Online self-cleaning medium filtering device

A medium filtration and self-cleaning technology, applied in the direction of filtration loop, filtration separation, filtration treatment, etc., can solve the problems of dirt adhesion, efficiency drop, shut down to clean sewage and waste water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

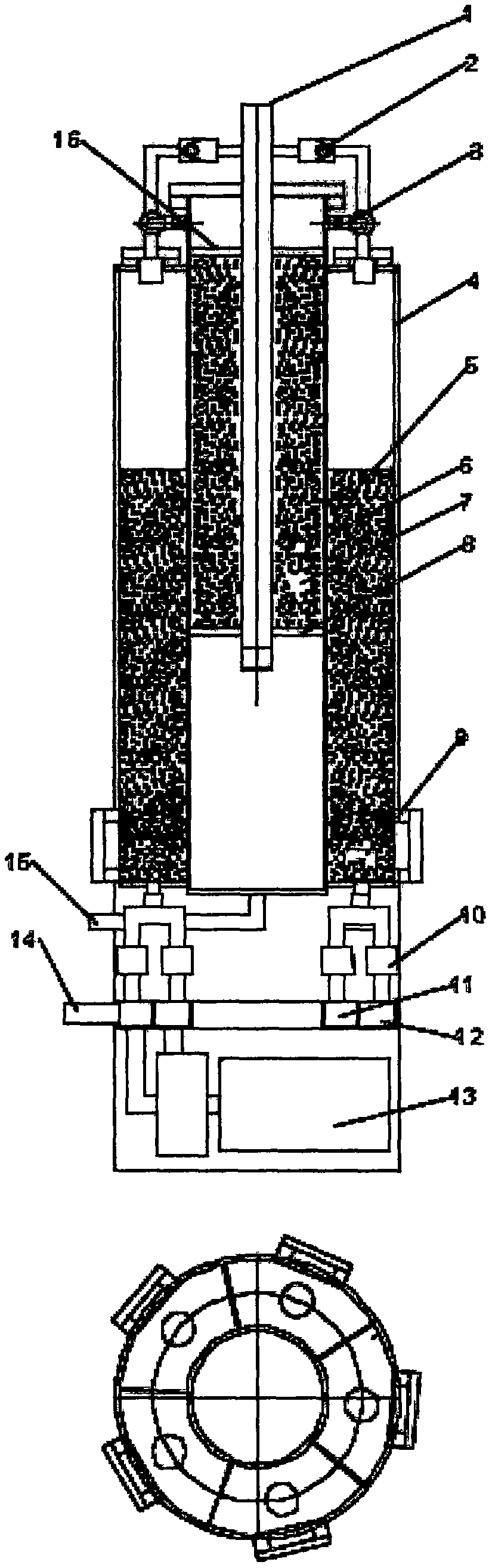

[0016] The present invention will be further described below in conjunction with accompanying drawing.

[0017] As shown in the accompanying drawing, an online self-cleaning medium filter device has 5 spatial structures.

[0018] As shown in the figure, an online self-cleaning medium filter device of the present invention includes a water inlet pipe 1, a backwash one-way valve 2, a water inlet one-way valve 3, a casing 4, a casing filter material 5, an inner cylinder 6, Inner cylinder filter material 7, lower screen plate 8, water distributor 9, control valve 10, backwash water collection chamber 11, water outlet water collection chamber 12, backwash pump 13, water outlet pipe 14, sewage pipe 15, upper plate 16 .

[0019] A kind of on-line self-cleaning media filtering device of the present invention its working procedure is as follows

[0020] Filtration process: The liquid enters from the upper end of the water inlet pipe 1, enters the lower part of the inner cylinder 6 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com