Pile sinking device and method for middle digging pulling-anchoring method pre-stressed centrifugal pipe pile (square pile)

A technology of prestressing and anchoring device, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of difficult quality assurance, high cost and high construction cost, and achieve the effect of ensuring safety, low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

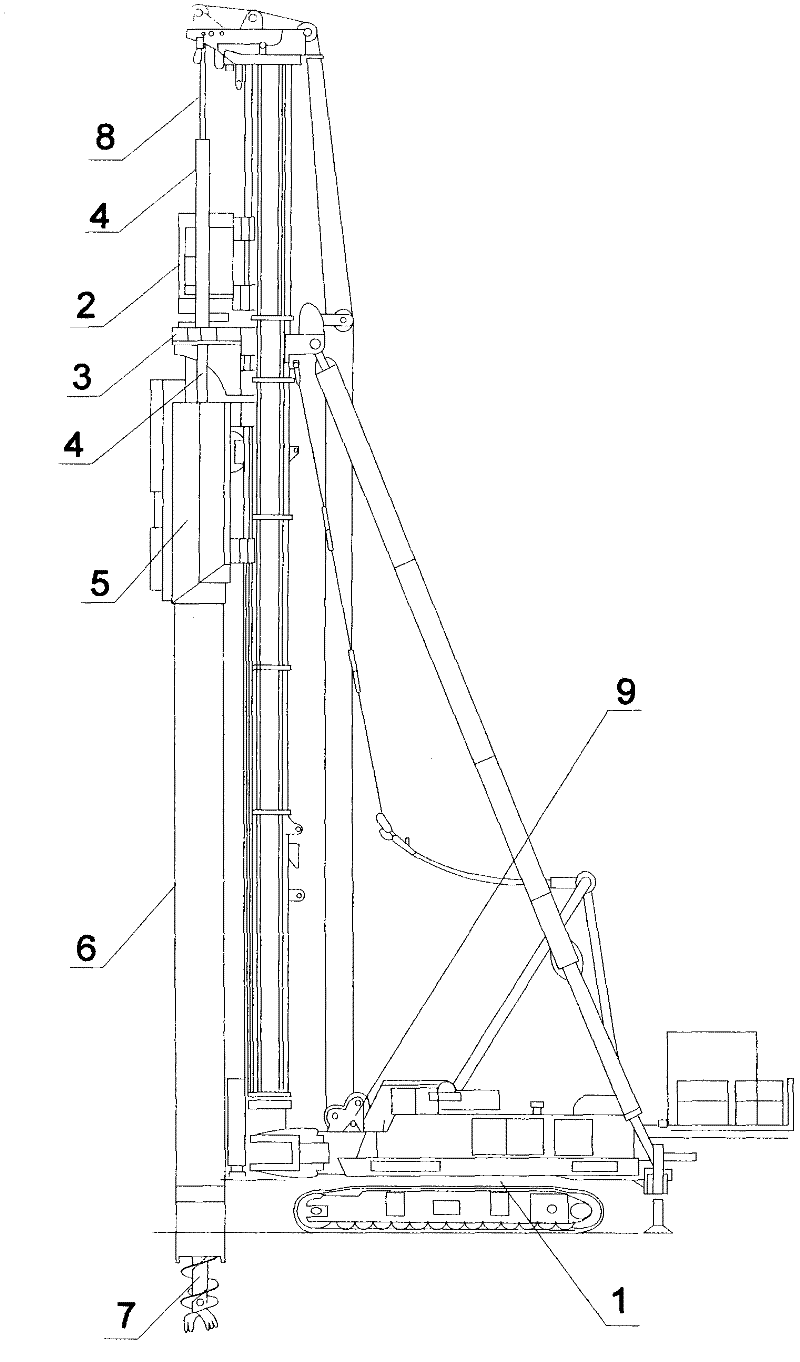

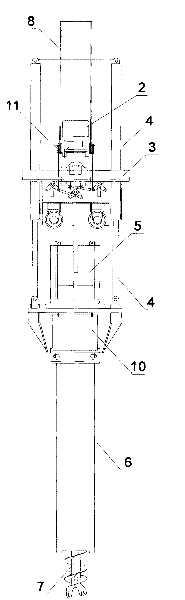

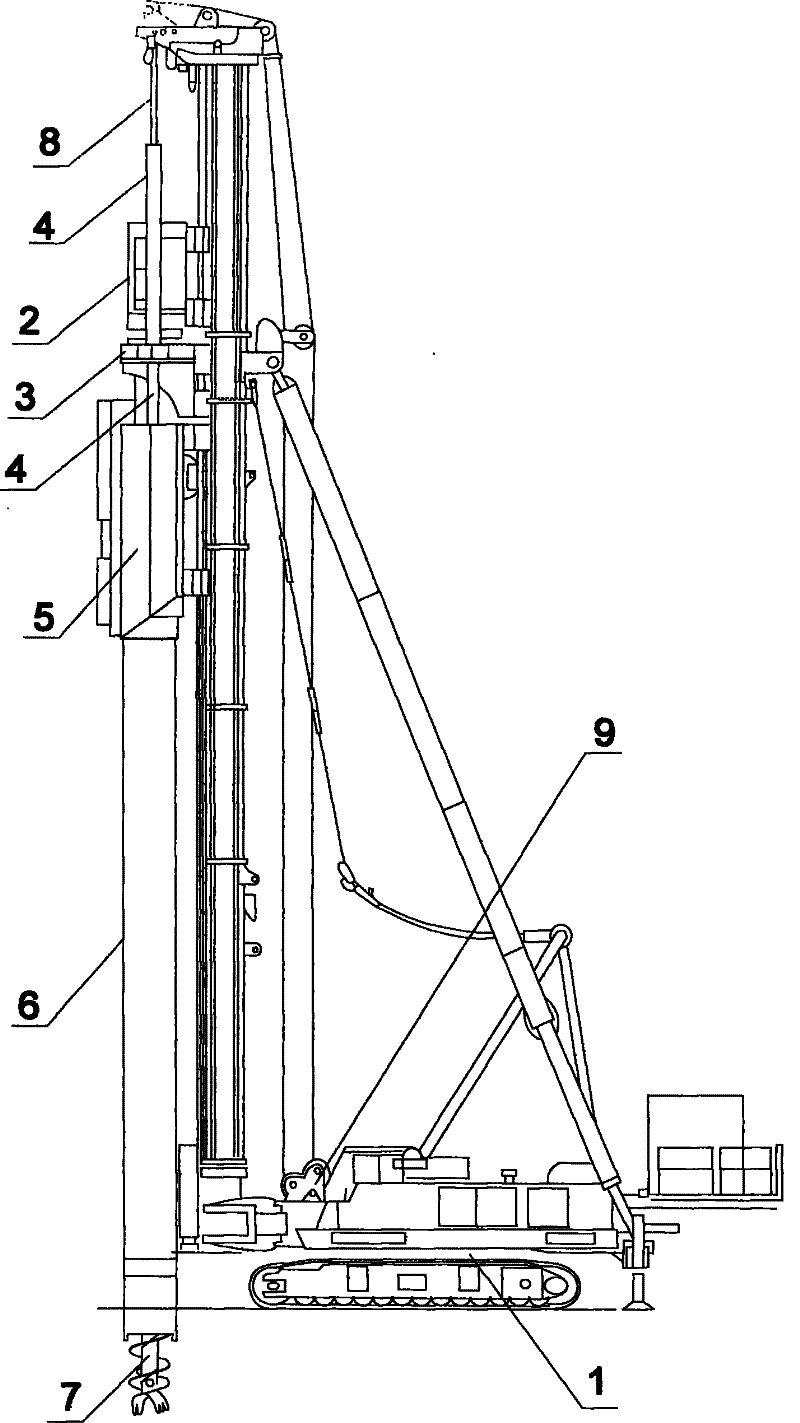

[0026] Such as Figure 1-2 Shown is a prestressed centrifugal tubular pile (square pile) pile sinking device with mid-digging and anchoring method, including a main engine 1, a winch 9 installed on the main engine, a power head 2, a hydraulic anchor pulling device 3, a press-in oil cylinder 4, Soil-borrowing box 5, pulley 11, steel wire rope 8, described power head 2, recovery box 5, oil pressure anchor device 3 are installed on the main engine 1, and described power head 2 upper end is equipped with pulley 11, and described pulley 11 is connected with a steel wire rope 8, the steel wire rope 8 is connected to the hoist 9 through the top of the host machine 1, the bottom of the power head 2 is connected to the soil-borrowing drill pipe 7, and the soil-borrowing drill pipe 7 is pulled through the oil pressure Anchor device 3, soil borrow box 5, pile cap 10, centrifugal pipe pile (square pile) 6 reach the bottom of the device, the oil pressure anchor device 3 is fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com