EPS vacuum forming process and forming system

A vacuum forming and process technology, which is applied in the field of expandable polystyrene molding, can solve the problems of easy hardening on the surface of EPS foam products, poor fusion of finished products, and slow penetration speed, etc., and achieve internal fusion of EPS foam products Excellent, reduce mold temperature, reduce the effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

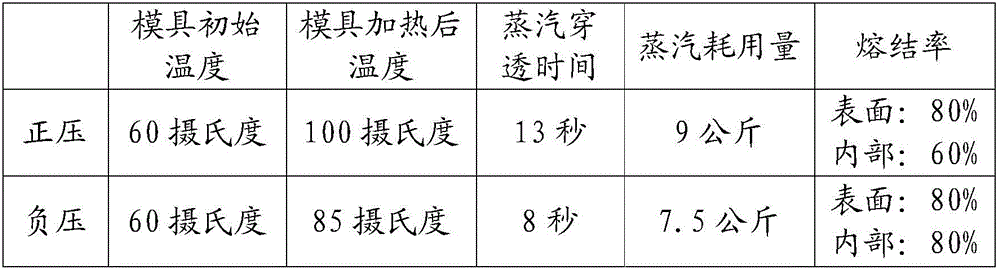

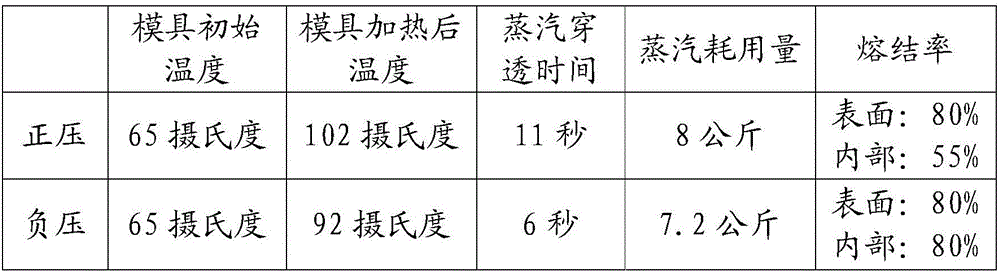

Embodiment 1

[0022] This embodiment provides an EPS vacuum forming process. The specific process flow is as follows, including: preheating, mold clamping, mold filling, heating, cooling and demoulding processes. In the prior art, the heating process adopts the positive pressure penetration heating method , In this embodiment, the negative pressure penetration heating method is adopted, and the negative pressure penetration heating method is specifically described as follows.

[0023] In the molding process of EPS foam products, the mold is preheated first, then the mold is closed, and the matured EPS foam particles are filled into the cavity of the mold, and then the heating process starts. Among them, in the heating process, high-temperature and high-pressure steam is passed into the mold 2 from the steam hole 4 on one side wall of the mold 2, and while the high-temperature and high-pressure steam is passed through, the steam hole 4 communicated with the steam hole 4 is provided on the mol...

Embodiment 2

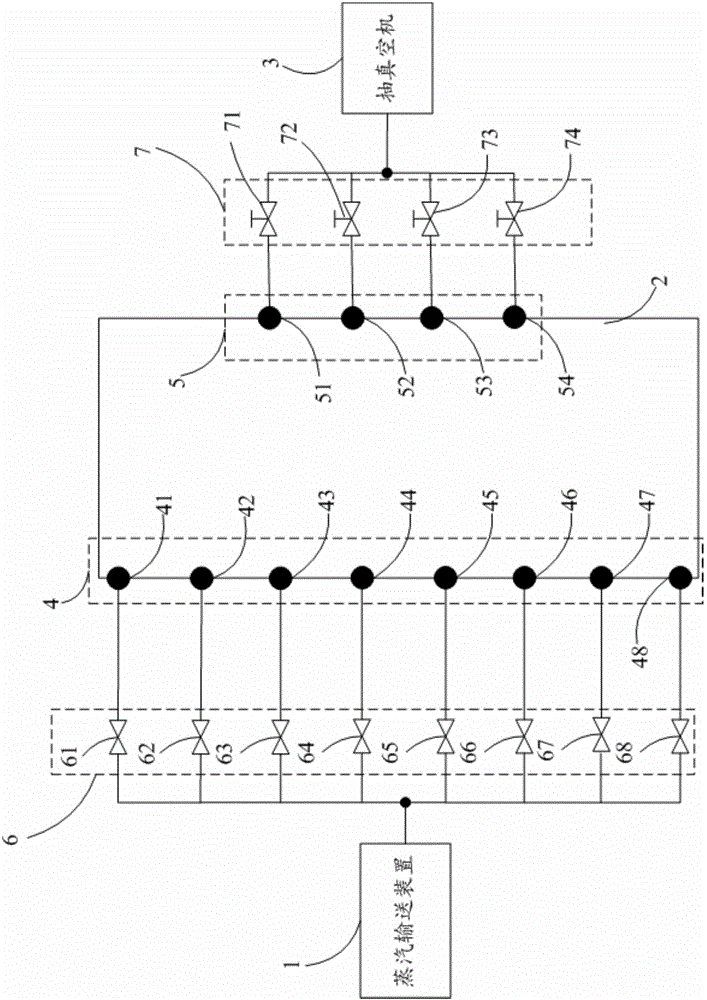

[0054] The present embodiment provides a kind of EPS vacuum forming system, such as figure 1 As shown, the EPS vacuum forming system includes: a steam delivery device 1 , a valve 6 , a mold 2 , a vacuum valve 7 and a vacuum machine 3 . The side wall of the mold 2 is provided with a steam hole 4 and a vacuum hole 5, wherein the steam hole 4 is located on one side wall of the mold 2, and the vacuum hole 5 is located on the other side wall of the mold 2 opposite to one side wall. , the steam hole 4 communicates with the true air hole 5; the output end of the steam delivery device 1 communicates with the steam hole 4 through the valve 6, and the vacuum hole 5 is connected with the vacuum machine 3 through the vacuum valve 7. Here, there can be only one steam conveying device 1, and the output end of this steam conveying device 1 is respectively connected to different steam holes 4 through a valve 6, that is, each steam hole 4 is equipped with a valve 6, each The steam hole 4 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com