Patents

Literature

38results about How to "No compaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

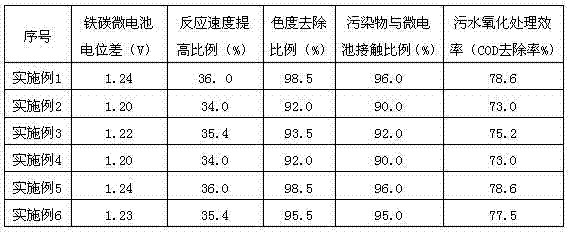

Efficient heterogeneous catalytic oxidation ferric-carbon micro-electrolysis packing and preparation method thereof

ActiveCN104761024ANo compactionHyperactive stateWater/sewage treatmentHigh current densityElectrolysis

The invention discloses efficient heterogeneous catalytic oxidation ferric-carbon micro-electrolysis packing and a preparation method thereof. The packing is prepared from the following raw materials in parts by weight: 45-65 parts of pure iron powder, 10-25 parts of cast iron powder, 2-8 parts of graphite powder, 5-15 parts of active carbon powder, 2-10 parts of copper powder, 2-10 parts of manganese powder, 2-10 parts of aluminum powder, 2-10 parts of fine wood bits, 1-6 parts of sodium silicate, 1-6 parts of sodium borate, 2-6 parts of pyrite dust and 5-15 parts of an adhesive. The efficient heterogeneous catalytic oxidation ferric-carbon micro-electrolysis packing disclosed by the invention is prepared by taking heterogeneous metal alloy with high potential difference as a catalyst and using a high-temperature micropore roasting technology and has the characteristics of heterogeneous metal and ferric-carbon integration, micropore framework type alloy structure, large specific surface area, low density, strong activity, high current density and the like; organic wastewater is treated so that COD, ammonia nitrogen and total phosphorus can be efficiently removed, the chroma can be reduced, the biodegradability can be improved, the treatment effect is extremely stable, and the phenomena of packing passivating, hardening and the like caused in the operation process can be avoided.

Owner:HUBEI QUANSHENG ENVIRONMENTAL PROTECTION SCI & TECH CO LTD

Method for extracting propolis by simulative biological fluid bed supercritical CO2 fluid

ActiveCN101530178AImprove extraction yieldImprove permeabilityFood preparationCyclic processLow speed

The invention provides a method for extracting propolis by simulative biological fluid bed supercritical CO2 fluid, which comprises that: bran (or rice bran and the like) taken as biomembrane carrier and original gum particles after physical treatment simulate a fluid bed in an extraction kettle to perform gridded filling, the supercritical CO2 fluid is used for extraction, and the lowest speed of a granular bed converting from a stationary state to fluidization is regulated by regulating temperature, pressure and flow rate of the fluid in the extraction process so as to reach the critical fluidization state; therefore, high-quality and high-yield propolis extract is obtained through a cyclic process of fluidization diffusion, dissolution and separation between granules and the fluid. The method improves the yield of the propolis extract, reduces the cost, and extracts nearly all terpene compounds and 40 to 50 percent of flavonoid compounds in the propolis at the same time; and products do not have organic solvent.

Owner:JIANGSU JIANGDAYUAN ECOLOGICAL BIOLOGICAL TECH

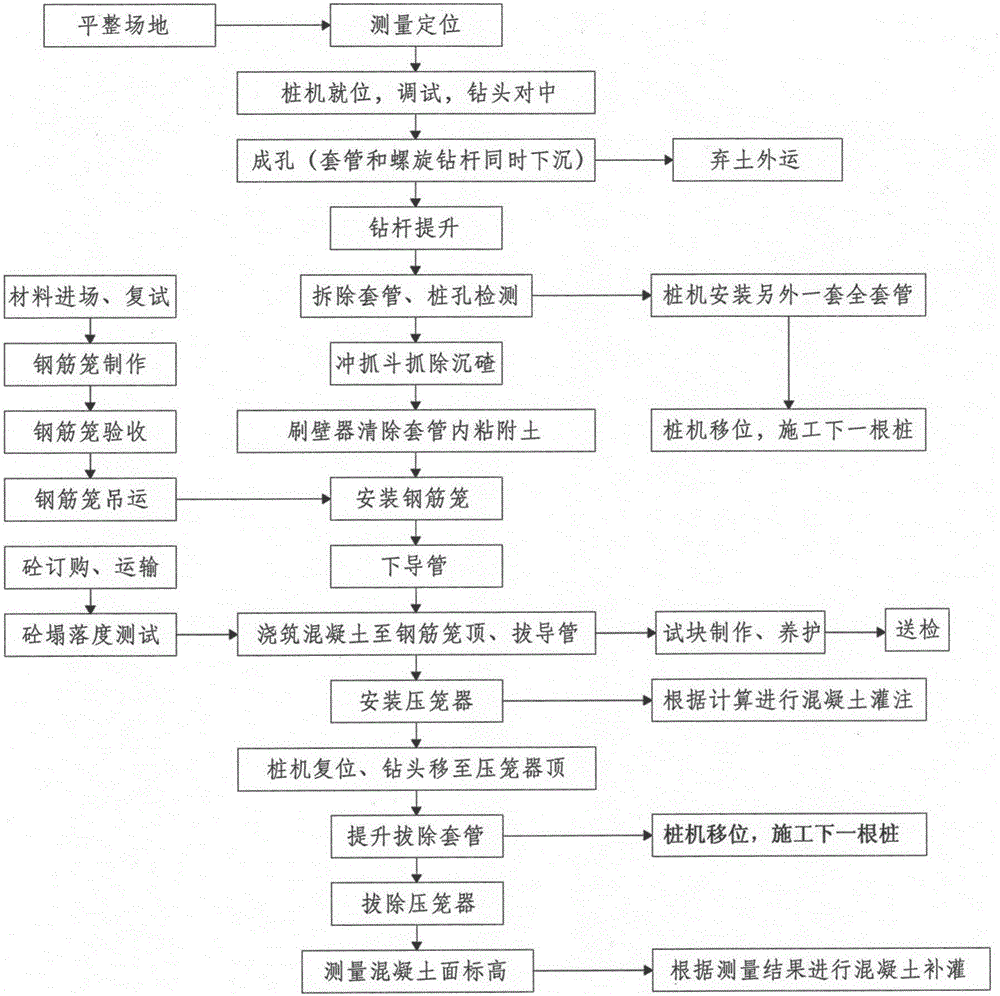

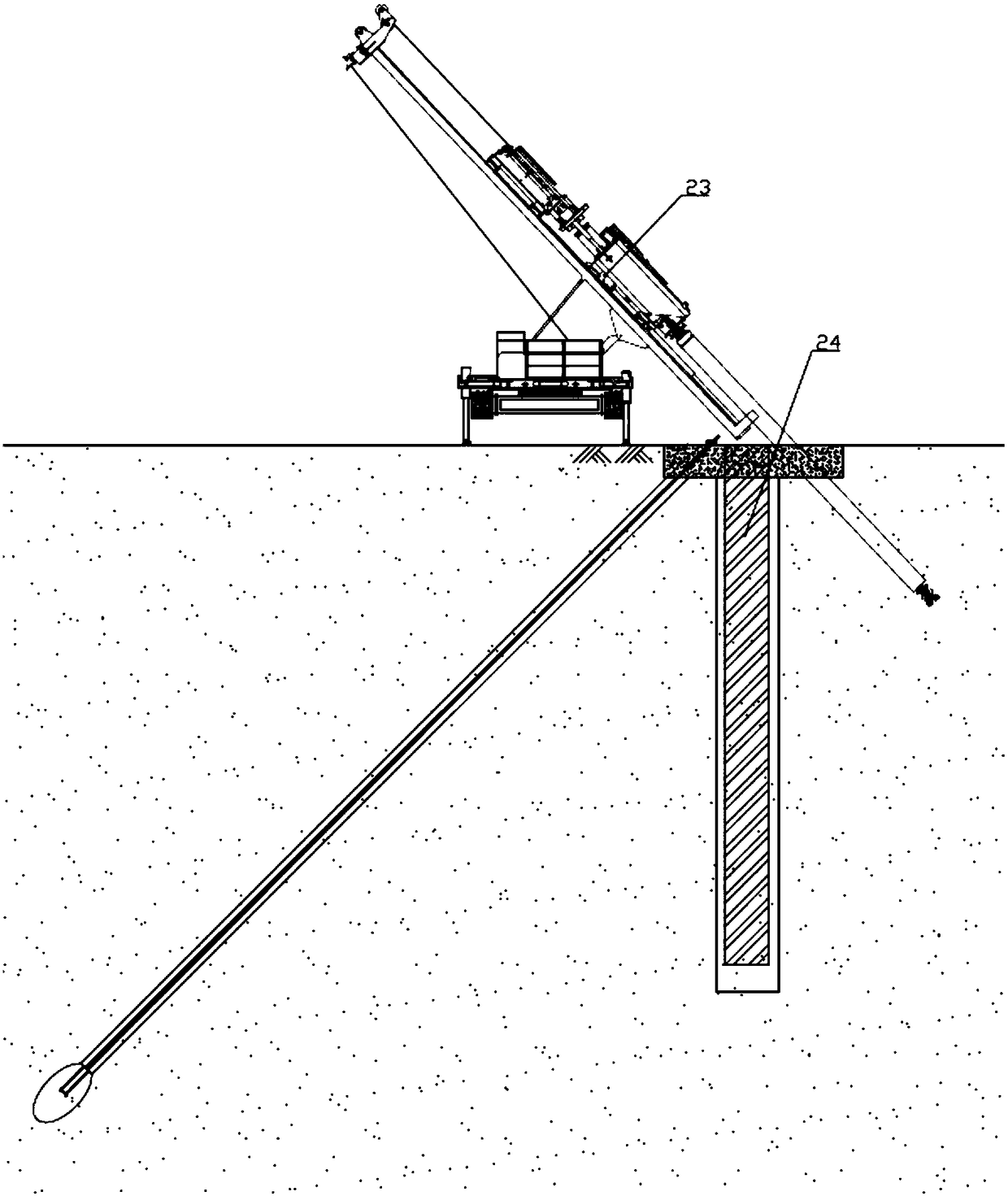

Construction method for full-casing long spiral bored piles

The invention provides a construction method for full-casing long spiral bored piles. The method includes the steps that firstly, a casing pipe and a spiral drill pipe of a full-casing long spiral drilling machine simultaneously rotate and sink so as to form a hole after being aligned with a pile position; secondly, the drilling machine is moved to the next pile for hole formation operation, and meanwhile, adhering soil on the inner wall of the casing pipes in the formed hole is removed in a brushing mode through a wall brushing device; thirdly, a reinforcement cage is hoisted into the hole, concrete is poured into the reinforcement cage, and concrete pouring is stopped after the concrete is poured to the top elevation of the reinforcement cage; fourthly, a cage pressing device is hoisted into the casing pipe, and concrete pouring continues; fifthly, a pile machine is located in place, and a drill bit is elevated to the cage pressing device to press the reinforcement cage; and finally, the casing pipe is lifted and pulled out, the cage pressing device is removed, and pile forming is completed. The construction method provided by the invention is high in construction efficiency, the wall of a formed pile hole is regular in shape, a pile body is high in perpendicularity, and the pile forming quality is good; soil squeezing, hole collapse and vibration are avoided, and construction noise is low; and slurry pollution in the construction process is avoided, the outward slurry transport cost is reduced, the cost is reduced, and the construction method is environmentally friendly.

Owner:上海腾尚基础工程有限公司

High substitution degree cyanoethyl cellulose and cellulose diacetate commixing hollow fibrous nano filter film and its preparation process

InactiveCN1762559AStable performanceGood interception performanceSemi-permeable membranesSolventAmount of substance

The invention relates to a nano hollow fiber filtration membrane, which is prepared by: mixing and dissolving the material, such as HCEC, CA, acetone, dioxohexacyclic compound, hexacyclic dioxide, and alcohol or ethanol; filtering, defoaming, spinning to form, and post-treating. Wherein, the total of HCEC and CA mixture takes up 20~30% to total mass by mass ratio as 2~3:7~8, the acetone and hexacyclic dioxide solvent is 70~80%; alcohol or ethanol is 10~20% of HCEC and CA mixture by mass ratio as 0.8~1.2:1. This invention has well cutting flow performance, compressive resistance, acid and base resistance, and obtains water flux more than 3.50mL / (cm2íñh), well desalinization ratio by bivalent salt more than 90% and monobasic salt ratio more than 60%.

Owner:GUANGDONG ZHONGKE GREEN SPRING WATER

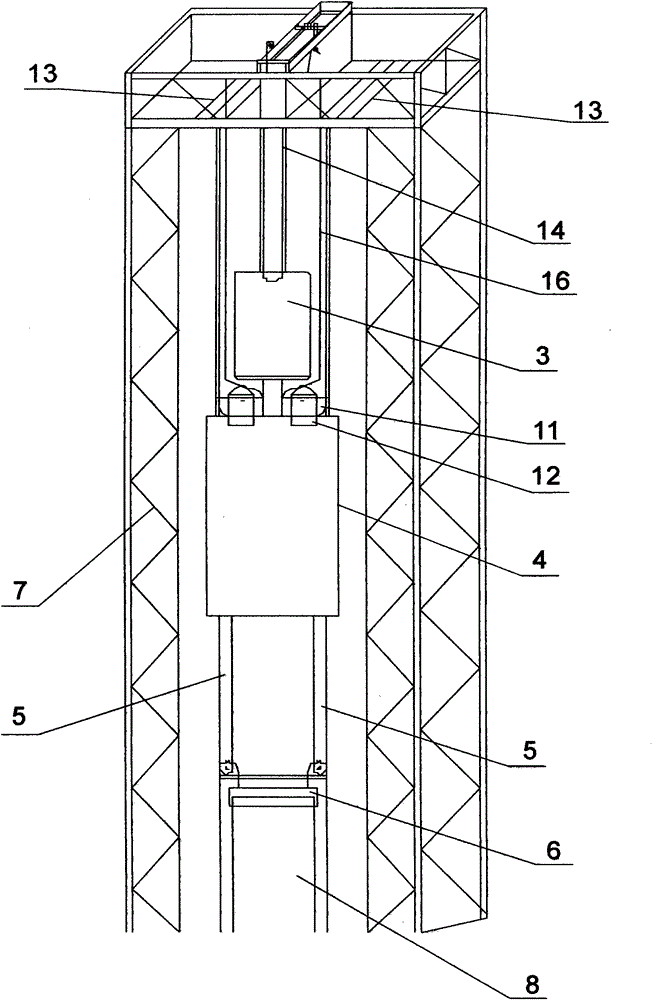

Pile sinking device and method for middle digging hydraulic method pre-stressed centrifugal pipe pile (square pile)

The invention discloses a pile sinking device for a middle digging hydraulic method pre-stressed centrifugal pipe pile (square pile). The pile sinking device comprises a main machine, a windlass, a bracket, a reaction frame, a power head, a soil sampling tank and a steel wire rope, wherein the windlass and the bracket are arranged on the main machine; the reaction frame, the soil sampling tank and the steel wire rope are arranged on the bracket; the power head is arranged inside the bracket; the lower side of the power head is connected with a soil sampling drilling rod; and the soil sampling drilling rod passes through the soil sampling tank, a piston rod and the centrifugal pipe pile (square pile) to the bottom of the device. The invention further provides a pile sinking method for the middle digging hydraulic method pre-stressed centrifugal pipe pile (square pile). The method comprises the following steps of: moving the main machine to a pile pressing position; making the main machine project into an inner tongue hole of the reaction frame through a tongue on the soil sampling tank; extending the piston rod to realize pile pressing; pressing the pile repeatedly, and separating the power head from the soil sampling drilling rod; connecting a second centrifugal pipe pile (square pile); and performing the steps once again. The pile sinking device has the advantages of safety, reliability, low cost, high efficiency, no noise, no pollution, no soil compression, no slurry, environmental friendliness and the like.

Owner:SHANGHAI CHENGDI CONSTR

Surface soil laminating sampler

InactiveCN105527120AAccurate control of sampling depthClear soil stratificationWithdrawing sample devicesEngineeringShake up

The invention belongs to the technical field of ecological study of soil science, environment science and the like, and discloses a surface soil laminating sampler. The surface soil laminating sampler comprises a fixing device and a cutter device, wherein the cutter device is used for cutting a surface soil sample; the fixing device is an iron pipe which is 3cm in inner diameter and 50cm in length and has a round upper part and a sharp lower part; the sharp lower part can be inserted into soil by about 30cm during a sampling process, so that a whole device can be fixed, and the cutter device is unlikely to shake up and down to affect the sampling quality. According to the surface soil laminating sampler disclosed by the invention, the sampling depth can be accurately controlled, soil is clearly laminated, no compaction is generated, and no cross-containmination is generated between different levels of samples.

