Method for generating aqua compound

A technology of hydrate and gas mixture, which is applied in the processing of gas mixture, water treatment and refining, petroleum industry, etc. It can solve the problems of low natural hydrate formation speed, low hydrate formation speed, and affecting the separation effect of mixed gas, and achieve Satisfy large-scale industrial applications, increase production speed, and achieve good separation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

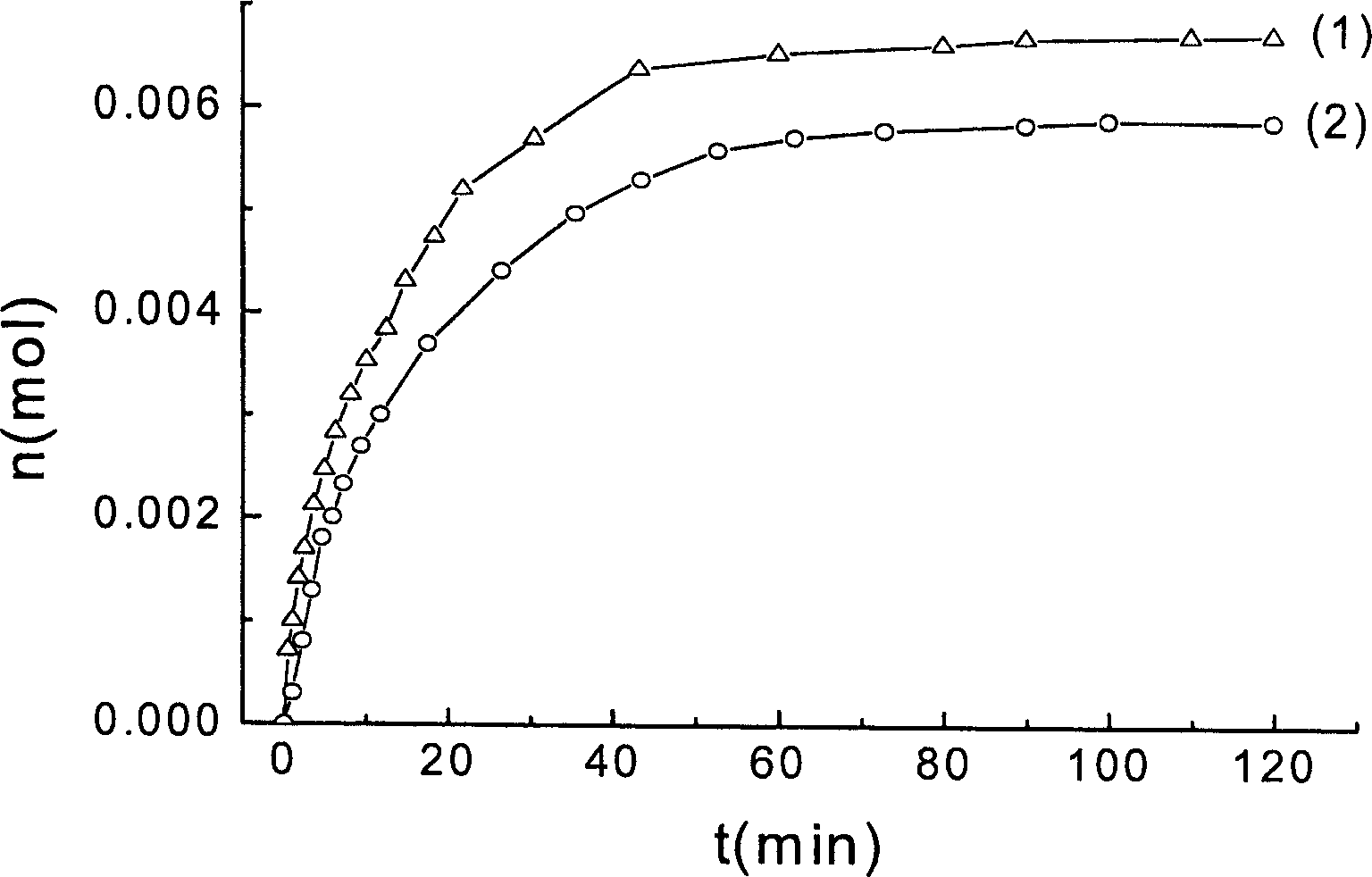

Embodiment Construction

[0022] Add the polymerization inhibitor into the aqueous solution containing the accelerator tetrahydrofuran (THF) in the specified proportion and mix evenly, then add the diesel oil in the specified proportion and mix thoroughly to make the system a stable emulsion. Transfer the emulsion to a fully transparent hydration reactor, and then install the reactor in an air bath with adjustable temperature. After the temperature of the system is adjusted to a certain value and stabilized, the mixed gas of methane and hydrogen of known composition is charged into the reactor. The temperature and pressure conditions in the reactor should meet the requirements of the mixed gas of methane and hydrogen to form hydrates, and should be controlled at 0-10°C and 1-5Mpa. When the gas is charged into the reactor, the system will start to form hydrates. The reaction kettle is made of transparent material, and there is a magnetic stirrer inside. By moving the magnetic stirrer up and down, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com