Electromagnetic heating roller used for corrugating machine, application of electromagnetic heating roller and corrugating machine electromagnetic heating method

A technology of electromagnetic heating roller and electromagnetic heater, which is applied in the direction of electric/magnetic/electromagnetic heating, ohmic resistance heating, induction heating, etc., can solve the problems of inability to form corrugated cardboard, uneven moisture base paper, uneven heating of base paper, etc. The heating operation is convenient and easy, the heating speed is fast, and the effect of moisture balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

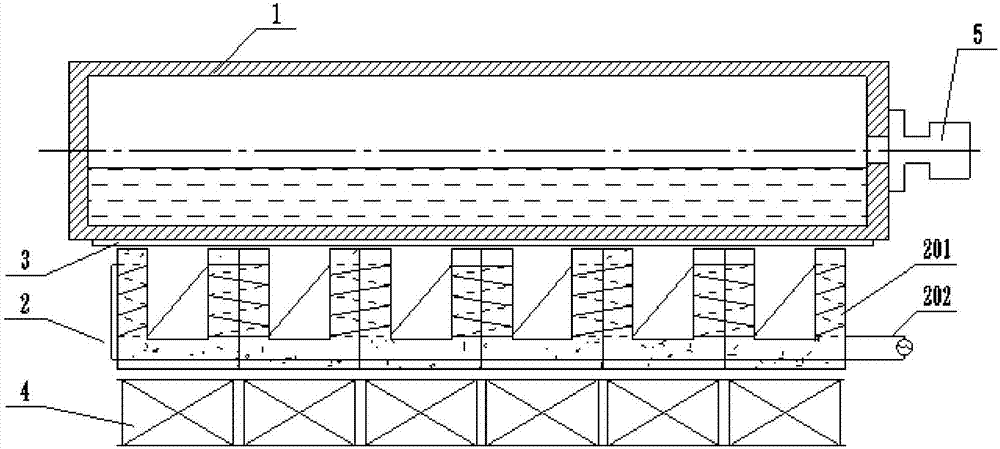

[0038] Such as figure 1 As shown, the present embodiment is an electromagnetic heating roller for corrugating machine, which includes a roller body 1 and an electromagnetic heater 2; wherein, the roller body 1 can be an upper corrugating roller, a lower corrugating roller or a pressure roller in a corrugating machine, and the upper corrugating roller The roller and the lower corrugating roller are used to extrude the core paper into a wave shape, and the pressure roller cooperates with the upper corrugating roller to bond the surface paper and the formed core paper; the electromagnetic heater 2 is used to heat the roller body 1 . In the prior art, the heating structure of the roller body 1 is basically by passing the heated heat-conducting liquid, such as water and heat-conducting oil, through one end of the roller, heating the roller and then passing it out from the other end, and then heating and introducing it into the roller. Recycling is formed. This method has been poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com