Owner:HENAN NORMAL UNIV

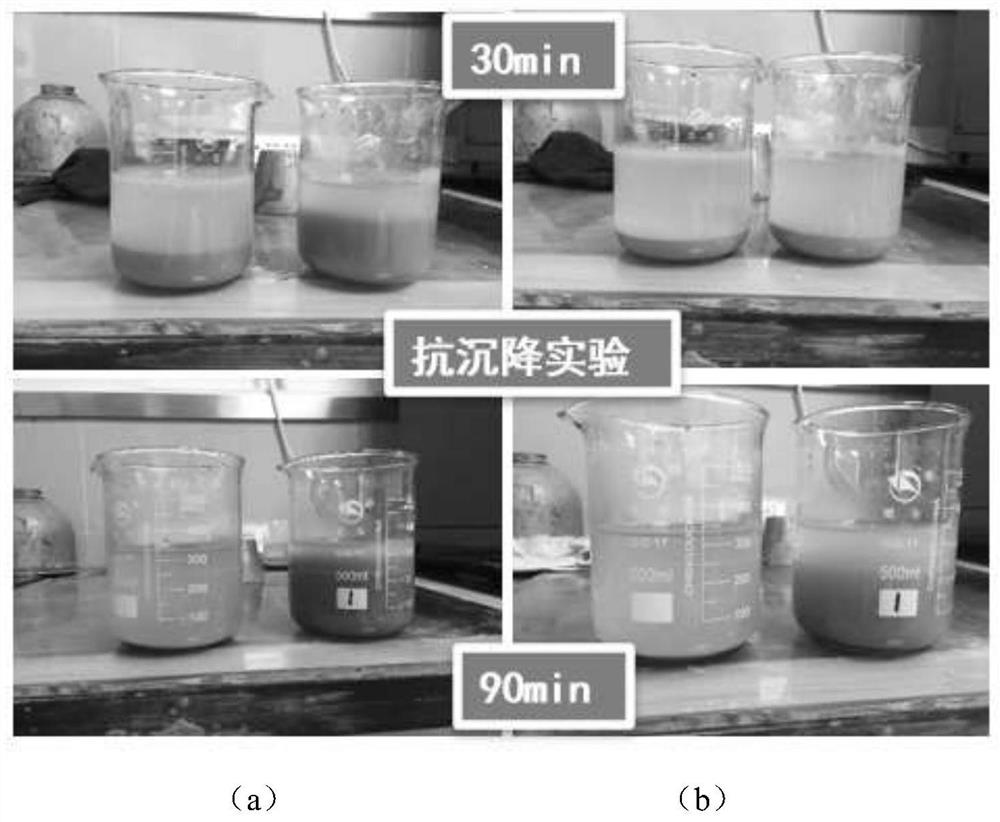

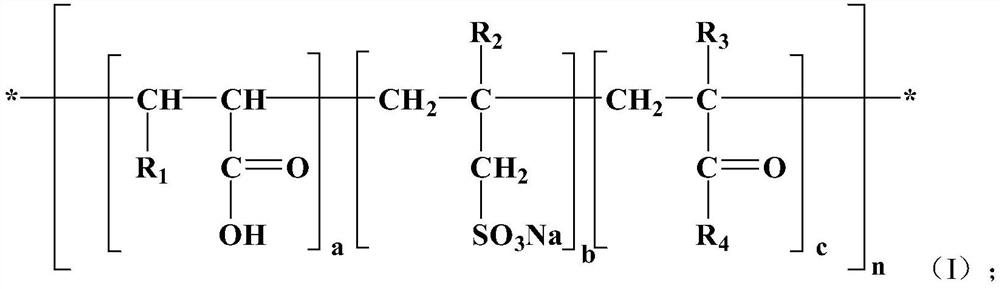

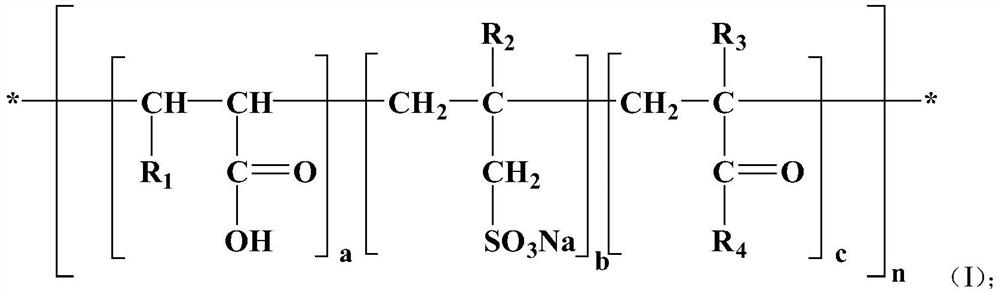

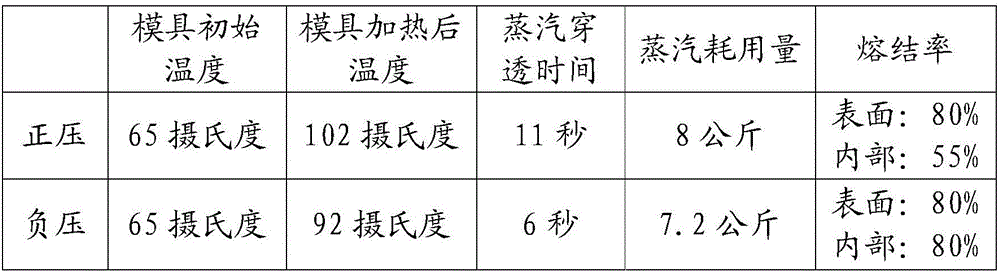

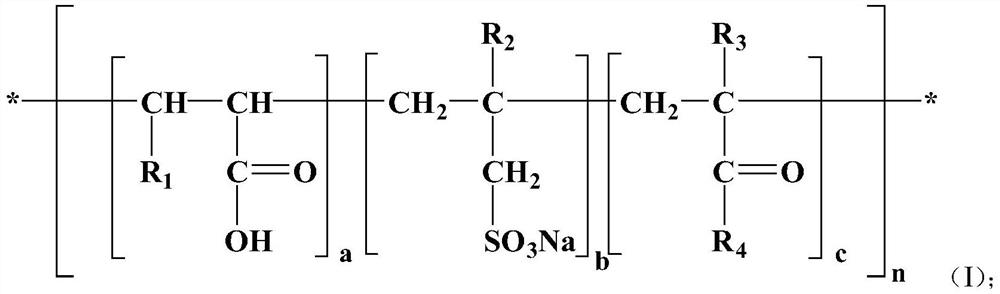

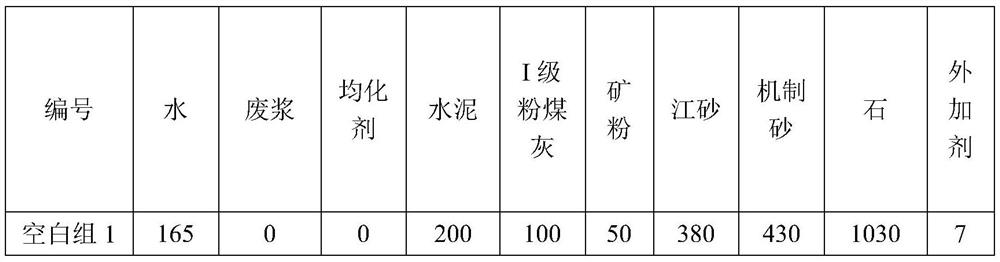

Homogenizing agent for mixing station waste slurry water

ActiveCN112430002AStrong repulsionInhibition dispersionScale removal and water softeningLiquid stateWastewater

The invention belongs to the technical field of concrete functional additives, and particularly relates to a homogenizing agent for mixing station waste slurry water, which is prepared by taking a dispersing component, a workability adjusting component, a mud inhibiting component, a pH value adjusting component and water as main raw materials. The homogenizing agent for the waste slurry water is in a liquid state at normal temperature, is good in homogeneity, meets related standards of admixtures for concrete, can effectively improve the workability, compressive strength and impermeability grade of the obtained concrete, reduces the bleeding rate of the concrete, realizes recycling of wastewater of a mixing station, and has important economic and environmental benefits.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

Pile sinking device and method for middle digging pulling-anchoring method pre-stressed centrifugal pipe pile (square pile)

The invention discloses a pile sinking device for a middle digging pulling-anchoring method pre-stressed centrifugal pipe pile (square pile). The pile sinking device comprises a main machine, a windlass, a power head, an oil pressure pulling-anchoring device, a press-in oil tank, a soil sampling tank, a pulley and a steel wire rope, wherein the windlass is arranged on the main machine; the power head, a recovering tank and the oil pressure pulling-anchoring device are arranged on the main machine; the lower side of the power head is connected with a soil sampling drilling rod; and the soil sampling drilling rod passes through the oil pressure pulling-anchoring device, the soil sampling tank, a pile cap and the centrifugal pipe pile (square pile) to the bottom of the device. The invention further provides a pile sinking method for the middle digging pulling-anchoring method pre-stressed centrifugal pipe pile (square pile). The method comprises the following steps of: driving the soil sampling drilling rod to realize soil digging through the power head; realizing retraction of the press-in oil cylinder under the action of the road holding of the soil sampling drilling rod; and realizing pile pressing by digging soil and pressing the pile synchronously through the soil sampling drilling rod. The pile sinking device has the advantages of safety, reliability, low cost, high efficiency, no noise, no pollution, no soil compression, no slurry, environmental friendliness and the like.

Owner:SHANGHAI CHENGDI CONSTR

Device and method for sinking pre-stressed centrifugal pipe pile (square pile) with in-pile boring and reverse drawing method

The invention discloses a device for sinking a pre-stressed centrifugal pipe pile (square pile) with an in-pile boring and reverse drawing method. The device comprises a host, a winch, a power head, a soil taking box, a pulley and a wire rope, wherein the winch is arranged on the host; the power head is arranged on the host; the lower part of the power head is connected with a soil taking drill stem; the lower end of the soil taking box is connected with a pile cap; the lower end of the pile cap is provided with a centrifugal pipe pile (square pile); and the soil taking drill stem penetrates through the soil taking box and the centrifugal pipe pile (square pile) to reach the bottom of the device. The invention also provides a method for sinking the pre-stressed centrifugal pipe pile (square pile) with the in-pile boring and reverse drawing method; and the method comprises the following steps of: firstly, moving the host to a pile pressing position; taking soil through the soil taking drill stem; meanwhile, pressing the pile through the pile cap; recovering the soil through the soil taking box while taking soil; pressing into a first pile and then connecting a second pile; and continuously performing said steps. The device and the method have the advantages of safety, reliability, low cost, high benefit, no noise, no pollution, no extruded soil, no mud, environmental friendliness and the like.

Owner:SHANGHAI CHENGDI CONSTR

Environment-friendly organic and inorganic fertilizer prepared with molasses alcohol waste mash used as raw material

InactiveCN104230604ASimple processShort fermentation timeBio-organic fraction processingClimate change adaptationSpray GranulationAlcohol

The invention discloses an environment-friendly organic and inorganic fertilizer prepared with molasses alcohol waste mash used as a raw material. High-temperature condensed bacilli are inoculated in just-discharged high-temperature molasses alcohol waste mash for fermentation, a metal complexing agent is added, then the molasses alcohol waste mash is kept to be evaporated at the high temperature for a period; the molasses alcohol waste mash is led into an anaerobic fermentation pool for anaerobic fermentation after being naturally cooled; then aerobic bacteria are added into the molasses alcohol waste mash, the mixture is mixed with organic filler and an inorganic fertilizer in a certain proportion for fermentation for 12-36 hours, the fermented molasses alcohol waste mash is subjected to degumming treatment and slurry-spraying granulation, then beneficial bacteria are added, and a finished product is obtained. According to the environment-friendly organic and inorganic fertilizer, other bacteria are removed through the high temperature, the metal complexing agent is added to remove heavy metals, bacterium fermentation effects at all phases are improved, the finished product has no obvious stink, the added organic filler is rich in inorganic nutrients and microelements such as N, P, K and the like, the production cost is saved, and the product quality is improved.

Owner:GUANGXI SOURCE OF THE FERTILIZER IND

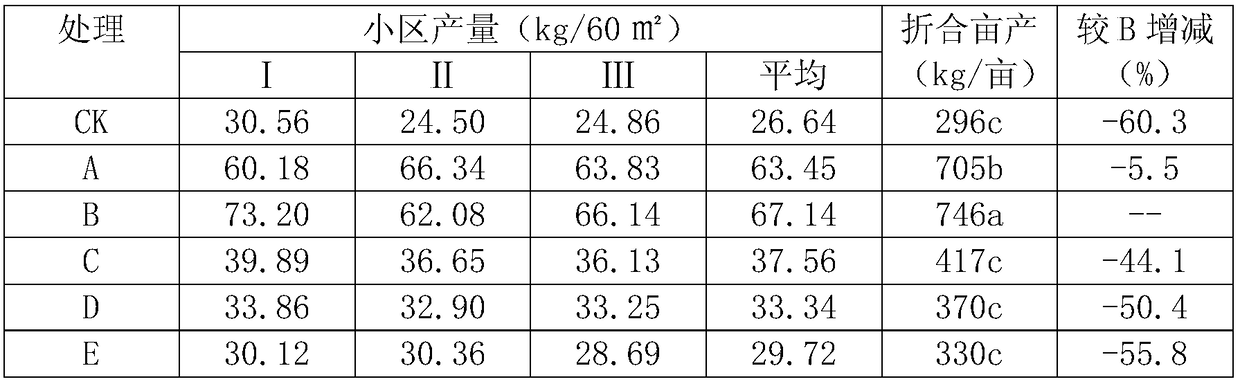

Fertilizing method for realizing high rice yield

InactiveCN109438049AReduce the number of applicationsReduce dosageSuperphosphatesExcrement fertilisersPotassiumPanicle

The invention discloses a fertilizing method for realizing high rice yield and relates to the technical field of agricultural planting. The method comprises the following steps: three times of fertilization of base fertilizer, additional fertilizer and panicle final fertilizer are applied in the whole growth period of the rice, the total amount ratio of nitrogen, phosphorus and potassium in threetimes of fertilization is 1:0.63:1.04, the total nitrogen amount for three times of fertilization is 20.90 kg / mu, total phosphorus amount for three times of fertilization is 13.25 kg / mu, and total potassium amount for three times of fertilization is 21.75 kg / mu. The fertilizing method, use amount and proportion are improved according to fertilizer demanding and absorbing rules of the rice in different growth periods, land utilization and land maintenance are combined, fertilizing times are reduced to 3 times from the traditional 4-5 times, fertilizing amount and proportion of nitrogen, phosphorus and potassium are quantified and reasonable, fertilizing periods are clear, so that production cost is reduced, and yield is increased.

Owner:玉林市农业科学院

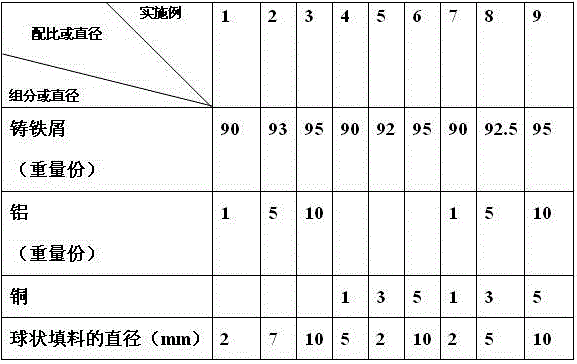

Catalytic microelectrolysis packing, as well as preparation method and application thereof

InactiveCN105645525AOvercoming easy hardeningOvercoming biasWater contaminantsWaste water treatment from textile industryCopperDyeing wastewater

The invention relates to catalytic microelectrolysis packing for treatment of pharmaceutical wastewater, heavy metal wastewater, printing and dyeing wastewater and the like. The catalytic microelectrolysis packing is spherical packing prepared from the following components in parts by weight: 90-95 parts of cast-iron scrap, 0-10 parts of aluminum and 0-5 parts of copper by means of weighing, mixing, melting and molding, wherein any one or both of aluminum and copper exist; the diameter of the spherical packing is 5-10mm; and the carbon content of the cast-iron scrap is 3-4 percent. The packing has the beneficial effects of overcoming inherent defects of easily caking, deflection and blockage of traditional microelectrolysis packing prepared from cast-iron scrap and improving the pollutant removal rate and wastewater COD removal rate, so that the biodegradability of wastewater can be improved.

