Magnetic motor

A magnetic motor and magnetic strip technology, applied in the field of magnetic motors, can solve the problems of small distribution area of repulsive force, inability to improve power working ability, and low efficiency of energy conversion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] This embodiment provides a magnetic motor. The magnetic motor is used as a general power drive source in the technical field of power equipment. It utilizes the working principle that the same type of magnetic poles repel each other and different types of magnetic poles attract each other. In the magnetic field, repulsion or suction is generated to perform power work. Make the magnetic motor rotate normally, thereby driving other objects or vehicles to move. Magnetic motors can use magnets or energized coils to generate magnetic force to form magnetic energy. Compared with gas, coal and gasoline as energy sources for power equipment, it is obvious that magnetic energy is not only more environmentally friendly, but also can make full use of magnetic energy and magnetic properties. The characteristics of unrestricted independent movement can replace other conventional energy sources to meet the needs of social development.

[0037] The magnetic motor in this embodiment, s...

Embodiment 2

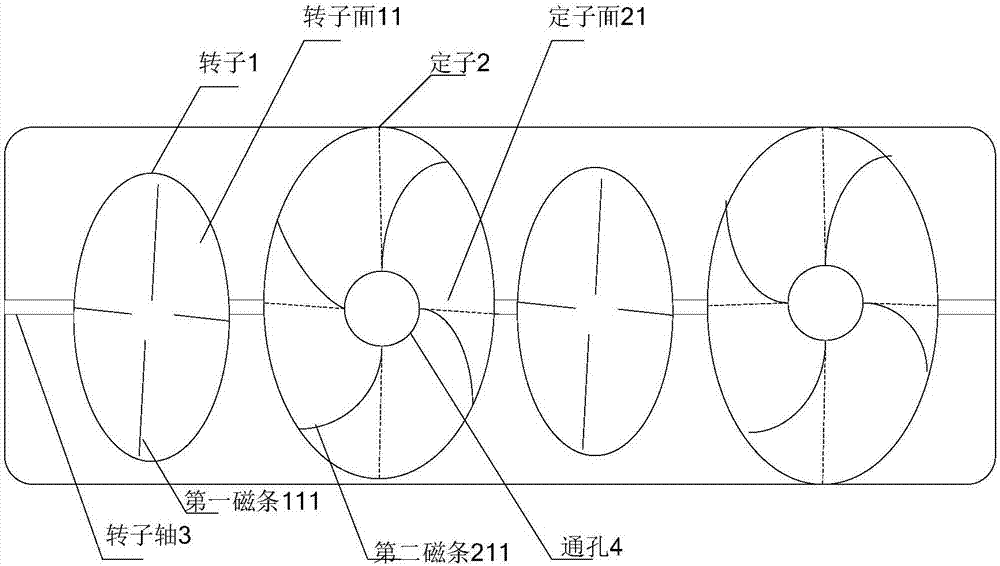

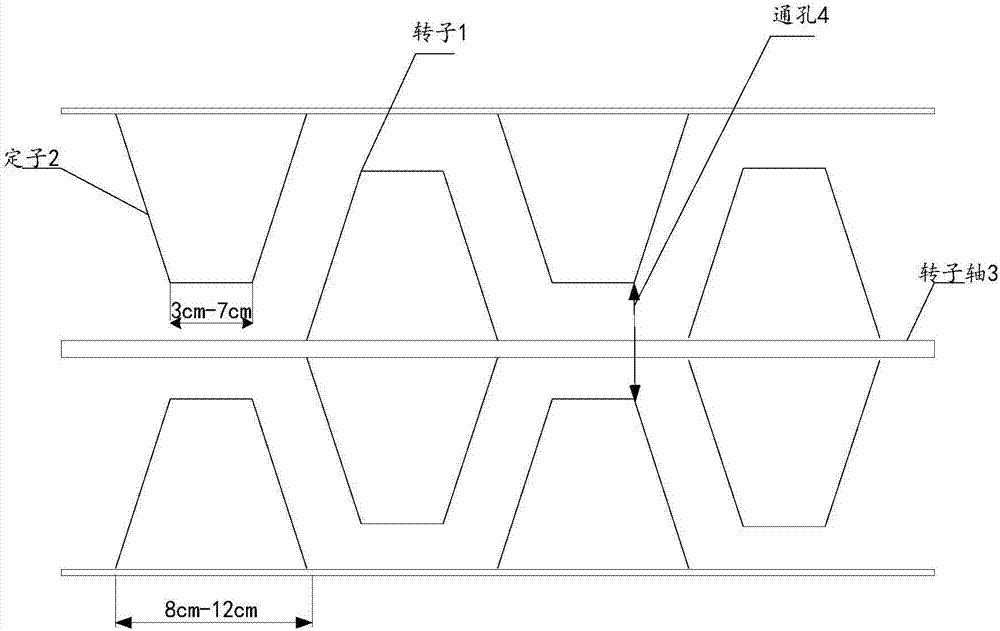

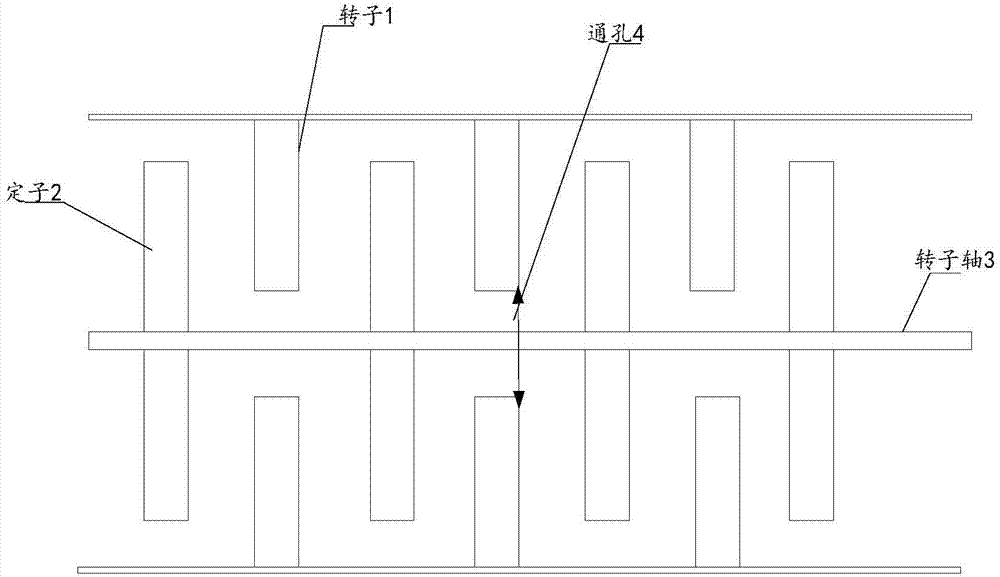

[0046] This embodiment provides a magnetic motor, including a stator 2 and a rotor 1, the rotor 1 is arranged on the rotor shaft 3, the stator 2 is arranged on the stator shell, the rotor shaft 3 is located in the center of the stator shell, and the rotor 1 and the stator 2 are arranged according to the preset Interlaced and juxtaposed at intervals, the stator 2 is formed with a through hole 4 for the passage of the rotor shaft 3, the rotor surface 11 of the adjacent rotor 1 and the stator 2 is opposite to the stator surface 21, and the stator 2 and the rotor 1 are arranged according to a preset interval , and the adjacent rotor surface 11 is parallel to the stator surface 21, such as Figure 5 It is shown that the first magnetic strips 111 extending radially from the rotor shaft 3 to the outer edge of the rotor surface 11 are arranged at intervals on the rotor surface 11, and the first magnetic strips 111 have a first inclined plane obliquely intersecting with the rotor surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com