Pile sinking device and pile sinking method for prestressed centrifugal pipe piles with mid-digging reverse pull method

A centrifugal tube and prestressing technology, applied in sheet pile walls, buildings, infrastructure engineering, etc., can solve the problems of difficult quality assurance, high cost, and high cost, and achieve the effect of ensuring safety, low cost, and high benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

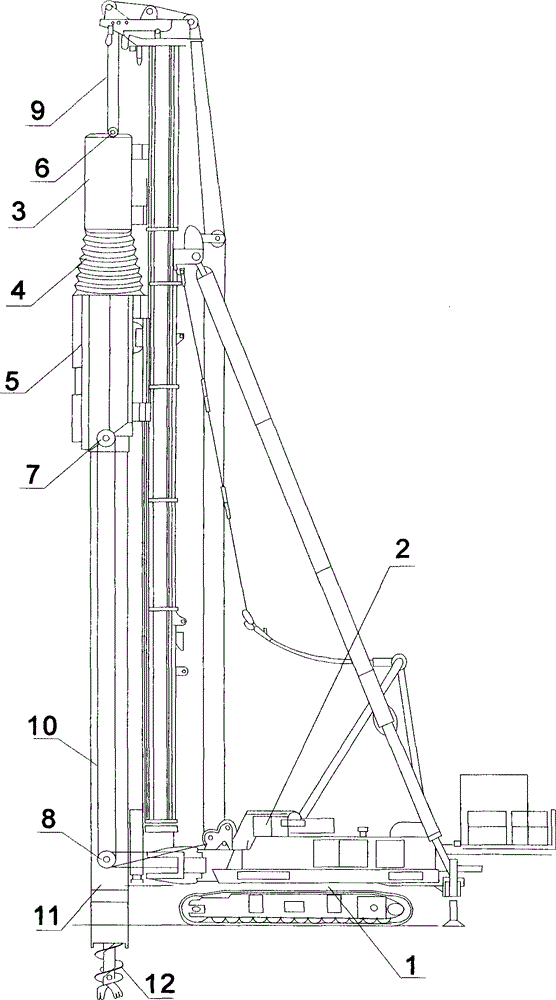

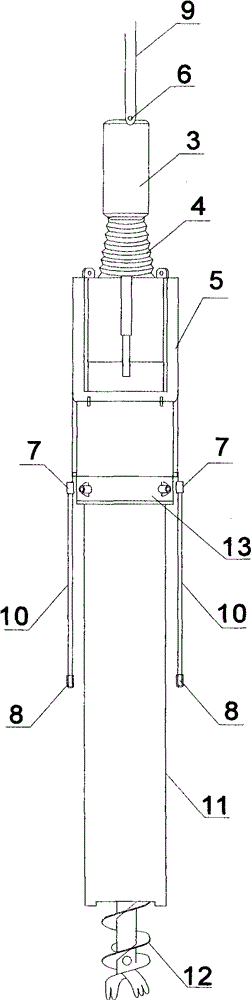

[0026] Such as Figure 1-2 Shown is a prestressed centrifugal tubular pile sinking device with the reverse pull method of mid-digging, including a main machine 1, a hoist 2 installed on the main machine, a power head 3, a soil borrow box 5, pulleys 6, 7, 8, and steel wire ropes 9, 10 , the power head 3 is installed on the main engine 1, the upper end of the power head 3 is equipped with a pulley 6, the pulley 6 is connected with a steel wire rope 9, and the steel wire rope 9 is connected with the hoist 2 through the top of the main engine 1, The bottom of the power head 3 is connected with the soil-borrowing drill pipe 12, and the lower end of the power head 3 is provided with a cover 4, and the lower end of the cover 4 is connected with the soil-borrowing box 5. Cover soil cover 4 and mainly play to prevent soil from falling off from soil borrowing box 5, and cover soil cover 4 can expand and contract simultaneously, described soil borrowing box 5 lower ends are connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com