Owner:NORTHERN ENG DESIGN & RES INST CO LTD

Wool fabric treatment process for improving bulkiness

InactiveCN107503111AImprove bulkFeel thickShrinking resistant fibresAnimal fibresOxidizing agentReducing agent

The invention relates to a wool fabric treatment process for improving bulkiness, which comprises first soaking the wool fabric in water added with sodium chloride at 35-50 DEG C for 60-80 min, wherein the mass ratio of sodium chloride to wool fabric is 1: 180; then add oxidizing agent, the mass ratio of oxidizing agent and wool fabric is 1:90, the temperature of the oxidation process is kept at 45 ° C for 30 minutes; then the softener is added, the mass ratio of softener and wool fabric is 1:120, and the temperature of the softening process is 1:120. Keep at 30°C for 20min; then add reducing agent, the mass ratio of reducing agent and wool fabric is 1:100, and the temperature of the reduction process is kept at 40°C for 30min. It is characterized in that: before adding softener, add Fluffing agent. The present invention has the advantages that: before adding softening agent, adding fluffing agent, through the action of fluffing agent, the finished wool fabric can have high bulkiness and thick hand feeling, and the surface of the fabric has no hardening phenomenon, which improves the warmth retention of wool fabric. sex and comfort.

Owner:JIANGSU SUNSHINE

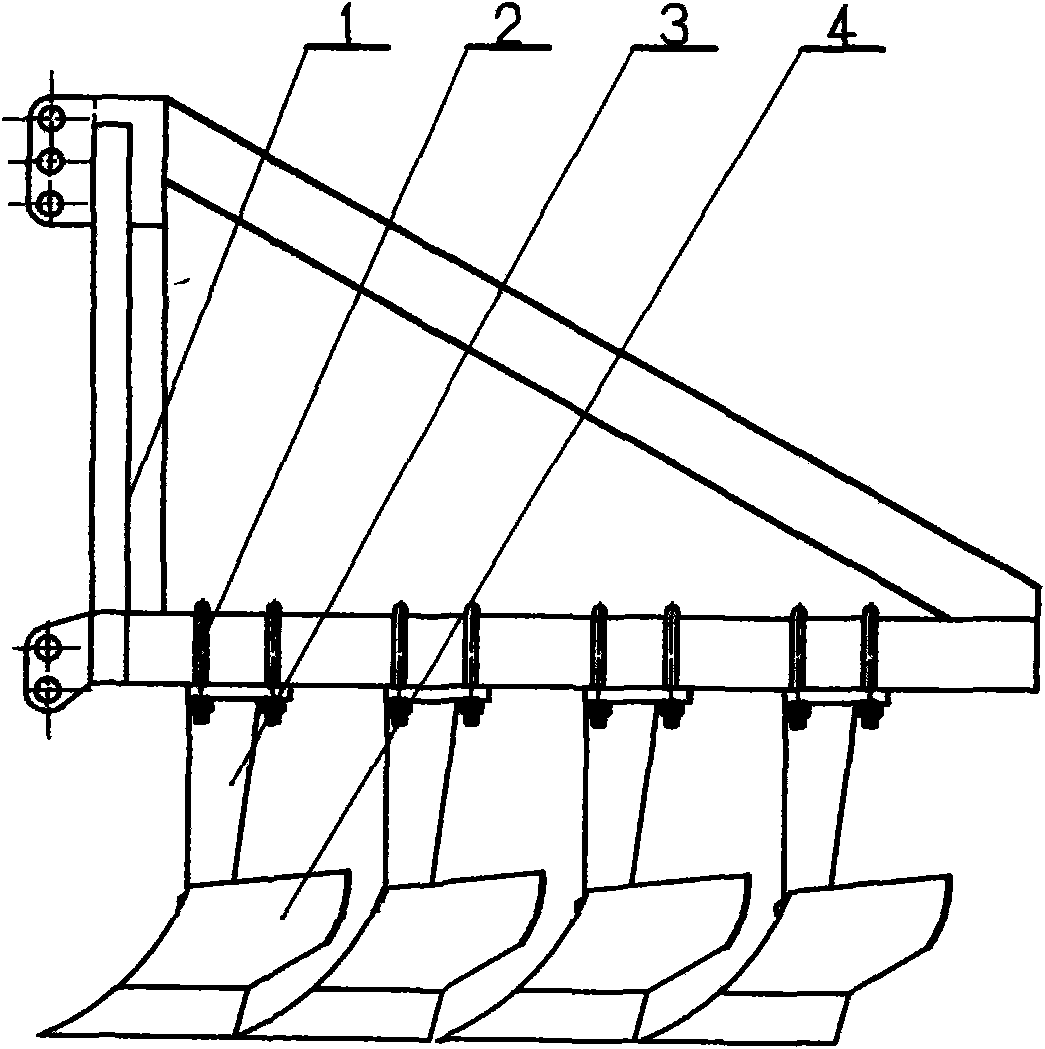

Two-way multi-share plough unit

The invention relates to a two-way multi-share plough unit, mainly comprising a plow stock 1, a U-shaped bolt 2, a plow standard 3, a plough share 4, a deep loosing shovel 5, a middle shovel plough 6,and the like. The plow standard 3 is fixed below the plow stock 1 through the U-shaped bolt 2; the plough share 4 is mounted in the middle of the plow standard 3; the deep loosing shovel 5 is mountedat the bottom of the plow standard 3; and the middle shovel plough 6 is mounted below a middle longitudinal beam of the plow stock 1; the plough share 4 is divided into a left group and a right groupwhich are respectively configured in a reverse U shape or a V shape, so that the width of the whole unit is increased by about one fold than the operating width of the traditional one-way plough andthe distance in the front and rear directions is reduced by about a half.

