Retractable hole dilating drill and hole dilating technology

A technology of reaming drill bit and rotary head, which is applied in the direction of drill bit, drilling equipment, earthwork drilling and mining, etc. It can solve the problems that cannot meet the requirements of pile foundation bearing capacity, etc., and achieve adjustable reaming diameter, improved pull-out resistance, and earthquake resistance. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

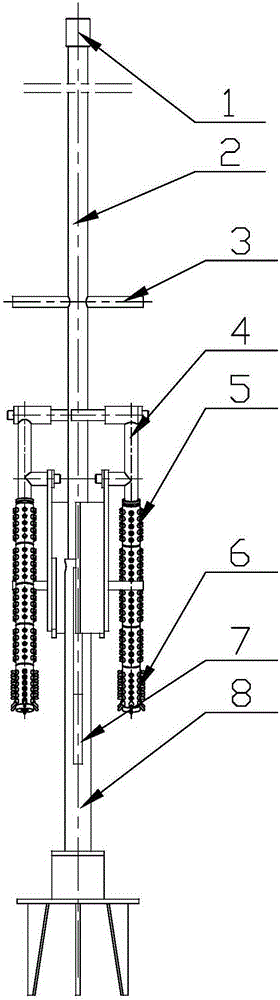

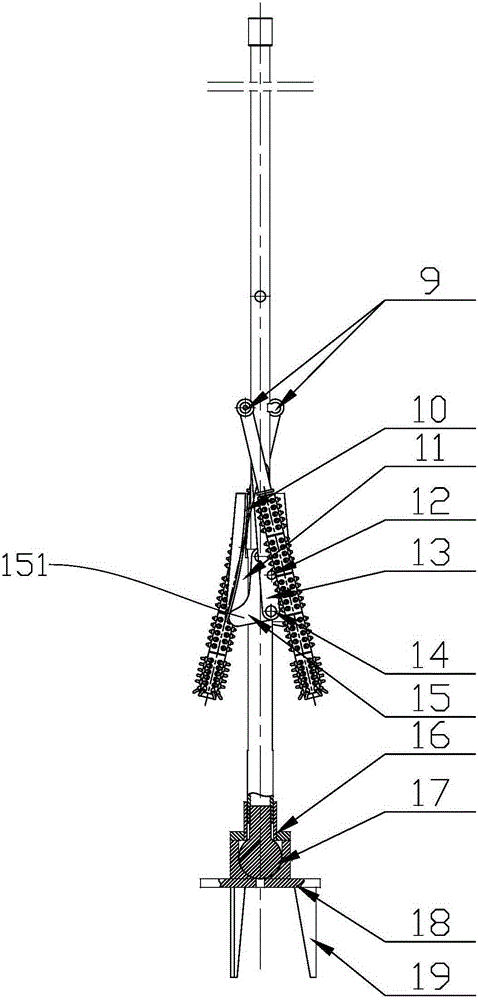

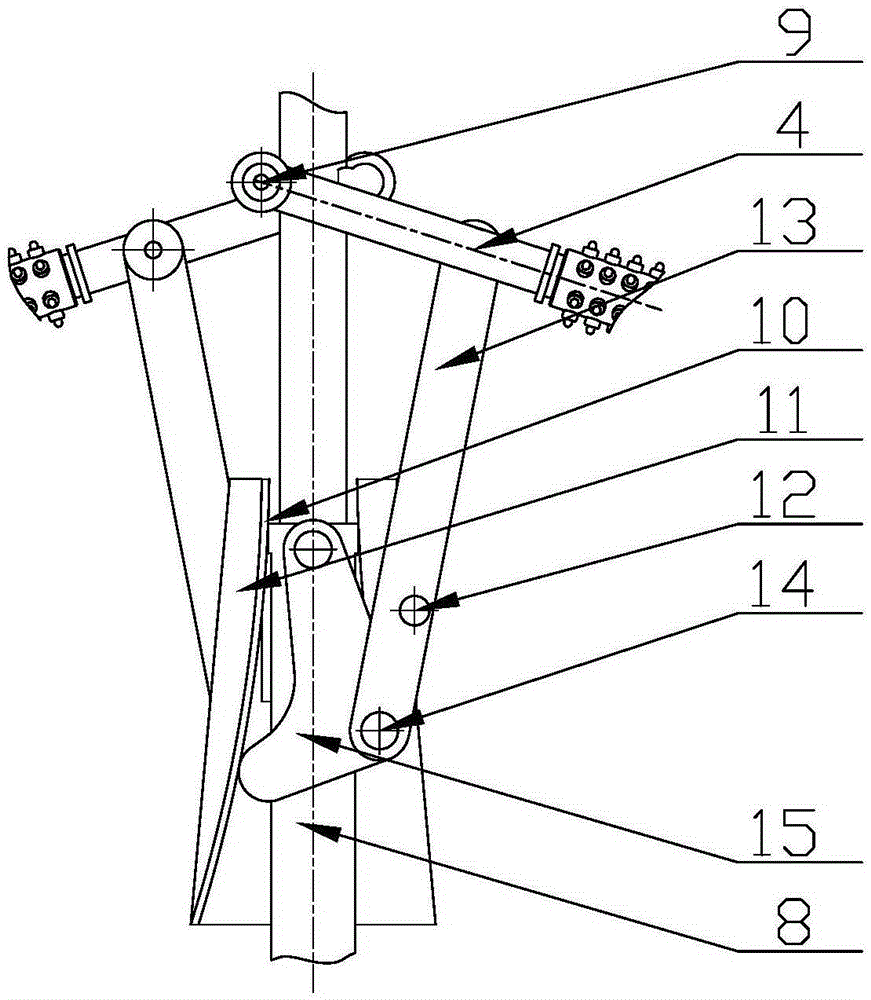

[0067] Such as Figure 1-5 As shown, the extended reaming drill mainly includes a lifting rotating shaft 2 and a rotary cutting device.

[0068] The upper end of the lifting rotating shaft 2 is set as a power connection joint 1 .

[0069] The rotary cutting device includes at least one rotary cutting arm 4, and a rotary cutting knife is arranged on the outer surface of the rotary cutting arm 4. One end of the rotary cutting arm 4 is hinged on the lifting rotating shaft, the hinge is the first hinged shaft 9, and the first hinged shaft 9 is perpendicular to the lifting rotating shaft 2. Between the rotary cutting arm 4 and the lifting rotating shaft 2, there is a telescopic drive device that drives the rotary cutting arm to rotate around the first hinge axis 9, and the maximum angle that the rotary cutter arm 4 rotates around the first hinge axis 9 is an obtuse angle. The telescopic driving device described in this embodiment is realized by using a mechanical structure.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com