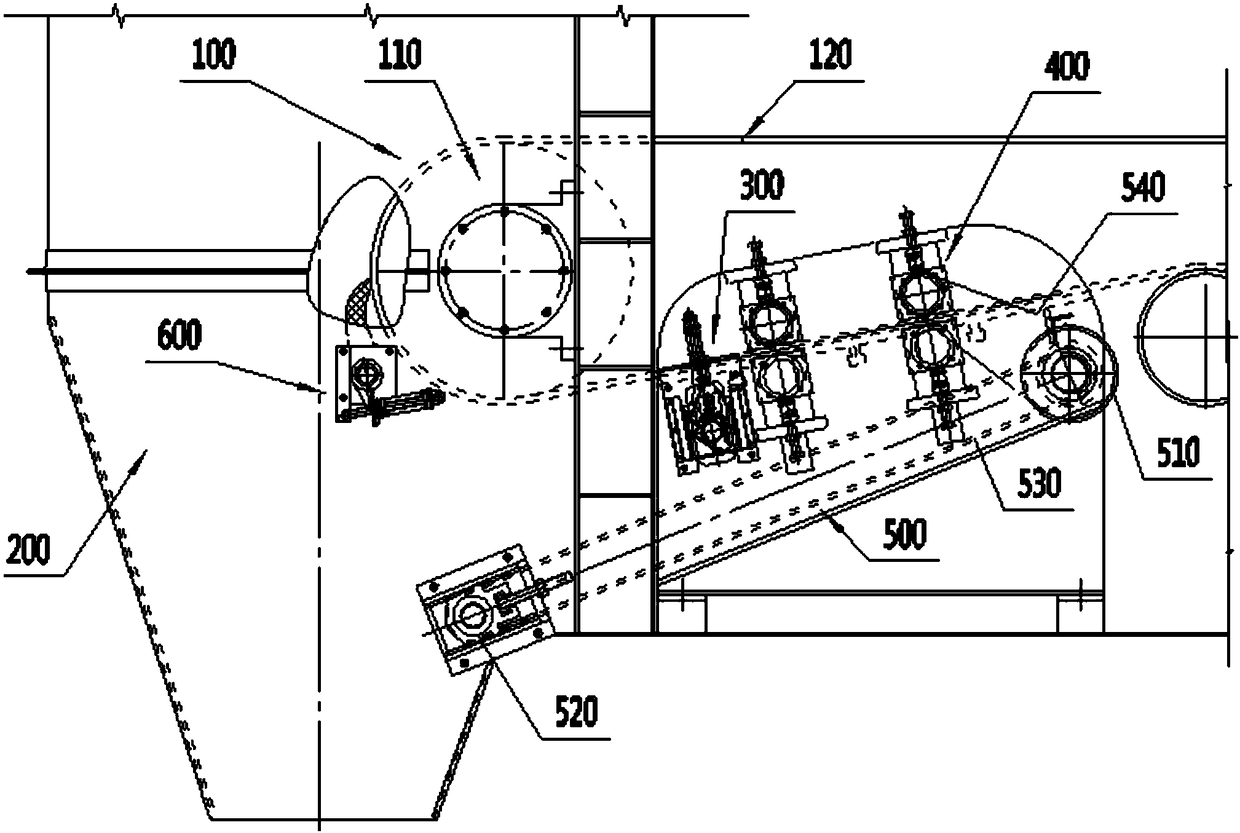

[0057] Such as figure 1 As shown, this embodiment provides a belt cleaning machine for cleaning the mineral materials bonded to the surface of the conveyor belt 120 during the process of conveying mineral materials from the belt conveyor 100 to the hopper 200. The cleaning machine adopts a multi-stage cleaning mechanism. Three stages are adopted here, and there are respectively a primary cleaning mechanism 600 , a secondary cleaning mechanism 300 and a tertiary cleaning mechanism 400 along the conveying direction of the conveyor belt 120 . Among them, the first-level cleaning mechanism 600 cleans the mineral materials with large surface volume and low viscosity on the conveyor belt 120, the secondary cleaning mechanism 300 further cleans the mineral materials with smaller volume and stronger cohesiveness, and the third-level cleaning mechanism 400 The differential rotary cleaning device in Example 1 is used for final cleaning, and deep cleaning is performed on the smaller and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com