Owner:郑宇虎 +1

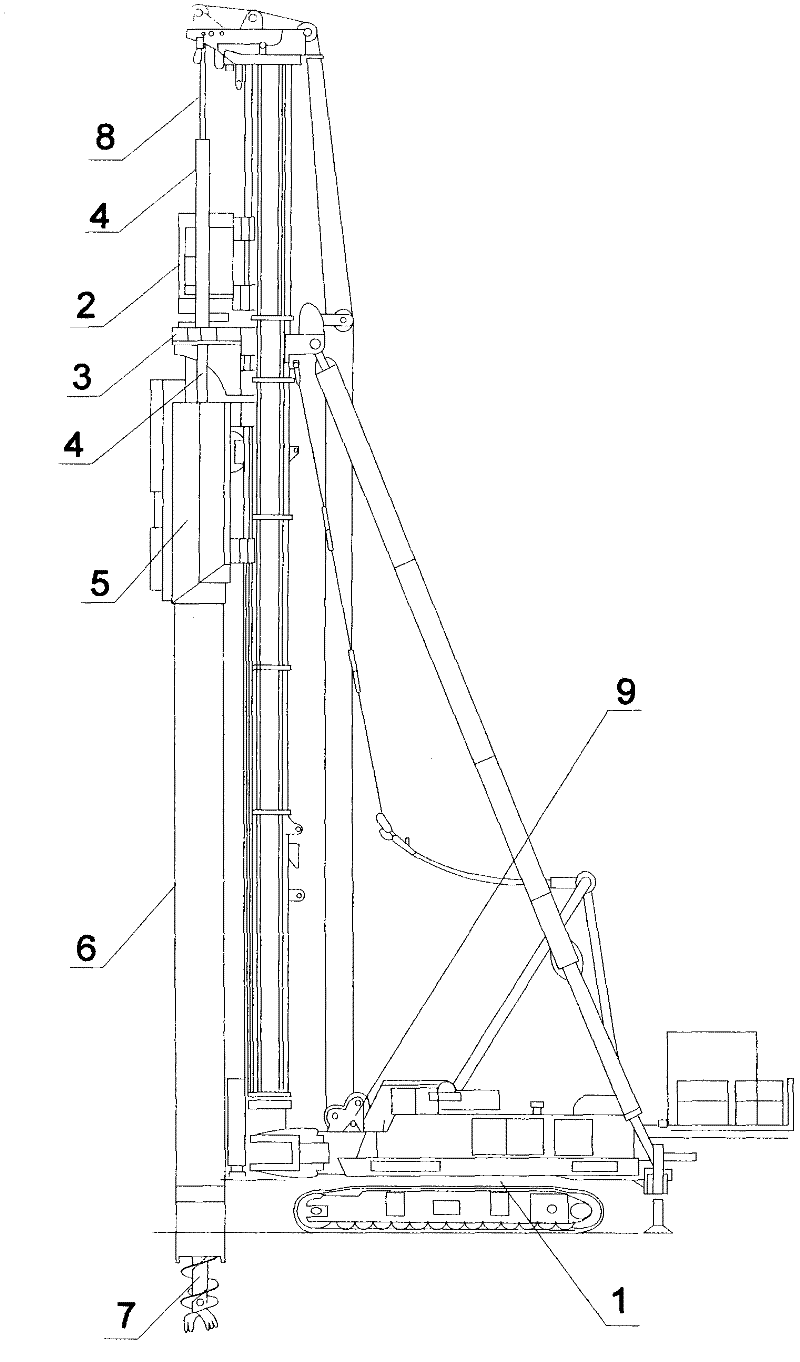

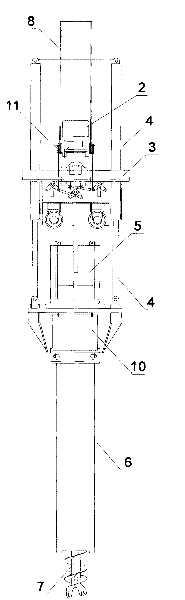

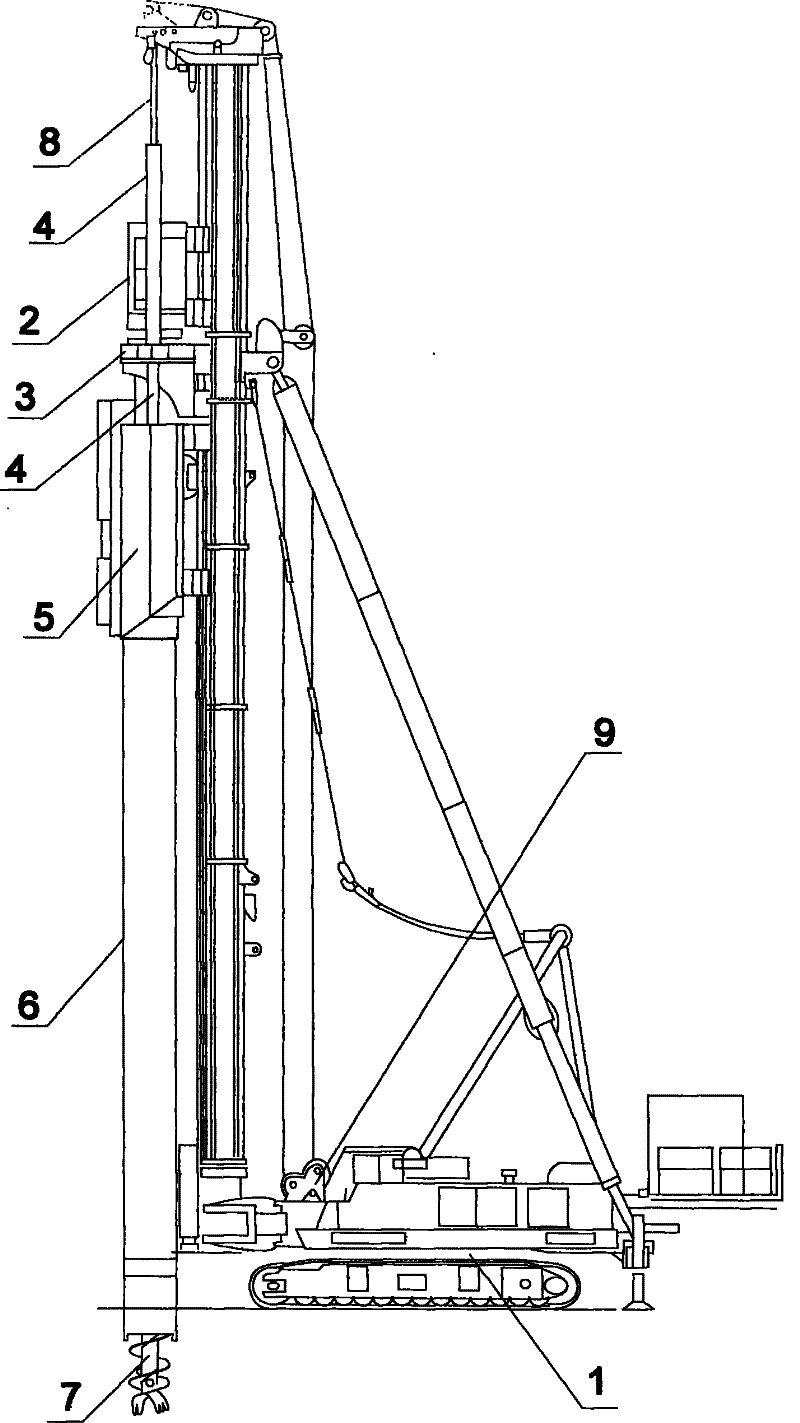

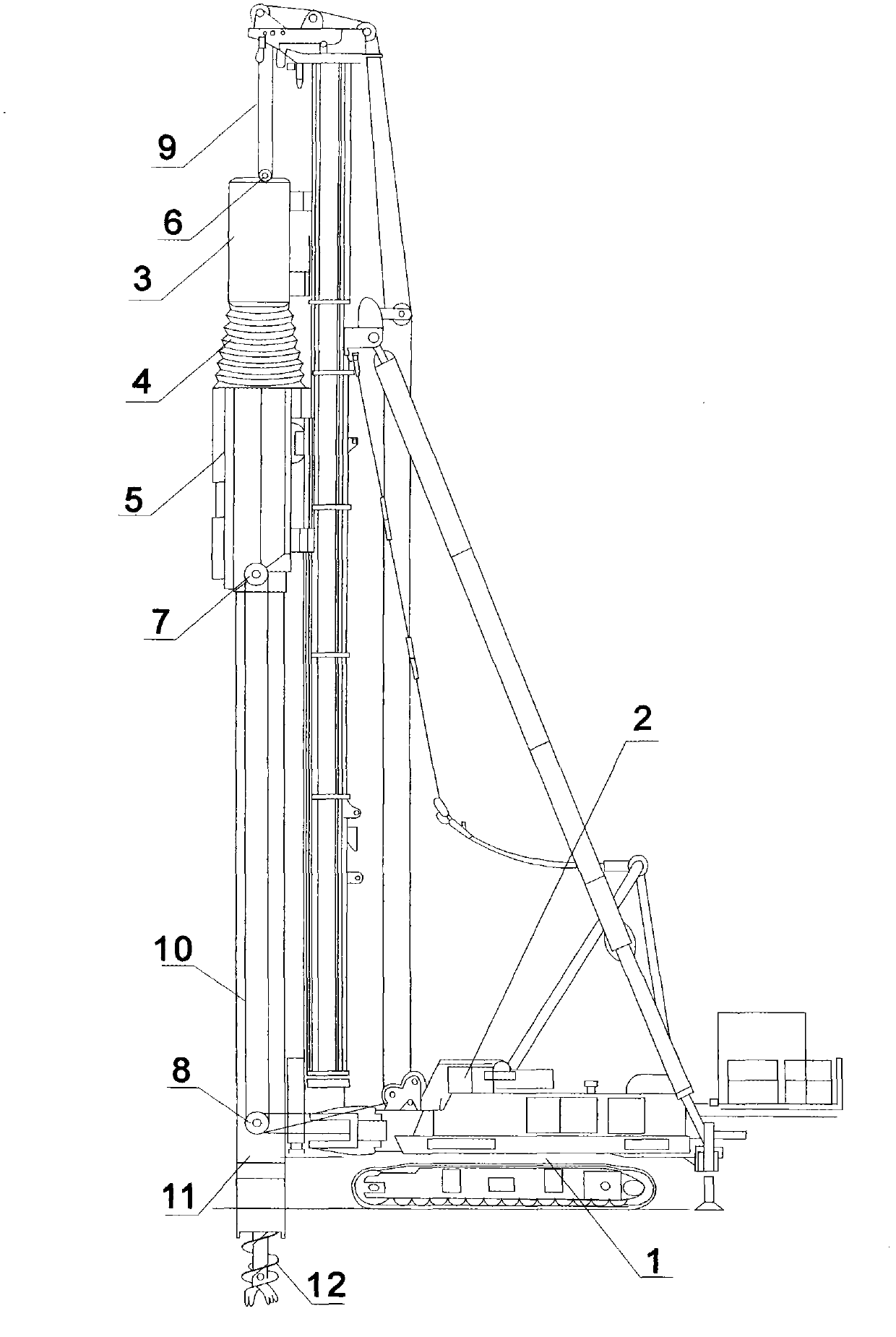

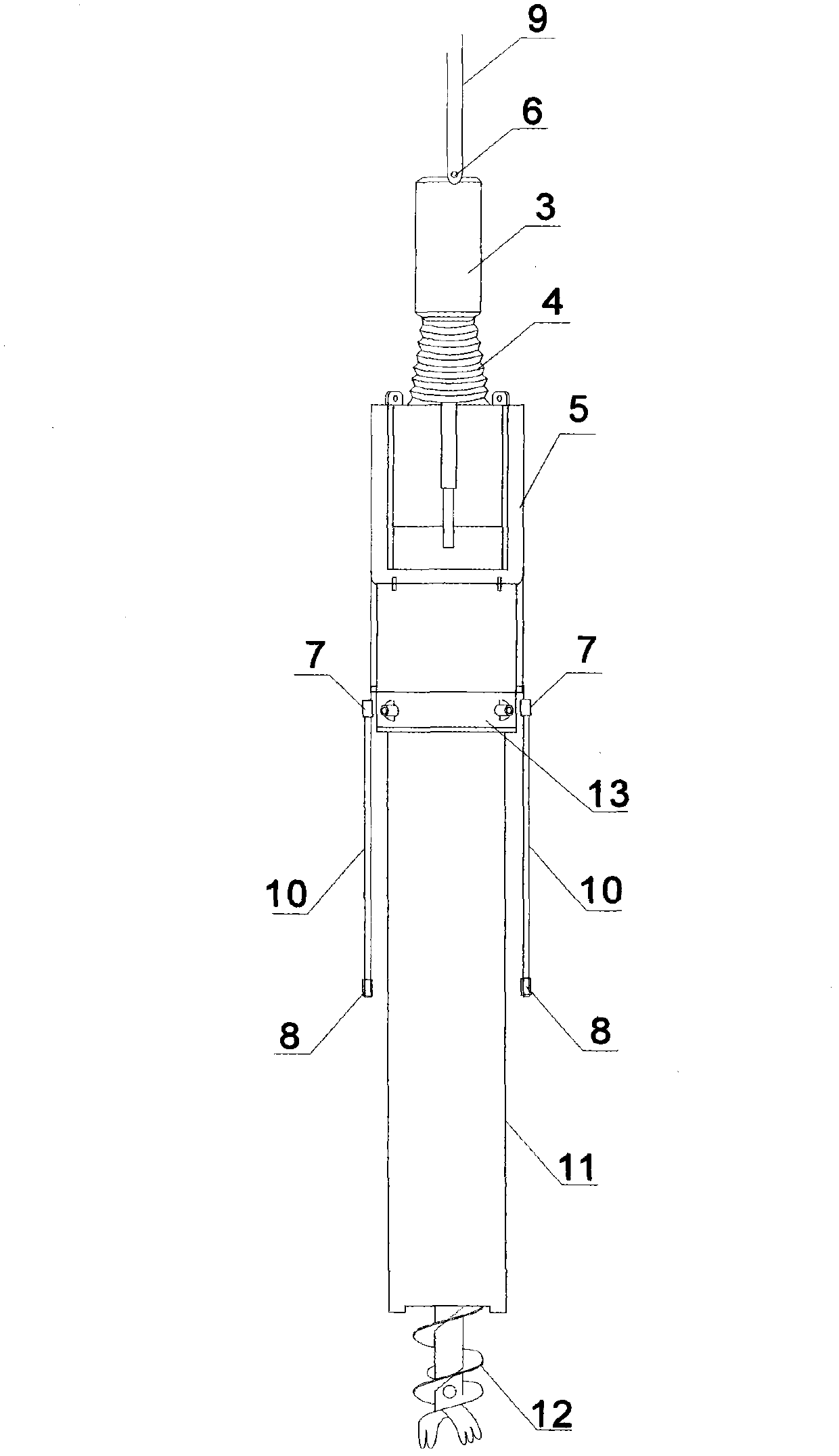

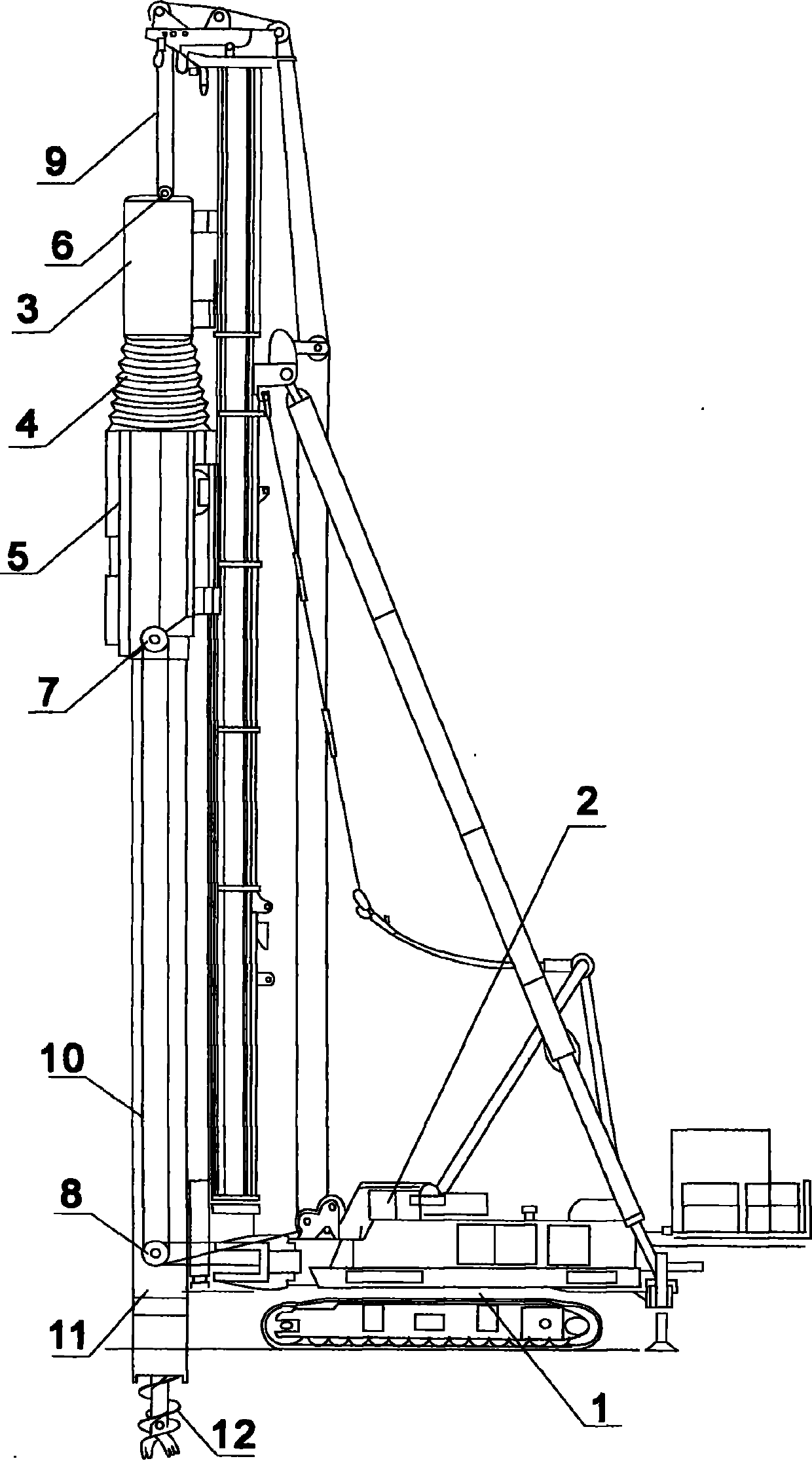

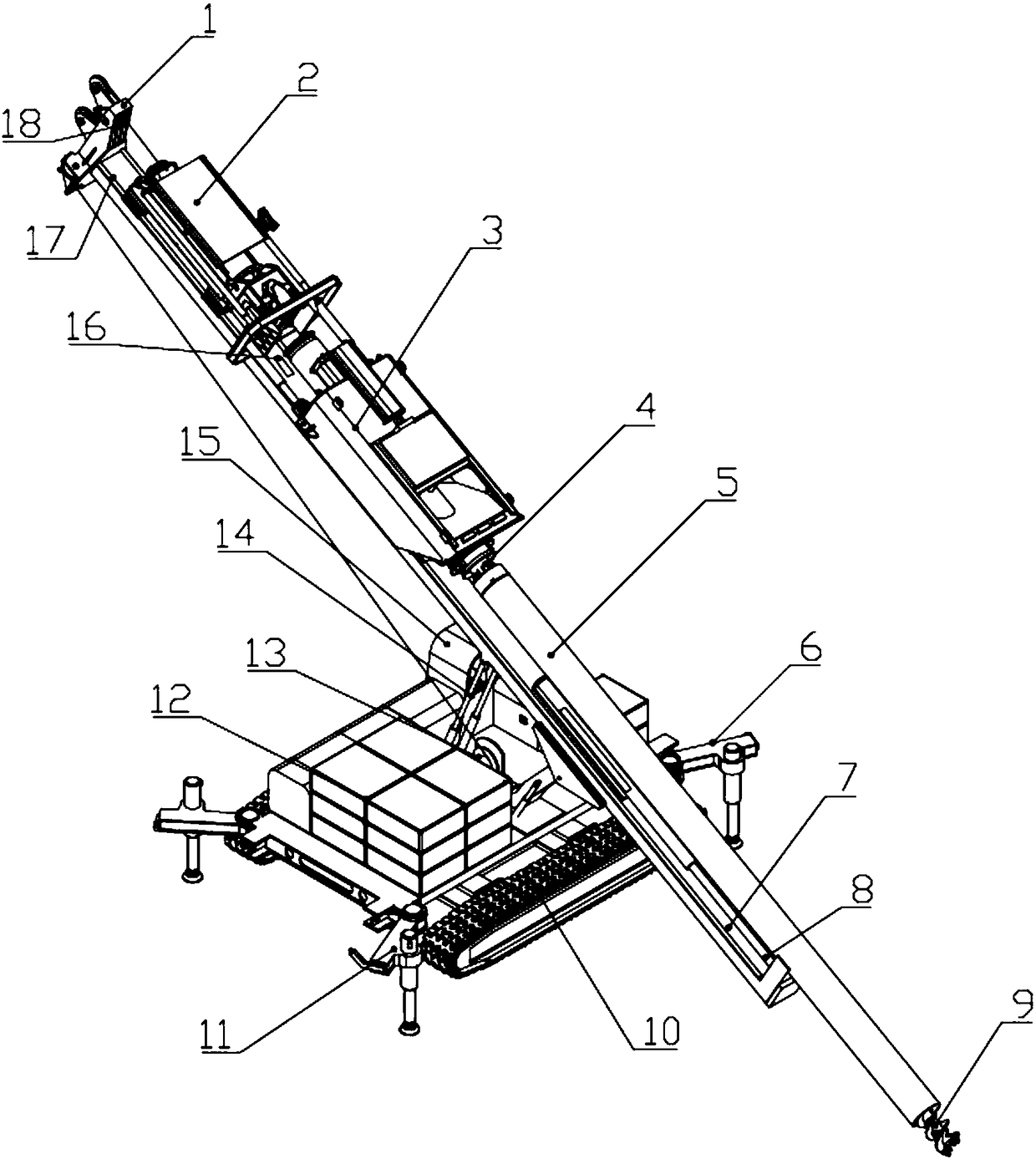

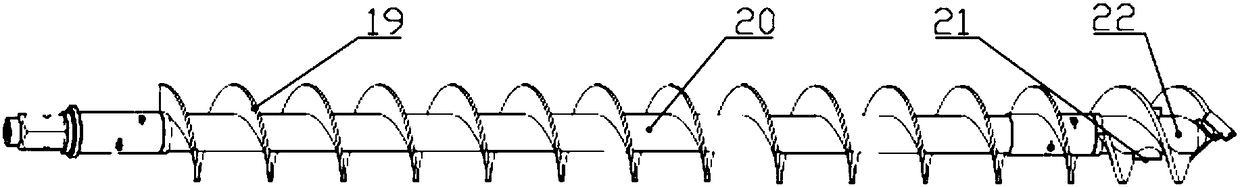

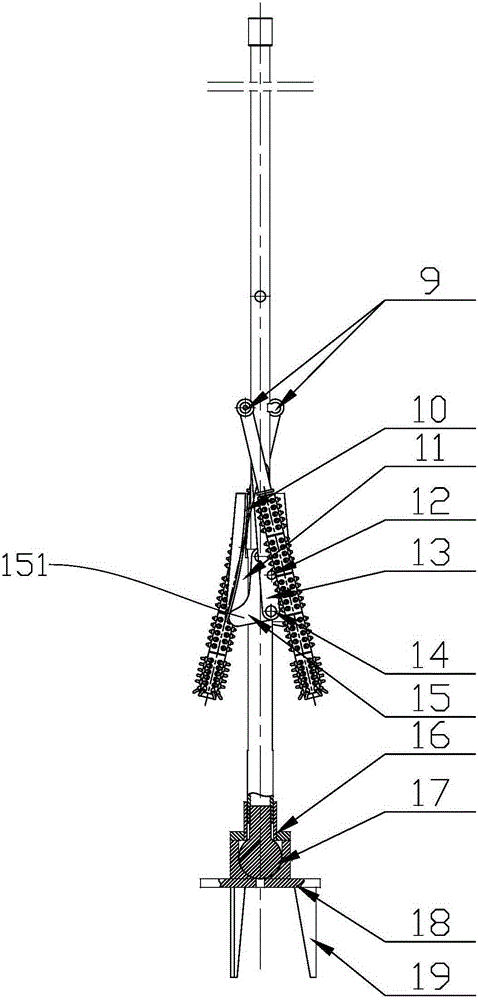

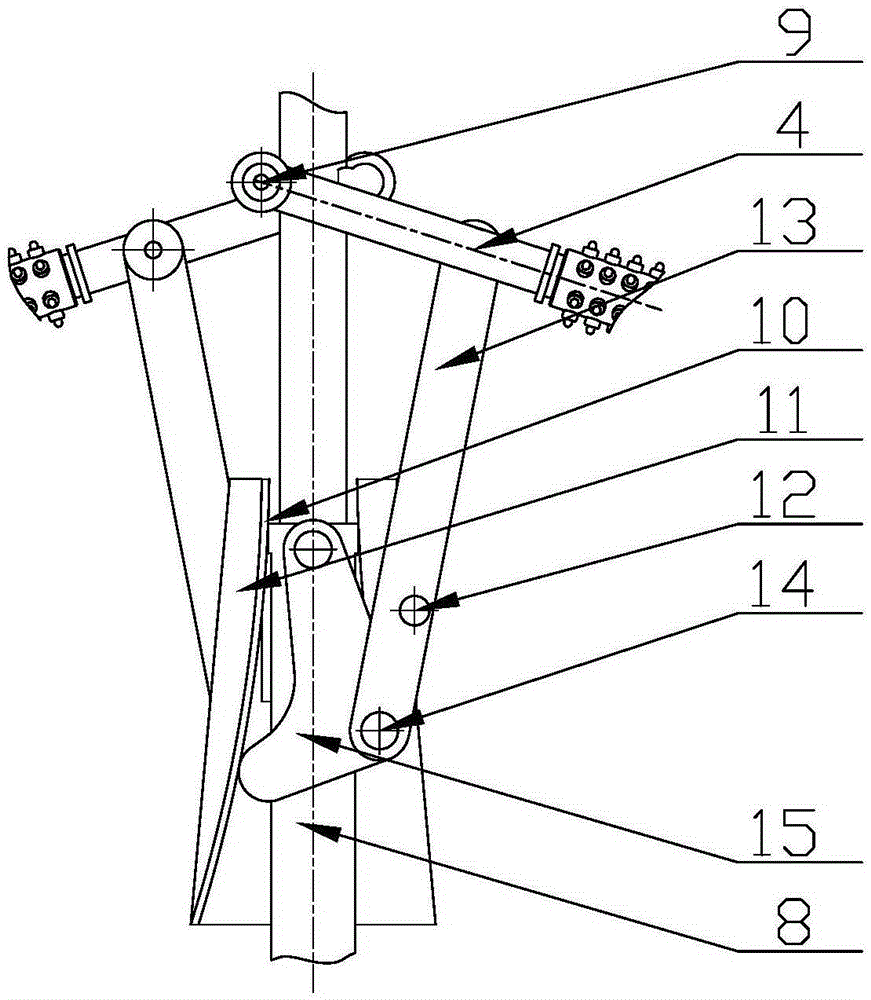

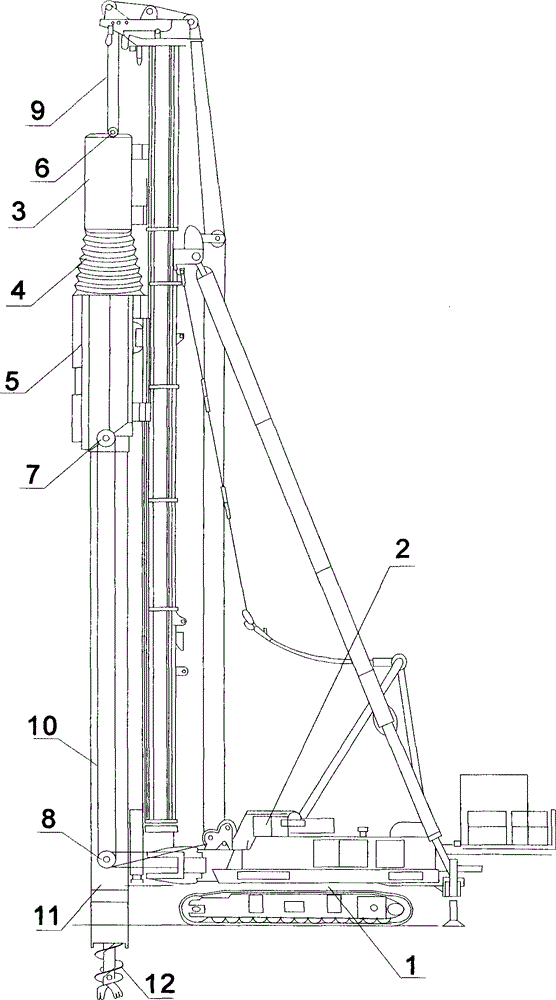

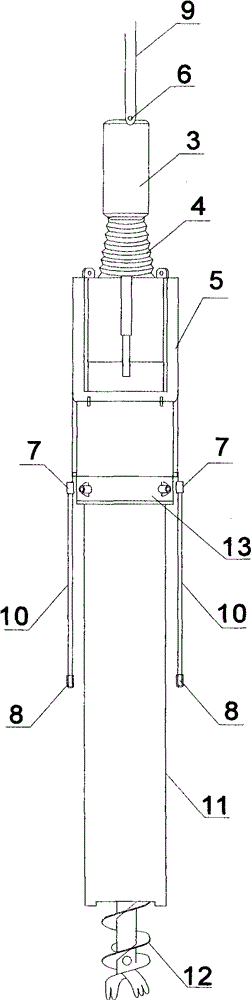

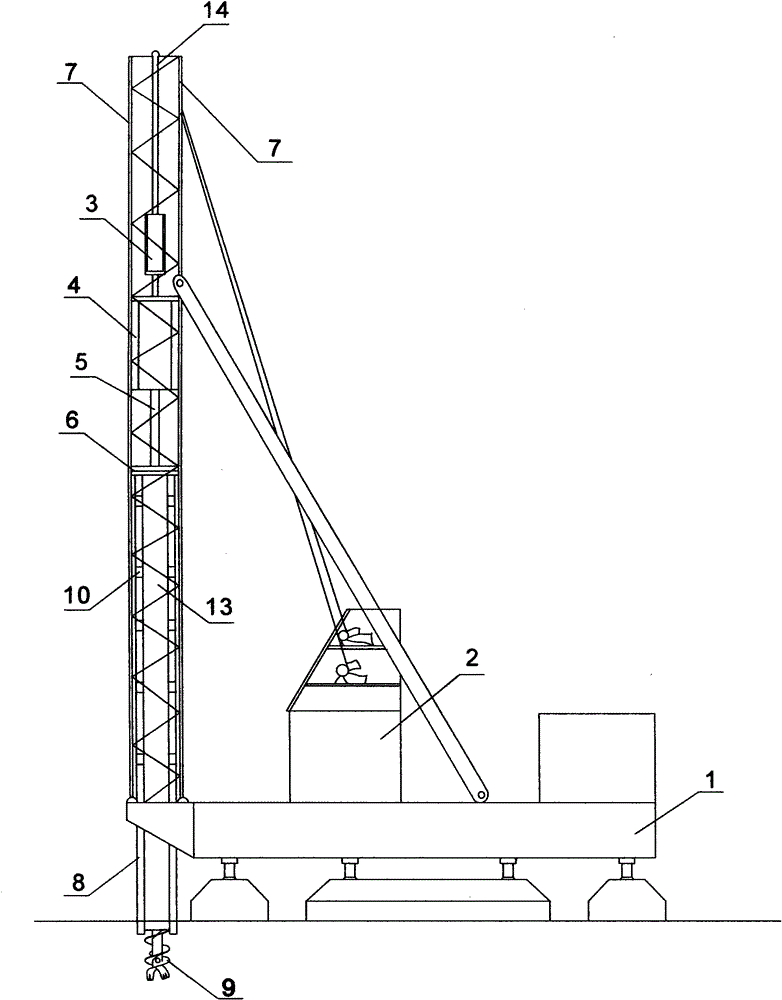

Direction-adjustable multifunctional inner-digging soil extraction pile planting device and construction method thereof

The invention discloses a direction-adjustable multifunctional inner-digging soil extraction pile planting device. The device comprises an airplane head, a power head, a soil storage box, a pile splicing device, a steel pipe and precast pile, a front support, an auxiliary support, a mast, a long spiral soil extraction drill, a crawler-type main engine, a rear support, a balance weight, a main winch, an adjustable middle support, a cab and an angle gauge. The airplane head is mounted at the top end of the mast and is connected with the crawler-type main engine through the main winch. The mast is connected with the crawler-type main engine through the adjustable middle support, and the mast and the adjustable middle support are arranged in an angle manner. The power head is mounted on the mast and is connected with a pulley at the top end of the airplane head through a steel wire rope. The steel wire rope drives the power head to move on a sliding rail of the mast. The soil storage box is mounted below the power head through an oil cylinder. The long spiral soil extraction drill is connected with the power head. The steel pipe and precast pile is connected with the soil storage box through the pile splicing device. The direction-adjustable multifunctional inner-digging soil extraction pile planting device has the advantages that construction is simple and convenient, the cost islow, the pile body construction length is large, and the effect is fast; no soil extrusion effect exists, and no influence is generated on surroundings; and direction-adjustable construction is achieved, and the application range is wide.

Owner:SHANGHAI CHENGDI CONSTR +1

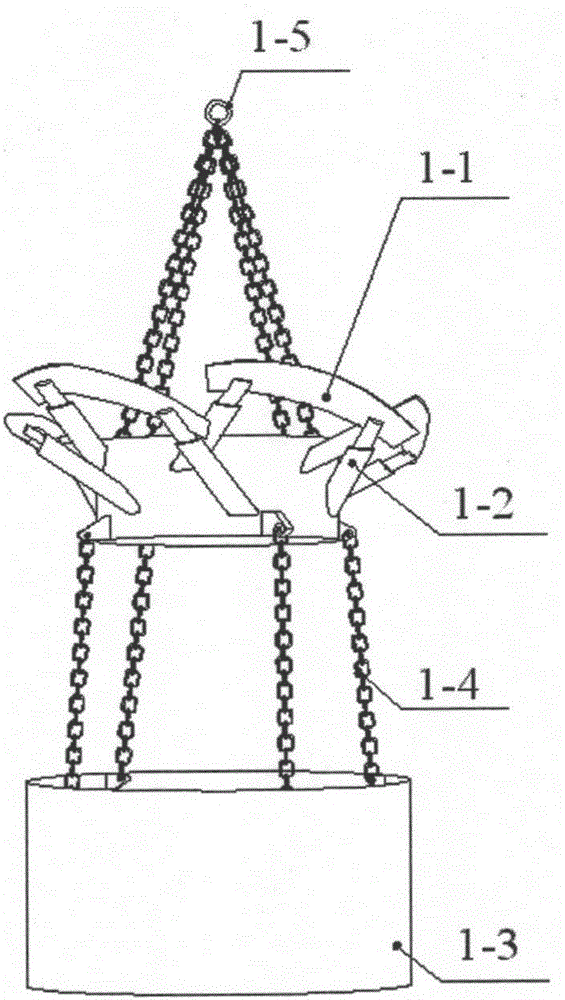

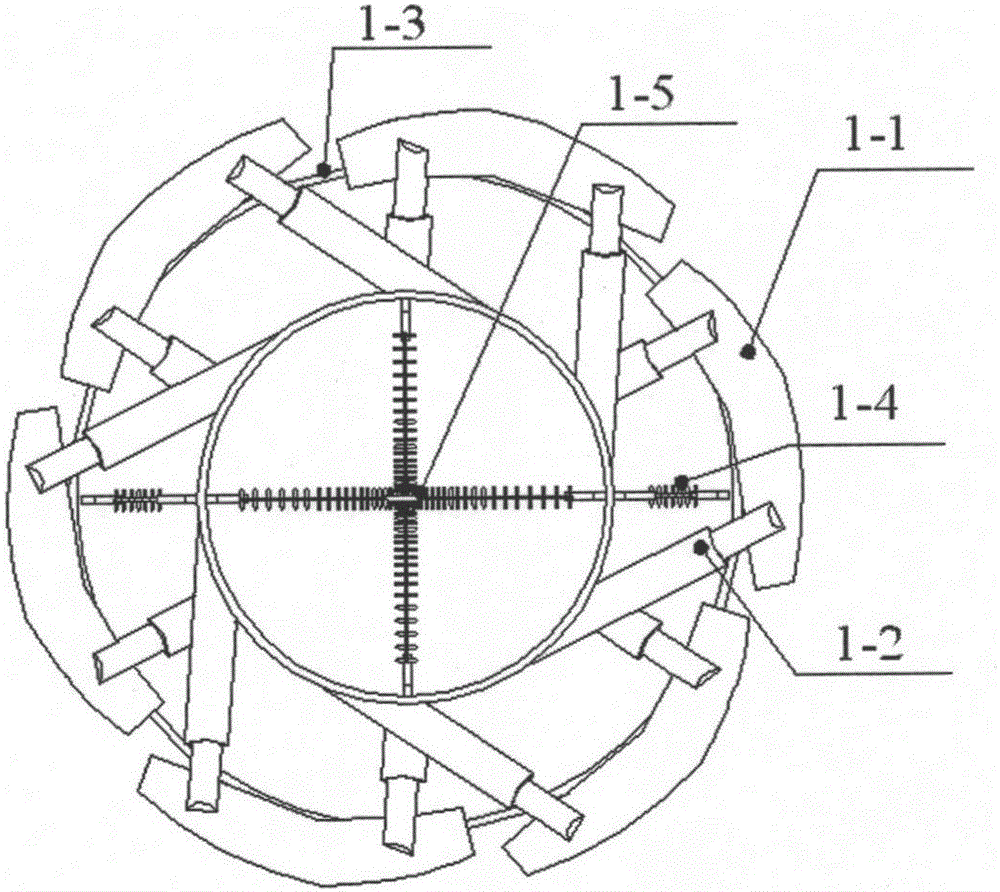

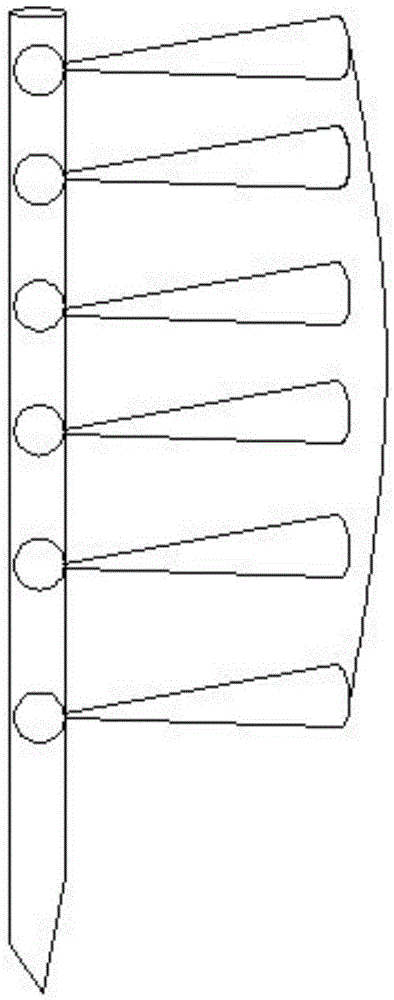

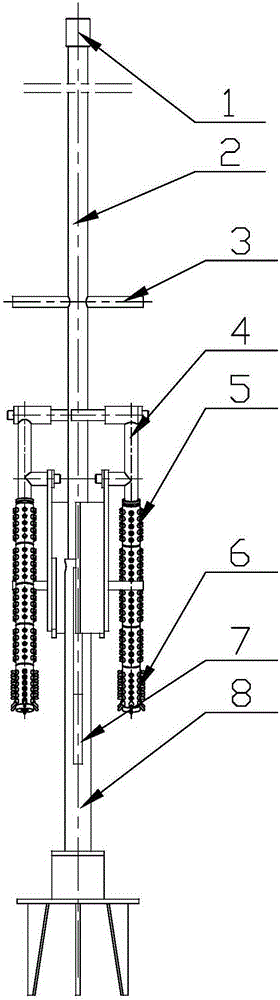

Retractable hole dilating drill and hole dilating technology

ActiveCN105178865AImprove bearing capacityGood shock resistanceDrill bitsDrilling machines and methodsRocker armDrill bit

The invention provides a retractable hole dilating drill and a hole dilating technology. The retractable hole dilating drill comprises a lifting rotating shaft and a rotary cutting device, wherein the upper end of the lifting rotating shaft is provided with a power connecting joint; the rotary cutting device comprises at least one rotary cutting rocker arm; a rotary cutting knife is arranged on the outer surface of the rotary cutting rocker arm; one end of the rotary cutting rocker arm is hinged to the lifting rotating