A kind of homogenizer for waste slurry water in mixing station

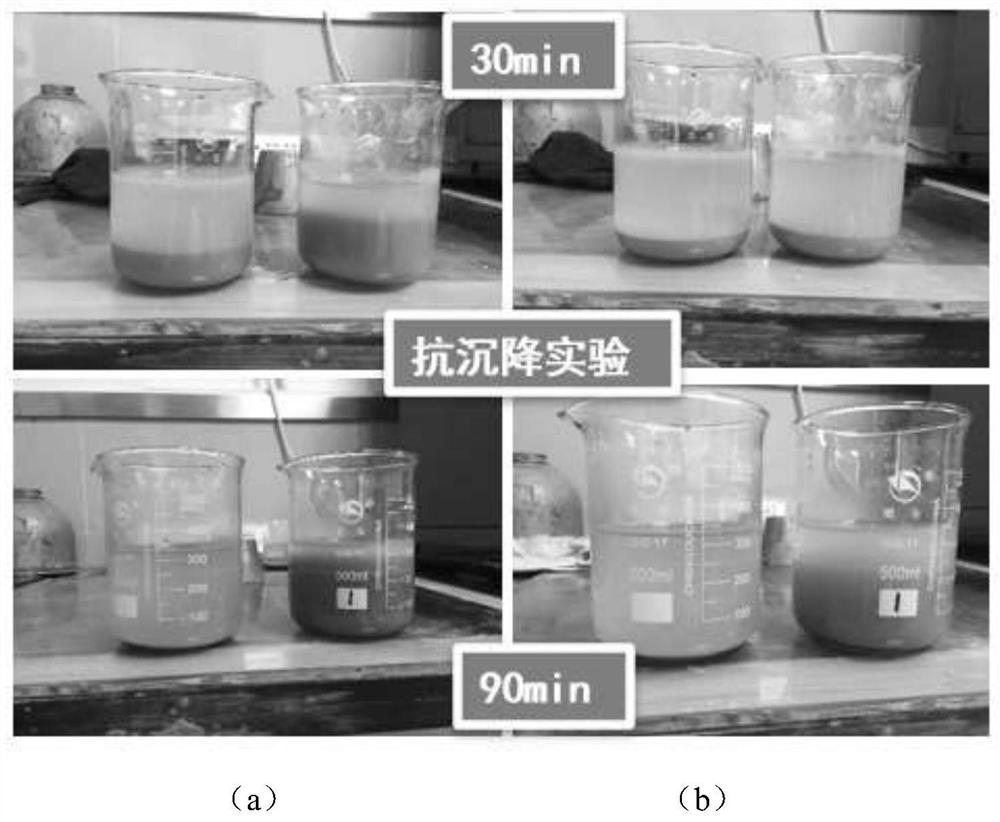

A technology of mixing station and leveling agent, which is applied in the field of leveling agent for waste slurry water in mixing stations, can solve the problems of increased processing difficulty, blockage of sewers, waste slurry water discharge, etc., to improve work performance and mechanical properties, The effect of inhibiting agglomeration and high alkalinity of waste pulp water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

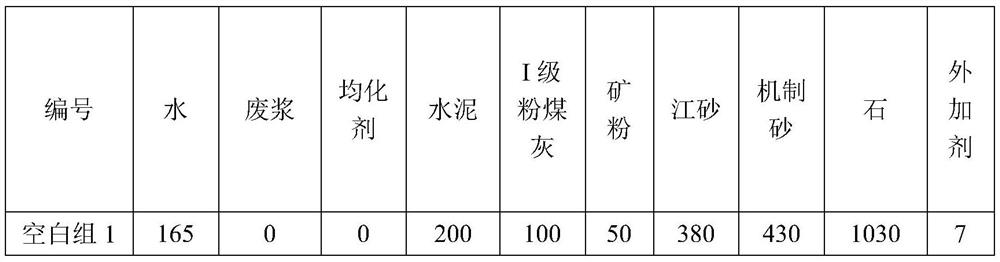

Embodiment 1

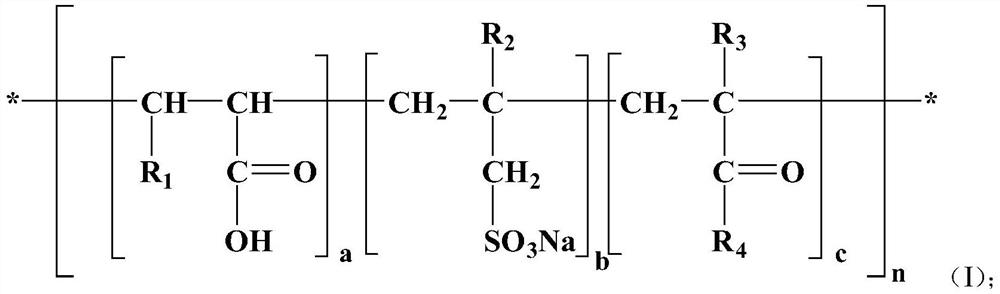

[0032] A leveling agent for waste slurry water in a mixing station, the preparation method thereof comprises the following steps:

[0033] 30g fumaric acid-hydroxybutyl acrylate-sodium sulfonate terpolymer (molecular weight 3000), 20g sodium polyepoxysuccinate (molecular weight 1000), 5g sodium polyglutamate (molecular weight 1.5 million), 10g dodecane Alkyldimethylbenzyl ammonium chloride, 10g sodium hydroxyethylidene diphosphate, 15g 3-hydroxy-1,3,5-pentatrilic acid and 800g deionized water are mixed uniformly to obtain the waste slurry water of the mixing station Use leveling agent JH-1 (effective solid content 9.6%).

Embodiment 2

[0035] A leveling agent for waste slurry water in a mixing station, the preparation method thereof comprises the following steps:

[0036] 40g acrylic acid-hydroxybutyl acrylate-sodium sulfonate terpolymer (molecular weight 3800), 30g sodium polyepoxysuccinate (molecular weight 1000), 3g sodium polyglutamate (molecular weight 1.8 million), 10g hexamethylenediamine tetra Methylenephosphonic acid potassium salt, 10g sodium hydroxyethylidene diphosphate, 15g D-glucuronic acid and 850g deionized water were mixed uniformly to obtain the leveling agent JH-2 (effective solid content 9.0 %).

Embodiment 3

[0038] A leveling agent for waste slurry water in a mixing station, the preparation method thereof comprises the following steps:

[0039]50g acrylic acid-hydroxypropyl acrylate-sodium sulfonate terpolymer (molecular weight 2500), 5g sodium polyglutamate (molecular weight 2 million), 20g potassium amino trimethylene phosphonate, 10g sodium hydroxyethylidene diphosphate, 15g 3-Hydroxy-1,3,5-glutaric acid, 10g D-glucuronic acid and 880g deionized water were mixed uniformly to obtain the leveling agent JH-3 (effective solid content 10.7%) for the waste slurry water of the mixing station. ).

[0040] The obtained leveling agent of the present invention is a colorless or light yellow liquid, and the specific physical and chemical properties test results are shown in Table 1 (homogeneous).

[0041] Table 1 The homogeneity test results of the leveling agents obtained in Examples 1-3

[0042] project JH-1 JH-2 JH-3 Exterior colorless liquid colorless liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com