shaft; an axis of a hinged position is perpendicular to an axis of the lifting rotating shaft; a retractable driving device for driving the rotary cutting rocker arm to rotate around the axis at the hinged position is arranged between the rotary cutting rocker arm and the lifting rotating shaft; and the maximum rotating angle of the rotary cutting rocker arm rotating around the axis at the hinged position is a blunt angle. Area of a portion, which is in contact with soil, of a pile end can be increased further by dilated holes, so that the bearing capacity of a pile foundation is increased further.

Owner:JINAN JIANGFUWAN AUTOMATION TECH

High substitution degree cyanoethyl cellulose and cellulose diacetate commixing hollow fibrous nano filter film and its preparation process

InactiveCN100335155CStable structure and performanceImprove interception effectSemi-permeable membranesFiberHollow fibre

The invention relates to a nano hollow fiber filtration membrane, which is prepared by: mixing and dissolving the material, such as HCEC, CA, acetone, dioxohexacyclic compound, hexacyclic dioxide, and alcohol or ethanol; filtering, defoaming, spinning to form, and post-treating. Wherein, the total of HCEC and CA mixture takes up 20-30% to total mass by mass ratio as 2-3:7-8, the acetone and hexacyclic dioxide solvent is 70-80%; alcohol or ethanol is 10-20% of HCEC and CA mixture by mass ratio as 0.8-1.2:1. This invention has well cutting flow performance, compressive resistance, acid and base resistance, and obtains water flux more than 3.50mL / (cm2.h), well desalinization ratio by bivalent salt more than 90% and monobasic salt ratio more than 60%.

Owner:GUANGDONG ZHONGKE GREEN SPRING WATER

Composite material for displaying latent fingerprint and preparation method thereof

InactiveCN108059954AGood biocompatibilityEasy to operateDiagnostic recording/measuringSensorsAlkaline earth metalFluorescence

The invention belongs to the technical field of light-emitting materials which contain beryllium, magnesium, an alkali metal or an alkaline-earth metal, and particularly relates to a composite material for displaying a latent fingerprint. The composite material for displaying the latent fingerprint is formed by compounding a gold nano-cluster and bovine serum albumin-supported montmorillonoid. Thecomposite material provided by the invention is safe and non-toxic, has high biocompatibility, and does not pollute a fingerprint carrier and a fingerprint residue when the latent fingerprint is displayed; the composite material can be excited by using ultraviolet light and visible light, and can also be excited by infrared light; the composite material effectively avoids background fluorescent interference, is beneficial to improvement of the quality of a fingerprint image, and avoids the damage of ultraviolet irradiation to the fingerprint carrier, a fingerprint substance and an operator; astreakline type (a first-grade characteristic) of a fingerprint and a general detail characteristic (a second-grade characteristic) of the fingerprint can be displayed, and a third-grade characteristic of the fingerprint, such as, sweat pores, can be displayed clearly; moreover, the stability is high.

Owner:喻彦林

Water supply and drainage device for energy-saving building construction

InactiveCN112275001AAvoid cloggingReduce the phenomenon of anti-cloudingStationary filtering element filtersWater filterMechanical engineering

The invention discloses a water supply and drainage device for energy-saving building construction. The water supply and drainage device comprises a supporting frame, a water treatment part and a driving mechanism. A spherical shell type water tank is arranged, an inlet is formed in the top of the spherical shell type water tank, a conical water filtering cover is arranged, the open end of the conical water filtering cover is located in the spherical shell type water tank and is in rolling fit with the inner wall of the spherical shell type water tank, and a bearing column is arranged in the middle of the conical water filtering cover and is in spherical hinge connection with the spherical center of the spherical shell type water tank, wherein a conical spiral guide rod is arranged at thebottom of the spherical shell type water tank, a rotating arm is arranged at the lower part of the spherical shell type water tank, the rotating arm is in contact with the conical spiral guide rod through a groove-shaped wheel, and the rotating arm rotates to drive the spherical shell type water tank to move around a sphere center;when the inlet on the spherical shell type water tank is in an inclined position, the conical water filtering cover is partially detached from the inlet, therefore, filtered large-particle impurities can be discharged, and the effects of filtering the large-particleimpurities and continuously discharging the large-particle impurities are achieved.

Owner:王婷

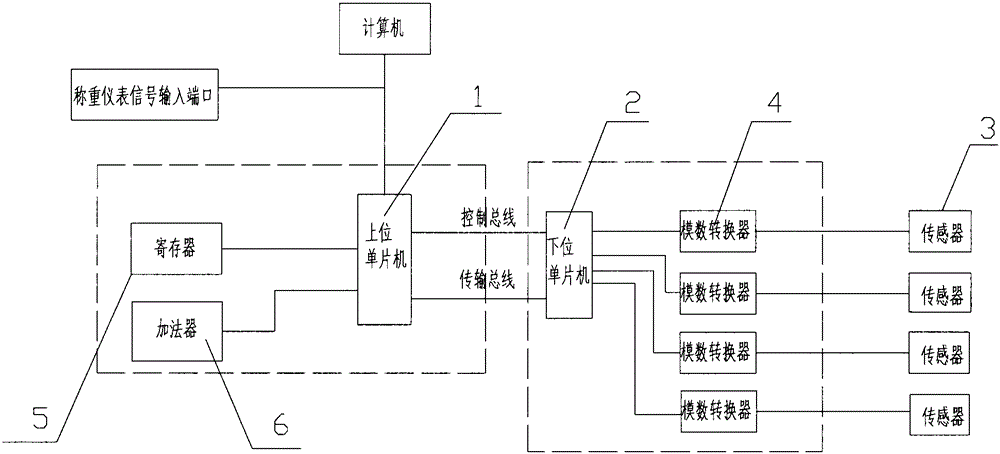

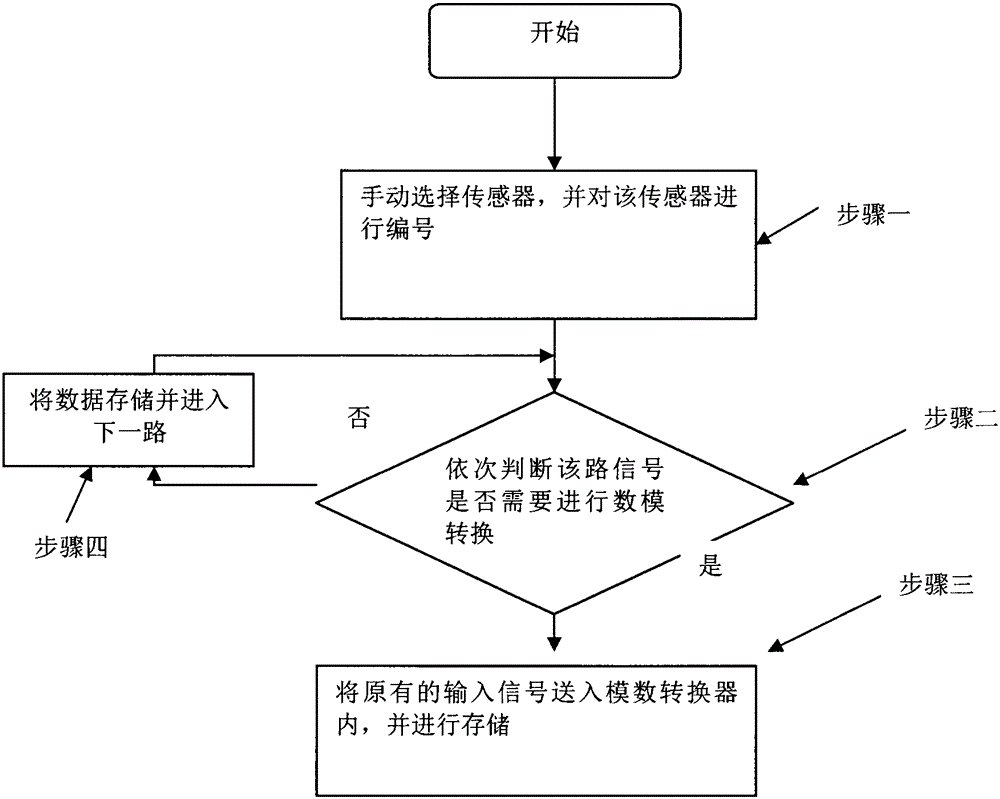

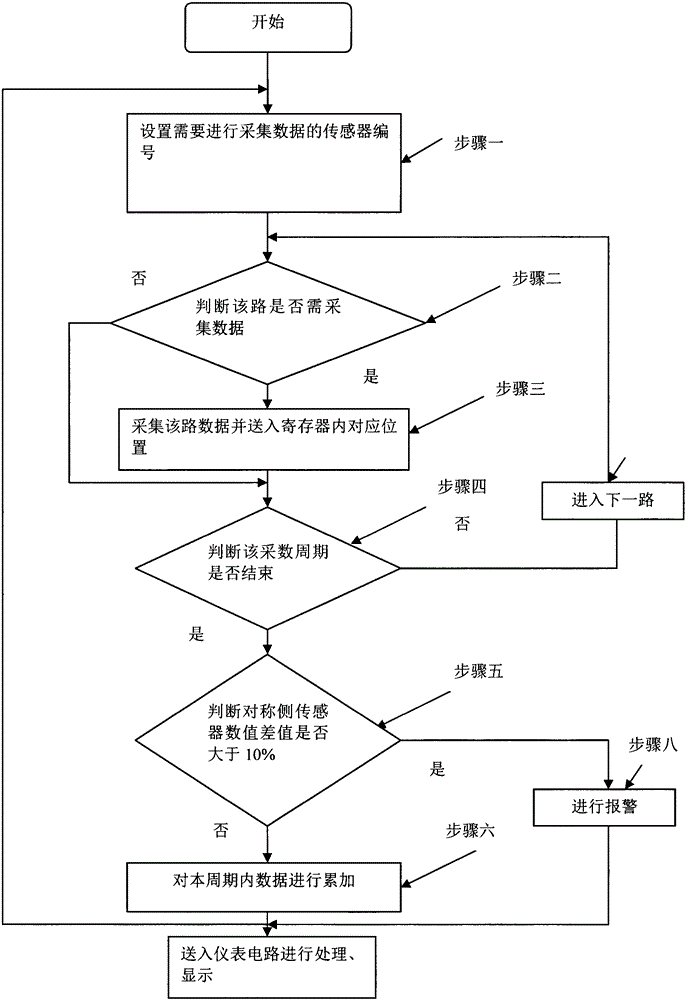

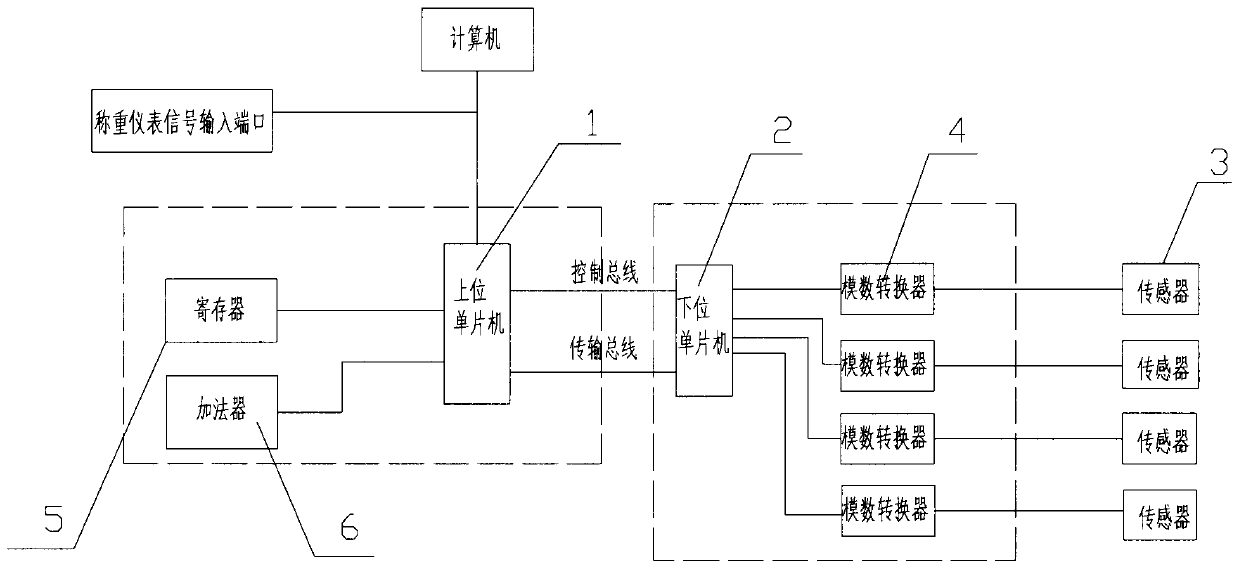

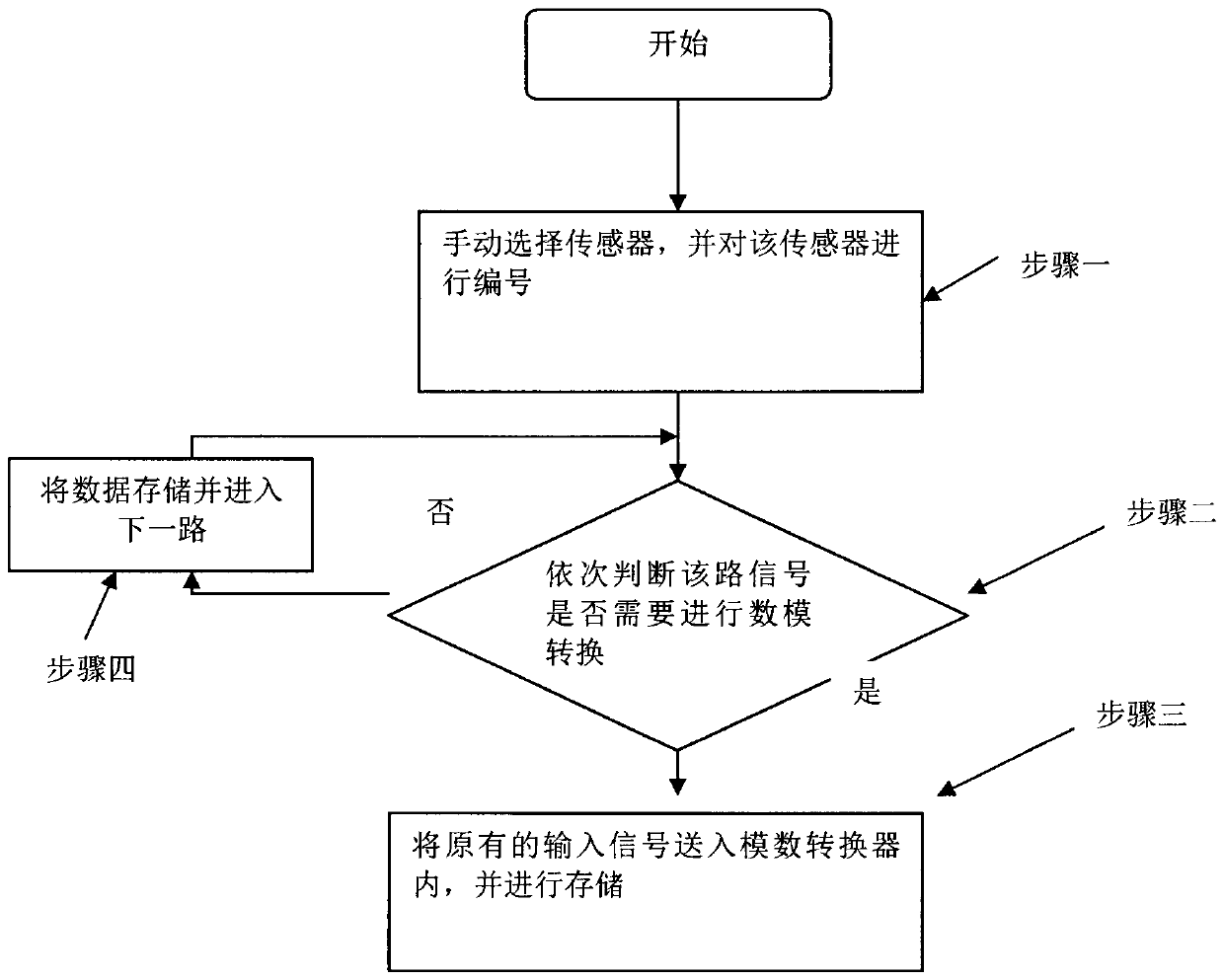

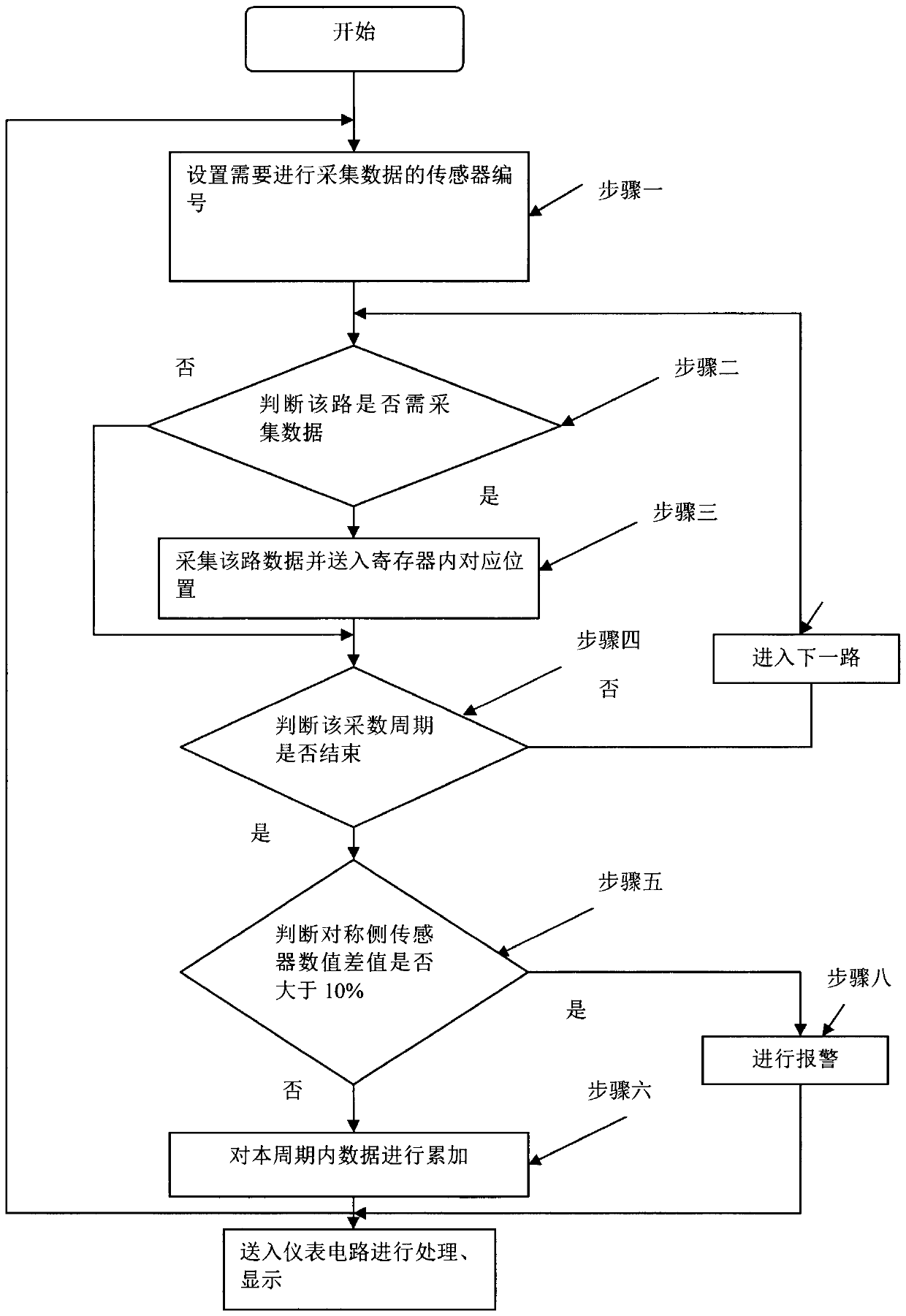

Multi-channel mixing type weighing system and method for multi-sensor weighing device

ActiveCN106153166AMeet different requirements of accuracyWrong positionWeighing apparatusElectricityMicrocontroller

The invention relates to a multi-channel mixing type weighing system for a multi-sensor weighing device. The multi-channel mixing type weighing system for the multi-sensor weighing device comprises an upper singlechip and a lower singlechip, wherein the upper singlechip and the lower singlechip are electrically connected with each other through a control bus and a transmission bus; the lower singlechip is electrically connected with four sensors for sensing the weight of an object on the weighing system; an analog-to-digital converter which is used for converting analog signals to digital signals is arranged between each sensor and the lower singlechip; the lower singlechip and the analog-to-digital converter form an analog-to-digital matcher system; each analog-to-digital converter is arranged between the corresponding sensor and the corresponding lower singlechip; the upper singlechip is electrically connected with a register for registering data; and the upper computer is electrically connected with an adding device which is used for processing weighing data signals.

Owner:刘嘉伟

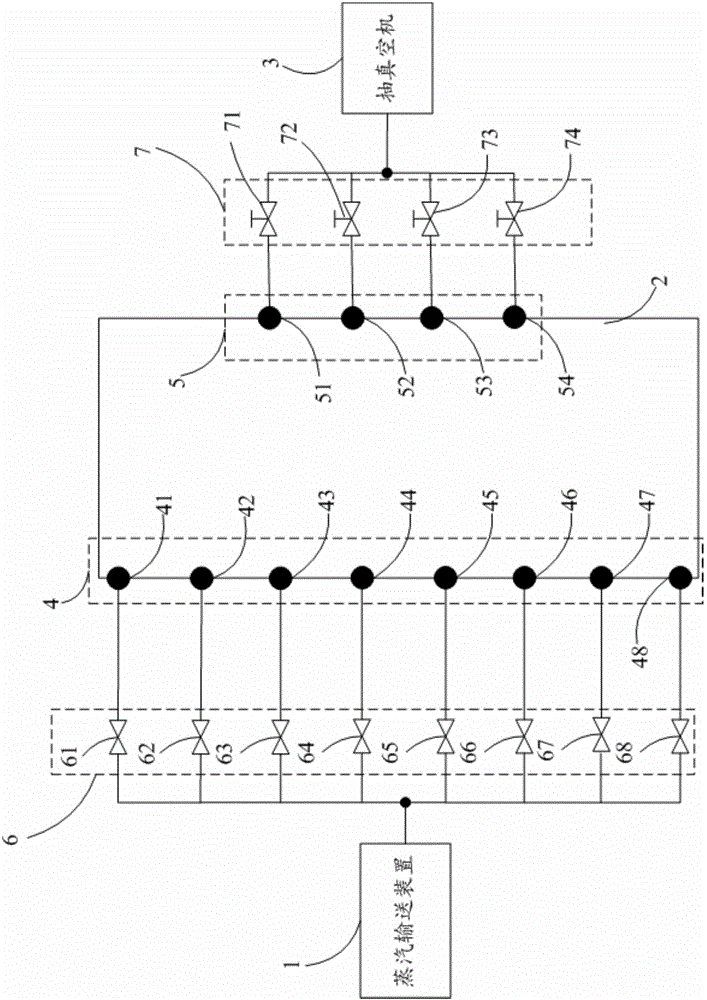

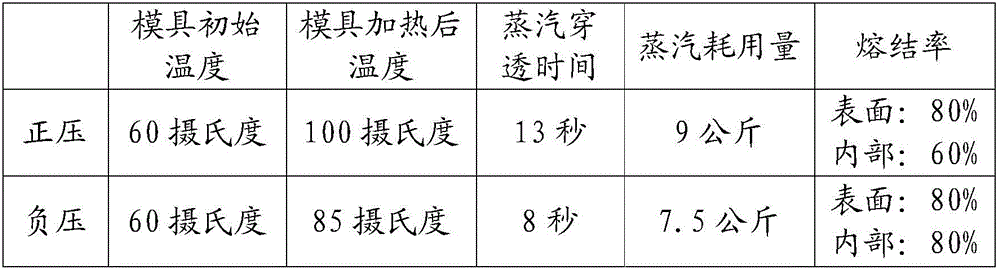

EPS vacuum forming process and forming system

The invention discloses an EPS vacuum forming process and forming system. The forming process comprises a heating procedure, wherein in the heating procedure, high-temperature and high-pressure steam is injected into a mold from steam holes in one side wall of the mold; meanwhile, through vacuum holes which communicate with the steam holes and are positioned in the other side wall, relative to the above side wall, of the mold, vacuum pumping treatment is performed on the interior of the mold, thereby forming a negative pressure difference between two relative sides of the mold; the steam linearly penetrates through the mold through the steam holes in one side wall of the mold, and reaches the vacuum holes on the other side, relative to the above side wall, of the mold; and when the steam linearly penetrates through the interior of the mold, the mold and EPS beads in the mold are heated. The EPS vacuum forming process and forming system have the advantages that a linear negative-pressure penetrating mode is adopted, thereby saving the penetrating time, reducing the heat exchange amount, and lowering the steam consumption; the linear penetrating speed is high, and the steam pressure almost remains unchanged in the penetrating process; and accordingly, almost no hardening phenomenon occurs on the surface of a formed EPS foam finished product, and the internal clinkering property is more excellent.

Owner:HUIZHOU JINGHUA PACKAGING PROD CO LTD

A kind of homogenizer for waste slurry water in mixing station

ActiveCN112430002BStrong repulsionInhibition dispersionScale removal and water softeningWastewaterSlurry

The invention belongs to the technical field of concrete functional additives, in particular to a leveling agent for mixing plant waste slurry water. prepared from raw materials. The leveling agent for waste slurry water is liquid at room temperature, has good homogeneity, meets the relevant standards for admixtures for concrete, can effectively improve the workability, compressive strength and impermeability grade of the obtained concrete, and reduces its bleeding It has important economic and environmental benefits to realize the recycling and reuse of wastewater from mixing plants.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

Pile sinking device and pile sinking method for prestressed centrifugal pipe piles with mid-digging reverse pull method

The invention discloses a device for sinking a pre-stressed centrifugal pipe pile (square pile) with an in-pile boring and reverse drawing method. The device comprises a host, a winch, a power head, a soil taking box, a pulley and a wire rope, wherein the winch is arranged on the host; the power head is arranged on the host; the lower part of the power head is connected with a soil taking drill stem; the lower end of the soil taking box is connected with a pile cap; the lower end of the pile cap is provided with a centrifugal pipe pile (square pile); and the soil taking drill stem penetrates through the soil taking box and the centrifugal pipe pile (square pile) to reach the bottom of the device. The invention also provides a method for sinking the pre-stressed centrifugal pipe pile (square pile) with the in-pile boring and reverse drawing method; and the method comprises the following steps of: firstly, moving the host to a pile pressing position; taking soil through the soil taking drill stem; meanwhile, pressing the pile through the pile cap; recovering the soil through the soil taking box while taking soil; pressing into a first pile and then connecting a second pile; and continuously performing said steps. The device and the method have the advantages of safety, reliability, low cost, high benefit, no noise, no pollution, no extruded soil, no mud, environmental friendliness and the like.

Owner:SHANGHAI CHENGDI CONSTR

Method for extracting propolis by simulative biological fluid bed supercritical CO2 fluid

The invention provides a method for extracting propolis by simulative biological fluid bed supercritical CO2 fluid, which comprises that: bran (or rice bran and the like) taken as biomembrane carrier and original gum particles after physical treatment simulate a fluid bed in an extraction kettle to perform gridded filling, the supercritical CO2 fluid is used for extraction, and the lowest speed of a granular bed converting from a stationary state to fluidization is regulated by regulating temperature, pressure and flow rate of the fluid in the extraction process so as to reach the critical fluidization state; therefore, high-quality and high-yield propolis extract is obtained through a cyclic process of fluidization diffusion, dissolution and separation between granules and the fluid. The method improves the yield of the propolis extract, reduces the cost, and extracts nearly all terpene compounds and 40 to 50 percent of flavonoid compounds in the propolis at the same time; and products do not have organic solvent.

Owner:JIANGSU JIANGDAYUAN ECOLOGICAL BIOLOGICAL TECH

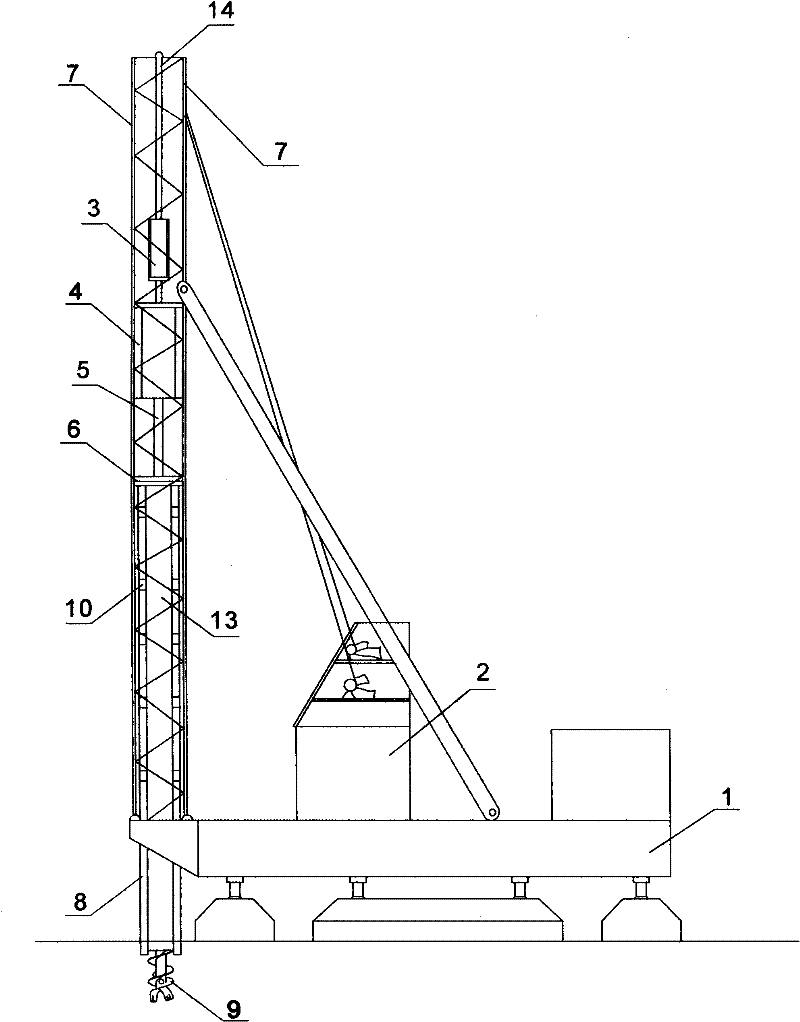

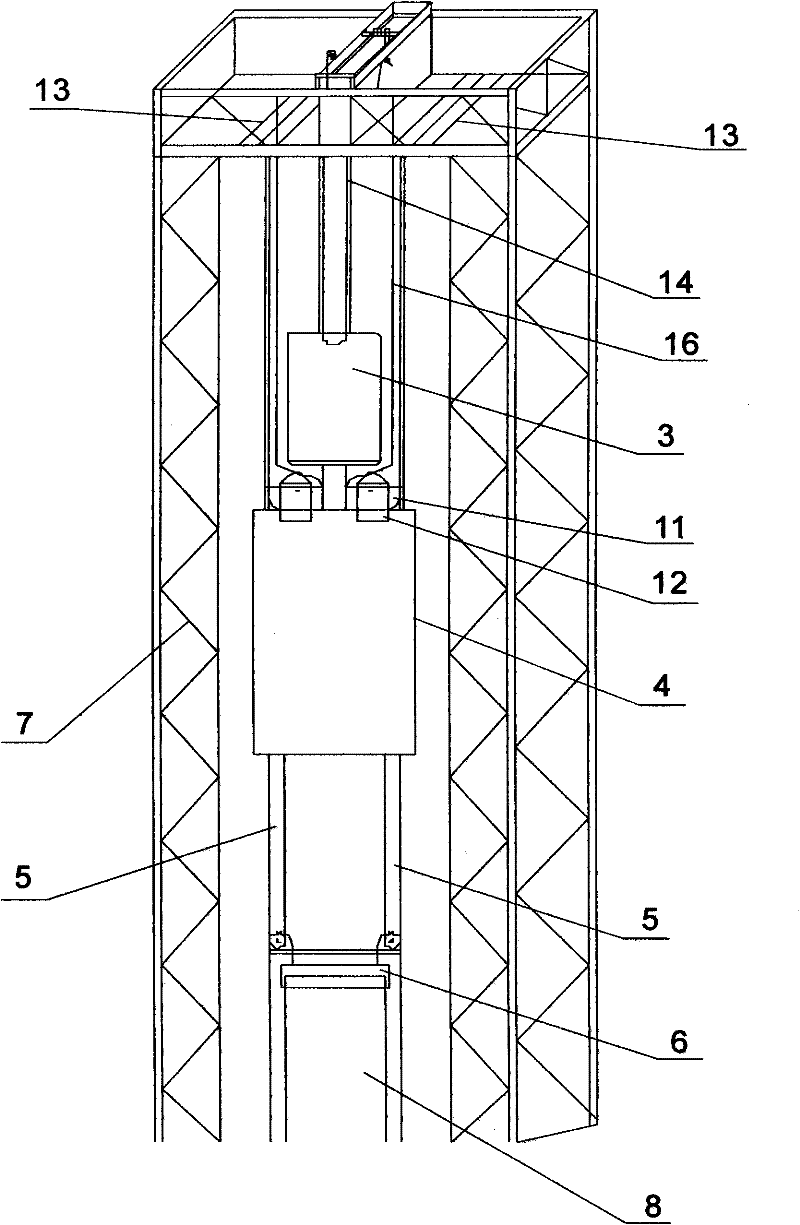

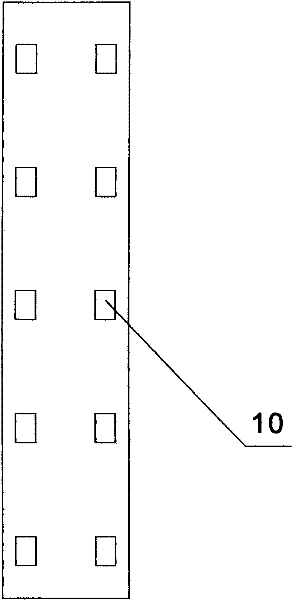

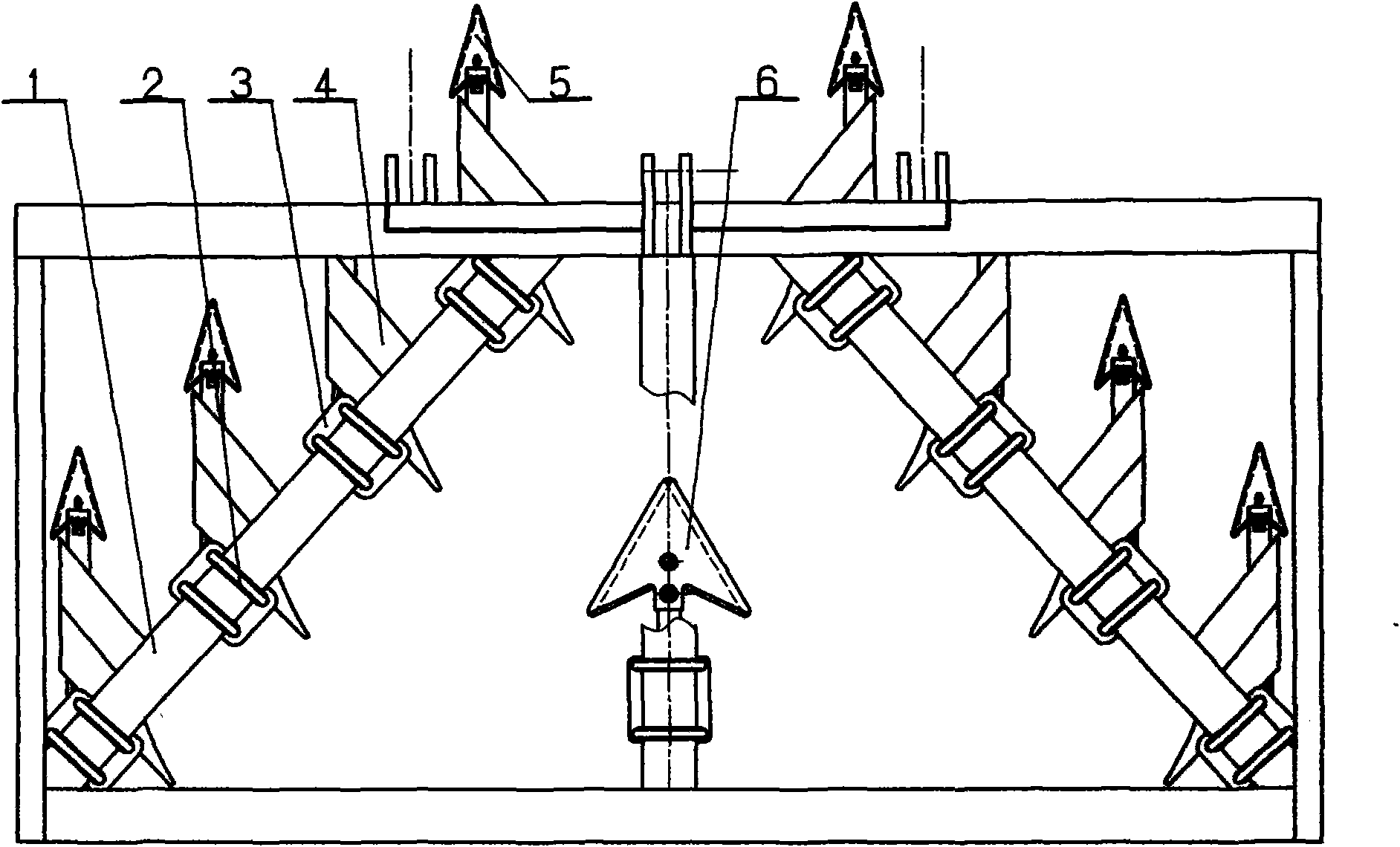

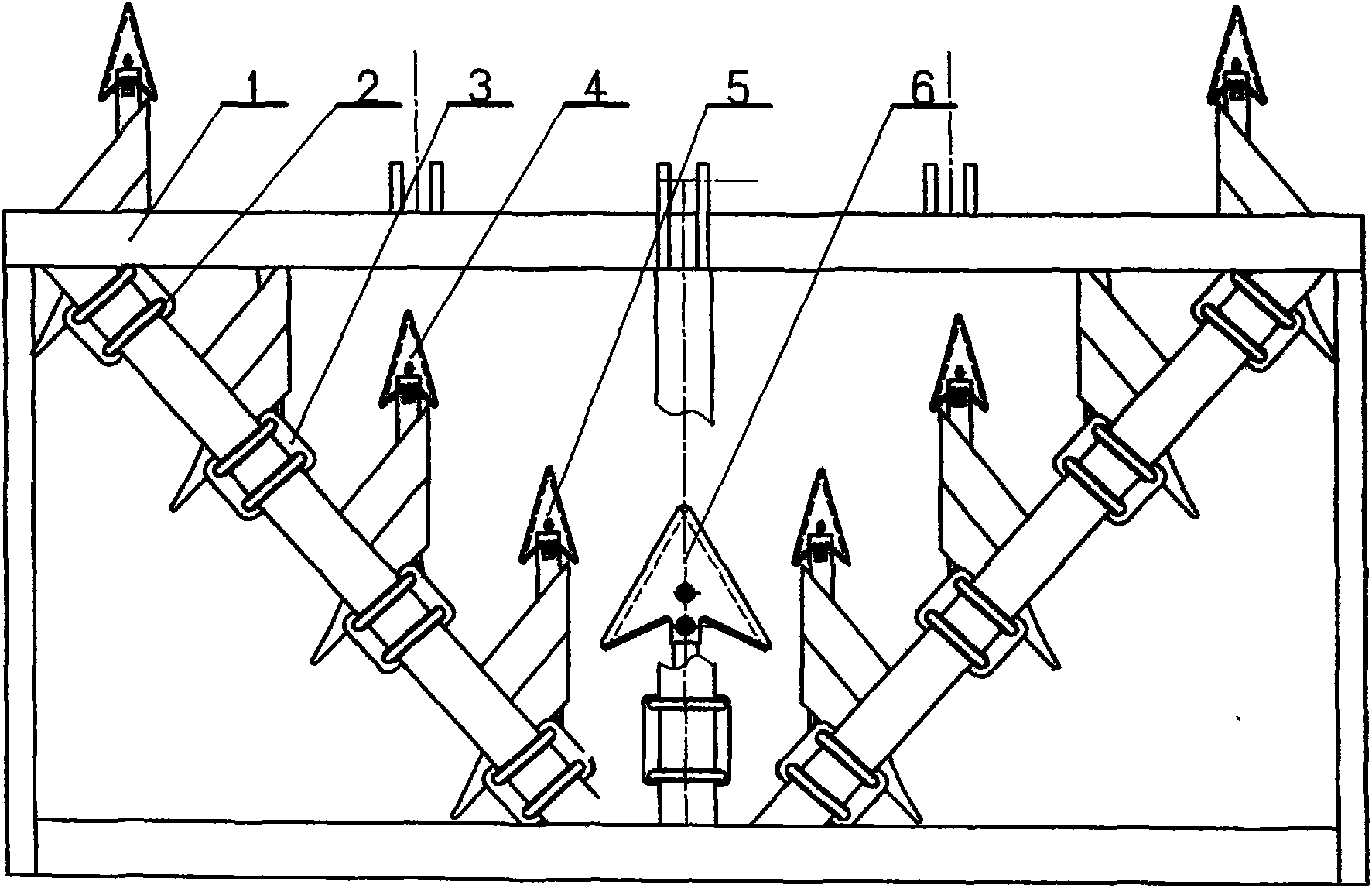

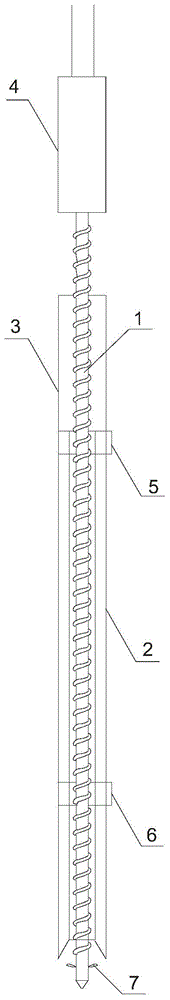

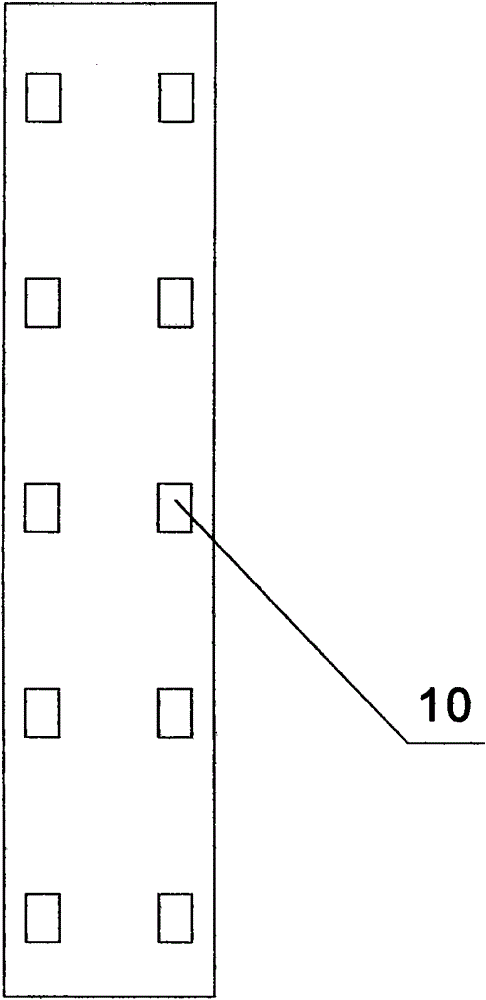

A middle digging pile sinking device for large-diameter pipe piles

ActiveCN102383429BReduce security costsImprove efficiencyDrilling rodsDrilling casingsPower equipmentEngineering

The invention discloses an intermediate digging and sinking device for a large-diameter pipe pile, which comprises an auger drill rod, a pipe pile, a soil storage box and a power head. The pipe pile is a cylinder with a circular through hole in the middle, and the lower part of the pipe pile The two sides of the top are set in the shape of sharp knives, the auger rod is inserted into the pipe pile, the upper end of the auger rod is connected to the power head, and the lower end is connected to a reverse-wing expansion bit, and the upper end of the pipe pile is provided with the above-mentioned soil storage box. An intermediate support is inserted into the connection between the pile and the soil storage box, and the intermediate support is fixed with the column of the external power equipment to stabilize the pipe pile. A certain part of the lower part of the pipe pile is provided with a lower support. The column of the equipment is fixed to stabilize the pipe pile. The power head is connected with the wire rope on the rotating wheel of the external power equipment. The invention has the advantages of stability, safety, low cost, high benefit, no pollution, no noise, no soil extrusion, environmental protection and the like.

Owner:SHANGHAI CHENGDI CONSTR

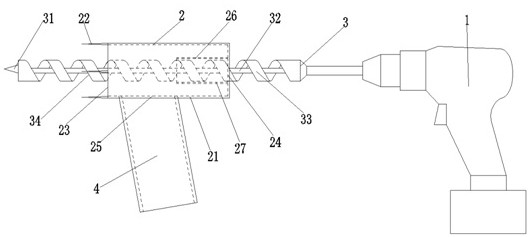

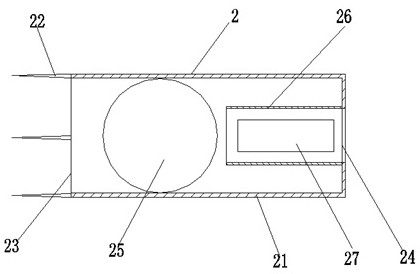

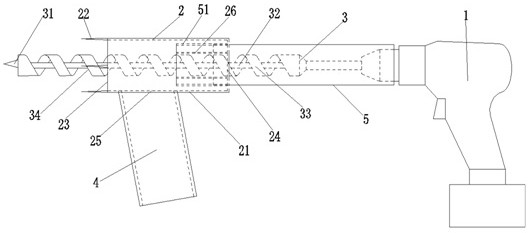

Hay sampling device

The invention discloses a hay sampling device which comprises an electric drill, a sampling barrel and a drill rod, the drill rod is detachably arranged on the electric drill, and the electric drill can drive the drill rod to rotate; the drill rod comprises a tip part, a shaft rod and a spiral conveying part, the tip part is arranged at one end of the shaft rod, the spiral conveying part spirally extends in the axial direction of the shaft rod, the sampling barrel comprises a barrel body and a plurality of fixing sharp feet, a first opening, a second opening and a discharging port are formed in the barrel body, and the fixing sharp feet are arranged on the first opening side of the barrel body; the drill rod tip part, the shaft rod and the spiral conveying part can penetrate through the barrel and the first opening through the second opening, the second opening is connected with the guide sleeve, and the guide sleeve is arranged in the barrel. The hay sampling device is high in sampling speed and large in single sampling amount, hay samples are easy to collect and not prone to leaking and scattering, and operation is easy and convenient.

Owner:河北省畜牧兽医研究所

Biological mildew removing agent and application thereof

PendingCN114128785AImprove antioxidant capacityThe effect of coordination promotion is obviousFood preservationAnimal feeding stuffBiotechnologyMicrobiology

The invention relates to the technical field of A01P1, in particular to a biological mildew removing agent and application thereof. The biological mildew removing agent is prepared from the following components in parts by weight: 50 to 70 parts of plant powder and 32 to 45 parts of yeast immune polysaccharide. The biological mildew removing agent has the advantages of excellent environment resistance, obvious antibacterial and mildew removing effects, and excellent storage stability and usability.

Owner:南京正农威生物技术有限公司

Pile sinking device and pile sinking method for prestressed centrifugal pipe piles by hydraulic method in middle excavation

Owner:SHANGHAI CHENGDI CONSTR

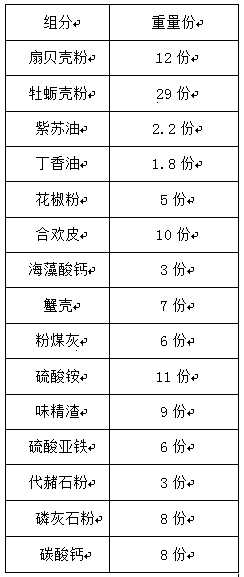

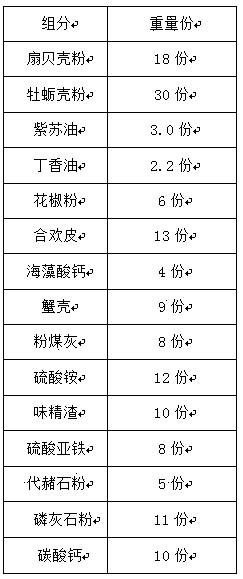

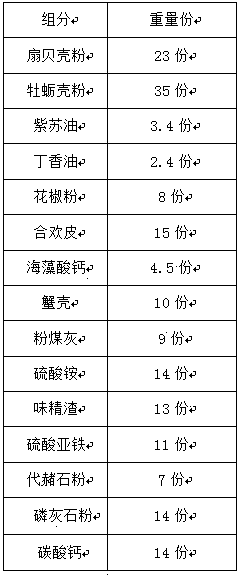

Long-acting shellfish-algae soil conditioner and preparation method therefor

The invention provides a long-acting shellfish-algae soil conditioner. The soil conditioner contains the following ingredients: scallop shell powder, oyster shell powder, perilla frutescens oil, clove oil, pericarpium zanthoxyli powder, cortex albiziae, calcium alginate, crab shells, pulverized coal ash, ammonium sulfate, monosodium glutamate residue, ferrous sulfate, raddle powder, ground phosphorite and calcium carbonate. The soil conditioner provided by the invention has a good impervious soil amendment effect; after amendment, soil has the total porosity of 55-60%, the soil retention of 17.5-18.1%, the average grain size of 2.1-2.6mm, the pH of 6.9-7.1 and the volume weight of 1.40-1.45g / cm<3>; and the effect holding time reaches 3 years.

Owner:潍坊欧普诺生物科技有限公司

A kind of multi-channel mixed weighing system and method for multi-sensor weighing instrument

ActiveCN106153166BMeet different requirements of accuracyWrong positionWeighing apparatusMicrocontrollerElectricity

The invention relates to a multi-channel mixing type weighing system for a multi-sensor weighing device. The multi-channel mixing type weighing system for the multi-sensor weighing device comprises an upper singlechip and a lower singlechip, wherein the upper singlechip and the lower singlechip are electrically connected with each other through a control bus and a transmission bus; the lower singlechip is electrically connected with four sensors for sensing the weight of an object on the weighing system; an analog-to-digital converter which is used for converting analog signals to digital signals is arranged between each sensor and the lower singlechip; the lower singlechip and the analog-to-digital converter form an analog-to-digital matcher system; each analog-to-digital converter is arranged between the corresponding sensor and the corresponding lower singlechip; the upper singlechip is electrically connected with a register for registering data; and the upper computer is electrically connected with an adding device which is used for processing weighing data signals.

Owner:刘嘉伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com